New Facade for Redmond Berry - Report

-

Upload

hizkia-irwanto-gouw -

Category

Documents

-

view

224 -

download

5

description

Transcript of New Facade for Redmond Berry - Report

Building Report: Redmond Barry

ABPL90268: Building Envelopes. Chris Jensen

Ben De Nardi 384121, Kai Ning Huang 314675, Hizkia Gouw 378785

Report 1: Redmond Barry

2

Contents:

1. Existing building report Pg. 3

2. Façade additions Pg. 5

3. Specifications Pg. 16

4. Suppliers Pg. 21

5. Glossary Pg. 24

6. References Pg. 25

Report 1: Redmond Barry

3

The Redmond Barry building.

The Redmond Barry building was built in 1961, and is named after Sir Redmond Barry. Sir

Redmond Barry was a judge in colonial Victoria, Australia and the first chancellor of Melbourne

University. It is located on the main campus of Melbourne University on Tin Alley.

West Wall

Existing building conditions

The building is considered an example of post-war modernist architecture, with the

landmark tower and use of cream bricks. The Redmond Barry is a 12 storey building constructed

using a slab and podium system of steel and reinforced concrete columns, with shear wall infill’s.

The podium is a low wall that acts as the foundations for the building. The shear walls

counter the effects of lateral forces on the building. In the Redmond Barry building these are the

brick infill walls that are expressed in the façade. The structural columns and floor slabs can also be

seen throughout the façade.

The north and south façade are composed of single brick walls with single layer glazing units

that are framed by the structural columns and floor slabs. The north wall has had aluminium sun

shades retro-fitted to the exterior. The east wall is the lift core and has a single brick wall enclosing

the lift cores. The west wall houses the fire stairs and is also a solid brick façade.

Report 1: Redmond Barry

4

The building is 61 metres long and 13 metres wide, the long axis of the building is on an east-

west plane.

Façade performance:

Improvements to the building envelope will bring the buildings energy performance up to

contemporary BCA (Building Council Australia) standards.

Overall performance improvement

Report 1: Redmond Barry

5

Façade Improvements

To improve the buildings energy performance and user comfort the following improvements

will be made to the façade. The building envelopes changes are aimed at improving the buildings:

• Thermal performance – especially in regards to cooling the building

• Natural daylight

These alterations will increase the buildings ability to passively deal with temperature

fluctuations and therefore decrease the need to consume energy to heat and cool the interior.

Daylight will also reduce the need for artificial lighting, also reducing energy use within the building.

Aesthetics:

Any alterations to the building’s façade will change the buildings appearance, whilst not a

primary consideration, it is a consideration.

The following alterations will be made to the Redmond Barry building.

Report 1: Redmond Barry

6

South Wall:

The space above the lecture theatres on the southern wall are extruded, which expands the

classroom spaces (refer to drawing A.007). Those blocks are similar in term of width and length (6 x

9-42 m), but vary in height (6, 8, and 10 levels height). The positions of those blocks are in line with

the existing column grid of the Redmond Berry (refer to drawing A.001). Curtain wall are installed in

the south façade of the extrusions, where precast concretes are used for the sides. A metal roof

cladding is used for each block.

Glazing:

The primary intention of using the glazed curtain wall on the south side is to maximise the

daylight into the building. This will brighten the space and reduce the need for artificial lighting

during the daytime. As there is no direct sunlight on the southern façade no shading devices will

need to be installed. Moreover, the use of curtain wall without shading would also provide

undistracted view from the inside.

On the southern wall a Unitized Curtain Wall system will be used as the construction

technique. The main benefit of this technique over traditional stick curtain walls is the speed of

construction. It also minimalizes the need for on-site labour and workers during the installation

Report 1: Redmond Barry

7

phase, as all the elements are not only pre-fabricated but also pre-assembled as a complete unit in

the factory.

This prefabrication method would also give huge advantage in term of the quality control.

For example, because of the units are specifically designed, the amount of movement between the

structure and the thermal movement of the frame at the joints between each curtain wall unit, can

be carefully engineered into the system. In addition, it will also reduce or eliminate the need of site

sealing. So, at the end, the installation of the curtain wall is less dependable on the quality of

workmanship onsite. The offset to these benefits is the increase in cost, both in construction and

shipping the modules to the site.

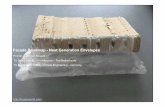

Each module of the curtain wall unit contains the combination of double glazing and a

spandrel panel. The use of double glazing (refer to drawing A.025) will reduce the heat loss from the

large areas of glazing within the curtain wall. The spandrel glasses (6mm Jasper Colour Viridian

Seraphic Standard) are used to cover the floor slabs to prevent them being seen from exterior. The

spandrel panels (refer to drawing A.025) are also need to be insulated in order to perform a fire

protection, accordance to AS1530.4.

Rockwool Fireseal Curtain Wall Batt from Bradford will be used as the insulation material. It

can provide fire protection to a curtain wall system for up to 2 hours. The rockwool insulation batts

are installed between the spandrel panels and the edge of the concrete slab.

The installation of the Unitized Curtain Wall will be done by Keystone Installation, a specialist

in façade installation constructing service. The installation process is a simple one (refer to drawing

A.023). The first step is to determine the position of the anchor assembly in the floor slabs, and then

install them in the correct position.

The second step is the erection of the curtain wall. The two common methods are

with a crane on either the outside or inside of the building. In this instance a ground based external

crane is preferable as it has more access and manoeuvrability.

The other typical crane used in high-rise construction is the tower crane. This requires the

crane to be attached to the building that is being constructed, which in this case is not possible, as all

four facades are being altered.

Report 1: Redmond Barry

8

Pre-cast concrete:

To create the extrusions above the existing lecture theatres precast concrete cladding panels

are installed. The speed of installation and quality control afforded, due to the controlled casting

environment, by precast concrete panels over in-situ concrete is the reason for using pre-cast panels

in this instance.

There will be two types of bearing connections that will be applied to hold the precast in

place (refer to drawing A.021). The first type of connection is using concrete corbels and cast in

dowel fixings (load carrying fixing), which connect the bottom of the panel with the floor slab. The

second type, tie-back fixing, will be used to tie the top of the panel into the concrete beam. In this

fixing, a steel angle will be bolted into the precast panel and the concrete beam.

In term of the performance, those precast panel will be insulated using bulk insulation inside

each panel (refer to drawing A.021). 75mm Bulk Insulation (Flexitel 24kg/m3) increases the r value of

the wall by a significant amount, which also means a better thermal resistance for the wall. In

addition, each concrete panel will also contain vents (200x300mm in size), which will allow fresh air

to be drawn from the exterior by the convection that is created by the trombe wall and thermal

chimneys. The opening of the vents is designed with a slight angle in order to prevent water

penetrating into the building. Wire mesh covers each vent, so insects and animals and some dirt

cannot get in.

Metal Roofing:

The roof of the extrusions will be covered by a metal roof. The precast concrete panels in the

side of the extrusion are extended to create a parapet of 500mm height. This parapet hides the

metal roof from the exterior of the building. The Lysaght Klip Lock 46 is used for the metal roofing.

The roof will have 2 degrees slope toward south wall (curtain wall) with a box gutter just behind the

parapet.

Two types of insulation will be used in the roof: reflective insulation and glass-wool

insulation. The reflective insulation material (thermofoil medium duty sarking foil) is installed just

beneath the metal roof. It performs as a waterproofing membrane and vapour barrier that providing

a secondary barrier against moisture, heat, wind, dust penetration, and condensation control under

Report 1: Redmond Barry

9

the metal roofing. Then the glass-wool insulation (Anticon 95) is placed in the space between the

purlin. It provides efficient thermal insulation for the roofing.

Concrete floor slab:

Floor board insulation

Concrete floor slabs are used for the extension from the existing floor slab. In order to

achieve a required R-value, board insulations (Kooltherm K10 FM Soffit Board) are installed just

under the floor slab (refer to drawing A.022). The dimension of each insulation board is 2270 x

1200mm, with 30mm thickness. Each soffit board is fully fixed to the concrete slab using 11

insulation fasteners provided by Kingspan. The insulation fasterners are penetrated into the slab by a

minimum of 40mm.

Report 1: Redmond Barry

10

North Wall:

The northern façade will be replaced with a double glass curtain wall. This wall will work to

allow more natural lighting into the building. It will also act as a trombe wall; this will improve

cooling within the building and maintain the interior air quality.

The exterior glazing unit will need to allow maximum daylight through. Typically with high

light transmission glazing products a high percentage of transmission means poor performance in it

insulating qualities. For the purpose of the trombe wall creating a hothouse effect beyond the initial

façade is a positive; therefore the exterior leaf will be single glazed panels. The thermal chimneys on

the east and west walls will act in tandem with the trombe wall in promoting convection.

Trombe wall diagram

The interior glazing will be a double glazed, with mechanized vents (refer to drawing ). The

double glazing improves the insulation of the wall whilst keeping maximum transparency. It will also

act as a fire barrier between floors.

The vents will be placed at the top and at the bottom of each section. The vents will be

automatically operated to maintain interior air temperature as well as for night purging. The cooler

air will be collected from the lower vents as well as vents in the southern wall, whilst the higher

vents will expel the warmer air from the interior. The vents will be operated by an automated

building management system (BMS). The aim will be to maintain a temperature range of 21° to 24°.

The BMS will also manage the night purge. The vents will be opened in the late evening to flush the

hot air out of the building and let it cool down over night. During the winter months, the night purge

will operate on reduced hours, so as to retain heat for the building users for the next day, but also

bring fresh air into the building.

Report 1: Redmond Barry

11

The roof of the trombe wall will be a metal cap. This will be painted black to promote the

heating of the air within the trombe wall.

The installation of the Trombe Wall glazing will be done by Keystone Installation. See South

wall details for installation process.

Fittings:

The hung curtain wall will be attached to the existing floors slabs by the components

supplied by Spider fittings. A connector bracket is attached to each floor slab (refer to drawing ),

from which tension rods are then thread through. The tension rods have the 4-point wall spiders

(refer to drawing ) threaded onto them. Each of the wall spiders has attachment points that routels

use to connect the glass. The routels have a silicon ring that thermally breaks the aluminium.

Glazing:

A single leaf of 6mm Clear VFloat glazing will be used on the exterior for the trombe wall.

This glass was picked for its high daylight transmission, 88%, allowing maximum daylight into the

building. The high U-value and SHGC act to the benefit of the trombe wall.

As the glazing heats up the air within the trombe wall cavity the hot air rises. As the hot air

rises it draws cooler air up via convection. This cooler air is supplied into the building through the

vents that are located on the southern side and at the bottom of each floor of the northern side. This

creates an internal atmosphere that is constantly supplied with fresh cool air.

The glazing will need to be lifted into place via a crane, with labourers in cherry pickers

attaching the glass to the pre-positioned wall spiders.

Double Glazing:

The internal wall of the trombe wall will be double glazed. Viridian windows make a Viridian

Energy tech unit which is two sheets of 4mm glass with a 12mm air gap. This arrangement continues

Report 1: Redmond Barry

12

to allow maximum daylight transmission, 75%, whilst also being an effective insulating barrier

between the internal and external environment.

A low U-value means that despite the increased temperature from the trombe wall this will

not be transferred to the interior environment of the building.

The double glazing can be fitted during the construction of the external glazing of the

trombe wall as it is set back from the external leaf of glass.

Metal roof:

An aluminium panel that is coloured black is fitted over the top of the trombe wall. It caps

across from the existing roof and encapsulates the front edge of the external glazing. This cap

prevents moisture entering the trombe wall environment and being black captures more heat to

heighten the working of the trombe wall.

Report 1: Redmond Barry

13

West Wall:

On the west wall two concrete thermal chimneys will be added. The northern one will work

with the trombe wall in removing hot air from the air cavity of the trombe wall. The southern

chimney will remove hot air from the interior of the building via direct vents into the bottom of each

floor. The existing brick veneer wall on the west wall will also be replaced by precast panel with

insulation and interior lining, which will increase the thermal performance of the wall and provide

flexibility to the connection between the thermal chimneys and the wall itself.

Thermal chimney diagram

Precast Concrete Panel:

150mm precast concrete panel will be employed in both west wall and thermal chimneys.

As mentioned above, the precast concrete panels have advantages on installation speed and quality

control; and this is the reason that precast concrete panel is the more preferable building material

than other types of concrete in this project.

The joints of the precast panels’ construction will be the open- drained joint. It consists of an

expansion chamber which acts as a rain barrier, a loose-fitting baffle which placed in the chamber, an

air-seal which placed at the interior face of the panel and a short length flashing sitting beneath. The

baffle in the chamber prevents direct entry of the wind-driven rainwater. The air pressure between

Report 1: Redmond Barry

14

the chamber and the baffle will be the same as the external air pressure. Thus, no rainwater will be

driven into the building because of the pressure difference. The air-seal at the face of interior is the

barrier of the external and internal air pressure. The water enters the joint will be eventually

discharged by the short length flashing.

The open-drained joint is designed for the mid-rise and high-rise buildings. The air-seal at the

rear is protected from the UV light; therefore the seal will perform perfectly in long-term. The joint

can also be installed from inside, which provide great flexibility to the builder for the west wall

construction. The open-drained joint is also able to tolerant large movement. However, in the

chimneys there is no floor supporting the panels horizontally, which might be an issue for the

construction. In order to prevent the chimneys from falling down, restraint connections will be used

between the vertical panel joints. Panels will be bolted with cleat at every vertical joint, and

therefore it stabilizes the panels against out-of-balance gravity loads and resists the horizontal wind-

loads.

The chimneys will be a simple precast panel construction, but the west wall will be precast

panels with insulation and interior lining because it has to achieve the standard R-Value in BCA. A

layer of insulation of R2.7 will be placed behind the precise panels to increase the R-Value of wall

significantly. The plasterboard will be the interior lining with supported by the battens (30mm x

75mm in size). Same as the south wall extrusion, the west wall connected to the chimneys will have

small openings (100mm height, 200mm width) at the bottom of each level. These opening allow the

ventilation between the interior and the chimneys. They will be covered by wire mesh to prevent

unwanted objects get into the building. And they could be shut down during the winter to stop the

ventilation and keep the heat inside the building.

Metal Roof:

Same as the south extrusion, the thermal chimneys will employ the Lysaght Klip Lock 406 as

the roof system. The parapet is deeper to 1000mm and the slope will be increased to 8 degrees. A

rotating turbine ventilator will be located on the roof of each chimney, which helps exhaust the hot

air from the chimney. The rotating turbine ventilator could potentially be an electricity generating

device which transfers the wind force from the hot air exhausting out into electricity.

Report 1: Redmond Barry

15

Window Glazing

The window glass on the chimney will be Viridian SuperClear glass 10mm which has light

transmission rate at 90%. The more transparent means the more direct sun light can get into the

chimneys and heat up and air quicker. A layer of metal absorber with black coating will be place

behind the window glazing to increase the light absorbing of the chimneys.

East Wall:

The brick veneer wall that surrounds the lift core will be retained; insulation will be pumped

into the cavity behind the brick wall to meet modern BCA standards for the R-value. The product of

the infill insulation will be Sealection 500 from Unsulfoam. It is a polyurethane foam insulation which

could be injected into the cavity of the wall leaves and set. This product at 90mm thick is R 2.4.

To the north of the brick wall a concrete thermal chimney will be added. This will function

with the trombe wall being installed on the north wall. The thermal chimneys added to the building

will be concrete, which heats up and creates a convection effect, drawing cool air up as the hot air

rises.

Report 1: Redmond Barry

16

Specifications

This next chapter will contain the specifications for each of the new component of the

improvements made to the Redmond Barry building.

Trombe Wall

Glazing:

The glazing will be sourced from an Australian company called Viridian Glass. The exterior

panes will be Clear Vfloat, and the interior units will be from the Viridian energy Tech range.

Product Name Pane thickness

(mm)

Pane size U-value SHGC Daylight %

Clear VFloat 6 913 x 3350 5.8 0.82 88%

Viridian

Energy Tech

4mm with a

12mm gap

various 1.9 0.74 75%

Vents:

The glazed vents will be sourced from Hanlon windows. The vents will be the aluminium

Awning/Casement windows, series 466, with the automated option. The cooling and heating

percentages are in comparison to a base case window. This is measured as an increase in

performance as a percentage

Product

name

Glazing size

(mm)

Vent size

(mm)

U-value SHGC Cooling % Heating %

Aluminium

Awning

Window

Series 466

247 x 346 410 x 400 4.6 .3 56% 40%

Report 1: Redmond Barry

17

Double Glazing:

The cavity created between the floor slabs and the structural columns will be double glazed.

These aluminium units will also come from Hanlon windows. They will be 4 different sizes from the

Thermal heat range, series 730.

Product

name

Glazing size

(mm)

Vent size

(mm)

U-value SHGC Cooling % Heating % Number of

frames

needed per

cavity

Series 730 2300 x 850 2366 x

863

3.8 .42 52% 36% 4

Series 730 338 x 850 346 x

863

3.8 .42 52% 36% 8

Series 730 2300 x 388 2366 x

346

3.8 .42 52% 36% 2

Wall Spiders:

The aluminium components used to hang the exterior glass wall will be sourced from China,

from Spider Fittings.

Spider fittings will provide the routels that attach the glazing to the wall spiders, which are

then attached to the concrete floor slaps by connectors, with the whole assemblage held taught by

the tension rods.

The curtain wall is attached to the floor slabs every three floors.

Product name Size (mm) $ per unit # of units (approx.)

Wall spider 2501 250 x 250 $17.70 1200

Connector Z01 145 x 46 (dia.) $5.00 150

Routel T02 115 x 59 (dia.) $5.80 4800

Tension Rods G01 –

12”

27(dia) $13.90 2400

Report 1: Redmond Barry

18

West Wall

R-Value:

Layer R-Value

Outside Surface air Film 0,030

150mm Precast Concrete 0,104

90mm Insulation Wall Batt 2.7

10mm Plasterboard 0,059

30mm Air Gap 0.2

Total 3.093

Thermal chimney:

R-Value:

Layer R-Value

Outside Surface air Film 0,030

150mm Precast Concrete 0,104

Total 0.134

East Wall

R-Value:

Layer R-Value

Outside Surface air Film 0,030

355mm Precast Concrete 0,26

90mm Foam Insulation 2.4

110mm Brick Wall 0.18

Total 2.87

Report 1: Redmond Barry

19

Thermal chimney:

R-Value:

Layer R-Value

Outside Surface air Film 0,030

150mm Precast Concrete 0,104

Total 0.134

Southern Wall

Sourced from Viridian glass the curtain wall will use Clear Vfloat glass and the Viridian

Seraphic Standard, Jasper colour.

Usage Product Name Panel

thickness

Panel size U-value SHGC Daylight %

Double Glass

panel

Clear VFloat 2 x 6mm with

air gap in

between

1520 x 2300,

1520 x 2910

5.8 0.82 88%

Spandrel Unit Viridian Seraphic

Standard (Colour:

Jasper)

6mm 1520 x 950 5,5 0.67 55%

Concrete:

R-Value

Layer R-Value

Outside Surface air Film 0,030

150mm Precast Concrete 0,104

25mm Airspace 0,170

75mm Bulk Insulation Wall Batt 2,1

13mm Plasterboard 0,076

Report 1: Redmond Barry

20

Inside Surface air Film 0,120

Total 2,6

Metal Roofing:

R-Value

Material R-Value

0,48mm Metal Roof 0,00

Reflective Insulation Material 1,387

80mm Ceiling Insulation 1,8

13mm Plasterboard 0,076

Total 3,263

Concrete Floor Slab:

R-Value

Material R-Value

1cm Thick Carper Flooring 0,18

200mm Concrete Slab 0,139

30mm Board Insulation 1,4

Total 1,718

Report 1: Redmond Barry

21

Suppliers

Glazing

Material Supplier Website

Clear VFloat Viridianglass http://www.viridianglass.com/Products/vfloat/default.as

px?ProductType=Specifier

Viridian Seraphic

Standard (Colour: Jasper)

Viridianglass http://www.viridianglass.com/Products/seraphic-

standard/default.aspx?ProductType=Specifier

Viridian Energy Tech Viridianglass http://www.viridianglass.com/Products/seraphic-

standard/default.aspx?ProductType=Specifier

Unitized Curtain Wall

Installer

Keystone

Installations

http://www.keystoneinstallations.com.au/

Window frames Hanlon

windows

http://www.hanlonwindows.com.au/products_aluminiu

m.php

Curtain wall components Spider fittings http://www.spiderfittings.org

Rockwool Fireseal Curtain

Wall Batt

(spandrel insulation)

Bradford

Insulations

http://wwwbradfordinsulation.com.au/Products/Comme

rcial/Fire-protection/fireseal-curtain-wall-batt.aspx

Pre-cast concrete

Material Supplier Website

150mm Precast Concrete SA Precast Pty http://www.saprecast.com.au/

75mm Bulk Insulation

(Flexitel 24kg/m3)

Bradford

Insulation

http://www.bradfordinsulation.com.au/Products/Comme

rical/HVAC/Flexitel.aspx

13mm Plasterboard

(Enviro Multistop)

Boral http://www.boral.com.au/

Sealection 500 Insulfoam http://www.insulfoamsolutions.com.au/Pages%20Builder

s/Performance.html

150mm Precast Concrete SA Precast Pty http://www.saprecast.com.au/

Report 1: Redmond Barry

22

Metal Roofing

Material Supplier Website

0,48mm Metal Roof

(Lysaght Klip-Lok 46)

Lysaght http://www.lysaght.com/product/lysaght-klip-lok-406

Reflective Insulation

Material (Thermofoil

Medium Duty Sarking

Foil)

Bradford

Insulation

http://www.bradfordinsulation.com.au/Products/Comme

rical/Thermofoil-Foil-Sarking/Thermofoil-MD-

Sarking.aspx

80mm Ceiling Insulation

(Anticon 95)

Bradford

Insulation

http://www.bradfordinsulation.com.au/Products/Comme

rical/roofing-blanket/Anticon.aspx

13mm Plasterboard

(Enviro Multistop)

Boral http://www.boral.com.au/

Concrete floor slab

Material Supplier Website

1cm Thick Carpet

Flooring (Chamonix)

Carpet Court http://www.carpetcourt.com.au/products/Carpet/urban-

lifestyle/Chamonix

200mm Concrete Slab SA Precast Pty http://www.saprecast.com.au/

30mm Board

Insulation

(Kooltherm® K10 FM

Soffit Board)

Kingspan http://www.kingspaninsulation.com.au/Products/Kingspan-

Kooltherm/Kooltherm-K10FM-Soffit-Board/R-values.aspx

Thermal Chimney

Material Supplier Website

5500 ISOWEB Window KAWNEER http://www.kawneer.com/kawneer/north_america/en/p

roduct.asp?cat_id=1910&prod_id=1867

GOLD™ HIGH

PERFORMANCE WALL

BATTS

Bradford http://www.bradfordinsulation.com.au/Products/Reside

ntial/Thermal-insulation/Gold-high-performance-

wall.aspx

Report 1: Redmond Barry

23

Regular 10mm

Plasterboard

Boral http://www.boral.com.au/productcatalogue/product.asp

x?country=AUS&product=930

0,48mm Metal Roof

(Lysaght Klip-Lok 46)

Lysaght http://www.lysaght.com/product/lysaght-klip-lok-406

150mm Precast Concrete SA Precast Pty http://www.saprecast.com.au/

Report 1: Redmond Barry

24

Glossary

U-value1:

The U-Value is a measure of the rate of heat gain or loss through a glazing unit. It is due to

the environmental differences between the indoor and outdoor air. The lower this number is the

better the glazing is for insulating the building.

SHGC (Solar Heat Gain Coefficient)2:

The SHGC is the proportion of total solar radiation that is transferred through the glass at a

normal rate of incidence. The lower this number is the better for insulating the building.

R-value

The R-Value is a measure of thermal resistance of a material.

The higher that the R-Value is indicates the greater the effectiveness of the buildings insulation. It is

also the reciprocal of the U-Value.

1http://www.viridianglass.com/default.aspx

2ibid

Report 1: Redmond Barry

25

References

http://artemisbs.com/curtain-wall-products/unitized-curtain-wall/

http://islandglass.bm/commercial/curtain-wall/unitized/

http://www.boral.com.au/

http://www.bradfordinsulation.com.au/Products/Commerical/HVAC/Flexitel.aspx

http://www.carpetcourt.com.au/products/Carpet/urban-lifestyle/Chamonix

http://www.enclos.com/news-

page/modular_prefab_the_installation_of_unitized_curtainwall_systems

http://www.hanlonwindows.com.au/products_aluminium.php

http://www.insulfoamsolutions.com.au/Pages%20Builders/Performance.html

http://www.keystoneinstallations.com.au/

http://www.kingspaninsulation.com.au/Products/Kingspan-Kooltherm/Kooltherm-K10FM-Soffit-

Board/R-values.aspx

http://www.lysaght.com/product/lysaght-klip-lok-406

http://www.saprecast.com.au/

http://www.spiderfittings.org

http://www.sustainability.vic.gov.au/resources/documents/Window_protection.pdf

http://www.syracuseglass.com/E-

DOCS/Spandrel%20Glass/EDOCS/Spandrel%20Glass%20Insulation.pdf

http://www.viridianglass.com/default.aspx

http://www.wausauwindow.com/education/curtainwall/curtainwall.pdf

http://wwwbradfordinsulation.com.au/Products/Commercial/Fire-protection/fireseal-curtain-wall-

batt.aspx