New High-Energy Nanofiber Anode Materials · Electrospinning •Electrospinning is a simple, yet...

Transcript of New High-Energy Nanofiber Anode Materials · Electrospinning •Electrospinning is a simple, yet...

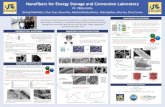

New High-Energy Nanofiber Anode Materials

Xiangwu Zhang, Peter Fedkiw, Saad Khan, and Alex Huang North Carolina State University, Raleigh, NC

Subcontractor:Jiang Fan

American Lithium Energy Corp, San Marcos, CA

May 9th, 2011

Project ID # ES010

This presentation does not contain any proprietary, confidential, or otherwise restricted information

2

OverviewTimeline

• Project start date: 09/16/2009 • Project end date: 08/15/2012• Percent complete: 55%

Barriers• Barriers Addressed

– Capacity– Cycle Life– Cost

Budget• Total project funding

– DOE share: $1,349,752 – Contractor share: $1,350,699

Partners• American Lithium Energy

Corp– Jiang Fan – 18650 Cells

• Tec-Cel Inc– Albert Bender– Pilot Production

Relevance:

3

Objective• Overall Objective

– Use electrospinning technology to integrate dissimilar materials (lithium alloy and carbon) into novel composite nanofiber anodes, which simultaneously have high energy density, reduced cost, and improved abuse tolerance

• FY11 Objectives– Capacity: At least twice the specific capacity of conventional

graphite electrodes

– Cycle life: 750 cycles of ~70% state of charge swing with less than 20% capacity fade

Relevance:

4

MilestonesMonth/Year Milestone or Go/No-Go Decision

August-10 • Establish guidelines for controlling the anode performance by selectively adjusting the processing and structures of the nanofiber anodes

• Assemble, cycle, and evaluate laboratory-scale coin cells• Determine baseline performance of anodes in 18650 cellsGo/No-Go Decision: Achieve initial specific capacities of 650 mAh/g and ~50 full

charge/discharge cycles for nanofiber anodes

August-11 • Fabricate nanofiber anodes that have improved performance• Assemble, cycle, and evaluate 18650 cellsGo/No-Go Decision: Achieve capacity (at least twice the specific capacity of

graphite) and cycle life (750 cycles of ~70% state-of-charge swing with less than 20% capacity fade) for nanofiber anodes

August-12 • Fabricate and deliver nanofiber anodes with specific capacities greater than 1200 mAh/g

• Fabricate and deliver 18650 cellsTarget: Deliver 18650 cells, in which nanofiber anodes have specific capacities

greater than 1200 mAh/g, with cell cycle life longer than 5000 cycles (~70% state-of-charge swing with less than 20% capacity fade)

Approach:

Background (1)

5

Silicon Anodes

• Silicon – Extremely high theoretical specific capacity of 4200 mAh g-1

• Challenge – 400% expansion and contraction causes early failures

0 500 1000 1500 2000 2500 3000 35000.0

0.5

1.0

1.5

2.0

Volta

ge (V

)

Capacity (mAh g)

Approach:

6

Background (2)Conventional Si/C Anodes

• Si/C anodes – Cycling life can be improved by preparing Si/C composite anodes, but it is still not sufficient for practical applications

• Challenge – To further increase capacity and cycle life simultaneously, a new processing technique must be developed to coat Si with a uniform carbon layer * PVC: polyvinyl chloride

PVC-based carbon-coated Sicomposite anode made byball-milling.

The inset shows the firstcharge-discharge curve of atypical Si anode.

0 5 10 15 20 250

500

1000

1500

0 1000 2000 30000

1

2

3

Carbon-coated Si (25 wt %)

Disc

harg

e Ca

pacit

y (m

Ah/g

)

Cycle Number

Si

Pote

ntia

l

(V v

s. L

i/Li+ )

Capacity (mAh/g)

Approach:

Our Approach

• Si nanoparticles are encapsulated in electrospun carbon nanofibers• The nanofiber structure will allow the anode to withstand repeated

cycles of expansion and contraction 7

Electrospun Si/C Nanofibers

Silicon nanoparticle– High Capacity

Carbon nanofiber– Long Cycle Life

Approach:

Electrospinning

• Electrospinning is a simple, yet versatile technique that can produce large quantities of nanofibers with controllable structures

Human hair with electrospun nanofibers in the background

8

www.mecc.co.jp

• Production-Scale Machines:

• Current commercial applications:– Freudenberg Nonwovens: air filters,

acoustic nonwovens, and wound pads– Donaldson Company: Ultra-Web®

filters for dust collection– eSpin Technologies: carbon nanofibers

for thermal insulation

Technical Accomplishments and Progress:

Technical Accomplishments and Progress

9

1. Preparation and performance of Si/C nanofiber anodes

2. Performance improvement of Si/C nanofiber anodes

3. Scale-up of Si/C nanofiber anodes4. Progress by March 11th

10

• Si/C nanofibers were prepared by electrospinning Si + PAN solutions in N,N-dimethylformamide, following by carbonization in Argon

Technical Accomplishments and Progress:

Si + PAN* solution Si/PAN precursor nanofibers

Si/C anode nanofibers

Electrospinning Carbonization

1. Preparation and Performance― Preparation of Si/C Nanofibers

* PAN: Polyacrylonitrile

Technical Accomplishments and Progress:

11

Anode: Si/C nanofibers from 15 wt % Si/PAN Electrolyte: 1 M LiPF6 in EC/EMCCurrent density: 100 mA g-1

Si/C nanofibers

Graphite

Cycle Number0 3 6 9 12 15 18 21

1200

1000

800

600

400

Cap

acity

(mA

h g-

1 )

0 200 400 600 800 1000 12000.0

0.5

1.0

1.5

2.0

2.5

3.0

25th 2nd

Volta

ge (V

)

Capacity (mAh g-1)

1st

• Si/C nanofibers have significantly higher capacities than graphite

1. Preparation and Performance― Baseline Performance of Si/C Nanofibers

Technical Accomplishments and Progress:

12

2. Performance Improvement

• Improve the anode performance by selectively adjusting the processing and structures of the nanofiber anodes:– Si type, size*, content, and dispersion*– Solution properties: viscosity, surface tension, and conductivity– Spinning conditions: voltage, flow rate, and needle-collector distance– Carbonization conditions: temperature*, time, and heating rate

Technical Accomplishments and Progress:

13

2. Performance Improvement― by Changing Si Particle Size

• Nanofiber anodes containing Si nanoparticles (30-50 nm) give the highest capacities

Anode: Si/C nanofibers from 15 wt % Si/PAN Electrolyte: 1 M LiPF6 in EC/EMCCurrent density: 50 mA g-1

0 5 10 15 200

200

400

600

800

1000

1200

1400Di

scha

rge

capa

city

(mAh

g-1

)

Cycle number

Si (20 - 30 nm) Si (30 - 50 nm) Si (50 - 70 nm)

Technical Accomplishments and Progress:

14* NaD: Sodium dodecanoateCH3(CH2)10COONa

• The addition of surfactant enhances Si particle dispersion, increases discharge capacity, and improves cycling performance

2. Performance Improvement― by Enhancing Si Dispersion

Si/C nanofibers from 10 wt% Si/PAN

Si/C nanofibers from 10 wt% Si/PAN + 0.1 mol/L NaD* 0 10 20 30 40 50

0

200

400

600

800

1000

Disc

harg

e ca

pacit

y (m

Ah g

-1)

Cycling number

Without surfactant With surfactant

Current density: 100 mA g-1

Technical Accomplishments and Progress:

15

2. Performance Improvement― by Changing Carbonization Temperature

• Increasing carbonization temperature leads to the formation of more ordered carbon matrix, which is beneficial in improving the anode cycling stability although the discharge capacity decreases

Anode: Si/C nanofibers from 20 wt % Si/PAN Electrolyte: 1 M LiPF6 in EC/EMCCurrent density: 50 mA g-1

XRD of carbon matrix

20 30 40 50 60 70 80 90

900 oC 800 oC

Inte

nsity

( Ar

b. U

nits

)

CuKα 2θ/θ0 5 10 15 20 25

0

400

800

1200

1600

2000

Disc

harg

e ca

paci

ty (m

Ah g

-1)

Cycle number

700oC 800oC 900oC

Technical Accomplishments and Progress:

16

3. Scale-Up― Lab Scale vs. Production Scale

• Si/C nanofiber anodes produced by production-scale machines have higher capacities than those produced using lab-scale device

Yflow’s eSpinning Unit:

0 5 10 15 200

200

400

600

800

1000

Yflow's eSpinning Unit Elmarco's NanospiderTM

Laboratory DeviceDi

scha

rge

capa

city

(mAh

g-1

)

Cycle number

Elmarco’s NanospiderTM:

Laboratory Device:

Anode: Si/C nanofibers from 10 wt % Si/PAN Electrolyte: 1 M LiPF6 in EC/EMCCurrent density: 100 mA g-1

17

Technical Accomplishments and Progress:

4. Progress by March 11th― Cycling Performance

0 50 100 150 200 2500

200

400

600

800

1000

0

20

40

60

80

100

Capa

city

n / C

apac

ity1

Disc

harg

e ca

paci

ty (m

Ah g

-1)

Cycle number

• No capacity loss was observed in the first 250 cycles• The test is still ongoing, and the target for FY11 is 750 cycles of

~70% state-of-charge swing with less than 20% capacity fade

• First two cyclesFull charge/discharge (cut-off voltages: 0.05 – 2.5 V)

• Following cycles70% state-of-charge swing, i.e., changing the current polarity if:1) capacity reaches 70% of first-

cycle capacity, or2) voltage reaches cut-off values:

0.05 – 2.5 V

Anode: Si/C nanofibers from 20 wt % Si/PAN Electrolyte: 1 M LiPF6 in EC/EMCCurrent density: 50 mA g-1 Test procedure

Collaborations/Partnerships:

18

Collaborations• American Lithium Energy Corp, San Marcos, CA (Industry)

– Jiang Fan, 760-591-0611, [email protected]– The assembling and testing of 18650 cells

• Tec-Cel Inc, Cary, NC (Industry)– Albert bender, 919-878-8464, [email protected] – Licensing the technology– Short-term target: pilot scale production– Longer-term target: full scale production

• Argonne National Laboratory, Argonne, IL (Federal)– Wenquan Lu, 630-252-3704, [email protected]– Improvement of carbon matrix structure by using ANL’s heat-treatment facility

• Indiana University-Purdue University Indianapolis, IN (University)– Jian Xie, 317-274-8850, [email protected] – Improvement of Coulombic efficiency by coating the anodes with graphene or

other materials

Proposed Future Work/Proposed Future Activities:

19

• Optimize the anode performance by selectively adjusting the processing and structures of the nanofibers:– Si content, type, size, content, and dispersion (increase capacity and improve

cycle life)– Surface coating using graphene or other materials (increase Coulombic

efficiency)– Solution properties: viscosity, surface tension, and conductivity– Spinning conditions: voltage, flow rate, and needle-collector distance– Carbonization conditions: temperature, time, and heating rate

FY12 Targets:• Anodes: Fabricate nanofiber anodes that have optimized

performance• 18650 cells: Deliver 18650 cells, in which the anode has a specific

capacity greater than 1200 mAh/g and cycle life longer than 5000 cycles of ~70% state of charge swing with less than 20% capacity fade

Future Work

20

Summary• Si/C nanofiber anodes have been prepared using the electrospinning

technique• 18650 cells have been assembled using Si/C nanofiber anodes• The performance of Si/C nanofiber anodes has been improved by selectively

adjusting the processing and structures of the nanofibers• The scale-up production is successful, and the resultant Si/C nanofiber

anodes have higher capacities than those produced using lab-scale device• The Year 2 work is still ongoing, and the current results show the FY11

Targets are achievable

FY10 Results FY11 Results(by March 2011)

FY11 Targets (by August 2011)

Capacity ~800 mAh g-1 ~950 mAh g-1Twice the specific

capacity of graphite (i.e., 744 mAh g-1)

Cycle Life50 full

charge/discharge cycles

250 cycles of ~70% state-of-charge swing without capacity fade

750 cycles of ~70% state-of-charge

swing with less than 20% capacity fade