New poly(ether-amide-imide) reinforced layer silicate nanocomposite: Synthesis and properties

Transcript of New poly(ether-amide-imide) reinforced layer silicate nanocomposite: Synthesis and properties

Arabian Journal of Chemistry (2012) xxx, xxx–xxx

King Saud University

Arabian Journal of Chemistry

www.ksu.edu.sawww.sciencedirect.com

ORIGINAL ARTICLE

New poly(ether-amide-imide) reinforced layer silicate

nanocomposite: Synthesis and properties

Khalil Faghihi a,*, Saed Aibod a, Meisam Shabanian b

a Polymer Research Laboratory, Department of Chemistry, Arak Branch, Islamic Azad University, Arak, Iranb Department of Chemistry, Farahan Branch, Islamic Azad University, Farahan, Iran

Received 18 September 2011; accepted 27 October 2012

*

27

E

Pe

18

ht

Pth

KEYWORDS

Poly(ether-amide-imide);

Nanocomposite;

Organoclay;

Morphology

Corresponding author. Mo

74031.

-mail address: k-faghihi@ar

er review under responsibilit

Production an

78-5352 ª 2012 King Saud U

tp://dx.doi.org/10.1016/j.arab

lease cite this article in presis and properties. Arab

bile: +9

aku.ac.ir

y of King

d hostin

niversity

jc.2012.1

ess as: Fian Jou

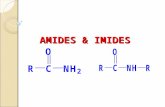

Abstract A new series of poly(ether-amide-imide)/organoclay were generated through solution

intercalation technique. Cloisite� 20A was used as a Modified montmorillonite for ample compat-

ibilization with the PEAI matrix. The poly(ether-amide-imide) (PEAI) 3 chains were synthesized by

the direct polycondensation reaction of N,N0-(4,40-diphenylether)bistrimellitimide 1 with 4,40-dia-

mino diphenyl ether two in the presence of triphenyl phosphite (TPP), CaCl2, pyridine and N-

methyl-2-pyrrolidone (NMP). Morphology and structure of the resulting PEAI-nanocomposite

films 3a–3b with (5–10 wt%) silicate particles were characterized by FTIR spectroscopy, X-ray dif-

fraction (XRD) and scanning electron microscopy (SEM). The effect of clay dispersion and the

interaction between clay and polymeric chains on the properties of nanocomposite films were inves-

tigated by using UV–Vis spectroscopy, thermogravimetric analysis (TGA) and water uptake mea-

surements.ª 2012 King Saud University. Production and hosting by Elsevier B.V. All rights reserved.

1. Introduction

Polymer-clay nanocomposites have received significant atten-tion, since the first report of polyamide-6-clay nanocomposites

by Toyota’s research group in 1990 (Lai et al., 2008). Subse-quent studies have discovered that physical and chemical prop-erties of organic polymers, such as thermal stability, (Lan

et al., 1994) mechanical strength, (Tyan et al., 1999) solvent

8 9188630427; fax: +98 861

(K. Faghihi).

Saud University.

g by Elsevier

. Production and hosting by Elsev

0.027

aghihi, K. et al., New poly(ethrnal of Chemistry (2012), http:

resistance, (Burnside and Giannelis, 1995) flame retardation,(Gilman et al., 2000) ionic conductivity, (Vaia et al., 1995)corrosion resistance, (Yu et al., 2004) gas barrier properties,(Messersmith and Giannelis, 1995), and dielectric properties

(Koo et al., 2003) are substantially improved by the introduc-tion of small portions of inorganic clay. Unique properties ofthe nanocomposites are usually observed when the ultra fine

silicate layers are homogenously dispersed throughout thepolymer matrix at nanoscale. The uniform dispersion ofsilicate layers is usually desirable for maximum reinforcement

of the materials. Due to the incompatibility of hydrophiliclayered silicates and hydrophobic polymer matrix, theindividual nanolayers are not easily separated and dispersed

in many polymers. For this purpose, silicate layers are usuallymodified with an intercalating agent to obtain organicallymodified clay prior to use in nanocomposite formation(Wilson et al., 1990).

ier B.V. All rights reserved.

er-amide-imide) reinforced layer silicate nanocomposite: Syn-//dx.doi.org/10.1016/j.arabjc.2012.10.027

2 K. Faghihi et al.

High-performance polymeric materials are currently receiv-ing considerable attention for their potential applications in ad-vanced technology demands. Aromatic polyimides are well

known high-performance polymers that show excellent thermal,mechanical and electrical properties (Cassidy, 1980; Saxenaet al., 2003). However, applications may be rather limited due

to their high softening or melting temperatures and their insol-uble nature in most organic solvents (Liaw et al., 2001).

Modification of high performance materials by increasing

the solubility and lowering the transition temperatures whilemaintaining thermal stability is of particular interest. Copoly-condensation is one of the possible ways for modification ofpolymer properties. Thus, for the processing of polyimides

many copolyimides, such as poly(amide-imide)s, poly(ester-imi-de)s, and other copolymers have been prepared (Mallakpourand Kowsari, 2006; Hajibeygi et al., 2011; Faghihi et al., 2010,

2011, 2009a,b; Hale et al., 1967; Johnson et al., 1967).Aromatic polymers that contain aryl ether linkages gener-

ally have lower glass transition temperatures, greater chain

flexibility and tractability in comparison to their correspond-ing polymers of these groups in the chain (Bottino et al.,2001; Gutch et al., 2003; Faghihi et al., 2009a,b).

The lower glass transition temperatures and also improvedsolubility are attributed to the flexible linkages that provide apolymer chain with a lower energy of internal rotation (Fag-hihi et al., 2009a,b).

In this article, two new PEAI-nanocomposite (PEAIN) filmswith 5% and 10% silicate particles were prepared by using aconvenient solution intercalation technique. Poly(ether-

amide-imide) was prepared by reacting 4,4-diamino diphenylether two with N,N0-(4,40-diphenylether)bistrimellitimide onein N-methyl-2-pyrrolidone (NMP). Structure and morphology

of the PEAIN were determined by FT-IR, UV–Vis, XRD andSEM, TGA and water absorption measurements. The newnanocomposites containing ether group have good solubility

with high thermal stability.

2. Experimental section

2.1. Materials

Trimellitic anhydride, 4,40-diamino diphenyl ether, acetic acid,

triphenyl phosphite (TPP), CaCl2, pyridine and N-methyl-2-pyrrolidone (NMP) were purchased from Merck ChemicalCompany and used without further purification. The organi-

cally modified Cloisite� 20A supplied by Southern Clay

Table 1 Organic modifiers and interlayer distance of the

clays.

Type of clay Organic modifier Concentration of

organic modifier

(meq/100 g clay)

Interlayer

distance g/cc

Cloisite� 20A

N+ HT

HT

CH3

CH395 1.77

HT=Hydrogenated Tallow (�65% C18; �30% C16; �5% C14).

Please cite this article in press as: Faghihi, K. et al., New poly(eththesis and properties. Arabian Journal of Chemistry (2012), http:

Products (TX), was used as polymer nano reinforcement.The organic modifier and the interlayer distance of the claysare shown in Table 1 to account for the structural

modifications of the functionalizations.

2.2. Monomer synthesis

2.2.1. Synthesis of N,N0-(4,40-diphenylether)bistrimellitimide 1

This compound was prepared according to our previous work

(Faghihi and Hajibeygi, 2004).

2.3. Polymer synthesis

A mixture of 1.1 g (2 mmol) of N,N’-(4,40-diphenylether)bistri-mellitimide, 0.4 g (2 mmol) of 4,40-diamino diphenyl ether 2,0.2 g of CaCl2, 0.6 mL of Pyridine, 2 mL of TPP, and 2 mLof NMP were heated while being stirred at 120 �C for 5 h.

The viscosity of the reaction solutions increased after 30 min,and additional NMP was added to the reaction mixture. Atthe end of the reaction, the obtained polymer solution was

trickled into stirred methanol. The yellow, stringy polymerwas washed thoroughly with hot water and methanol, collectedby filtration, and dried at 100 �C under reduced pressure. The

resulting polymer 3 was dried under vacuum to leave 0.13 g(97%) of solid polymer. The inherent viscosity of this solublePEAI 3 was 0.42 dL/g. IR (KBr): 3235 (m), 3064 (m), 1776(w), 1726 (s), 1672 (s), 1605 (m), 1508 (m), 1421 (m), 1380

(m), 1302 (s), 1220 (m), 1141 (m), 794 (w), 756 (w), 725(w).

2.4. PEAI-nanocomposite synthesis of 3a and 3b

PEAI-nanocomposites 3a and 3b were produced by the solu-tion intercalation method, two different amounts of organo-clay particles (5 and 10 wt.%) were mixed with appropriate

amounts of PEAI solution in N-methyl-2-pyrrolidone (NMP)to yield particular nanocomposite concentrations. To controlthe dispersibility of organoclay in poly(amide-imide) matrix,

constant stirring was applied at 25 �C for 24 h. Nanocompositefilms were cast by pouring the solutions of each concentrationinto Petri dishes placed on a leveled surface followed by theevaporation of solvent at 70 �C for 12 h. Films were dried at

80 �C under vacuum to a constant weight. Scheme 1 showsthe flow sheet diagram and the synthetic scheme for PEAI-nanocomposite films 3a and 3b.

Scheme 1 Synthetic route of N,N0-(4,40-diphenylether)

bistrimellitimide.

er-amide-imide) reinforced layer silicate nanocomposite: Syn-//dx.doi.org/10.1016/j.arabjc.2012.10.027

New poly(ether-amide-imide) reinforced layer silicate nanocomposite: Synthesis and properties 3

2.5. Measurements

IR spectra were recorded on a Galaxy series FTIR 5000 spec-trophotometer (England). Band intensities are assigned asweak (w), medium (m), strong (s) and band shapes as shoulder

(sh), sharp (s) and broad (br). UV–Vis absorptions were re-corded at 25 �C in the 190–700 nm spectral regions with a Per-kin-Elmer Lambda 15 spectrophotometer on NMP solutionsby using cell path lengths of 1 cm. Inherent viscosity was mea-

sured by a standard procedure using a Technico� viscometer.Thermogravimetric analysis (TGA) data were taken on a Met-tler TA4000 System under N2 atmosphere at a rate of 10 �C/min. The morphology of nanocomposite film was investigatedon a Cambridge S260 scanning electron microscope (SEM).

3. Results and discussion

3.1. Monomer synthesis

Diacid 1 was synthesized by the condensation reaction of twoequimolars of trimellitic anhydride with one equimolar of 4,40-

diamino diphenyl ether in acetic acid solution (Scheme 1).The chemical structure of diacid 3 was confirmed by FT-IR

and 1H-NMR spectroscopy.

3.2. PEAI-nanocomposite films

PEAI-Nanocomposites were prepared by the appropriateamounts of Cloisite� 20A and PEAI in NMP (Scheme 2).

PEAI-nanocomposite films were transparent and yellowish

Scheme 2 Flow sheet diagram for the synthes

Please cite this article in press as: Faghihi, K. et al., New poly(eththesis and properties. Arabian Journal of Chemistry (2012), http:

brown in color. The incorporation of organoclay changedthe color of films to dark yellowish brown. Moreover, a de-crease in the transparency was observed at higher clay con-

tents. Scheme 2 shows the flow-sheet diagram and thesynthetic scheme for PEAI-nanocomposite films 3a and 3b.

3.3. FT-IR spectroscopy analysis

FT-IR data of PEAI-nanocomposite films 3b and 3b showedthe characteristic absorption bands of the Si-O and Mg-O moi-

eties at 1019 and 1018 cm�1 respectively. The incorporation oforganic groups in PEAI-nanocomposite films was confirmedby the presence of peaks around 1776, 1726, 1380, 725 (imide

rings) and 1650 (amide carbonyl group) (Fig. 1).

3.4. X-ray diffraction analysis

The XRD is most useful for the measurement of interlayer

spacing of the organoclay upon the formation of the nanocom-posites. It supplies information on the change of d-spacing ofordered immiscible and ordered intercalated nanocomposites.

Fig. 2 shows the XRD patterns of PEAI-nanocomposite films3a and 3b containing 5 and 10 wt.% of silicate particles. TheCloisite� Na gives a distinct peak around 2h equal to 8.93,

which corresponds to a basal spacing of around 1.00 nm.The organically modified Cloisite� 20A employed for thepreparation of nanocomposites has a typical peak at 2h equalto 6.56 increased d-spacing, when the amount of organoclay

increased (5–10 wt.%) in the nanocomposites. These resultsindicated a significant expansion of the silicate layer after the

is of PEAI-nanocomposite films 3a and 3b.

er-amide-imide) reinforced layer silicate nanocomposite: Syn-//dx.doi.org/10.1016/j.arabjc.2012.10.027

Figure 1 FT-IR spectra of PEAI, nanocomposites 3a and 3b.

Figure 2 X-ray diffraction patterns of organoclay, PEAI-nano-

composites 3a and 3b.

4 K. Faghihi et al.

insertion of PEAI chains. The shift in the diffraction peaks ofPEAI-Nanocomposite films confirms that intercalation has ta-ken place. This is direct evidence that PEAI-Nanocompositeshave been formed as the nature of intercalating agent also af-

fects the organoclay dispersion in the polymer matrix. Usuallythere are two types of nanocomposites depending upon the dis-persion of clay particles. The first type is an intercalated poly-

mer clay nanocomposite, which consists of well ordered multilayers of polymer chain and silicate layers a few nanometersthick. The second type is an exfoliated polymer–clay nanocom-

posite, in which there is a loss of ordered structures due to theextensive penetration of polymer chain into the layer of sili-cate. Such part would not produce distinct peaks in the

XRD pattern (Krishnan et al., 2007).

3.5. Scanning electron microscopy

In order to investigate the morphology, fractured surfaces of

PEAI-nanocomposite films were studied using SEM. Themicrographs of the nanocomposites containing 5 and

Please cite this article in press as: Faghihi, K. et al., New poly(eththesis and properties. Arabian Journal of Chemistry (2012), http:

10 wt.% silica in the matrix are shown in Fig. 3. The resultsshow a fine dispersion of silica particles in the matrix whenthe concentration of inorganic phase is increased. Nanocom-

posite films have a homogeneous distribution with no preferen-tial accumulation of silica in any region across the films. Themicrographs also indicate the presence of interconnected silica

domains in the continuous polyamide phase, which demon-strates better compatibility between smaller silica nanoparti-cles and the PEAI in the nanocomposite films.

3.6. Optical clarity of PEAI-nanocomposite films

Optical clarity of PEAI-nanocomposite films containing 5–

10 wt.% clay platelets and neat PEAI was compared by UV–Vis spectroscopy in the region of 260–800 nm. Fig. 4 showsthe UV–Vis transmission spectra of pure PEAI and PEAI-nanocomposite films containing 5 and 10 wt.% clay platelets.

These spectra show that the UV–Visible region (250–800 nm)is affected by the presence of clay particles and exhibiting lowtransparency reflected to the primarily intercalated composites.

Results show that pure PEAI and PEAI-nanocomposite filmswith various amounts of silica are transparent. The maximumtransmittance was found for the PEAI. The transparency of

these naocomposites depends upon the size and spatial distribu-tion of silica particles in the PEAI matrix. Nanocomposite filmswere transparent because the average size of ceramic particles issmaller than the wavelength of light, and the distribution of

particles is relatively uniform. Ultimately the tendency for theagglomeration of small particles into larger ones may increase,which decreases the homogeneity of the system. As particle size

becomes larger, the transmittance values decrease.

3.7. Thermal properties

The thermal properties of PEAI-nanocomposite films contain-ing 5 and 10 wt.% clay platelets and neat PEAI were investi-gated by TGA in a nitrogen atmosphere at a heating rate of

10 �C/min (Fig. 5). Initial decomposition temperature, 5%and 10% weight loss temperatures (T5, T10) and char yieldsare summarized in Table 2. These samples exhibited goodresistance to thermal decomposition. T5 for neat PEAI and

PEAI-nanocomposite films containing 5 and 10 wt.% clayplatelets ranged from 270 to 337 �C and T10 for them rangedfrom 388 to 418 �C, and residual weights at 800 �C ranged

from 38% to 44.5% in nitrogen respectively. Incorporationof organoclay into the PEAI matrix also enhanced the thermalstability of the nanocomposites. Thus, we can speculate that

interacting PEAI chains between the clay layers serve to im-prove the thermal stability of nanocomposites. The additionof organoclay in polymeric matrix can significantly improve

the thermal stability of PEAI.

3.8. Water absorption measurements

The water absorption of PEAI-nanocomposite films was car-

ried out using a procedure under ASTM D570-81 (Zulfiqarand Sarwar, 2008). The results showed a monotonic maximumwater uptake for the pure polyamide (16.01%) but an asymp-

totic decrease thereafter (Table 2). The exposure of polargroups to the surface of polymer where water molecules devel-op secondary bond forces with these groups. The clay platelets

er-amide-imide) reinforced layer silicate nanocomposite: Syn-//dx.doi.org/10.1016/j.arabjc.2012.10.027

Figure 3 SEM micrographs of the PEAI-nanocomposites with various silica contents (wt%): 5 and 10.

Figure 4 UV–Vis spectra of PEAI 5, PEAI-nanocomposite films

3a–3b.

Figure 5 TGA–DTG curve for (a) PEAI, (b) PEAI-nanocom-

posite 3a, and (c) PEAI-nanocomposite 3b.

Table 2 Thermal behaviors and water uptake of neat PEAI 3

and PEAI-nanocomposite films 3a and 3b.

Polyimide T5 (�C) a T10 (�C)b Char Yield c Water uptake (%)

3 270 388 38 16.01

3a 337 400 40 13.85

3b 327 418 44.5 11.55

a,b Temperature at which 5% or 10% weight loss was recorded by

TGA at a heating rate of 10 �C/min in N2.c Weight percentage of material left after TGA analysis at a

maximum temperature of 800 �C in N2.

New poly(ether-amide-imide) reinforced layer silicate nanocomposite: Synthesis and properties 5

Please cite this article in press as: Faghihi, K. et al., New poly(eththesis and properties. Arabian Journal of Chemistry (2012), http:

obviously restrict the access of water to the hydrogen-bondingsites on the polymer chains. The weight gain by the films grad-

ually decreased as the clay content was increased. It is appar-ently due to the mutual interaction between the organic andinorganic phases. This interaction resulted in the lesser avail-

ability of polar groups to interact with water. Secondly, theimpermeable clay layers mandate a tortuous pathway for apermeant to transverse the nanocomposite. The enhanced bar-

rier characteristics, chemical resistance and reduced solventuptake of PEAI-nanocomposites all benefit from the hindereddiffusion pathways through the nanocomposite.

4. Conclusions

The PEAI-nanocomposites were successfully prepared usingthe solution intercalation method. The structure and the uni-

form dispersion of organoclay throughout the PEAI matrixwere confirmed by FTIR, XRD and SEM analyses. The opti-cal clarity and water absorption property of PEAI-nanocom-

posites were decreased significantly with increasingorganoclay contents in the PEAI matrix. On the contrary thethermal stability of PEAI-nanocomposites was increased

er-amide-imide) reinforced layer silicate nanocomposite: Syn-//dx.doi.org/10.1016/j.arabjc.2012.10.027

6 K. Faghihi et al.

significantly with increasing the organoclay contents in thePEAI matrix. The enhancements in the thermal stability ofthe nanocomposite films 3a and 3b caused by introducing

organoclay may be due to the strong interactions betweenpolymeric matrix and organoclay generating well intercalationand dispersion of clay platelets in the PEAI matrix. Thermal

and organosoluble properties can make these nanocompositesattractive for practical applications such as processable high-performance engineering plastics.

References

Bottino, F.A., Pasquale, G.D., Scalia, L., Pollicino, A., 2001. Polymer

42, 3323.

Burnside, S.D., Giannelis, E.P., 1995. Chem. Mater. 7, 1597.

Cassidy, P.E., 1980. Thermally Stable Polymers. Marcel Dekker, New

York.

Faghihi, Kh., Hajibeygi, M., 2004. J. Appl. Polym. Sci. 92, 3447.

Faghihi, Kh., Hajibeygi, M., Shabanian, M., 2009a. Macromol. Res.

17, 739.

Faghihi, Kh., Hajibeygi, M., Shabanian, M., 2010. Polym. Int. 59, 218.

Faghihi, Kh., Shabani, F., Shabanian, M., 2011. J. Macromol. Sci. A

48, 381.

Faghihi, Kh., Shabanian, M., Hajibeygi, M., 2009b. Macromol. Res.

17, 912.

Gilman, J.W., Jackson, C.L., Morgan, A.B., Hayyis Jr., R., Manias,

E., Giannelis, E.P., Wuthenow, M., Hilton, D., Philips, S.H., 2000.

Chem. Mater. 12, 1866.

Gutch, P.K., Banerjee, S., Jaiswal, D.K., 2003. J. Appl. Polym. Sci. 89,

691.

Please cite this article in press as: Faghihi, K. et al., New poly(eththesis and properties. Arabian Journal of Chemistry (2012), http:

Hajibeygi, M., Faghihi, Kh., Shabanian, M., 2011. J. Appl. Polym. Sci.

121, 2877.

Hale, W.F., Farnham, A.G., Johnson, R.N., Clendinning, R.A., 1967.

J. Polym. Sci. Part A: Polym. Chem. 5, 2399.

Johnson, R.N., Farnham, A.G., Clendinning, R.A., Hal, W.F.,

Merriman, C.N., 1967. J. Polym. Sci. Part A: Polym. Chem. 5,

2375.

Koo, C.M., Kim, S.O., Chung, I.J., 2003. Macromolecules 36, 2748.

Krishnan, P.S.G., Wisanto, A.E., Osiyemi, S., Ling, C., 2007. Polym.

Inter. 56, 787.

Lai, M.C., Jang, C.G., Chang, K.C., Hsu, S.C., Hsieh, M.F., Yeh,

J.M., 2008. J. Appl. Polym. Sci. 109, 1730.

Lan, T., Kaviratna, P.D., Pinnavaia, T.J., 1994. Chem. Mater. 6, 573.

Liaw, D.J., Liaw, B.Y., Hsu, P.N., Hwang, C.Y., 2001. Chem. Mater.

13, 1811.

Mallakpour, S., Kowsari, E., 2006. Polym. Adv. Technol. 17, 174.

Messersmith, P.B., Giannelis, E.P., 1995. J. Polym. Sci. Part A: Polym.

Chem. 33, 1047.

Saxena, A., Rao, V.L., Prabhakaran, P.V., Ninan, K.N., 2003. Eur.

Polym. J. 39, 401.

Tyan, H.L., Liu, Y.C., Wei, K.H.T., 1999. Chem. Mater. 11, 1942.

Vaia, R.A., Vasudevan, S., Krawiec, W., Scanlon, L.G., Giannelis,

E.P., 1995. Adv. Mater. 7, 154.

Wilson, D., Stenzenberger, H.D., Hergenrother, P.M., 1990. Polyim-

ide. Chapman & Hall, New York.

Yu, Y.H., Yeh, J.M., Liou, S.J., Chang, Y.P., 2004. Acta. Mater. 52,

475.

Zulfiqar, S., Sarwar, M.I., 2008. J. Incl. Phenom. Macrocycl. Chem.

62, 353.

er-amide-imide) reinforced layer silicate nanocomposite: Syn-//dx.doi.org/10.1016/j.arabjc.2012.10.027

![Nanocomposite [5]](https://static.fdocuments.in/doc/165x107/577c7ecf1a28abe054a26499/nanocomposite-5.jpg)