New Holland BC5000 Series Square Balers...set the gold standard for haymaking. In fact, New...

Transcript of New Holland BC5000 Series Square Balers...set the gold standard for haymaking. In fact, New...

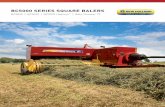

For generations, New Holland hasset the gold standard for haymaking.In fact, New Holland’s reputation forinnovation and quality began withthe small square baler, a machine thatrevolutionized hay and straw harvest-ing and put New Holland on the map.

When New Holland introducedthe first successful automatic haybaler over 70 years ago, farmersimmediately recognized its value andrushed to buy it. More than 700,000balers later, New Holland is still theleader in balers, with a well-earned

reputation for quality, reliability and engineering excellence. There have been more

New Holland small square balerssold than any other brand with goodreason – New Holland is the hay-making specialist.

Aproud heritage of innovation

New Holland is the haytools leader.

2

3The back-breaking work of putting up hay became easier with the introduction of automated balers.

Ed Nolt, inventor of the first successful automatic baler, field tests an engi-neering prototype in the mid-1940s. His design revolutionized hay andstraw harvesting and earned New Holland a place of honor in the history of agricultural machinery.

The first production units of the New Holland Model 73 baler started coming off the assembly line in 1940. The first baler (shown here restored toits original condition) was an instant success, with more than 20,000 balersof the original design made in the next several years.

In 2009, this model BC5070 was designed with special edition decals to commemorate the 700,000th small square baler built since 1937

44

Reliable, hard-working balersBC5000 Series Small Square Balers

Model BC5050 BC5060 BC5070 BC5070 BC5080Hayliner

Bale size 14” x 18” 14” x 18” 14” x 18” 14” x 18” 16” x 18”(36 x 46 cm) (36 x 46 cm) (36 x 46 cm) (36 x 46 cm) (41 x 46 cm)

Pick-up width 65” 65” 75” 75” 75”(1.65 m) (1.65 m) (1. 9 m) (1. 9 m) (1. 9 m)

Feeding system Flow-Action Rotary- Rotary- Rotary- Rotary-System Feeding Feeding Feeding Feeding

Feed Opening 283 sq. in 283 sq. in 283 sq. in 283 sq. in 318 sq. in(719 cm) (719 cm) (719 cm) (719 cm) (808 cm)

Plunger speed 79 SPM 93 SPM 93 SPM 93 SPM 93 SPM(strokes/min)

Tying Twine only Twine or wire HD twine HD twine HD twine Mechanism knotter or knotter only knotter only

wire twister

Min. PTO hp 35 hp 62 hp 75 hp 75 hp 80 hp(26 kW) (45 kW) (56 kW) (56 kW) (60 kW)

PTO Category Category 4 Category 6 HD Category 6 HD Category 6 HD Category 6 HD

Proven performanceCommercial haying operations

and operators who custom-bale for horse farms are big fans of New Holland square balers. That’sbecause their livelihood depends onmaking consistent bales that meet the exacting demands of horse andlivestock owners. They put their trust in the proven performance ofNew Holland balers.

Convenient feedingNew Holland bales are the only

choice for hand feeding. You canquickly separate the flakes, and withNew Holland’s consistent bale density,you know exactly how much eachanimal receives.

Crop-saving capacity and reliabilityYou’ll find many more award-

winning benefits to help increaseyour productivity:• The SuperSweep™ pickup savesvaluable crop• The plunger runs on sealed bear-ings and packs uniform, densebales in all crop conditions• A gear-driven knotter ties thou-sands of bales without a miss• The exclusive Power-Pivot PTOprovides extra maneuverability

Your choice for quality, uniform bales.

5

66

Models BC5070, BC5070 HAYLINER™ & BC5080

It’s the best-selling square baler in North America for big haying operations and custom operators! With an extra wide 75-inch SuperSweep pickup andhigh-capacity rotary feeding system, the Model BC5070 makes 14 x 18 bales and handles bigger, wider windrows.

High-capacity balers for large operations and commercial growers

BC5070 (14” x 18”)The BC5070 baler offers larger

baling operations a wide, 75-inch, six-bar SuperSweep pickup guidedby a 15 x 6.0-6 pneumatic gaugewheel to quickly gather the largestwindrows. The twine knotter mecha-nism is an upgraded heavy-dutydesign with a split frame for easyservicing and reliability to last forthousands of bales. To make thedensest bales possible, the BC5070 isalso available with a durable, wiretwisting system.

BC5070 Hayliner™ (14” x 18”)The BC5070 Hayliner baler pro-

vides professional-grade performancefor commercial operations, offeringsuperior bale density and shape—ideal bale qualities for pickup by balewagons. The BC5070 Hayliner baleris equipped with industry-exclusive,hydraformatic, four-way bale tension,cast-iron hay wedges, hardenedplunger rails, and a bale case that’sboth 12 inches longer and 19% heav-ier for unsurpassed reliability, baleafter bale. Best of all, the twine box is35% larger than the standard BC5070to accept larger twine balls so youspend more time baling hay.

BC5080 (16'' x 18'')The BC5080 baler makes a 14%

larger bale compared to a 14''x18''bale of the same length, packingmore hay into every bale to reducehandling costs. The solid bales areideal for handling by automatic balewagons. Commercial hay growers,custom operators, and export hayoperations choose the BC5080because it makes quick work of bighaying jobs and keeps baling yearafter year.

77

A big eight-ball twine box on the BC5070Hayliner and BC5080 keep you baling longerwithout rethreading. Conveniently located atthe rear of the baler, the box has a hinged lid tokeep twine clean and dry.

A replaceable bale chamber floor on theBC5080 increases the life of the bale chamber- abig asset in sandy and abrasive conditions.

BC5050 (14” x 18”)The BC5050 baler offers traditionalfarm operations a low power require-ment and lighter weight baler that’s a good match for tractors with as littleas 35 horsepower. The 65-inchSuperSweep™ pickup with four tinebars cleanly gathers the crop whilethe Flow-Action™ feeding systemand 79 plunger strokes per minuteprovide capacity well suited to small-er-acreage operations. Available withtwine tying only.

BC5060 (14” x 18”)The BC5060 baler provides increasedcapacity suited to traditional farmoperations. The upgraded 65-inch,five-bar SuperSweep pickup, exclusive rotary feeding system, and18% faster plunger speed comparedto the BC5050 make it possible to balemore acres every day. It’s availablewith standard-duty twine knotter foreasy service or reliable wire twistingsystem.

Balers for traditional farm operations

The BC5070 Hayliner™ and BC5080 are fast, dependable, and make solid,quality bales that are easier to handle withautomatic bale wagons. Large-scale haygrowers and custom operators choose theBC5070 Hayliner™ and BC5080 becausethey make short work of big haying jobs,and keep running strong, year after year.

You can rely on your New Hollandbaler to make consistent, high-qualitybales season after season. They’redesigned to produce dense, uniformbales that stack and transport easily.

SuperSweep pickupsAll balers feature wide Super-

Sweep pickups. The BC5050 andBC5060 have a 65-inch-width pickup;70 inches with the flare. The pickup

for the BC5070 and BC5080 measures75 inches across; 80 inches with theflare.Pair this wider pickup area with

the exclusive action of the Super-Sweep pickup, and you’ll get theextra crop that’s missed by conven-tional pickups. Multiple rows of pickup teeth work between narrowflanged guards, saving stems andprotein-rich leaves. Pickup teeth are

made of durable music wire for extra-long life. Guards also protect tinesfrom damage. A floating windguard (13-rod on

the BC5080 and BC5070, eight-rod onthe BC5060 and BC5050) ensures thatthe windrow is fed smoothly. Thepickup gauge wheel guides the pickupacross the changing terrain and is easily adjustable to five positions.

What makes a quality bale?

SuperSweep™ pickup saves valuable crop.

8

The belt-driven SuperSweep pick-up is protected against overloads soit’s sure to provide a long, trouble-free life. Plus, the “lost motion drive”capability lets you back up the balerwithout damaging pickup teeth.

Stronger plungerHigh-strength steel is used

throughout the plunger mechanismfor reliable baling. Plunger rails havebeen repositioned to eliminate groov-ing in the bale.

Dependable tyingReliable twine knotters or wire

twisters go thousands of bales with-out a miss. Knotters have hard-sur-face material at important wearpoints for long life and smooth tying.

9

The adjustable feeder back (Model BC5050) letsyou control crop flow into the bale chamber. Simplyloosen three bolts on each side, set at the desiredposition, and then retighten the bolts.

Tension springs are the economical way to adjustbale tension. A one-half-inch increase in springtension equals 600 pounds of increased force.

Adjustable bale tension doors on the BC5050,BC5060, and BC5070 make it easy to change baledensity at the bale case.

The plunger runs on sealed ball bearingrollers and wear-resistant white-iron slidesfor minimal maintenance and fewer adjustments.

The rugged bale chamber is designed for betterbale formation. Six hay dogs hold charges in placefor firm, quality bales.

You can also equip your baler with hydrafor-matic bale tension control. This feature helpsmaintain uniform bale density in varying cropconditions.

Compare theSuperSweep pickup

tooth on the left to thestraight tooth used on

ordinary pickups. Thatextra curve makes the differ-ence in gathering more crops.

Pickups are manually raised and latched intotransport position. Hydraulic pickup lift simplifiesraising and lowering the pickup. It’s standard onthe BC5080 and BC5070 Hayliner, and optionalon other models.

“Thousands of bales without a miss.” It holdstrue for the dependable knotters and twisters thatgo on New Holland balers. Knotters and twistersare gear-driven for a simpler, easy-to-maintaindesign. Twisters are available on Models BC5060and BC5070 only. A heavy-duty PTO is standard on Models

BC5060, BC5070, BC5080.

Rotary feeding system (ModelsBC5060, BC5070, BC5080)The exclusive New Holland rotary

feeding system is durable, reliable,easy to service, and easy to adjust. It produces a smoother, even flow ofmaterial through the baler thatreduces leaf loss and produces uni-form, high quality bales.A mechanically simple system, the

rotary feeder consists of heavy-duty,paired rotating tines and a feederfork.The system is timed to keep

material flowing evenly into the balechamber, by allowing the tines tooverlap for smooth, continuous cropmovement. Finally, the double packerfork folds the hay into the bale case.The packer fork is adjustable to getoptimum bale shape in different cropconditions.

Flow-Action® feeder (Model BC5050)The BC5050 features the exclusive

time-proven Flow-Action® feeder. Six feeder tines are mounted on along feeder bar which runs on sealedroller bearings for quiet, friction-freeoperation.The tines measure just the right

amount of crop and gently move it tothe bale chamber. Leaves don’t shat-ter – and that means a higher qualitybale. Plus, two sets of the tines areadjustable to handle difficult crops.Both feeding systems are chain

driven for durability and reliability,and are easy to service and adjust.

Reliable feeders make every bale a quality bale

10

Smooth, even flow guarantees uniform bales.

Nobody understands balingquite like New Holland. That’s whyyou can rely on your New Hollandbaler to be more productive, morereliable and easier to use and main-tain than ever before.

Easy to use, easy to service.

11

More productive time in the field

New pickup drive chain access shieldprovides easy entry for servicing. (ModelsBC5070 and BC5080.)

Redesigned knotter gear drive makes servicingor replacing the pickup belt simple.

The replaceable feeder floor on all modelsexcept model BC5050 provide wear resistance,easier serviceability, and extended baler life.

Hydraformatic oil pump is conveniently located for easier serviceability. (Models BC5060,BC5070, BC5080.)

Category 6 heavy-duty driveline for outstanding durability on BC5060, BC5070,BC5080 models.

New flip-up front gearbox shieldingmakesit a cinch to access key service points, like themain gearbox and hydraformatic system.

The capacity you want, and the rugged reliability you need

12

The capacity you want, and the rugged reliability you need

1. Adjustable packer fork on theBC5060, BC5070 and BC5080 can beeasily adjusted to handle variouscrops for consistent bale formation.

2. New Holland tying systems areproven for their “thousands of baleswithout a miss”. Gear drives makethem even easier to keep in time.

3. Rugged bale chamber isdesigned for better bale formation.Six hay dogs hold charges in place forfirm, quality bales.

4. High-capacity feeding systems.The rotary feeder is standard on theBC5060, BC5070 and BC5080. The

BC5050 uses the time-proven Flow-Action® feeder. Both systems areadjustable to work in varying crops,from alfalfa to slippery grasses.

5. Floating windguard controls thewindrow and forms a smooth mat forpositive feeding.

6. Flotation tires are standardequipment. They smooth out the ridein the roughest fields, yet are gentleon tender alfalfa regrowth.

7. Belt-driven pickup acts as a slipclutch to prevent overloads. Thepicukup can be backed up overwindrows without damaging thepickup teeth ("lost motion drive").

8. Pickup gauge wheel is standardequipment. It compensates for unevenfield conditions as it protects pickupteeth. Flotation tire (shown) is stan-dard on Models BC5070 and BC5080.

9. Strong plunger rides on sealedball bearings and white iron slideblocks which provide optimum baleshape and density. Two bearings andone plunger rail are adjustable formaintaining proper alignment.

10. Large feed opening handlesthe big-capacity pickup and feeder.

10

11

16

9

8

7

6

5

4 3

2 1

Proven design and durability are built in.

18

1313

11. Fast plunger speed, longplunger stroke. Thirty-inch stroke forall balers; speed is set to maximizebaler capacity (from 79 or 93 SPM,depending on the model).

12. Large flywheel providessmooth power transfer.

13. Slip clutch protection. Two-disc clutch along with overrunningdrives, provides gentle load engage-ment, long life, and greater loadcapacity.

14. Category 6 heavy-duty drive-line on the BC5080, BC5070, andBC5060 (Category 4 on the BC5050)lets you push more power into the

baler for high-capacitybaling.

15. Heavy-duty tongue attachesdirectly to the axle (not the balechamber) to keep towing stressesfrom passing through the chamber.Two field positions are available foruse with various tractor widths.(Optional hydraulic tongue swing kitavailable.)

16. Super-wide, SuperSweeppickup is standard on all balers.Curved teeth get the short fine cropother pickups miss while pickup visibility ensures plug-free feeding.

17. Exclusive Power-Pivot PTOis standard on all models. You canmake tight turns with less wear onthe universal joints.

18. Smooth main-drive gearbox.Tapered roller bearings and heat-treated, alloy-steel gears run in oil forsmooth, quiet working. Shearboltprotects from overloads.

15

14

13

12

17

A. Larger flotation tires (11Lx14 right and14L16.1 left) give the smoothest ride possible andreduce soil compaction.

B. Hydraformatic four-way bale tension allows forincreased bale density to make the heaviest balespossible with the turn of one knob.

C. The bale case is longer by 12 inches to holdthe bale longer, maintaining bale shape andreducing bale length variations. The bale case is 19% thicker than the standard BC5070 forincreased durability.

D. Cast-iron hay wedges replace the front set of sheet metal wedges for longer life and better performance in straw.

E. Hardened plunger rails withstandthe heaviest loads and wear lessfor a long, trouble-free service life.

F. Large twine box holds larger twine balls so youcan use higher knot strength twine and spendmore time baling with fewer broken bales.

BC5070 HAYLINER™ ADVANTAGES

A

B

CDE

F

14

Better balers deserve better throwers.

Save time, increase productivity with a bale thrower.

Improve productivityIncrease productivity by throwing

bales – as they’re made – right intoyour bale wagon. The Model 72 belt-type bale thrower offers reliable performance and a clean design.The 72 is compatible with Models

BC5050, BC5060 and BC5070 balers(not compatible with the BC5070Hayliner™). It can completely fill an18-foot wagon with bales up to 38inches long and 65 pounds in weightwithout restricting baler capacity.(Higher bale weights are possible.)Plus, the thrower’s simple design

allows for easy adjustments and servicing. And its durable design provides trouble-free operation, season after season.

Other featuresThe 72 is designed to make baling

less of a chore. Tractor-mounted elec-tric distance controls make changingthrowing speed a snap. Plus, an indi-cator on the baler lets you know at aglance the distance bales are thrown.The thrower can also be set to drop

bales directly on the ground if needed,without removing it from the baler.1. Direction control. This double-

acting hydraulic cylinder pivots thethrower up to 30 degrees, left or right,for turning or baling on a contour.Simply move the tractor remote con-trol valve lever to position the thrower.2. Wagon hitch.Attaches to the

baler axle to keep towing stresseswhere they belong. Adjusts to narrowroad width for easy transport.

3. Rod spacers.Adjustable to control apron spacing when balinglight, springy, or semi-cured material.4. Diamond-tread belts. Strong

and durable.

Distance and direction controller attaches tothe tractor. The toggle switch controls the speedof the throwing belts for distance.

15

Distance Indicator is easily visible from thetractor seat. It shows you the relative distancebales are thrown: six is the farthest distance(fastest belt speed); one is shortest.

SPECIFICATIONS MODEL 72 Thrower

Bale Size:

Cross section . . . . . . . . . . . . . . . . . .14x18 in. (36x46 cm) Length (max.) . . . . . . . . . . . . . . . . . .38 in. (96.5 cm)Weight:Maximum . . . . . . . . . . . . . . . . . . . .80 lb. (36.3 kg)Maximum recommended with 18-ft. wagon . . . . . . . . . . . . . .65 lb. (29.5 kg)Baler Models . . . . . . . . . . . . . . . . . .Works with New Holland BC5050,

BC5060, BC5070 twine-tie balers

Apron Belt (two) . . . . . . . . . . . . . . . .12 in. (30.5 cm) wide, 2 ply, diamond-tread

Apron Belt Speed (max.) . . . . . . . .2570 feet per min. (783 m/min.)

Apron Belt Roller Speed:

Maximum . . . . . . . . . . . . . . . . . . . . .1946 rpmAs shipped . . . . . . . . . . . . . . . . . . . .1870 rpmPower . . . . . . . . . . . . . . . . . . . . . . . .Hydraulic, driven from baler flywheel

Movement . . . . . . . . . . . . . . . . . . . .Horizontal; 30 degrees right, left(0.52 rad). Controlled by hydrauliccylinder.

Dimensions:

Weight (approx., with wagon hitch) . .655 lbs. (297 kg)Height (from top of bale case) . . . . .31.5 in. (79.9 cm)Length (approx., beyond end of bale case) . . . . . . . . . . . . . . . . . . . .58.1 in. (147.6 cm)Design, materials and/or specifications are subject to change without notice and without liability therefore.Specifications are applicable to units sold in Canada, the United States, its territories and possessions, and mayvary outside these areas.

Other companies talk about haymaking. Only New Hollanddelivers a complete product line ofhigh-quality hay equipment.

No more waiting on the weathermanCropSaver™ preservative appli-

cation systems allow you to get bal-ing sooner, work late into theevenings, and even bale with aheavy dew. That is because whentreated with CropSaver™ preserva-tive, hay can be baled at moisturesup to 30% without worrying aboutheating or mold damage.CropSaver™ Buffered Acid is effec-tive on all types of hay, is non-corro-sive to baling equipment, and safefor all livestock, including horses.

Clear big fields of bales fastFor over 40 years, New Holland

bale wagons have transformed theback-breaking labor of moving andstacking bales into a job that's almosteffortless. New Holland makes thisjob faster than ever with the H9800Series self-propelled automatic balewagons.The Stack Command™ con-trol system allows you to programand control how you want to stackthe bales on the wagon from thecomfort of the cab.New Holland also offers Model

1037—a pull-type bale wagon thatyou can pull behind your tractorand pick up, load and stack balesright from your seat.

Look no further for all your haymaking needs.

16

Options and completing packages make the best even better.

For automatic bale retrieval,New Holland offers pull-type and self-propelled bale wagons.

CropSaver™ is a safe solution used to help preserve all types of hay including alfalfa andgrass.

The automatic CropSaver applicators featuretwin star wheels mounted on the underside ofthe bale chute that measure the moisture in eachbale and continuously adapt the application rateevery three second to moisture changes.

The automatic CropSaver applicator with strokecounter utilizes position sensors to detect wheneach bale is tied, the number of strokes per baleand determines the tons per hour harvested.Displayed on the monitor, this informationallows the operator to adjust baling speed tomaximize productivity and maintain an accurate bale length.

Make good, tight bales withNew Holland twineIf your aim is to make premium-

quality bales, it only makes sense touse a New Holland baler and top-quality twine. All New Hollandtwine has been tested and proven to work in New Holland balers.

New Holland natural twine istreated to resist mildew, rot, rodentsand insects, and is uniform in thick-ness and strength throughout theentire length. That’s why New Hollandnatural twine has fewer tying prob-lems and a higher knot strength thancompetitive twines.

New Holland plastic twine setsthe standard for quality, strength,and long-lasting durability. It won’trot, and is non-toxic and harmless ifeaten by animals. New Hollandplastic twine will work with anyproperly adjusted twine baler with-out modifications.

17

Quarter-turn bale chute drops bales on their sides so twine is kept away from the ground to pre-vent rotting. Sets bale into proper position for retrieval by automatic bale wagon. Bale case extensionis also recommended when using the quarter-turn bale chute.

Triple-purpose chute supports bales as theyleave the chamber; can be set to roll bales to theleft, away from the next windrow. (Also becomesthe base for bale-loading chute.)

Hydraulic tongue swing uses hydraulic mus-cle to swing the baler into transport or workingposition quickly and easily.

Road lights provide visibility when towing andturn signals for safety

Worklights. Bright halogen lights provideample illumination for night baling.

Don’t be fooled—not all twines are createdequal. You can rely on quality twine from NewHolland—available in natural fiber and plastic.

Hydraulic pickup lift. (Shown from rear ofbaler.) When baling, raise or lower your pickupas needed to adjust to differing terrain withoutleaving your tractor seat.

Specifications

18

MODEL BC5050 Bale Size:Cross section 14 x 18 in. (36 x 46 cm) Length .................................................................................

SuperSweep™ Pickup:Width inside 65 in. (1.65 m) Width on flare 70 in. (1.8 m) Number of tines 88Number of tine bars 4Floating Windguard Eight rods Drive ...........................................................................................................................................................V Gauge Wheel 3.00 x 12; semi-pneumatic Hydraulic Pickup Lift Optional

Bale Chamber:Feeding System Flow-Action® Feeder Number Feed Rotors —Packer Fork — Feed Opening 283 sq. in. (1826 sq. cm) Standard Density System Adjustable springs & tension doors Optional Density System — Bale Case Standard-Duty

Plunger:Stroke length 30 in. (76.2 cm) Speed (540 rpm) 79 SPM Material High Strength Steel Plunger Rail Standard-Duty

Tying Mechanisms:Twine knotter Standard-DutyBillhook StandardWire twister —Protection ShearboltTwine capacity 4-Twine Ball Wire capacity —

Main Drive:Flywheel weight 248 lb (112 kg) PTO Power-Pivot, Three-joint PTO PTO Category Cat. 4 Protection ................................................................................................................................................................S Gearbox .....................................................................................................................................H

Flotation Tires:Right side 25 x 7.0-15, 6PR Left side 27 x 9.05-15, 6PR

Model 72 Bale Thrower:Compatible YES

Dimensions:Height (max.) 58 in. (146 cm) Width 108 in. (275 cm) Length (transport less chute) 198 in. (502 cm) Weight (twine) 3,085 lb (1399 kg) Weight (wire) —

Tractor Requirement*Minimum horsepower 35 hp (26 kW) Minimum weight .......................................................................................................................................T Hydraulic requirement —

19

BC5060 BC5070 BC5070 Hayliner™ BC5080 14 x 18 in. (36 x 46 cm) 14 x 18 in. (36 x 46 cm) 14 x 18 in. (36 x 46 cm) 16 x 18 in. (41 x 48 cm) ...........................................................................................Adjustable, 12 to 52 in. (31 to 132 cm)...........................................................................................................................

65 in. (1.65 m) 75 in. (1.9 m) 75 in. (1.9 m) 75 in. (1.9 m) 70 in. (1.8 m) 80 in. (2 m) 80 in. (2 m) 80 in. (2 m) 110 156 156 156 5 6 6 6

F Eight rods Thirteen rods Thirteen rods Thirteen rods ..........................................................................V-belt to roller chain to “lost motion” reel drive .........................................................................................................................

G 3.00 x 12; semi-pneumatic 15 x 6.00 x 6; pneumatic 15 x 6.00 x 6; pneumatic 15 x 6.00 x 6; pneumatic Optional Optional Standard Optional

High-Capacity, Rotary Feeding System High-Capacity, Rotary Feeding System High-Capacity, Rotary Feeding System High-Capacity, Rotary Feeding System 2 3 3 3

P Standard - Adjustable Standard - Adjustable Standard - Adjustable Standard - Adjustable 283 sq. in. (1826 sq. cm) 283 sq. in. (1826 sq. cm) 283 sq. in. (1826 sq. cm) 318 sq. in. (2052 sq. cm.)

Adjustable springs & tension doors Adjustable springs & tension doors 4-way Hydroformatic 4-way Hydroformatic 2-way Hydroformatic & tension doors 2-way Hydroformatic & tension doors — —

Standard-Duty Standard-Duty Heavy-Duty Heavy-Duty

30 in. (76.2 cm) 30 in. (76.2 cm) 30 in. (76.2 cm) 30 in. (76.2 cm) 93 SPM 93 SPM 93 SPM 93 SPM

High Strength Steel High Strength Steel High Strength Steel High Strength Steel Standard-Duty Standard-Duty Heavy-Duty Heavy-Duty

Standard-Duty Heavy-Duty Heavy-Duty Heavy-Duty

Standard Hardened-Steel Hardened-Steel Hardened-Steel Available Available — —

P Shearbolt Shearbolt Shearbolt Shearbolt 6-Twine Ball 8-Twine Ball 8-Lg. Twine Ball 8-Lg. Twine Ball 4-Wire Coil 4-Wire Coil — —

M 248 lb (112 kg) 248 lb (112 kg) 248 lb (112 kg) 357 lb (162 kg)

Power-Pivot, Three-joint PTO Power-Pivot, Three-joint PTO Power-Pivot, Three-joint PTO Power-Pivot, Three-joint PTO Cat. 6 HD Cat. 6 HD Cat. 6 HD Cat. 6 HD

................................................................................Shearbolt, overrunning and slip clutches................................................................................................................................... ....................................................Heat-treated hypoid gears on tapered roller bearings running in an oil bath .......................................................................................................

F 27 x 9.5-15, 6PR 27 x 9.5-15, 6PR 11L x 14, 6PR 11L x 14, 6PR 31 x 13.50-15, 6PR 31 x 13.50-15, 6PR 14L x 16.1, 8PR 14L x 16.1, 8PR

YES YES NO NO

70 in. (178 cm) 71 in. (180 cm) 71 in. (180 cm) 71 in. (180 cm) 110 in. (279 cm) 120 in. (304 cm) 120 in. (304 cm) 120 in. (304 cm) 205 in. (521 cm) 205 in. (521 cm) 217 in. (551 cm) 217 in. (551 cm) 3,400 lb (1542 kg) 3,715 lb (1685 kg) 3940 lb (1787 kg) 4,200 lb (1905 kg) 3,536 lb (1603 kg) 3,851 lb (1746 kg) — —

T 62 hp (45 kW) 75 hp (56 kW) 75 hp (56 kW) 80 hp (60 kW) ......................................................Tractor weight must be greater than baler weight; excludes bale thrower ......................................................................................................... — — 1 double acting, 1 single acting 1 double acting, 1 single acting

TOP SERVICE IS MANAGED IN CLOSE PARTNERSHIP WITH NEW HOLLAND DEALERS AND SERVICE TEAMS.

TOP AVAILABILITYYear-round support and information— just by callingone toll-free number.

TOP SPEEDExpress parts delivery whenand where you need it.

TOP PRIORITYFast-track solutions maximizeyour productivity — becauseyour harvest can’t wait.

TOP SATISFACTIONWe drive and track the solutionyou need, keeping you informed— until you are back to work.

Safety begins with a thorough understandingof the equipment. Always make sure you andyour operators read the Operator’s Manualbefore using the equipment. Pay close attention to all safety and operating decalsand never operate machinery withoutall shields, protective devices andstructures in place.

NH31505051 • 111130 • SG • PRINTED IN U.S.A.

Design, materials and/or specifications are subject to change without noticeand without liability therefor. Specifications are applicable to units sold inCanada, the United States, its territories and possessions, and may vary outsidethese areas.

© 2011 CNH America LLC. All rights reserved. New Holland and CNH Capitalare registered trademarks of CNH America LLC. Any trademarks referred toherein, in association with goods and/or services of companies other than CNHAmerica LLC, are the property of those respective companies.

NEW HOLLAND TOP SERVICESM

TOTAL SUPPORT, TIMELY INFORMATION FOR NEW HOLLAND CUSTOMERS.

Learn more at www.newholland.com/na

VALUE, SERVICE AND SOLUTIONSThere’s a certain way of thinking that comes from living on a farm.Farming takes equal parts brain and brawn. Not to mention thickskin, calloused hands and a fair share of know how. Seasoned farmers know it helps to have equipment that’s built by farmers, soldby farmers and used by farmers.You might call that instinct, but wecall it FARM RAISED.

Support at every step. When you place your confidence in New Holland agricultural equipment, you get the finest in localsupport. Your New Holland dealer understands the many challengesyou face and stands behind you at every step with the equipment,parts, service and financial solutions to make your job easier. Look to New Holland for a complete selection of equipment, including a full line of tractors, hay & forage equipment, harvesting,crop production and material handling equipment.

Quality parts and service. Turn to your New Holland dealer after thesale for expert, factory-trained service and genuine New Holland–branded parts. Your dealer has the very latest service updates andtraining to ensure your equipment keeps working productively seasonafter season.

Financing solutions. Your New Holland dealer can tell you aboutsmart ways to turn your financial challenges into opportunities witha portfolio of innovative financial services available through CNHCapital, including customized financing, leasing, insurance andthe purchasing convenience of a Commercial Revolving Account.

For reliable equipment, parts and service — or just honest adviceon farming and finance— turn to New Holland and your trusted New Holland dealer. We know. We’re farmers, too.

We are proud to support the FFA.