PWC Gibraltar - Doing Business and Investing in Gibraltar 2012

New Power plant station North Mole Gibraltar: Example of ...

Transcript of New Power plant station North Mole Gibraltar: Example of ...

New Power Plant North Mole Gibraltar:

Example of CO2 footprint improvement with Gas and Dual Fuel engines

Author: Hans Jörg Lauer MAN Diesel & Turbo SE, Stadtbachstrasse 1, Augsburg, Germany

Co-Author: Nikki Wood, Engain, The Old Church School, Butts Hill, Frome, Bath, BA11 1HR, United Kingdom Carsten Dommermuth, MAN Diesel & Turbo SE, Stadtbachstrasse 1, Augsburg, Germany

Key contributor:

Bouygues Energies & Services, 19 rue Stephenson, 78063 Saint-Quentin-en-Yvelines cedex, France

Electrify Europe 2018 Page 2 of 24 MAN Diesel & Turbo SE

Table of Contents

Introduction

Gibraltar

Today’s and future power generation in Gibraltar

Technology selection

Leverage for CO2 emission reduction

Requirements for the new power plant

Natural Gas (NG)

LNG Prices

Description of the new North Mole Power Plant

MAN Diesel & Turbo 51/60DF and 51/60G engines

LNG supply of the North Mole power station

Emissions

About MAN Diesel & Turbo

About Bouygues Energies & Services

About Gasnor

References

Electrify Europe 2018 Page 3 of 24 MAN Diesel & Turbo SE

Abbreviations

CO Carbon monoxide

CO2 Carbon dioxide

DF Dual Fuel

EIA Environnemental Impact Assessment

EU European Union

EPC Engineering-Procurement-Construction

ha Hectare

HFO Heavy Fuel Oil

GDP Gross Domestic Product

GEA Gibraltar Electricity Authority

LNG Liquefied Natural Gas

MMBTU Million British Thermal Units, 1 MMBTU = 293.071 kWh

MW Megawatt

MW(e) Megawatt of electricity

m Meter

m2 Meter squared

m3 Meter cubed

NG Natural Gas

NO2 Nitrogen dioxide

NOx Nitrous oxides

SCR Selective Catalytic Reduction

SO2 Sulphur dioxide

TSP Total Suspend Particles

UK United Kingdom

VOC Volatile Organic Compounds

Electrify Europe 2018 Page 4 of 24 MAN Diesel & Turbo SE

List of Figures

Figure 1: Picture from Gibraltar

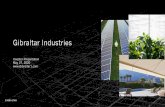

Figure 2: New Power station, North Mole, Gibraltar

Figure 3: Development of wholesale price natural gas

Figure 4: Design of the new power plant

Figure 5: MAN 18V51/60G engine

Figure 6: Picture of a LNG Terminal, similar to the LNG Terminal of Gibraltar

List of Tables

Table 1: Carbon content of fuels for electrical power generating

Table 2: Comparison of different prime mover technologies and their related CO2 emissions

Electrify Europe 2018 Page 5 of 24 MAN Diesel & Turbo SE

Introduction

Gibraltar’s existing energy infrastructure is not capable of meeting future demand, and under

the EU’s time extension to meet air quality levels, the HM Government of Gibraltar

contracted the design and build of a new power facility which is future proofed and allows

flexibility for expansion, is economically advantageous, and incorporates the highest safety

and environmental performance.

The decision was taken for an engine power plant based on Gas and Dual Fuel (DF) engines.

The gas engines operate with Natural Gas (NG), complying with the current environmental

policy requirements of the European Union IEA Directive 2011/92 / EU. If power demand is

higher than the available gas engine power, DF engines will start. In emergency cases, such

as failure in gas supply, the DF engines switch to full automatic diesel operation.

The fuel supply for the new power plant will be ensured via a new LNG (Liquefied Natural

Gas) Terminal and a new Diesel Tank Farm close to new power plant. The use of LNG for

the new power plant reduces operating costs and limits atmospheric emissions of NOx, CO2

and SO2.

This report describes the existing and new power generation technologies used in Gibraltar,

the reasons for the chosen option, and the companies involved in the new power plant design

and installation.

This paper was created in collaboration with Engain (Co-author), Gibraltar Electricity

Authority, Bouygues Energies & Services (Key contributor) and Gasnor (a subsidiary of

Shell).

Electrify Europe 2018 Page 6 of 24 MAN Diesel & Turbo SE

Gibraltar

Figure 1: picture from Gibraltar, source www.forces.net

Gibraltar is a peninsula that borders with Spain to the north, and is bounded by marine waters

to the east, west and south. The country covers an area of approximately 6.5 km², which

includes a flat, sandy isthmus and reclaimed land upon which the main town of Gibraltar has

expanded, and the iconic Rock of Gibraltar which is a UNESCO World Heritage site that

dominates the skyline with limestone sheer cliffs up to 426 m altitude and which supports

protected wildlife.

Gibraltar is an overseas territory of the United Kingdom with self-government. It covers all

political areas except defense, foreign policy and domestic security, which are presided over

by the United Kingdom. The resident population is around 35,000 habitants and tourists

currently contribute around 1 million people during the peak season including day visits from

cruise ships.

It is from this situation, that the people of Gibraltar have an irrefutable need to modernize and

improve the security and reliability of an independent energy supply.

Electrify Europe 2018 Page 7 of 24 MAN Diesel & Turbo SE

Today’s and future power generation in Gibraltar

Today, Gibraltar has an available generating capacity of approximately 60 MW(e). The

generating capacity is covered by about 40 engines and turbines between 0.6 MW(e) and

approx. 5 MW(e), which are distributed to different locations across the country.

The Waterport Power Station site, which originally had a generating capacity of

approximately 15.6 MW(e) (3 x 5.2MW(e)), produces at a reduced capacity after a fire in

April 2014. The engines of the OESCO power plant were dismantled and the ISGS power

plant is only in stand-by mode. To meet the energy needs, additional gensets were installed at

the North Mole, some of these plants no longer meet today’s environmental standards or no

longer work economically. The EU provided Gibraltar with a time extension for

improvements in air quality, and temporary gensets were installed to augment the existing

Waterport plant.

Figure 2: New Power station, North Mole, Gibraltar, Source: New Power Station, North Mole, Gibraltar,

Environmental Statement, Volume 1: Traffic and Transportation, page 103

In order to secure the country's energy supply economically, environmentally and

sustainably, Gibraltar has decided to build one new centralized power plant. This plant will

provide sufficient capacity for the peak demands currently experienced and for future

increased. When the new power plant becomes operational, the existing plant and gensets

Electrify Europe 2018 Page 8 of 24 MAN Diesel & Turbo SE

will be decommissioned..

As the area of the country is very small and the new power plant will be only a few meters

from residential buildings, the new power plant must meet the latest environmental air quality

requirements for human health. Additionally, the Rock of Gibraltar is an important wildlife

site and it had to be demonstrated that air emissions from any new plant would not

deleteriously affect the ecology. The new power plant has to comply with the current

environmental policy requirements of the European Union IEA Directive 2011/92 / EU,

which are valid for new power plants in Europe.

The critical requirements for the new power plant were the reduction of the CO2 emissions,

improvement economic efficiencies, maximum security in the energy generation sector, and

flexibility for future increases in power output.

Technology selection

One of the main techniques for reducing the existing CO2 emission with a new power plant is

choosing the technology with the highest electrical efficiency currently available on the market.

The technology which has the highest “best in class” output performance in CO2 emissions per

kWh is the internal combustion engine (IC engine). Combustion engines work in regards to the

thermodynamic process in an Otto-Cycle or with the classical diesel principle in a self-igniting

process. The Otto-Cycle uses a spark plug and an electrical signal for starting the combustion

process whereas the diesel engine works with a pilot fuel, which starts (whilst under pressure)

the ignition process in the combustion chamber. The diesel engine offers a dual fuel operation

mode, due to the fuel flexibility, meaning that an operator can easily choose between diesel

operating (liquid mode) or gaseous operating according to the OEMs fuel specification.

Leverage for CO2 emission reduction

By using the most effective technologies and best resources, CO2 can be reduced. The second

step to reduce CO2 levels is the type of fuel you use for combustion. Table 1 below shows the

various fuels used across the industry, with their relative carbon content in grams.

Electrify Europe 2018 Page 9 of 24 MAN Diesel & Turbo SE

Table 1: Carbon content of fuels for electrical power generating

Fuel type for electrical power generating g CO2 /kWh

Natural Gas 202

Distillate Oil (e.g. light fuel oil diesel) 267

Residual fuel (e.g. heavy fuel oil) 278

Hard coal 340

Lignite /brown coal 360-430

It is easy to see that the lowest CO2 content of all available fossil fuels in power generating is

natural gas. Natural gas offers over 50% CO2 reductions when compared with hard coal and

lignite as a fuel.

As mentioned in addition to the carbon content of the fuel, the electrical efficiency – meaning

the conversion rate of fuel into electricity - is the second catalyst for reducing the CO2 footprint

of a power generating solution.1

Table 2 shows a selection of state of the art generating technology and their electrical

efficiencies with the specific CO2 emissions per kWh.

As reference and base line you see the current Gibraltar installation which was built in 1981 as

a state of the art technology running on heavy fuel oil for close to one decade then moving on

to Light fuel oil to date.

1 http://www.iea.org/media/statistics/co2highlights.pdf

Electrify Europe 2018 Page 10 of 24 MAN Diesel & Turbo SE

Table 2: Comparison of different prime mover technologies and their related CO2 emissions

Prime mover technology selection

without combined heat and power

solutions

Electrical

Efficiency

Specific CO2 emissions of various power plant

types depending on electrical efficiency and

carbon content of the main fuel

Existing Light fuel oil (MGO) fired

power plant in Gibraltar. Engines are

built in 1981

Approx. 35% Approx. 622

Today’s state of the art power plant technology

Natural gas power plants

Gas engine power plant single cycle 45% 448

Gas engine power plant combined

cycle

50% 404

Gas turbine plant open cycle/industrial

GT

34% 594

Gas turbine plant combined cycle

Due to the higher capital expenses

mostly in large applications above 200

MW(e)

59-60% 342-336

Oil based power plants

Modern Heavy fuel oil power plant

with two stage turbocharged engines

(e.g. MAN 18V48/60TS)

49% 567

Coal fired power plants (steam turbine and plants)

Hard coal power plant with

supercritical parameters (with cooling

tower)

45% 755

Electrify Europe 2018 Page 11 of 24 MAN Diesel & Turbo SE

Lignite power plant with supercritical

parameters (with cooling tower)

45% 800-955

Formula for calculating the specific CO2 emissions of various power plant solutions depending

on their electrical efficiency and the specific carbon content of the used fuels.2

𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆 𝐶𝐶02 𝐸𝐸𝐸𝐸𝑆𝑆𝐸𝐸𝐸𝐸𝑆𝑆𝐸𝐸𝐸𝐸𝐸𝐸 𝐸𝐸𝑆𝑆 𝑡𝑡ℎ𝑆𝑆 𝑃𝑃𝐸𝐸𝑃𝑃𝑆𝑆𝑃𝑃 𝑃𝑃𝑃𝑃𝑃𝑃𝐸𝐸𝑡𝑡 =𝐶𝐶𝑃𝑃𝑃𝑃𝐶𝐶𝐸𝐸𝐸𝐸 𝑆𝑆𝐸𝐸𝐸𝐸𝑡𝑡𝑆𝑆𝐸𝐸𝑡𝑡 𝐸𝐸𝑆𝑆 𝑡𝑡ℎ𝑆𝑆 𝐹𝐹𝐹𝐹𝑆𝑆𝑃𝑃 (𝑆𝑆𝐸𝐸 𝑔𝑔

𝑘𝑘𝑘𝑘ℎ)𝐸𝐸𝑃𝑃𝑆𝑆𝑆𝑆𝑡𝑡𝑃𝑃𝑆𝑆𝑆𝑆𝑃𝑃𝑃𝑃 𝐸𝐸𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝐸𝐸𝑆𝑆𝐸𝐸 𝐸𝐸𝑆𝑆 𝑡𝑡ℎ𝑆𝑆 𝑃𝑃𝐸𝐸𝑃𝑃𝑆𝑆𝑃𝑃 𝑃𝑃𝑃𝑃𝑃𝑃𝐸𝐸𝑡𝑡 (𝑆𝑆𝐸𝐸 %)

Requirements for the new power plant

In the future there is a continuous expected energy demand of between 16 minimum and 42

MW(e) maximum, with loading steps of approx. 5 MW(e). With a growing economy,

population increases and associated supporting new infrastructure and buildings, energy

demand is forecast to increase to approx. 51 MW(e) by 2027.

The current energy supply of the existing power plants is based on diesel fuel. Due to

environmental and economic aspects, however, diesel fuel was not considered a sustainable

option for the new power plant. Natural gas was determined as the main fuel and, in future,

diesel fuel will only be necessary to start and operate the dual fuel engines in gas mode or for

emergency operation.

Options for gas fuel compared a gas turbine plant and a gas engine power plant. Due to the

non-homogeneous energy demand with load steps of about 5 MW, and the fact that no heat

energy is needed, a gas turbine power plant was discarded and the decision was made in

favour of a gas engine power plant. With the move from several small power plants to a new

central power plant, based on highly efficient medium-speed gas engines, HM Government of

Gibraltar plans to achieve a future cost advantage of around £ 8M per year.

The construction of the new North Mole Power Plant together with the LNG storage terminal

has an immense significance for Gibraltar. It is entirely new technology and has received

2 https://www.iea.org/publications/freepublications/publication/CO2EmissionsfromFuelCombustion

Highlights2017.pdf

Electrify Europe 2018 Page 12 of 24 MAN Diesel & Turbo SE

much attention and focus, being one of the biggest infrastructure investments Gibraltar has

ever made.

The decision was taken for 3 gas engines, 14.4 MW(e) each, and 3 dual fuel engines, 13.7

MW(e) each. The gas supply will be provided by a new LNG storage facility located in direct

proximity to the power plant. Between the new LNG storage facility and the new power plant

a diesel tank farm will also be installed.

The prime movers for the new power plant are 3 MAN 14V51/60 G engines and 3 MAN

14V51/60 DF engines. An extension for a 7th engine is possible. It is envisaged that there

will be always 4 engines in operation in the configuration with 6 engines, and 5 engines in

operation in the configuration with 7 engines. The two additional engines are installed as

back-up for if one of the engines has to undergo scheduled maintenance but another has an

unscheduled breakdown at the same time. With the number of engines it is ensured that the

current energy demand of 41 MW(e), and the required power is always available.

Renewable energies were also investigated for the new energy supply. By the year 2020,

15% of the energy requirement in Gibraltar must be generated by renewable energy. Due to

the exposed location of the town (small area, peninsula, rocks, industrial area and harbor in

close proximity), classic renewable energy such as wind energy and large solar fields are not

possible. Nuclear power plants and biomass power plants were also excluded due to their

requirements for larger areas of land. Further energy supply systems such as smaller solar

panels and micro-wind turbines are planned or already under construction. Feasibility studies

on wave and tidal generators or negotiations on energy procurement via neighboring

countries are also underway.

Electrify Europe 2018 Page 13 of 24 MAN Diesel & Turbo SE

Natural Gas (NG)

Natural gas is a combustible gas that is extracted from underground sources. It consists

mainly of the hydrocarbon methane (CH4), but may also contain various other gases, in

particular carbon dioxide, nitrogen, ethane, ethene, propane, butane and small amounts of

noble gases. A distinction is made between so-called H-gas (high caloric gas) and L-gas.

Both gas qualities differ in composition and calorific value. So-called H (high caloric gas)

gas contains at least 87% methane and has a higher calorific value than L gas.

The calorific value of natural gas is typically between 32 MJ/kg (L-gas) and 45 MJ/kg (H

gas). 1 m³ has a calorific value between 31 MJ = 8.6 kWh (L-gas) and 41 MJ = 11.4 kWh (H-

gas). The natural gas, used in the Gibraltar Power Plant will be similar the L as or the H gas

quality.

Natural gas is used in large quantities for both energy generation and for chemical processes.

The main applications in the energy generation are gas turbines and gas engines (gas or dual

fuel engines) and the production of heat by combustion in boilers. When used in gas engines

(eg. in natural gas vehicles or power plants), the high knocking resistance of methane is

advantageous because it allows a high compression ratio, which results in a high power

density.

Gas is particularly efficient for the production of electrical energy in gas-fired power plants.

These power plants have the advantage of very fast start ramps and high production

flexibility. That is why engine-based power plants, are an ideal complement to renewable

energies to compensate for fluctuations in their production.

Natural gas can burn very clean without major technical effort. There is almost no soot, and

the exhaust contains virtually no unburned hydrocarbons. Sulfur dioxide (SO2) almost does

not arise as (purified) natural gas hardly contains any sulfur. However, minor quantities of

toxic nitrogen oxides are produced; these emissions can be kept low by optimized

combustion technology.

CO2 emissions per kilowatt-hour of gas produced are significantly lower compared to other

fossil fuels.

Natural gas can be transported as liquefied natural gas (LNG) in large tankers. The gas is

compressed for transport at temperatures of -162°C and has a volume of about 1/600 of the

Electrify Europe 2018 Page 14 of 24 MAN Diesel & Turbo SE

original volume. For the liquefaction approx. 10% to 25% of the calorific value of the natural

gas must be used. Therefore, transportation as liquefied natural gas is economically

reasonable only for long transport distances and of course only where no pipelines are

available.

Like all fossil fuels, natural gas is not infinitely available. As the global reserves of natural

gas are significantly higher than oil, it can be assumed that the global natural gas reserves

will remain available for a long time to come. Every year, further natural gas fields are being

redefined. Although number of existing natural gas sources in Europe decline, this is

sufficiently compensated by the development of new fields. The amount of shale gas

produced in the USA has sustainably changed both the security of supply and the price

situation positively. Other large gas fields can be found in Russia, Algeria and the Middle

East.3

LNG Prices

Figure 3: Development of wholesale natural gas prices (source: EU Quarterly Report on European gas Markets,

DG ENER/Platts/Thomson Reuters/BAFA)

The above illustration shows the price development of LNG in different markets. In the years

2011 to 2015, prices have fallen overall. Wholesales prices in the USA at the Henry Hub

(HH) have fluctuated between 2.5 und 5 USD/MMBTU over the past few years. In Europe,

wholesales prices reached about double this level, fluctuating within the range of 7-11 USD

3 RP-Energie-Lexikon, Autor: Dr. Rüdiger Paschotta (G+)

Electrify Europe 2018 Page 15 of 24 MAN Diesel & Turbo SE

MMBTU (National Balancing point). Importers in the Asia / Pacific Region had to pay the

highest prices. As a result of high demand of LNG, from Japan following the shutdown of

nuclear power station, and from China, combined with low availability of LNG, prices

reached high levels, with a range of 15-20 USD / MMBTU. In 2014 and 2015 markets were

characterized by a supply surplus. In a buyer’s market, international trading prices fell

significantly and came closer to each throughout the world. Currently, the US PP price is

about 2 USD / MMTBU while European and Asian prices have converged at the level of 5.5

USD / MMBTU or 8.5 US / MMBTU (Japan). As a result of this development, the European

market is becoming increasingly attractive for LNG volumes especially from North America

but also from the Middle East (Qatar). Sea freight costs between East coast USA and Europe

are about one half to one third lower than for shipment from USU to Asia” 4

Description of the new North Mole Power Plant

The new power plant is located along the North Mole Breakwater and in close proximity to

residential areas built on the reclaimed land around the west side of the main town towards

the Bay of Gibraltar.

Figure 4: Design of the new power plant, Source: Bouygues Energies & Services

4 DVGW Deutscher Verein des Gas- und Wasserfaches e.V., Natural gas: a secure and reliable partner in the

energy transition, page 6

Electrify Europe 2018 Page 16 of 24 MAN Diesel & Turbo SE

The new power plant will be built exclusively for power generation. There is no provision for

thermal energy production. The construction of the power plant essentially comprises the

following components:

Scope of Supply MAN Diesel & Turbo

- 3 x 14V51/60DF engines and 3 x 14V51/60G engines incl. mechanical and electrical

auxiliaries, such as lube oil system, HT and LT cooling water system, fuel gas system,

engine control system with genset interface, genset control interface and engine

digitalization system

- Air cooled ABB alternators

Scope of supply Bouygues Energies & Services

- Gas supply from the LNG terminal to the power plant

- Air inlet system

- Exhaust gas system including stacks and silencers

- SCR exhaust after treatment, incl. urea stock

- Compressed air

- Air cooled radiator cooling systems

- Fire detection system

- Water treatment

- Piping

- Cabling

- Operating building for the engines, central control room and facilities

- 11 kV station switchboard

- Assembly, commission and supervision

- Civil works

An administration building with security fencing, gates, guard house, on-site roads and

parking areas will be built for the Gibraltar Electricity Authority.

Each of the 6 engines receives its own concrete housing for enhanced safety and noise

insulation properties. This is in an explosion-proof version and built so that it should keep a

possible fire contained for about 2 hours.

Electrify Europe 2018 Page 17 of 24 MAN Diesel & Turbo SE

The new power plant is also located in the immediate vicinity of Gibraltar International

Airport and the runway is only a few meters away from the façade of the new power station.

In order to ensure safe airport operation, the maximum height of the engine stacks has had to

be limited to 25 m.

Between the LNG storage terminal and the new power plant is the new diesel tank farm.

Diesel is needed in a dual fuel engine as a pilot oil to ignite the gas mixture. The volume of

the tank farm is designed for about 20 days.

MAN Diesel & Turbo 51/60DF and 51/60G engines

For the North Mole Power Station project, 3 engines of the type 14V51/60DF (dual fuel) and

3 engines of type 51/60G were selected.

In the designation of the engine number 14 stands for the number of cylinders, V for the V-

arrangement of the cylinders (as opposed to a possible L (in line arrangement), 51 stands for

the cylinder diameter in cm and 60 for the stroke in cm. The engine speed is 500 1/min.

From the designation 14V51/60DF and 14V51/60G it can be seen that both engines have the

same cylinder / stroke / bore arrangements.

Figure 5: MAN 18V51/60G engine, Source: MAN Diesel & Turbo SE

The engine 51/60G stands for a pure gas engine. That engine type has a spark plug and is

working according to the Otto principle.

Electrify Europe 2018 Page 18 of 24 MAN Diesel & Turbo SE

The 51/60DF is a dual fuel engine. This engine can run on different fuels (diesel, heavy fuel

oil, natural gas and other gases) and can work in diesel (liquid) mode or gas mode. That

engine type is based on the diesel principle and has no spark plug. In diesel mode the

combustion of the diesel engine is initiated by the injection of diesel fuel at approx. 135 bar

into the compressed air. In gas mode, the engine need a small amount of diesel fuel (about

1% of about 1000 bar) to ignite as a gas-air mixture cannot ignite itself.

The 14V51/60G engine has an electrical output of 14.362 kW(e) and achieves a net

efficiency of more than 45%. Even at 50% partial load, the engine still achieves a net

efficiency of more than 41%. The dual fuel engine has an electrical output of 13,678 kW(e) in

both gas and diesel operation. The net electrical efficiency in gas operation at 100% load is

more than 44% and reaches more than 38% at 50% part load. In diesel operation, the net

efficiency is more than 40% and reaches more than 39% in the 50% partial load operation.

These data are based on DIN ISO 3046-1 and a natural gas with a methane number of 80, a

Net Caloric Value (NCV) of 28,000 kJ / m³ and a NCV of diesel 42700 kJ / kg. Both engines

have no derating up to 40° C ambient temperature.

Another special feature of the 51/60DF is that the engine can switch flexibly between the

liquid mode and the gaseous mode. This engine starts in liquid mode, but then switches to gas

operation after a few seconds. However, the switch from diesel fuel to gas fuel can also be

carried out from 15% partial load. Change from diesel fuel to gas fuel takes about 120 sec.

The change from gaseous operation to liquid operation can be done much faster and at any

load. This change has no loss of performance and is necessary for emergency operation or in

the event that there is an unforeseen breakdown in the gas supply.

Due to the small difference in the electrical efficiencies in the fas operation of both engines,

the possibility of an extremely fast change from gas operation to diesel operation, dual fuel

engines are particularly suitable for power plants with high relevance to safety. As that

engine type can for emergency reasons with diesel fuel, it’s often used in areas where there is

no regulated gas supply, or where gas availability is planned at a later stage or on islands

where the power must be available at any time.

Electrify Europe 2018 Page 19 of 24 MAN Diesel & Turbo SE

LNG supply for the North Mole Power Station

The decision for the location of the new LNG storage terminal was taken for both economic,

environmental/ sustainability and security reasons.

The LNG storage terminal is just a few meters away from the new power plant, in line with

the power plant and the diesel tank farm. This ensures the shortest possible transport of the

gas from the LNG storage terminal to the power plant.

Figure 6: Picture of a LNG Terminal, similar to the LNG Terminal of Gibraltar, Source: Shell

The LNG is transported to the LNG storage terminal via a -"small scale" carrier at a

temperature of about -162°C. It is extracted via special loading arm into 5 double walled

stainless steel tanks, each with 1000 m³ storage capacity. The ship can be unloaded overnight,

this is to ensure that disruption to the port and airport remain as low as possible. The LNG

from the storage tanks is transferred via pumps to the vaporizers, where it is converted from

the liquid state to the gaseous state, according to the needs of the power plant operator. The

necessary heat for that conversion comes from the waste heat of the power plant. This saves

both energy and CO2.

When operating the LNG storage terminal, reliability and safety always have top priority.

The terminal will be inspected at regular intervals by the operator and supervisory authorities

for operational safety.

The regasification terminal will be operated by Gasnor under an asset management

agreement, a 100% Shell-owned subsidiary with over ten years of operational experience in

small-scale LNG projects in North Western Europe.

Electrify Europe 2018 Page 20 of 24 MAN Diesel & Turbo SE

Emissions

MAN gas engines on Gibraltar produce high-efficiency electricity and reduce the emission of

NOx, particulate matter and CO2 during gas operation.

MAN's new 51/60 Gas and 51/60DF engines will replace existing diesel engine power plants

and improve ambient air quality. The monitoring takes place via a continuous measuring

system, which continuously records the concentration of nitrogen oxides, carbon monoxides

and particles and stores them in a central computer system. Thus, an absolute monitoring of

the exhaust gas quality is guaranteed. If no gas is available, the 51/60 DF can also be

switched to diesel mode. Thus, the power supply is guaranteed on Gibraltar. In the following

exhaust gas analysis, however, only the gas operation is considered, as this represents the

intended operating mode.

NOx

The engines already maintain low concentrations inside the engine. A subsequent SCR

catalyst additionally reduces the NOx concentrations so that the local emissions legislation is

complied with without any problems. Low raw emissions also help to save urea to keep

catalyst operating costs low. Compared to diesel engines, SCR catalysis can achieve

significantly higher nitrogen conversion rates because the particle concentration in gas

operation is much lower, thus keeping the catalyst stone clean. Thus, the new regulations

with the nitrogen oxide limit of 75mg / Nm3 @ 15% O2 can be maintained catalytically.

Furthermore, the operating costs of the SCR catalyst in gas operation are much lower than in

diesel engines, since the urea consumption is much lower and the catalysts pollute less.

CO

With the clean exhaust gas operation of the MAN gas engines, the CO emission can be

significantly reduced via an oxidation catalytic (OXYCAT) converter without any problems.

Even at low exhaust gas temperatures, a conversion of CO to CO2 takes place and helps to

keep the ambient air clean. Although the CO2 concentration is increased, the overall CO2

balance is much better compared to liquid fuel engines. The limit values of the European

Directive of 100mg / Nm3 @ 15% O2 can be met without any problem.

Electrify Europe 2018 Page 21 of 24 MAN Diesel & Turbo SE

Volatile Organic Compounds (VOC)

The MAN gas engine has an optimized combustion process and already complies with the

new European legislation at 100% engine load. The built-in oxidation catalyst also reduces

hydrocarbon emissions.

Total Suspended Particles (TSP)

Due to the clean combustion in gas operation and the low lubricating oil input low dust

concentrations are ejected and hardly increase the dust load of the environment. Values of

less than 10mg / Nm3 @ 15% O2 are maintained.

About MAN Diesel & Turbo

Based in Augsburg, Germany, MAN Diesel & Turbo is one of the world's leading creators of

pioneering solutions based on large engines and turbomachinery. The company employs around

15,000 staff and is represented in more than 100 sites globally with manufacturing bases in Germany,

Denmark, France, Switzerland, Czech Republic, India and China.

The product portfolio comprises four-stroke and two-stroke engines with power outputs ranging from

625 kW to 87 MW for power and marine applications. MAN Diesel & Turbo also designs and

manufactures gas turbines of up to 13 MW, steam turbines of up to 160 MW and compressors with

volume flows of up to 1.5 million m³/h and pressures of up to 1,000 bar. The product range includes

gas engines, turbochargers, propellers, chemical reactors, cryogenic equipment, energy management

and energy storage solutions. Additional services and supplies include tailor-made solutions like

engine- or turbine-based power plants, ship propulsion systems, and turbomachinery trains for the oil

& gas as well as the process industries. Customers receive worldwide after-sales services marketed

under the MAN PrimeServ brand.

MAN Diesel & Turbo has been creating pioneering solutions since 1758, when the St. Antony

ironworks laid the foundation for the development of the coal and steel industry in Germany. In 1897,

Rudolf Diesel completed development work on his engine in the halls of today’s MAN Diesel &

Turbo in Augsburg. The world’s first diesel engine, the original, was built and tested there.

MAN Diesel & Turbo is a company in the Power Engineering business area of MAN SE

Electrify Europe 2018 Page 22 of 24 MAN Diesel & Turbo SE

About Engain

Engain (Environmental Gain Ltd) is an international environmental consultancy providing

scientific advice on international environmental laws and policies relating to the consenting

of major infrastructure schemes, including medium sized power plant.

In Gibraltar, Engain assisted HM Government of Gibraltar, Bouygues Energies and Services

and the Gibraltar Electricity Authority during the options assessment, and design and

planning stages of the new power station. Engain conducted the Environmental Impact

Assessment studies for the planning consent, and managed the permit for the operation of the

new power station. This involved specialist air quality and other scientific studies to assess

the suitability of the power station in close proximity to houses, transport infrastructure and

the marine environment.

Engain has been established in the UK and Europe for over 15 years and offers

comprehensive ecological and environmental services and expertise, with a focus on

unlocking environmental potential to achieve planning consent – for power, water and

transport projects, strategic property developments and complex brownfield regeneration.

About Bouygues Energies & Services

Bouygues Energies & Services is a 100% subsidiary of Bouygues Construction, an

international group principally active in the construction industry. Bouygues Construction is a

French company with sales of € 32.4bn and 118.000 employees.

Bouygues Energies & Services - Power Generation Division is the division dedicated to the

Engineering, Procurement, and Construction (EPC) of thermal (gas, HFO, LFO) and biomass

power plants. The company has about 13.600 employees with a turnover of about € 2.3 Bn.

Bouygues Energies & Services has been awarded the contract for the construction of the

power plant in Gibraltar. It includes the construction in EPC (Engineering Procurement

Construction) of the entire power plant.

Electrify Europe 2018 Page 23 of 24 MAN Diesel & Turbo SE

About Gasnor

Gasnor is a 100% subsidiary of Shell and specialized in small scale LNG projects. For more

than 10 years, Gasnor has extensive experience in small scale LNG projects in North Western

Europe. Shell has more than 50 years’ experience with LNG technology.

Electrify Europe 2018 Page 24 of 24 MAN Diesel & Turbo SE

References

Engain, New Power Station, North Mole, Gibraltar: Environmental Statement, Volume 1: Main Report

Engain, New Power Station, North Mole, Gibraltar, July 2015, Non Technical Summary

DVGW Deutscher Verein des Gas- und Wasserfaches e.V., Natural gas: a secure and reliable

partner in the energy transition

Bouygues Energies & Services, Presentation of Bouygues Construction

https://www.energie-lexikon.info/erdgas.html, RP-Energie-Lexikon, Autor: Dr. Rüdiger

Paschotta (G+)

https://de.wikipedia.org/wiki/Gibraltar

Shell: Gibraltar, Liquified Natural Gas Project Outline, October 2015

International Energy Agency, https://www.iea.org/publications/freepublications/publication/

CO2EmissionsfromFuelCombustionHighlights2017.pdf, 2017

International Energy Agency, http://www.iea.org/media/statistics/co2highlights.pdf , 2011