New Mains Design Workshop Final V1 -...

Transcript of New Mains Design Workshop Final V1 -...

NEW MAINS DESIGN WORKSHOP 24th October 2014 Timothy Balding CH2MHILL Jonathan Cockram United Utilities Adrian Watkins HydroCo

New Mains Design Workshop Page | 1 www.cwmag.org

Summary This report has been written to summarise the outputs from the ‘New Mains Design Workshop’ held on 24th October 2014 as part of the Cleanwater Modelling Advisory Group 3rd Annual Conference. The workshop was intended to be a springboard of ideas, to compare and contrast differing opinions relating to the design of mains from a modelling point of view, and then to document the outputs. As such, these guidelines are just that – an opportunity to consider what other companies do, to incorporate best practice and to inform choices. They are in not meant to be firm ‘set in stone’ rules. Factor Consensus Comments Minimum Pressure (m) 20m At critical point in the main Maximum Pressure (m) SDR rating Not >90m pressure max

pressure. *Pressure Range (m) 20-30m Range of pressure important

(20-30m max). Not >40m range.

Headloss (m/km) 5m/km or less <5m/km acceptable especially in smaller diameter mains

Velocities (m/s) 1.0 m/s or less <1m/s acceptable especially in larger diameter mains.

*Trunk Mains Less strict – higher velocities, higher headlosses, lower pressures allowable

It was generally felt that when designing trunk mains, factors would be relaxed to incorporate pump efficiency/run time cost/carbon optimisation.

Model Type Calibrated Peak model Domestic Demand ‘worst case’ Unaccounted For Water (UFW)

Un-decided

Commercial Demand Discuss with Developer Instantaneous Demand Un-decided Fire Flows Not considered Developer will usually be told

what the Network is capable of rather than designed for

*Not a separate discussion point but came out of general topics To summarise, the over-riding main driver for sizing a pipe was the final pressure predicted to be experienced at the end/critical point of the pipe. A view on the headloss across the length of the pipe was also considered important. These are not hard and fast rules, one of the benefits of modelling is that a larger, holistic view can be taken of the whole system.

New Mains Design Workshop Page | 2 www.cwmag.org

Contents Introduction Discussions-

Minimum Pressure Maximum Pressure Headloss Velocity Base Model Type Domestic Demand Unaccounted For Water (UFW) Commercial Demand Instantaneous Demand Fire Flows

Conclusions References Bibliography Acknowledgements Appendices

New Mains Design Workshop Page | 3 www.cwmag.org

Introduction One of the uses of hydraulic models is to assess the flow, velocity and headloss in existing and new pipes, and to help form decisions on suitable pipe sizing. Given the considerable expense of pipe laying, options to downsize/line/pipeburst need to be carefully evaluated by engineers. The current legislation for supplying a domestic property is 10m @ 9 l/min at the first tap in the property. Most companies adopt a surrogate value of 15m minimum pressure in the main supplying the property to allow for variations in ground level and headlosses etc. However, there is no legislation for high pressure, velocity or headloss. Factors such as SDR rating, pressure management, existing mains, customers internal plumbing fittings, supply system type (pumped or gravity) will have an impact on design decisions. The workshop was delivered in two sections - Design criteria (headloss, velocity etc), followed by model specific issues, such as model type and demand loadings. The workshop was designed to draw out a consensus from the attendees by presenting ideas, creating a group discussion environment, and getting each group to complete a multi-choice set of questions. The attendees were separated into 5 tables, each of 8 people, with care taken to ensure that each table represented a mix of water company and consultant personnel. Each criteria was discussed with reference to its impact on pipe design as follows: Minimum Pressure 4 out of 5 groups considered that 20m should be used as a minimum modelled pressure, at the critical point in the main. 15m was the other minimum pressure considered, if necessary. Other points raised included existing DMA pressure, and that a lower pressure could be accepted in a trunk main system, where no customers are supplied. The aim is not to create customer complaints but to reduce them by identifying properties at risk of pressures less than 20m. Also significant is the change in minimum pressure – customers may notice, and complain about, a sudden drop in pressure. Any DMA changes might mean the critical point will move. Building height, and requirements for commercial customers to maintain a certain pressure for processes need to be considered. Some organisations model further into buildings – would we ever need to model into domestic properties in the future?

New Mains Design Workshop Page | 4 www.cwmag.org

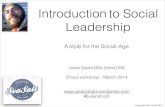

Maximum Pressure 3 out of 5 groups considered that maximum pressure would be defined by the SDR rating of the existing pipe/s within the area, or of the pipe to be installed. One group agreed a range would be a better criteria and another group also thought a maximum of 60m pressure in a distribution system should be an advisable limit. Plumbing fittings can suffer at high pressures, so a new development would need to be advised if pressure was likely to be more than 90m. Some organisations have received water hammer complaints from high pressure areas. Wherever possible, pressure reduction/management would be considered. The SDR rating of existing pipes might not be known. In trunk mains a higher pressure could be considered and a suitable pipe material would be chosen to deal with it. Here the range of pressure/diurnal variation came out as a discussion point. A range of 20-30m was considered OK, but not greater than 40m. The issue of ‘Calm Networks’ was discussed.

Reducing the pipe size to increase headloss and therefore decrease pressure was not acceptable – other methods of pressure management would need to be introduced. Headloss In general headloss is not used as a trigger point for mains design, although a headloss of 5m/km or less was considered by 3 out of 5 groups to be acceptable. The table overleaf considers the headlosses through various pipe sizes at a set velocity of 1.0 m/s. The table shows that headlosses in the smaller mains (approximately

0

10

20

30

40

50

60

00:00 06:00 12:00 18:00 00:00

Pressure (m)

Time

Maximum / Minimum DMA Headloss Envelope

Pressure Profile Headloss Envolope (Maximum ) Headloss Envolope (Minimum )

New Mains Design Workshop Page | 5 www.cwmag.org

below 8”) are very high and 5m/km appears to be a good upper value to use when designing these mains.

Most groups felt that this was very much subject to individual circumstances, and that ultimately the level of service experienced by a customer would over-ride any specified headloss limits. The total headloss across the length of the pipe was discussed as more important than a high headloss over a short length, though network technicians/engineers should be made aware of any high headlosses. The question was raised regarding under which demand circumstances this could be used as a design limit, and whether turbulent flow should be considered. Velocity All groups felt a maximum velocity of 1m/s could be applied for both metal and plastic mains, with this limit relaxed for pumped systems. The question was raised as to whether there is any published work that recommends 1m/s as a guideline or whether it has been developed as a rule of thumb. Nobody was aware of any published data. The table overleaf compares velocities against pipe sizes for headlosses at 3, 5 and 8m/km. This shows that if headloss is solely used to size mains the velocities and flow rates are generally low for the smaller mains, and high for the larger mains. It is therefore probably more appropriate to use the 1m/s velocity limit for the larger mains (above 8”) and the 5m/km headloss limit for the smaller mains.

New Mains Design Workshop Page | 6 www.cwmag.org

In pumped systems it was accepted that velocities could be higher for the duration of the pumping time. The point was made that velocities throughout the rest of the system need to be assessed. While velocity as a parameter was considered in mains design, there are other important factors that also need to be considered. The discussion moved onto

New Mains Design Workshop Page | 7 www.cwmag.org

PODDS, conditioning flows, ‘self-cleansing’ velocities, Reynolds number and laminar or turbulent flow, gradient and the critical velocity for air in the mains and time of travel. These particular topics are complex and were not discussed in enough detail to include in this document. Section 5 – Base Model Many types of model exist across the industry and there is a large variation in their construction and the way they have been calibration. Types of model that may be available include:

All-Mains Strategic Simplified Un-calibrated

All groups agreed that ideally a calibrated Peak Model should be used for pipe sizing exercises, in order to model the ‘worst case’. In some cases, an average model is used with an ‘educated view’ on peak flows for new mains. Domestic Demand Domestic demand loadings were discussed in relation to using to models for assessing the impact of new developments on the model. A wide variation of preferences was expressed here, 2 groups prefer to use DMA values from the model, 2 prefer to use June Return published values and 1 prefers standard default values. The point was raised that all three could be tried and the ‘worst’ taken. In general, the DMA values seem to be used mostly for ease. Peaking factor was also discussed – this varies on the number of properties in the development. This point was not fully determined; the general feeling was that modeller experience comes into play here to get results that are meaningful. Unaccounted For Water As for Domestic Demand, there was a wide range of variation in the figures used. 2 groups prefer standard default values, 1 group prefers model UFW values, 1 group prefers June Return published figures. A value of 60-65l/p/d was mentioned as a minimum background leakage level, with values varying 105-150l/p/d for UFW. With so many factors affecting UFW (pipe material, quality of contractor, background, pressure management), do water companies want to admit to it at all? It’s less dependent on socio/economic factors so a standard value is more applicable.

New Mains Design Workshop Page | 8 www.cwmag.org

Should we assume no leakage in a new system/pipe? Should we use a peaking factor to account for it? Organisations may be sending a politically incorrect message to developers if they specify UFW, and should they pay for UFW as well as demand? There seemed to be many unanswered questions in relation to the leakage element of demand when considering the impact of new developments and this needs to be discussed further. Commercial Demand Most groups discuss the developer requirements and then adjust compared to similar developments or businesses. There was a feeling that developers need to be better educated and need tools to correctly estimate their demand. Other methods include loading units or demand by footprint, and/or applying demand to the standard modelling profiles (24/1610hr etc) Instantaneous Demand Demand in network models are typically calculated on a 15minute basis taking the average flow in this period. They do not consider instantaneous flow rates which occur over very short periods of time, which can have a detrimental effect on the performance of the system. This is particularly relevant to the main that connects a development to the main distribution network (site specific supply main) as its performance is very dependent on the how many of the properties are using water simultaneously. Please note - instantaneous demands should not be used to size or assess the performance of the main distribution network. A variety of methods are used to estimate instantaneous demand, with more than one method being used at any one time. One group uses Loading Units, several use published values of Domestic demand applied to peaking curve, several use standard values of Domestic demand applied to peaking curve, and a few use estimate of properties vs peak flow. From the discussions it became apparent that some organisations don’t consider instantaneous demand in design. The variance in peaking factor with the number of properties supplied was discussed, i.e. the more properties the lower the peaking factor. Also discussed was the different approaches at differing numbers of properties, i.e. plumbers rules for 10-50 units, or model profiles for 50+. With a small number of properties, there is usually a minimum pipe diameter to be used which over-rides the value of calculating a peak demand for pipe sizing. Fire Flows The general consensus here is that Fire Flows aren’t specifically modelled or allowed for but that the developer will be told what the network is capable of.

New Mains Design Workshop Page | 9 www.cwmag.org

Some organisations will provide information as a matter of course, others only if specifically requested. Certain new developments (e.g. schools) may request a fire flow requirement is provided for. It is understood from Section 57 of the Water Industry Act 1991 that water companies have a duty to provide water free of charge for firefighting, including water used for testing and training purposes’ but have no duty to provide infrastructure specific to firefighting, i.e. hydrants or additional mains capacity. As such, the mains network is designed to meet the normal (non-fire) requirements of the customers. Legislation does not specify the pressure and flow which must be made available at a fire hydrant, but desired flow rates have been specified in the “National Guidance Document on the Provision of Water for Fire Fighting” and the following is taken from Appendix 5 of the guidance document: Guideline Requirements for Fire Fighting water Housing developments with units of detached or semi-detached houses of not more than two floors should have a water supply capable of delivering a minimum of eight litres per second through any single hydrant. Multi occupied housing developments with units of more than two floors should have a water supply capable of delivering a minimum of 20 to 35 litres per second through any single hydrant on the development. Although the actual flow available from hydrants may be less than this in many cases it would seem sensible to use these published figures and pass comment on the system performance. Conclusions In conclusion, there are certain parameters that were deemed to be critical in designing new mains – in particular the [legal] requirement to provide a minimum pressure to customers. Other parameters are much more left to individual company and/or modeller experience, such as domestic and commercial demand, and UFW. Yet these can have significant effects on the results obtained and therefore the main sizing exercise. Suggested future work would include further definition of growth, peaking factors and loading units for domestic and commercial developments.

New Mains Design Workshop Page | 10 www.cwmag.org

References National Guidance Document on the Provision of Water for Fire Fighting” - Water UK, January 2007 Water Industry Act 1991 Acknowledgements We would like to express our sincere thanks towards Adrian Watkins, Jonathon Cockram and Tim Balding who devoted their time and knowledge in the creation of this document. We would also like to acknowledge the support from their respective companies: HydroCo Ltd, United Utilities and C2HM Hill. Thanks should also go to Fiona Page for her input into collating the notes for the document and Teddy Belrain who provided meeting rooms and technical input at the early stages of the Workshop planning.