New Class of Liquid Phosphite Stabilizers The Green Solution

-

Upload

uriah-cameron -

Category

Documents

-

view

64 -

download

1

description

Transcript of New Class of Liquid Phosphite Stabilizers The Green Solution

New Class of Liquid Phosphite StabilizersThe Green SolutionThe Green Solution

Dr. Michael JakupcaDr. Don Stevenson, Jacob Lance, Nina Ruegg

Dover Chemical Corporation

SPE Polyolefins Conference 2011Houston, Texas

Polyolefin Stabilizers

Most polyolefin stabilizer packages include a primary antioxidant (such as a hindered phenolic) and a secondary antioxidant (usually an organophosphite)

POLYMER R· ROO·ArOH Primary AO

ArO·ROH ROOH

P(OR)3 P(OR)3 Secondary AO

O

hv, heatMet. Cat.

O2

Common Antioxidants for LLDPE

C18H CO -CH2-CH2 OH

O

37

P O C9H19

3

P O

3

O P

O

O

O

P

O

O

TNPP (trisnonylphenyl phosphite) Commodity Solid Phosphite (SP-1)

High Performance Solid Phosphite (SP-2) Commodity Hindered Phenolic (AO-1)

Commodity Phosphite Stabilizers

TNPP and SP-1 are the most widely used commercially available phosphites

Good cost-performanceGood hydrolytic stabilityGlobally registeredGlobal indirect food contact clearance

TNPP is a liquid, SP-1 is a solid

Trisnonylphenyl Phosphite (TNPP)

TNPP is in many ways the ideal phosphite. It offers several advantages over SP-1

TNPP is the most cost effective phosphite availableTNPP does not show compatibility/bloom issues in LLDPE applications, especially film

• SP-1 can bloom at >1,000ppm in certain LLDPE resins/applications

The use of TNPP is often dictated by the type of additive handling unit, solid or liquid handling

Currently, TNPP is the only liquid phosphite available with global indirect food contact clearance for all polymer applications (GRAS)

TNPP Global StatusTNPP has been used safely in food contact polymers for more than 30 years. There are no governmental mandated use restrictions on TNPP

TNPP can be used in all food contact polymers in the US without limitations (21 CFR 178.2010, Antioxidants and/or Stabilizers for Polymers) - GRAS

“The quantity used shall not exceed the amount reasonably required to accomplish the intended technical effect.”

TNPP also approved for use in the EUBroad approval and high SML Specific Migration Limit (SML) = 30 mg/kg

TNPP in EU Risk Assessment

2001 European Union NP Assessment discussed TNPP. With regards to human health concerns, the EU concluded there were no consumer exposure scenarios, including for TNPP, of concern given low exposure and limited mammalian toxicity concerns

TNPP is currently in the final stages of an environmental EU risk assessment

R1=R2=R3=alkyl AlkylAlkyl PhosphitesR1=R2=R3=aryl ArylAryl Phosphites

R1R2R3=alkyl/aryl Alkyl/ArylAlkyl/Aryl

Examples R = phenyl, 2-ethylhexyl, isodecyl, nonylphenyl

RO OR

OR

P

TNPP Replacement?

There are many types of commercially available phosphites…

Phosphite : Ligand Choice

The structure of the ligand has a large effect on phosphite properties

Physical form: solid or liquidHydrolytic stabilityCompatibility in the polymerActivity-performanceVolatility-thermal stabilityCost

Hydrolytic Stability

Phosphites can be hydrolyzed/degraded when exposed to water, especially under acidic environments.

P(OR)3 + H2O

O ||HP(OR)2 + ROH

O ||HP(OR)2 + 2 H2O H3PO3 + 2 ROH

Acidic =“ Black Specks”

Hydrolytic Stability

Hydrolysis resistance trend

Alkyl < Akyl-Aryl < Aryl < Hindered Aryl

Least MostHydrolytic Stability Hydrolytic Stability

Hydrolytic Stability (Aryl>Alkyl)

(Phosphites exposed to 60°C, 85% Humidity)

P

O

O

O

H21C10O

P OC10H21

H21C10O

O

O

P OC10H21

OC10H21P

O

H21C10O

0

100

0 1 2 3 4 5 6

Exposure Time (Hours)

Per

cent

Rem

aini

ng

0

100

0 1 2 3 4 5 6

Exposure Time (Hours)

Per

cen

t R

emai

nin

g

O

O

P OC10H21

O

O

P OC10H21

OC10H21P

O

H21C10OOC10H21P

O

H21C10O

Structure of Ligands Effect Hydrolytic Stability

Phosphites exposed to 60°C, 85% Humidity

Hydrolytic Stability (Effect of Steric Hindrance)

Neat Phosphites Exposed to 40°C & 85% Humidity

Hours to Failure % Hydrolyzed

Phosphite A <10 >50%

Phosphite B ~48 >50%

Phosphite C >2000 <5%

Phosphite A

Phosphite B

Phosphite C

Phosphite Activity (Depends on Polymer)

Peroxide decompositionP(OR)3 + R’OOH O=P(OR)3 + R’OH

Arbuzov and related reactionsP(OR)3 + Cl-R’ (labile) (RO)2P(O)-R’ + RCl

P(OR)3 + HCl (RO)2P(O)H + RCl

2P(OR)3 + ZnCl2 Zn[OP(OR)2]2 + 2RCl

HydrolysisP(OR)3 + H2O (RO)2P-OH + ROH

Addition reactionP(OR)3 + -C=C- O=P(OR)2-C-C-R

MostlyFor PVC

Competitive Oxidation : Alkyl vs. ArylIn general, Alkyl Phosphites are more active at scavenging

hydroperoxides than Aryl Phosphites

Concentration versus time in paraffin solvent at 200°C

Aryl Phosphite

AlkylPhosphite

Rate ofOxidation

Phosphite Polyolefin Stabilizers

Polyolefin phosphite stabilizers are generally composed of hindered aryl ligands (alkylphenols)

Hydrolytic stability is needed to prevent black specks and poor material handling

% Phosphorus is key to performance

Two phosphites dominate the commodity market

P O C9H19

3

P O

3

Liquid Solid

Compatibility

The choice of alkylphenol also dictates the compatibility of the phosphite in the resinEspecially important is compatibility in LLDPE during cast film processing (highly amorphous)Lack of compatibility results in plate-out on equipment as well as post process bloom or surface exudationOne of drawbacks of SP-1

Compatibility By Gloss MeasurementsIt is known that SP-1 can bloom in LLDPE applications at levels above 1000ppm. The bloom can be accurately detected by this technique.TNPP does not bloom because of the greater solubility of nonylphenol.

Compatibility LimitFor SP-1 in thisResin is <1,200ppm

0

20

40

60

80

100

0 5 10 15 20

Days In Oven at 70°C

Surf

ace

Glo

ss V

alue

500ppm 800ppm 1200ppm 1500ppm

P O

3

Antibloom Packages

Antibloom agents have been developed that prevent the bloom of phosphite SP-2

Cleared for use in food contact applications

Alkylphenols in the “Spotlight”Monosubstituted para-alkylphenols as a class

Monoalkylphenols from C4 to C12 have shown low levels of petri-dish ED activity

Butyl-, octyl-, nonylphenol, (Bisphenol A)Petri dish experiments are a screening tool, and are extremely sensitive, do NOT represent in vivo activity

This is a perception issue, not a safety issue

Alkylphenols

Increasing sensitivity of analytical methods and negative perception Alkylphenols are not readily biodegradableEU is particularly sensitive to these issues

Increased Focus on Purity and Tougher Hygienic Requirements in EU

New tests methods with ppb detection limits have been developed that ensure “unsuspected substances” do not migrate into drinking water intended for human consumption (EN 15768)May include intermediates, additives and additive byproducts.

New Liquid Green Phosphite (LGP-11)

New technology, patent pendingContains no alkylphenolsComposed of non-toxic biodegradable raw materialsHigh MW, low migration/low exposureExcellent process stability (5% phosphorus), compatibility, hydrolytic stability, long term aging and resistance to gas fade

No Alkylphenols

New technology has been developed that preserves the thermal and hydrolytic stability of phosphites that previously was only obtained through the use of alkylphenols

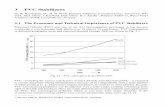

Thermal Stability TGA Weight Loss

0

10

20

30

40

50

60

70

80

90

100

0 100 200 300 400

Temperature (°C)

Wei

gh

t P

erce

nt

Solid Phosphite SP1 TNPP LGP-11

Hydrolytic Stability

Neat Phosphites Exposed to 50°C, 85% HumidityAll Phosphites Contain 1% TIPA

0

10

20

30

40

50

60

70

80

90

TNPP LGP11 TLP

4 Hours8 Hours24 Hours

% PhosphiteRemaining

Performance EvaluationPerformance measured with multiple pass extrusion in LLDPE, MI and YI retention

Co-rotating twin screw extruderCompounding: 170-175-180-190°CMulti-pass: 180-205-225-245°C

Phosphites levels indicated, formulations also contained 500ppm AO-1

Melt Flow Index - LLDPE 2.16kg/190°C

0.2

0.4

0.6

0.8

1

1.2

0 1 2 3 4 5

Extrusion Pass

MF

I (g

/10m

in)

800ppm TNPP 800ppm LGP11 1400ppm TNPP 1400ppm LGP11

Melt Flow Index - LLDPE21.6kg/190°C

202224

2628303234

0 1 2 3 4 5

Extrusion Pass

MF

I (g

/10m

in)

800ppm TNPP 800ppm LGP11 1400ppm TNPP 1400ppm LGP11

Yellowness Index - LLDPE

-2

-1

0

1

2

3

0 1 2 3 4 5

Extrusion Pass

YI

Un

its

800-TNPP 800-LGP11 1400-TNPP 1400-LGP11

Gel Counts – LLDPE Cast Film Extrusion

0

1000

2000

3000

4000

5000

6000

7000

8000

800ppm TNPP 800ppm LGP11

< 150 µm150-300 µm300-600 µm600-1000 µm

Gas Fade Resistance in LLDPE at 60°C

05

10152025303540

0 5 10 15 20 25

Days in NOx Chamber

YI

Un

its

1400ppm TNPP 1400ppm LGP-11

0

20

40

60

80

100

0 5 10 15 20 25 30

2000ppm TNPP 2000ppm LGP-11 1500ppm Solid Phosphite SP-1

Days in Oven at 60°C

Glo

ss

Solid phosphite SP1 is not compatible at 1500ppm

Compatibility at 2000ppm in LLDPE

Migration From The Polymer

Assuming Fickian diffusion, migration rates decrease with an increase in molecular weightMolecular weight of LGP11 is >> TNPPDecreased exposure from consumer packaging, especially in food contact applications

Conclusions

LGP-11 is a high MW liquid phosphite that offers better performance than typical commodity phosphites such as TNPP and SP1

Process stability (MI/YI), compatibility, NOx and oven aging, thermal stability

LGP-11 is alkylphenol free and is based on nontoxic biodegradable raw materials, and thus avoids many of the negative perception issues associated with phenolic based antioxidants.

Questions?