New Ew Specs for Hal Nov 2009-Sept 2012

-

Upload

shuja-mehdi -

Category

Documents

-

view

29 -

download

5

Transcript of New Ew Specs for Hal Nov 2009-Sept 2012

-

New Formation Specifications for Heavy Axle Load (Case Study For Availability Of Blanket Material)

-

Approval of Guidelines by Railway Board RDSO prepared the Guidelines Critical items Reviewed by CAO/Cs Committee Formation Specifications for New Lines/Doubling/GC Works to be carried out on IR, for existing axle loads in the range 22.5t to 25t , should also be kept as same as those for 25 T as per new specifications.Railway Board has approved the committees recommendations & the New Secifications/Guidelines vide letter No.2007/CE-I/Geotech/02dated 26.10.09. - The guidelines is to be put to use only on new works and would not apply to on going project. - This may be first tried for a year and half to get the field appreciation and correction, if any.

The approved guidelines have been already circulated to the Zonal Railways for adoption. Also available on website http://www.rdso.gov.in/engineering/literature/geo_reports/0014.pdf

-

Formation Heavy Axle Load

New Formation Specifications vis a vis Existing GE: G-1 2003Availability of blanket materialCost Comparison (New Formation specification verses Existing Guidelines)

-

The Existing Guidelines of Earthwork in Railway Projects, GE:G-1, July 2003 stipulates :(A) Organic soils, Dispersive soils will be treated as Unsuitable Soils etc.

Type of Soil SUBGRADEBlanket Thickness For 22.5 T axle LoadRocky sub grade, GW, SWNILGP, SP, GM & GM-GC45 cmGC, SC, SM, SM-SC60 cmCL, ML, CI, MI, CL-ML 100 cmCH, MH soilsUnsuitable for use in top 3 m of bank

-

(B) There is provision of additional blanket thickness to cater for Heavy Axle Loads in Existing Guidelines, GE:G-1 also which is :

For axle load > 22.5t and up to 25t there is a provision of additional blanket thickness of 30cm of superior quality material in upper part For axle load > 25t up to 30t there is a provision of additional blanket thickness of 45cm of superior quality material in upper part The same is shown in the enveloping curve in the next slide

-

Advantages of Blanket Layer

Let us understand advantages of blanket

1 It reduces traffic induced stresses at top of sub-grade to a tolerable limit to avoid track foundation failure.2It prevents penetration of ballast into sub-grade and upward migration of sub-grade fines into ballast.3It intercepts downward percolation of water, facilitates run off of water from top surface of blanket layer and provide drainage path for upward movement of water from subgrade.4 Blanket provide separation layer to prevent mud pumping by checking the attrition of subgrade particles by ballast.

-

New Specification & Guidelines of Formation for Heavy Axle LoadsConsists of:

Soil Exploration SurveysMethodology for Ground ImprovementFormation Layers Thickness & Material Specification including blanketQuality Assurance Tests

-

Concept adopted in New Specifications / DesignIt is with objective of selecting the granular layer thickness based on threshold strength of the subgrade soil. To limit the stress on the subgrade soils to less than a threshold stress To prevent subgrade failure due to excessive plastic deformation, which is more pertinent in case of cohesive soils viz clay type soil. CBR value and particle size distribution are governing factor for the formation design.

-

New Specification consists of :Multi layer system which includes blanket, prepared subgrade over embankment fill.

The 2 different system are as under:

Single LayerBlanket Layer over Embankment fill

Two Layerii) Blanket+ Prepared subgrade over Embankment fill

BlanketE/Fill

BlanketPre/SubgradeE/Fill

-

Subsoil RequirementsWe have talked about the multilayer system however subsoil parameters are equally important since subsoil is the foundation of the Formation Ground Conditions requirements are given below

2.1 Ground Soil/Sub-soil Strata should have Minimum Undrained shear strength of soil, = 25 KPa or SPT (N-value > 5)2.2 Otherwise Ground Improvement is required, if Undrained shear strength of soil, < 25 KPa or SPT (N-value < 5)

-

Soil Grouping

The soils to be used in earth fill is locally available soils. The soil grouping has been done for embankment fill & prepared subgrade both, as under :

SQ3 (fines 10 Min.)SQ2 (fines: 12 to 50 %) CBR 5-8 (min)SQ1 (fines > 50%) & CBR 3-4 (min)

Fines Particles finer than 75 micron

For prepared subgrade, additional requirements is to have Plasticity Index < 12

-

Comparision of Soil Grouping of New Specifications with GE:G-1Therefore, it can be concluded that all usable soils as per GE:G-1 are also falling in the new soil grouping & combination (multi layer) thereof in the new specifications.

As Per Existing GE : G-1(based on IS classification) New Specifications (Governing factor)Likely Soils types falling in groups of new specificationsRocky sub grade, GW, SW GP, SP, GM & GM-GCSQ3 (Fines 10)GW, GP, SW, SP, GW-GM, GW-GC, GP-GM, GP-GC, SW-SM, SW-SC, SP-SM, SP-SC GC, SC, SM, SM-SCSQ2 (Fines 12-50%)(CBR 5 8)GM, GC, SM, SC CL, ML, CI, MI, CL-ML SQ1 (Fines >50%)(CBR 3) CL, ML, CL-ML, CI, MI, CH, MH Unsuitable Soils Organic soils, Dispersive soils, CH, MH (not in top 3m) etc.Unsuitable Soil Organic Soils, Dispersive soils,Soils with CBR < 3 CH, MH with CBR < 3

-

New Blanket Specificationi) Cu > 7 and Cc between 1 and 3. ii) Fines (passing 75 microns) :3% to 10%iii) Los Angeles Abrasion value < 35-40%iv) Minimum CBR value 25 of the blanket material compacted at 100% of MDDv) Size gradation within specified range or enveloping curves.vi) Filter Criteria should be satisfied with subgrade layer, as given below :(OPTIONAL)Criteria1: D15 (blanket) < 5 x D85 (sub-grade)Criteria2: D15(blanket) >4to5 D15 (sub-grade)Criteria3: D50(blanket) < 25 x D50 (sub-grade)

-

Gradation of Blanket Material

SLIS Sieve SizePercent Passing (by weight)1.40 mm1002.20 mm80 - 1003.10 mm65 - 854.4.75 mm40 - 705.2 mm25 - 506.600 micron12 - 357.425 micron10 - 308.212 micron5 - 229.75 micron3 - 10

-

Gradation of Blanket Material & Comparison with Highway Granular Sub-base

-

Explanation of Blanket Enveloping curves w.r.t. Railway Embankment & Highways

1. Distribution of larger size particles is more as per new enveloping curve to meet with Heavy Axle Load requirements. 2. Railway new enveloping curves covers larger %age and range of finer particles than Highways. 3. Railway Blanket Specifications are liberal in comparison to Highways.

-

Axle LoadThickness (cm)20406080100120140025 T 30 T32.5 TBlanket Embankment Fill (Top Layer) SQ3100755060Single Layer System (Blanket on Embankment Fill) 180200 807575 1007580SQ1* SQ2 SQ3 SQ2 SQ3Soil Type Below Blanket SQ2 SQ3 Min. CBR of Top Layer of Embankment FillCBR 6 generally but not < 5 in isolated casesCBR 6 generally but not < 5 in isolated casesCBR 7 generally but not < 6 in isolated cases1160Embankment Fill (Top Layer) SQ2Embankment Fill (Top Layer) SQ1

-

Two Layer System (Blanket + Prepared Subgrade on Embankment Fill)Prepared Subgrade of SQ2 Soil

-

Comparison of Blanket Thickness (25 T)

With the New Formation Specifications, following reduction in Blanket Thickness have been achieved.

Soil Type As per Existing GE:G-1New Specification (Single Layer)New Specification (Two Layer)SQ1130 cm100 cm30 45 cmCan be used in embankment fill but to be overlain by SQ2/SQ3 soil SQ290 cm75 cm45 cmSQ375 cm60 cm30 cm

-

Comparison of Blanket Thickness (30 T) With the New Formation Specifications, following reduction in Blanket Thickness can be achieved :

Soil Type As per Existing GE:G-1New Specification (Single Layer)New Specification (Two Layer)SQ1145 cmCan be used in embankment fill but to be overlain by SQ2/SQ3 soil 45 60 cmCan be used in embankment fill but to be overlain by SQ2/SQ3 soilSQ21058060SQ390 7545

-

Advantages of New Specifications1. Requirement of Blanket Material is reduced considerably which will reduce the overall cost.2. Materials like prepared subgrade have been brought in requiring lesser stringent specifications. 3. This will enhance use of locally available materials. 4. Economic optimization is possible by varying thickness depending upon available materials.

-

Quality Assurance TestsThere are three Quality assurance tests

1. CBR Test : CBR test is required to be conducted for ground soil, embankment fill, prepared sub-grade & blanket material to ensure the minimum specified CBR value of these materials to be used in construction. This test is carried out on soil sample in laboratory as per procedure, detailed in IS : 2720 (Part 16) - 1987.

-

Quality Assurance Tests2. Compaction Test: Heavy compaction Test is required to be conducted to determine the Maximum Dry Density of soil. In-situ density is measured in the field by Sand Replacement Method (IS: 2720 part 28) or Core Cutter Method (IS: 2720 part 29) to calculate the degree of compaction w.r.t. MDD.

-

Quality Assurance Tests

3. Plate Load test for Ev2 Value (Optional) EV2 Elastic Modulus at 2nd Loading in Plate Load Test

Plate Load Test is required to be conducted in-situ for measurement of EV2, as per procedure detailed in German Code DIN:18134, 2001, titled Determining Deformation & Strength Characteristics Of Soil By Plate Loading Test.

-

Case studyMechanical Production of Blanket MaterialMost of the time naturally available materials do not meet the desired specifications of blanket material.

Blanket material can be produced by mechanical process from crushing or blending method or combination of these two methods.

-

Crushing Methodology Rock Boulders are crushed & sieved from different sieves to produce aggregates of different sizes. Trials and permutations of feed speed, crushing cycle, sieve combinations may be required to arrive at the required particle size gradation.These aggregates are mixed in pre-determined proportions over conveyers and mixed with water, stored.

-

Blanketing in Chandigarh Ludhiana New BG Line

Crusher Plant visited in the month of May 2005 & Nov. 2009 at Chandigarh to inspect crushing methodology for production of blanket material. Details are as follows:

Name of crusher owner: Hargobind Stone crusher Site : Panchkula, ChandigarhMake of crusher: Gurudev, Lalkuwan, DelhiSource of stone: River GhaggarPlant capacity: 830 cft/hour (Approximately)

-

Unloading of Blanket Material at site

-

Compaction of Blanket Material with Vibratory Roller

-

Finished Blanket after Compaction

-

In-situ density measurement of Blanket Layer

-

Gradation of Blanket Material in Chandigarh Ludhiana project

-

Gradation of Blanket Material in Chandigarh Ludhiana project

-

Components : Four bin aggregate unitPug mill mixer unitWater tank and metering systemConveyor beltsStorage silos (optional)Anti segregation surge hopperAutomation and controlsDifferent available materials, coarse aggregate, local sand/soil are blended in pre-determined ratio. Case Study BLENDING METHODOLOGY FOR BLANKET PRODUCTION

-

Blanket by Blending in Southern RlyGauge conversion project between Manamadurai and VirudhunagarMost of the alignment of track passes through the land of black cotton soil. A gravel quarry was identified at 35 km away from the work site. This material not satisfying blanket Specification.Blending of Gravelly material was done with available sand using Pug-mill Blender.

-

Gradation of Available Gravelly Material

-

Gradation of available Sand for Blending

-

Mix ration of gravel to sand was taken 4 (Gravel) : 1 Sand and tested for gradation found OK.

-

Materials : storage, conveying, blending and loading process

-

Degree of Compaction achieved : 98.1 to 99.6 %Blanket : Laying, Compaction, Finished Surface & Quality check

-

Tentative Cost Comparison of Existing GE-1 and new specifications (all 2 alternatives) For working out the cost we have taken actual rate of blanket material & earth fill being used of Section Chandigarh - Morinda (NR) & rates of SQ1 & SQ3 soil has been assumed bearing in mind the transportation cost aspect.Analysis has been done for Bank Height of 1.75m ( maximum depth of variation in Formation Layers) & Single Line

Type of MaterialRate (in Rs./cum) Rate of blanket material 948 (Actual)Rate of SQ3 Soil 200 (assumed)Rate of SQ2 Soil (SM Type)133 (Actual)

-

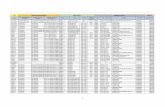

Tentative Cost Comparison (Chandigarh - Morinda, NR)

Axle Load Layer SystemSoil Type in prepared subgrade/subgradeTotal Cost/km25t

As per GE:G-1 SQ2SQ387,54,07083,04,480Single SQ2SQ3 75,10,530 (85.8 %) 66,89,120 (80.5 %)2-layerSQ2SQ3 52,53,645 (60.0 %) 49,02,840 (59.0 %)30tAs per GE:G-1 SQ2SQ31,00,70,295 94,46,180SingleSQ2SQ3 79,18,030 (78.6 %) 80,80,700 (85.5 %)2-layerSQ2SQ3 63,45,080 (63.0 %) 59,67,860 (63.2 %)32.5tSingleSQ2SQ396,21,38084,98,2502-layerSQ2SQ3 63,45,080 (65.9%) 59,67,860 (70.2 %)

-

Tentative Cost Comparison of Existing GE-1 and new specifications (all 2 alternatives) For working out the cost we have taken actual rate of blanket material & earth fill being used of Section Manmadurai - Virudhunaagar (SR) & rates of SQ1 & SQ3 soil has been assumed bearing in mind the transportation cost aspect.Analysis has been done for Bank Height of 1.75m (maximum depth of variation in Formation Layers) & Single Line

Type of MaterialRate (in Rs./cum) Rate of blanket material 825 (Actual)Rate of SQ3 Soil 200 (assumed)Rate of SQ2 Soil (SC Type)180 (Actual)

-

Tentative Cost Comparison Manmadurai - Virudhunaagar (SR)

-

Tentative Cost Comparison of Existing GE-1 and New specifications (all 2 alternatives) For working out the cost we have taken actual rate of blanket material & earth fill being used of Section Palval _ Bhooteswar (RVNL) & rates of SQ2, SQ3 soil has been assumed adding the transportation cost over and above the soil being used in earth fillAnalysis has been done for Bank Height of 1.75m (maximum depth of variation in Formation Layers) & Double Line

Type of MaterialRate (in Rs./cum)Rate of blanket material 700 (Actual)Rate of SQ3 Soil 200 (assumed)Rate of SQ2 Soil120 (assumed)Rate of SQ1 Soil 60 (Actual)

-

Tentative Cost Comparison (Palval Bhooteshwar, NR)

-

Tentative Cost Comparison of Existing GE-1 and new specifications (all 2 alternatives) For working out the cost we have taken actual rate of blanket material & earth fill being used of Section Rewari Ajmer (RVNL) & rates of SQ2 & SQ3 soil has been assumed bearing in mind the transportation cost aspect.Analysis has been done for Bank Height of 1.75m ( maximum depth of variation in Formation Layers) & for Double Line

Type of MaterialRate (in Rs./cum) Rate of blanket material 400 (Actual)Rate of SQ3 Soil 200 (assumed)Rate of SQ2 Soil150 (assumed)Rate of SQ1 Soil 107 (Actual)

-

Tentative Cost Comparison (Rewari - Ajmer, NR)

-

MANUFACTURING OF BLANKETING MATERIAL THROUGH CRUSHERS

SOURCE-GHAGGAR RIVER BED MATERIALTYPE-JAW CRUSHER - 15 x 30 AND 10 x 20 CUMROLLER CRUSHER - 34 x 22 (dia)SCREEN SIZES - 75mm x 30mmOPENINGS OF SCREEN - 4,15,22,32,50, 72mmDUST PRODUCED APPROX - 20%BALANCE - 80% STONES FOR CRUSHING

-

CRUSHER MANUFACTURERS

INTERNATIONAL ENGG. WORKS , MAHARANTI ROAD, BADARPUR, DELHI.- GURUDEO SINGH ENGG. WORKS.- BHARTI ENGG. WORKS.- HARJEET ENGG. WORKS.

-

COST OF MANUFACTURING OF BLANKET MATERIALFactors contributing are - INITIAL COST OF BOULDERS - ROYALTY LABOUR COST DEPRECIATED COST OF CRUSHERSCOST OF MODIFICATIONS TO THE CRUSHING UNITSPOWER CONSUMTION WASTAGE OF RAW MATERIAL

-

Mechanical Production of Blanket Material

-

Blending Methodology

Blanket material could be obtained by proper blending of two or more soils or in combination with soils and crushed material like stone chips or quarry dust. Before approving such sources, trials for blending to judge the final product, needs to be done. Detail methodology of blending to be adopted to produce large quantity of blanket material with consistent quality, needs also to be laid down in advance. Blending of either natural or crushed materials in a pre decided ratio could be adopted. Theoretical and laboratory trials are required in order to establish the desirable ratio of the blending materials. This exercise may be done in advance before finalizing the contracts for such a material.

-

The methodology of blending trials is explained below:

Identify the usable materials/soils. Take equal weight of the soils for sieve analysis. Write down the weight retained at each sieving stage for all the soils. Apportion a percentage component to each soil and work out a theoretical mix. Draw particle size distribution curve of the mix to find out desirability of gradation. If not successful, make another trial, and so on. Trials and plotting work can also be done using simple computer programs. Mechanical blenders using simple technology are now available in the market.

Two types of mechanical blenders are quite common:

-

Drum type blenders Drum type machines may involve weigh batching or manual feeding of material. They involve more moving parts. Hence, these machines are both manpower and maintenance intensive. They may pose a problem of segregation of material and as such do not afford any cost advantage either in the short or long run. These may be suitable for small quantities and not for large-scale production as required in construction projects.

Pug mill type blenders:For continuous production of mix in large quantities, the best way is to feed the aggregates/ soils of pre decided gradation by way of 3 or 4 bins with conveyor belt. The required output grading can be achieved by adjustment of gate openings of bins. The use of pug mill type blenders is found very cost effective, as the manpower involvement is very little and only 4-5 people can run a plant of 100 tph. The pug mill blender consists of:

-

The other important features of this technology are:

Automatic feeding of soils/aggregates under gravityArrangement for precise control of mixing of waterEither direct loading into trucks, or optional storage at plantAvailability of domestic manufacturers, and low cost of set upAdvantage of removal and relocation with ease

-

World Railway PracticeUIC (Mainly European Rlys)AAR (American & Canadian Rly)Australian Railways

-

THICKNESS OF STRUCTURAL LAYERS Sub Grade -BLANKET- UIC PRACTICESIt Is A Multilayer Concept.Soils Are Divided Into QS0, QS1, QS2, QS3 Types.QS0 Soils Are Avoidable.

-

THICKNESS OF STRUCTURAL LAYERS Sub Grade - BLANKET- UIC PRACTICES

QS1 Soils Are Equivalent To Cohesive Soils, Fines > 40% (CH, CI, CL, MH, MI, ML, SC, GC, GM, SM) & CBR (min) 2-3QS2 Type Of Soils Contain Fines 15%-40% (SW-SM, GW-GM Etc. And Moderately Hard Crushed Rocks) & CBR >5 (min)QS3 Type Of Soils, Fines < 15% (GW, GP, SW, SP & Hard Crushed Rocks) CBR 10-17(min)

-

e = E + a + b + c + d + f Thickness (e) Of Track-bed LayersE = 0.70m For prepared subgrade of QS1 soil E = 0.55m For prepared subgrade of QS2 soil E = 0.45m For prepared subgrade of QS3 soila Thickness factor depending on GMT b Thickness factor based on Type of Sleeper and its lengthc _ Thickness factor based on difficult working condition on existing lines d Thickness factor based on max. axle loadf - geo-textile to be provide for QS1 & QS2 soil used in prepared sub grade Prepared subgrade thickness : 35 50 cm UIC Code 719 R - 2008

-

UIC SPECIFICATIONS FOR BLANKET MATERIALThe Blanket Layer Comprises Of :- A Foundation Layer Sandy Gravel Having Good Filtering Characteristics Not Required On QS3 prepared sub grade- A Sand Filter Layer or a Geo-textile Filter For prepared sub grade of QS1 or QS2 soil

Sandy Gravel Layer Directly Below Ballast Must Be Well Graded And Sufficiently Durable e.g. - Los Angeles Abrasion Value < 20 Or 25 - For Silty And Clayey Soils Blanket Material Should Have 20% Fine Sand (< 0.2 mm)

-

Practices of American Railways

American Railway Engineering and Maintenance-of-way Association (AREMA) Manual of Railway Engineering 2002 recommends use of 12 inches ballast and 12 inches sub-ballast on main track.

Use of soils with Plasticity Index > 12 for a depth of 4 feet below sub-ballast should be avoided, if possible.

-

AREMA Specifications for Sub-ballast

(American Railway Engineers and Maintenance-of-way Association AREMA Manual 2001) Material to be used is similar to highway bases and sub-bases such as crushed stone, natural or crushed gravel, natural or manufactured sands, crushed slag etc.Sub-ballast shall be granular material so graded as to prevent penetration into sub-grade and penetration of ballast into sub-ballast zone.Filter principles should be used in drainage to the grading of sub-grade.Maximum size of sub-ballast should not exceed maximum size of ballast.Not more than 5% of the sub-ballast should pass No. 200 sieve (60 micron).

-

Blanket (Capping) Layer in Australian Railways

-

Blanket (Capping) Layer in Australian Railways Particle Size DistributionAtterberg Limits -Liquid Limit : Maximum 30 (35 for arid areas)Plastic Limit : Maximum 20Plasticity Index : 2 - 10 (2 - 15 for arid areas) Linear Shrinkage : Maximum 3%Maximum Dry Density : Minimum 2.0 t/cumSoaked CBR : Minimum 50 on material compacted to 95% (min.) Maximum Dry Density

-

Case study for Blending of Blanket Material

NHAI project site between Sultanpur-Utratia Bye Pass Road, near Lucknow was visited in the month of June 2005 in connection with production of blanket by blending.

Details are as follows:

Name of work executing agency: Atlanta, Mumbai

Location: Amar Saheed Path, Lucknow

-

(iii)Makes of blender: Gujrat Appolo Equipment Ahemdabad (iv)Plant capacity: 160 ton per hour(v)Approximate cost: 50 lakhs(vi)Number of persons for operating the plant: 7vii)Alternative Power supply:Can be operated by 125 KVA GenaratorviiiNumber of bins: Four(ix)Salient features: Four bins, pug mills, wet mix computerized blender

-

Comparison of Blanket Specification

Existing Specification Proposed Specification RemarksCu > 4 (preferably > 7) Cu > 7 To ensure better well-graded material Cc between 1 and 3Cc between 1 and 3SameFines

-

Thickness details of different layers- Single layer systemMinimum EV2 determined from 2nd step Plate Load Test on top of compacted blanket layer (Ref : German Code : DIN 18134 2001) *As in-situ Assurance Test

Layers Axle Load 25TAxle Load 30 TAxle Load 32.5TBlanket60 cm - SQ375 cm - SQ2 100 cm - SQ1 SQ2/SQ3 are preferred soil below blanket.

Blanket Compacted upto 98 % MDD*Min. EV2 100 MPa*75 cm for SQ3, 80 cm for SQ2SQ1 Not to be provided in Top Layer of Embankment & overlain by SQ2/SQ3 soils80 cm for SQ3, 100 cm for SQ2SQ1 Not to be provided in Top Layer of Embankment & overlain by SQ2/SQ3 soils SQ2/SQ3 are preferred soil below blanket. Blanket Compacted upto 100% MDD*Min. EV2 120 MPa *

-

Thickness details of different layers- Single layer system(Organic soils to be avoided in Embankment Fill)

Layers Axle Load 25TAxle Load 30 TAxle Load 32.5TTop Layer of Subgrade of Thickness

Embankment Fill :All soils SQ1,SQ2, SQ3 are permitted in Embankment Fill. 50 cm SQ1/ SQ2/SQ3 soilsCBR > = 5 generally, but not < 4 in isolated cases(For SQ1 soil, CBR > = 4 generally, but not < 3 in isolated cases)

Compacted upto 98% of MDDMin. EV2 = 45 MPa 75 cmSQ2/SQ3 soils

CBR > = 6 generally but not

-

Typical Embankment X-section for Single Layer System (Blanket on Embankment Fill)

-

Thickness details of different layers - Two Layer Minimum EV2 determined from 2nd step Plate Load Test on top of compacted blanket layer (Ref : German Code : DIN 18134 2001) *As in-situ Assurance Test

Layers Axle Load 25TAxle Load 30 TAxle Load 32.5TBlanket30 cm - SQ345 cm - SQ2 SQ2/SQ3 are preferred soil below blanket. Blanket Compacted upto 100 % MDD*

Min. EV2 100 MPa*45 cm for SQ3, 60 cm for SQ2SQ1 Not to be used in prepared subgrade45 cm for SQ3, 60 cm for SQ2SQ1 Not to be used in prepared subgrade

SQ2/SQ3 are preferred soil below blanket. Blanket Compacted upto 100% MDD*Min. EV2 120 MPa *

-

Thickness details of different layers - Two Layer

Specification of Prepared Subgarade : SQ2/SQ3, Plasticity Index 12

Layers Axle Load 25TAxle Load 30 TAxle Load 32.5TPrepared Subgrade (good soil)100 cm

CBR > = 5 generally, but not < 4 in isolated cases

Compacted upto 98% of MDDMinimum EV2 = 45 MPa100 cm

CBR > = 7generally but not = 8 generally but not

-

Thickness details of different layers - Two Layer (Organic soils to be avoided)

Layers Axle Load 25TAxle Load 30 TAxle Load 32.5TEmbankment Fill All soils SQ1,SQ2, SQ3 are permitted in Embankment Fill.CBR > = 4 generally, but not < 3 in isolated cases Compacted upto 98% of MDDMinimum EV2 = 30 MPaCBR > = 5 generally but not

-

Typical Embankment X-section for Two Layer System

(Blanket + Prepared Subgrade on Embankment Fill)

-

Number of persons- 10 labourers, 1 foreman, 2 helpers for operating the plant Storage capacity : 4000 cubic feet Power: 5 HP to 7HPAlternative power supply : Can be operated by 320 KVA Generator Number of bins: ThreeNumber of sieve combination: Three of 20 mm, 10 mm & 6 mm sizes Tank ( For water): For wet mixing facilities

-

Field Trials of Proposed Formation Specifications Railway Board has Ordered for conducting Field Trials of the recommended Formation Specifications to study the implications of introduction of new specifications and quality assurance tests

Trial sites have been selected * Udhana Jalgaon doubling project, WR * Bina Bhopal 3rd Line, executed by RVNL

-

Review Committee Railway Board nominated committee of CAO/C of WR, SR, NCR, Sr.EDGE/RDSO & RVNL to deliberate availability of materials and costs aspects & Formation Specifications for New linew/Doubling/GC for axle loads in range of 22.5 to 25t.

Committee recommended :

- Three layer system consisting of blanket, crusher run & prepared subgrade over embankment fill is not considered necessary from materials availability & cost considerations. - There will be no difficulty in getting adequate quality soil for construction of formation all over India. - Blanket Specifications are slightly improved over previous one but with lesser requirement in quantity. - Blanket material can produced be mechanically, as done in Highway Organization like NHAI.

-

Recommendations of Review Committee - Cost of earthwork would vary from region to region but no significant addition in cost of earthwork in formation is envisaged on account of new specifications. - The rate of blanket material will go up primarily due to mechanical production and blending. However, on a holistic view, the increase in cost may not be very significant especially when compared to the additional advantage accrued with such better specification. - Formation Specifications for New Lines/Doubling/GC Works to be carried out on IR, for existing axle loads in the range 22.5t to 25t should be also be kept as same as those for 25 T as per new specifications.

-

Crushing MethodologyIn the event of non-availability of natural source of blanket material, depending on the proximity of project site from the parent rock/boulder sources, it may be decided to crush the rock/boulder in order to produce crushed blanket material. Crushed blanket material may be produced as sole product or in conjunction with ballast or any other nominal size.Trials and permutations of feed speed, crushing cycle, sieve combinations may be required to arrive at the required particle size gradation.It is possible achieve near total produce of desired gradation through production cycle management. Alternately, it may be possible to get by-products of other sizes in the desired proportion and blanket material as main produce or vice-versa.Optimisation of production rates and costs can be achieved by controlling the output at each sieve stage.It is ideal to mix the required quantity of water for OMC (accounting for loss/gain of moisture due to weather conditions) at the crusher plant and transport the material in wet condition.

-

Sampling of blanket Material

-

Compaction of Blanket Material with Vibratory Roller

-

Tentative Cost Comparison of Existing GE-1 and new specifications (all 2 alternatives) For working out the cost we have taken actual rate of blanket material & earth fill being used of Section Chandigarh - Morinda (NR) & rates of SQ3 soil has been assumed bearing in mind the transportation cost aspect.Analysis has been done for Bank Height of 1.75m ( maximum depth of variation in Formation Layers) & double line

-

Tentative Cost Comparison (Chandigarh Morinda, NR)

-

Tentative Cost Comparison of Existing GE-1 and new specifications (all 2 alternatives) For working out the cost we have taken actual rate of blanket material & earth fill being used of Section Manmadurai - Virudhunaagar (SR) & rates of SQ1 & SQ3 soil has been assumed bearing in mind the transportation cost aspect.

-

Tentative Cost Comparison Manmadurai - Virudhunaagar (SR)

********

![[Clement Hal] Clement, Hal - Needle 1 - Needle](https://static.fdocuments.in/doc/165x107/577cb1001a28aba7118b67ae/clement-hal-clement-hal-needle-1-needle.jpg)

![HAL BUILDING KIT [HAL BK] - med-eng.com](https://static.fdocuments.in/doc/165x107/61d33d1fef11de717d4ff131/hal-building-kit-hal-bk-med-engcom.jpg)

![[Clement Hal] Clement, Hal - Iceworld](https://static.fdocuments.in/doc/165x107/577cb1001a28aba7118b67ac/clement-hal-clement-hal-iceworld.jpg)