New DIAMOND SURFACE SENSITIVITY TO VARIOUS ATOMIC...

Transcript of New DIAMOND SURFACE SENSITIVITY TO VARIOUS ATOMIC...

DIAMOND SURFACE SENSITIVITY TO VARIOUS ATOMIC OXYGEN SIMULATION ENVIRONMENTS

Z. Shpilman(1, 2), I. Gouzman(1), E. Grossman(1), L. Shen(3), T. K. Minton(3), and A. Hoffman(4)

1Space Environment Section, Soreq NRC, Yavne 81800, Israel

2Department of Physics, Technion, Haifa 32000, Israel 3Department of Chemistry and Biochemistry, Montana State University, Bozeman, MT 59717

4Schulich Faculty of Chemistry, Technion, Haifa 32000, Israel ABSTRACT Kapton polyimide is used as a standard for low Earth orbit (LEO) equivalent atomic oxygen (AO) flux assessment in ground-based simulation facilities. AO sources in these facilities produce, a variety of reactive species, such as thermal or hyperthermal O atoms, UV radiation, or energetic ions. The reaction mechanisms at the surfaces of test materials undoubtedly depend on the nature of the exposure environment. The obtained Kapton surface morphology is, however, not very sensitive to these interactions and shows similar carpet-like texture after exposure to significantly different environments. CVD polycrystalline diamond film interaction with oxidizing species also depends on the particular exposure environment. However, in this case the difference is well pronounced in the resulting surface morphology, which can be used to evaluate the nature of the exposure environment. The interaction of thermal AO, hyperthermal AO, and energetic oxygen ions with CVD diamond surfaces has been investigated with a focus on the relationship between surface structure and exposure environment. Thermal AO (~0.04 eV) produced by a modified radio frequency (RF) plasma, hyperthermal (~5 eV) AO produced by a laser-detonation source, and a combination of thermal AO and a high current of oxygen ions in the RF plasma afterglow were used as exposure species. Tapping mode atomic force microscopy (AFM) was used to probe surface morphology at the nanometric scale. Changes of the diamond surface morphology after exposure to thermal AO were mild. By contrast, exposure of the diamond films to a hyperthermal AO beam resulted in severe damage to the surface morphology. This exposure resulted in the etching of selective crystal facets. Certain facets became roughened into an array of steps and ledges; other facets, such as (100) facets show relative endurance. Exposure of polycrystalline diamond films to a high current of ions results in a non-selective formation of a round granular phase on top of the entire diamond facet. The obtained diamond surface morphology was found to be sensitive to the nature of the AO exposure environment, giving an indication of the presence of ions or hyperthermal oxygen atoms.

1. INTRODUCTION The low Earth orbit (LEO) environment, at altitudes ranging from 200 to 800 km, is hazardous and exposes spacecraft to atomic oxygen (AO), VUV radiation, ionizing radiation (electrons, protons), ultra high vacuum, thermal cycles, and hypervelocity micro-meteorites and debris [1]. AO, formed by VUV-induced molecular oxygen dissociation, is the most serious hazard for satellite external surfaces, due to its oxidative and erosive potential [1-4]. The residual atmosphere in LEO is composed mainly of thermal oxygen atoms and nitrogen molecules. The density of oxygen atoms is rather low, ~108 cm-3, but their collisions with the external surfaces of space vehicles orbiting at a velocity of ~7.5 km·sec-1 result in an impact energy equivalent to ~4.5 eV and a flux of 1014-1015 O·cm-2·sec-1. The ability to test materials in space is limited. Therefore, the search for reliable ground simulation methods has been undertaken. The variety of ground simulation facilities used for studying materials degradation under AO attack includes RF and ECR plasmas, low energy ion neutralization, electron stimulated desorption, photo-dissociation, supersonic, and laser detonation sources [3, 5]. Kapton® polyimide is commonly used for applications in LEO such as thermal blankets for satellites and it has been tested in all materials related in-flight experiments [6-9]. Therefore, its reaction efficiency in LEO is relatively well known and the accepted value is 3x10-24 cm3·O-atom-1. Kapton is used as a standard for the assessment of the effective AO flux in ground exposure facilities [10]. It is well known that none of the exposure facilities is able to create a perfect simulation and each one has its own drawbacks [3, 11]. Usually, exposure facilities consist of a mixed environment of AO, UV radiation, ions, and excited species in one simulation facility. Observation of the morphology of Kapton films indicates that exposure to various AO simulation environments results in a similar granular texture, denoted as "carpet-like” morphology. Thus, the ability to differentiate between different environments by simple morphological characterization is problematic. In this work Kapton polyimide and CVD diamond films are exposed to various AO exposure environments, including hyperthermal AO, thermal

AO, and an oxygen RF plasma that consists of thermal AO, energetic ions and UV radiation. Morphology of the films was studied and revealed that Kapton shows similar granular texture upon exposure to RF plasma or hyperthermal AO. In contrast, diamond morphology shows granular texture only upon exposure to the RF plasma environment, whereas hyperthermal AO exposure results in a preferential etching of the diamond facets. Therefore, it is suggested that diamond can be used as a testing material for AO ground simulation facilities with regard to composition of the exposure environment. 2. EXPERIMENTAL Polycrystalline diamond films with sub-micron grain size were grown on 1.2 × 1.2 cm2 Si substrates in a standard hot filament (HF)-CVD system [12-15] for 1 hour. Before deposition the Si substrate was treated in mixed slurry of diamond and titanium particles in order to increase the nucleation density. Deposition parameters were: gas pressure of 50 torr, gas flow of 100 sccm, substrate temperature of 800°C, and gas mixtures of 1:99 CH4/H2 or CD4/D2, which resulted in continuous films with thicknesses of 1 µm and 300 nm, respectively [13]. Thermal atomic oxygen exposure was carried out using a modified RF-plasma system (LB-3000 by Advanced Energy), shown in Fig. 1. The system was operated with a feed gas of 99.999% pure oxygen, at a pressure of 50 mTorr, gas flow of 10 sccm, and power of 2000 W. A simple method was used to convert the RF-plasma source into a pure thermal AO source, as described elsewhere [11]. Redirection of the afterglow through two right angle deflections results in a strong reduction of ion current and UV radiation flux. This is mainly due to supply of electrons from the metallic chamber walls, and radiation absorption by the chamber walls, respectively. The existence of pure thermal AO after two right angle turns, denoted as position C, was verified by measuring mass loss of Kapton polyimide, while ions, electrons, excited species, and UV radiation fluxes were shown to be negligible. The position after only one right angle turn, denoted as position B, consists of thermal AO with an addition of UV radiation flux similar to that of space and some quantity of electronically excited specie, ions and electrons current. Thus, a modified RF plasma system provides a versatile low cost ground simulation facility of the LEO AO environment [11]. In the present work, Kapton polyimide samples were exposed in positions B, and C to a total fluence of ~5x1019

O·cm-2 as measured according to their mass loss.

Fig. 1. A photograph of the modified RF plasma system. Different locations used for system

characterization and samples' AO exposure are indicated.

The diamond samples were exposed in the afterglow of the plasma system to pure thermal AO, at position C (Fig. 1). A total fluence of 5.5x1019 O·cm-2 was measured according to Kapton polyimide mass loss. Diamond films were also exposed to oxygen in front of the RF plasma source (position A) up to a total LEO

equivalent AO fluence 1x1020 O⋅cm-2. A Faraday cup was used to measure the ion flux emerging from the oxygen RF plasma system. The ion and electron fluxes were inferred from the measured total current by the use of a retarding bias [11, 14]. The total current of ions and electrons measured without an applied bias was ~2.2 µA; the ion current obtained with an applied negative bias of -70 V, which stops most of the electrons, was 4.75 µA. This current, resulted in a total ion dose of 5.6x1016 cm-2 for 30 min of exposure. Hyperthermal AO exposure was carried out by a laser detonation source [16] producing oxygen atoms with an average energy of 5 eV and an energy spread (full width at half maximum) of 2.5 eV. The diamond and polyimide samples were exposed to a total fluence of ~3x1019 O·cm-2 and ~6x1019 O·cm-2, according to Kapton surface recession [10]. The surface morphology of the exposed samples was studied by atomic force microscopy (AFM) (MultiMode, Nanoscope IV from Veeco) operated in a Tapping mode. For the polyimide samples which usually show a uniform surface, the height images were used, while for the diamond samples, which are relatively rough, the amplitude images were used. Each of these images shows better lateral resolution in the corresponding type of surfaces.

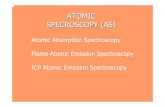

3. RESULTS AND DISCUSSION Fig. 2 shows AFM height images of polyimide Kapton films before and after exposure to different oxidizing environments. Fig. 2(a) shows the pristine polyimide film, which is particularly smooth, with RMS roughness lower than 1 nm. Following exposure to thermal AO (position C in Fig. 1), the film remains rather smooth, with RMS roughness of about 3 nm (Fig. 2(b)). However, there is measurable mass loss of the exposed film (of about 200 µgr.), corresponded to a total fluence of ~5x1019 O·cm-2. The AFM image of the Kapton sample exposed to RF plasma at position B, a position containing thermal AO, a minor amount of ions, UV radiation, and excited species, with the same

total fluence, is shown in Fig. 2(c). The surface possesses a “carpet-like” texture with grain size of about 100 nm, and RMS roughness increases to about 16 nm. Kapton exposure in position A results even in a more severe damage, with higher surface roughness, as published previously [11]. However, also in this case, the surface morphology resembles a carpet-like structure. Following exposure of a polyimide film to hyperthermal AO with similar total fluence, there is also a creation of a carpet like texture, but with a smaller grain size, ~40 nm, and lower RMS roughness of about 7 nm (Fig. 2(d)). In this case, the grain size distribution appears to be more homogenous.

Fig. 2. AFM height images, of Kapton-HN polyimide samples before (a), and after exposure to pure thermal AO (b), a mixed environment of thermal AO, UV and low flux of ions (c), and hyperthermal 5eV AO (d). Height scale is 200nm,

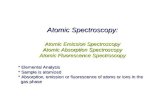

scan size 5x5µm. Fig. 3 shows the AFM images of polycrystalline diamond films before and after exposure to thermal AO, RF plasma, and hyperthermal AO. Fig 3(a) reveals the pristine polycrystalline diamond film. This film

consists of crystallites in various orientations and sizes, with secondary nucleation of terrace like features on some of the facets. Because of the inherent roughness of the films it is hard to correlate between local

roughness of certain facets and the total image RMS; therefore, the RMS of the presented images is not mentioned. Following exposure to thermal AO, Fig. 3(b), only a subtle smoothing is observed on terrace features on the crystallite and facet edges. Following exposure to the RF plasma at position A (see Fig 1), which provides a combined environment of thermal AO and a high current of ions and electrons, the entire surface is covered with a granular texture, with grain

size of ~40 nm, while the general facet structure is maintained (Fig 3(c)). Exposure to hyperthermal AO results in selective etching of particular facets (Fig 3(d)). Square-shaped (100) oriented facets remain smooth and are etched mainly at their edges, while triangular-shaped (111) oriented facets are severely etched, and transformed into an array of steps and ledges.

Fig. 3. AFM amplitude images of HF-CVD diamond film before (a) and after exposure to thermal AO (b), exposure to

oxygen plasma (c), and exposure to hyperthermal AO (d). Scan size 2x2 µm; height scale 500 mV (a-b) and 800 mV (c-d).

A comparison of the surface morphology changes that occur at either Kapton polyimide or CVD diamond films following exposure to AO is rather difficult. However, this comparison could provide an additional insight into AO - surface interaction under different oxidizing conditions. The developed surface morphology depends on the physical and chemical properties of the materials, such as structure, density, and chemical bonding. Diamond is a crystalline material which consists of C-C bonds configured in sp3

hybridization. Kapton is a semi-crystalline polymer which consists of chains of PMDA-ODA molecules with aromatic bonds, carbonyl groups, and C-N bonds. Therefore, in general, diamond should show higher inertness to oxidizing environments and radiation. Following exposure to pure thermal AO, both Kapton and diamond surfaces become smoother, although the mass loss in the polyimide film is two orders of magnitudes higher relative to the diamond film [11, 15]. It may be observed that the polyimide film is

etched uniformly, while etching of the diamond film occurs only in energetically favorable locations such as edges and terrace features, Figs. 2(b), and 3(b), respectively. In both cases, however, the morphological changes are subtle. When UV radiation accompanies thermal AO exposure, the situation is more complicated. The UV radiation interacts with oxygen molecules, affecting the gas phase composition by creating excited species and increasing the atomic oxygen concentration [1]. However, diamond itself is not sensitive to UV radiation, and is known to be a radiation hard material, i.e. able to withstand high power deep-UV lasers [17, 18]. Therefore, diamond is studied as a prospective UV, electron, and neutron radiation detector [18]. Diamond can also withstand a high dose of ion irradiation before it will convert into graphite, which eventually happens, when the total ion dose exceeds the so called “critical dose” [19]. Up to this critical dose, the damaged diamond layer can be repaired by annealing, changing from graphite back into the diamond structure [20]. Kapton, on the other hand, possesses higher sensitivity to UV radiation and this radiation may contribute to its degradation [21-23]. It can be processed by UV laser radiation [21], an advantage that makes it useful in microelectronics, as a photoresist. An excimer laser (248 nm) with energy of less than 1 mJ·cm-2 for 25 pulses can produce holes in the polyimide sample [22]. Following an exposure to high energy ions there is a removal of hydrogen and oxygen from the polyimide surface layer, darkening of the Kapton film, and creation of a brittle sub-surface layer [23]. The interaction with the mixed environment in front of the RF plasma source (position A in Fig. 1) resulted in pitting of the diamond surface and creation of a granular phase on top of the entire diamond facet structure, as shown in Fig. 3(c). Taking into account that UV radiation does not affect the diamond morphology, and that thermal AO only produces subtle smoothing of the diamond facets, it can be concluded that there is a direct correlation between pitting on the diamond surface and the presence of energetic ions. Under exposure to the RF plasma, which contains UV radiation, ions and excited species, the major effect on the diamond film morphology can therefore be attributed to energetic ions. Energetic ions with energies of tens to a few hundreds of eV might lead to physical sputtering in addition to chemical interaction with the surface. 100-500 eV oxygen ion damage events are concentrated 3-10 Å below the diamond surface, as was calculated by the Stopping Range of Ions in Matter (SRIM) computer code [24]. For polyimide (using Kapton’s stoichiometry, C22O5N2, and density, 1.4 gr⋅cm-3) the calculations show a wider distribution of damage events in the depth between 5 and 40 Å, for the same

energies. The lateral damage in this case is larger than the one calculated for diamond, resulting in a larger volume for the damaged layer. Utilizing the measured ion current, the calculated range of damage, and the vacancies produced per ion, it is calculated that the vacancy density in diamond is a few orders of magnitude higher than the critical dose for the transformation of diamond into graphite (1x1020 vacancies/cm3). The ion current measured in the present work was 5.6x1016 ions/cm2; assuming the production of 1 vacancy/ion at an ion energy range of 100-200 eV and major damage range of 4 Å, the density of vacancies is calculated to be ~1x1024 vacancies/cm3. Therefore, there is a totally damaged graphitic layer in the sub-surface region of diamond (3-10 Å) that is etched and removed upon the high dose of ions emerging from the RF plasma source. It is assumed that the damage by ions in the polyimide film will also lead to the sub-surface graphitization and creation of easily-etched layer, which is larger than that of diamond. Exposure of polyimide and diamond films to hyperthermal AO results in totally different surface structures. Exposed polymers reveal a distribution of grain size and surface roughness which vary according to the polymer chemical composition, crystallinity, and manufacturing procedure [25]. Polyimide surface shows a small granular phase, which is typical for polymer degradation following exposure to hyperthermal AO in LEO and in ground simulation facilities [8, 9, 16]. Exposed diamond film reveals preferential etching. This preferential etching was recently explained based on an activated adsorption mechanism [26, 27], which acts as the limiting step in the diamond etching process. Different facets of diamond, mainly (111) and (100), were shown to have different adsorption energies, depending on the surface structure [28]. It is assumed that the entire energy of the incident hyperthermal oxygen atoms is used for adsorption on the diamond surface. The chemisorption energies for a full monolayer configurations of –C=O (carbonyl) or C-O-C (ether) on the (100) diamond surface were calculated to be between 8.4-8.6 eV [28]. These configurations are therefore energetically out of reach for the incident AO atoms of the laser detonation simulation facility (5±2.5 eV) [27]. The only configuration that is energetically possible on the (100) diamond surface under these exposure conditions is the half-monolayer carbonyl configuration, with a calculated chemisorption energy of 5.83 eV. This configuration can limit the creation of volatile products such as CO2, therefore, limiting the initiation of the etching process, and creating a passivating top layer. On the other hand, adsorption on the (111) surface is possible in several configurations including the carbonyl and ether full monolayer configurations, with chemisorption energies of about 6 eV. This full

coverage could facilitate the creation of volatile products and enable the progress of the etching. Following hyperthermal AO exposure of the polyimide film there is no difference between various areas on the film, and the entire film is etched uniformly to produce a granular texture (see Fig. 2(d)) [16, 25]. The activation energies for hyperthermal AO erosion on polyimide films were measured to be between zero and 0.3 eV [29]. Therefore, hyperthermal AO that impinges on a polyimide surface will react directly or, perhaps, after transient thermalization (the latter mechanism only applies at elevated surface temperatures) [16] . Direct reaction with hyperthermal O atoms is responsible for Kapton etching at room temperature. In the case of thermal AO exposure, the average energy of the impinging O atoms is very low (~0.04 eV), and it is only the high energy Boltzmann tail of the distribution that accounts for etching at room temperature. At higher temperatures, a larger fraction of atom-surface collisions would be expected to overcome the reaction threshold and lead to etching. Thus, on lower temperature surfaces as used in the present studies, a tiny fraction of thermal O atoms probably react after physisorbing on the surface [30]. Regardless of whether the impinging O atoms are thermal or hyperthermal, additional reactions may occur at radical sites generated by the initial reactions, and carbon-containing volatile species may be formed, resulting in surface erosion. The end result is controlled by the initial reactivity and directionality of the impinging species. The ability to identify the presence of ions in the AO simulation facilities is important in order to validate their reliability. The use of surface morphology to reveal the presence of ionic species could be, therefore, valuable. Polyimide films show similar granular features on the surface following exposure to various environments. These features can be attributed to ions, UV radiation, hyperthermal AO or to a combined effect of these environments. Diamond, on the other hand, is not affected by UV radiation, and shows different morphological changes upon exposure to hyperthermal AO or energetic ions. A clear correlation between the presence of ions and the appearance of a homogenous pitting on the entire diamond surface was observed. Therefore, these results could be useful for the characterization of the AO simulation facilities. However, the effect of ion dose and ion energy on the diamond surface morphology should be further clarified. 4. CONCLUSIONS In this study the morphological changes of polyimide and diamond films following exposure to different oxidizing environments are reported. The correlation between morphological changes and the nature of

reactive species in the exposure facilities was established. Polyimide produces similar carpet-like textures following exposures to hyperthermal AO, or mixed environment of UV radiation, ions, and thermal AO. Diamond reacts differently to each environment. Exposure of diamond to hyperthermal AO results in a selective etching: the (100) facets show high resistance, while the (111) facets are severely etched. Exposure to ions results in a uniform pitting and formation of a carpet-like texture on the entire diamond surface. Therefore, diamond surface morphology is more sensitive to changes in the exposure environment and can specifically indicate the presence of ions and characterize the reliability of the AO simulation facilities and purity of the exposure environment. REFERENCES 1. Tribble, A. C., The space environment:

Implementation for spacecraft design, Princeton University Press, Princeton, New Jersey (1995).

2. Packirisamy, S., Schwam, D., and Litt, M. H., Atomic oxygen resistant coating for low earth orbit space structures, Journal of Materials Science, 30, 308 (1995).

3. Minton, T. K., and Garton, D. J., Dynamics of Atomic-Oxygen-Induced Polymer Degradation in Low Earth Orbit, in Chemical Dynamics in Extreme Environments (Advanced Series in Physical Chemistry), Dressler, R. A., Ed., World Scientific, Singapore, pp. 420 (2001).

4. Grossman, E., and Gouzman, I., Space environment effects on polymers in low earth orbit, Nuclear Instruments & Methods in Physics Research Section B-Beam Interactions with Materials and Atoms, 208, 48 (2003).

5. Caledonia, G. E., Krech, R. H., and Green, B. D., High Flux Source of Energetic Oxygen Atoms For Material Degradation Studies, AIAA journal, 25, 59 (1987).

6. Silverman, E. M., Space Environmental Effects on Spacecraft – LEO Material Selection Guide, Langley Research Center (1995).

7. De Groh, K. K., Banks, B. A., McCarthy, C. E., Rucker, R. N., Roberts, L. M., and Berger, L. A., Analyses of the MISSE PEACE Polymers international space station environmental exposure experiment, in European Space Agency, (Special Publication) ESA SP 616 (2006).

8. NASA/SDIO Space Environment Effects on Material Workshop, NASA Langley Research Center, Hampton, VA (1989).

9. Gregory, J. C., Peters, P. N., and Swann, J. T., Atomic Oxygen Effects Measurements For Shuttle Missions STS-8 And 41-G, in Technical Memorandum 100459, Vol. 2, Visentine, J., Ed., NASA, Houston, TX, pp. 2.1 (1988).

10. ASTM-E-2089-00, Standard Practices for Ground Laboratory Atomic Oxygen Interaction Evaluation of Materials for Space Applications, Vol. 15.03, American Society for Testing and Materials (2002).

11. Shpilman, Z., Gouzman, I., Lempert, G., Grossman, E., and Hoffman, A., Rf plasma system as an atomic oxygen exposure facility, Review of Scientific Instruments, 79, Art. no. 025106 (2008).

12. Akhvlediani, R., Lior, I., Michaelson, S., and Hoffman, A., Nanometer rough, sub-micrometer-thick and continuous diamond chemical vapor deposition film promoted by a synergetic ultrasonic effect, Diamond and Related Materials, 11, 545 (2002).

13. Ternyak, O., Michaelson, S., Tkach, L., Akhvlediani, R., and Hoffman, A., The impact of gas isotopic exchange on the growth rate and hydrogen (deuterium) bonding within CVD diamond films, Physica Status Solidi (A), 204, 2839 (2007).

14. Shpilman, Z., Gouzman, I., Grossman, E., Akhvlediani, R., and Hoffman, A., Chemical and morphological aspects of diamond film oxidation and regeneration, Physica Status Solidi (A), 205, 2130 (2008).

15. Shpilman, Z., Gouzman, I., Grossman, E., Akhvlediani, R., and Hoffman, A., Hydrogen plasma and atomic oxygen treatments of diamond: Chemical versus morphological effects, Applied Physics Letters, 92, Article Number: 234103 (2008).

16. Buczala, D. M., Brunsvold, A. L., and Minton, T. K., Erosion of Kapton® H by hyperthermal atomic oxygen, Journal of Spacecraft and Rockets, 43, 421 (2006).

17. Whitfield, M. D., Lansley, S. P., Gaudin, O., McKeag, R. D., Rizvi, N., and Jackman, R. B., Diamond photoconductors: Operational lifetime and radiation hardness under deep-UV excimer laser irradiation, Diamond and Related Materials, 10, 715 (2001).

18. Manfredotti, C., CVD diamond detectors for nuclear and dosimetric applications, Diamond and Related Materials, 14, 531 (2005).

19. Uzan-Saguy, C., Cytermann, C., Brener, R., Richter, V., Shaanan, M., and Kalish, R., Damage threshold for ion-beam induced graphitization of diamond, Applied Physics Letters, 67, 1194 (1995).

20. Kalish, R., and Prawer, S., Graphitization of diamond by ion impact: Fundamentals and applications, Nuclear Inst. and Methods in Physics Research, B, 106, 492 (1995).

21. Srinivasan, R., Hall, R. R., Loehle, W. D., Wilson, W. D., and Allbee, D. C., Chemical transformations of the polyimide Kapton brought

about by ultraviolet laser radiation, Journal of Applied Physics, 78, 4881 (1995).

22. Adhi, K. P., Owings, R. L., Railkar, T. A., Brown, W. D., and Malshe, A. P., Chemical modifications in femtosecond ultraviolet (248 nm) excimer laser radiation-processed polyimide, Applied Surface Science, 225, 324 (2004).

23. Kaneko, T., Watamori, M., Makita, H., Araujo, C., and Kano, G., Damage evaluation after ion beam irradiation on polyimide films using ERD and RBS techniques simultaneously, Nuclear Instruments and Methods in Physics Research, Section B: Beam Interactions with Materials and Atoms, 219-220, 236 (2004).

24. Ziegler, J. F., The Stopping and Range of Ions in Matter, http://www.srim.org/ (2008).

25. Waters, D. L., Banks, B. A., De Groh, K. K., Miller, S. K. R., and Thorson, S. D., The atomic oxygen erosion depth and cone height of various materials at hyperthermal energy, High Performance Polymers, 20, 512 (2008).

26. Gregory, J. C., and Peters, P. N., Atomic Oxygen Effects Measurements For Shuttle Missions STS-8 And 41-G, in Technical Memorandum 100459, Vol. 2, Visentine, J., Ed., NASA, Houston, TX, pp. 4.1 (1988).

27. Shpilman, Z., Gouzman, I., Grossman, E., Shen, L., Minton, T. K., and Hoffman, A., Resistance of Diamond (100) to hyperthemal atomic oxygen attack, Applied Physics Letters, (Submitted).

28. Zheng, X. M., and Smith, P. V., The stable configurations for oxygen chemisorption on the diamond (100) and (111) surfaces, Surface Science, 262, 219 (1992).

29. Yokota, K., Tagawa, M., and Ohmae, N., Temperature dependence in erosion rates of polyimide under hyperthermal atomic oxygen exposures, Journal of Spacecraft and Rockets, 40, 143 (2003).

30. Golub, M. A., and Wydeven, T., Reaction of atomic oxygen (O(3P)) with various polymer films, Polymer Degradation Stability, 22, 325 (1988).