Ice cream Truck Service Toronto & Ice Cream Truck Mississauga

National Ice Cream Retailers Association · PDF filedoes not come from the traditional and...

Transcript of National Ice Cream Retailers Association · PDF filedoes not come from the traditional and...

National Ice Cream Retailers Association

FEBRUARY 2010 - $25.00

SUPPLIER MEMBER SPOTLIGHT

FUNDAMENTALS OF DAIRY MIX FORMULATION By Andrew JonesLloyd’s of Pennsylvania, Inc.

Milk is milk, cream is cream and mix is mix, right? This might be the general public’s opinion, but in the ice cream industry, we know it’s not that simple. Variations in bovine species, diet and processing equipment create a vast array of finished product options. You also need to take into con-sideration formula differences, available raw materials, cost parameters and quality. Deviations in products of the exact same type can reach into the thousands.

Let’s take a look at the science behind the first phase of a frozen dessert mix, which will open the door to understand-ing the products that you serve in your market. There are five primary parts to a formulation; Water, Milkfat, MSNF (milk solids non fat), Sugars and Stabilizers.

Water, essential for all life on earth, is commonly referred to as the Universal Solvent and would make sense to be the predominant ingredient in most food products. Liquid dairy mixes contain 55-70% of water depending upon the type of frozen dessert application. Higher fat and total solid mixes have proportionally less water in contrast with lower fat and reduced solid formulas. Total solids is also a critical calcula-tion and will be discussed later.

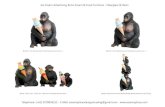

Milkfat, better known as butterfat, is one of the components of milk and is the crème de la crème of ice cream. Sorry, I couldn’t resist! In the United States the primary source is from cows, but is produced for human consumption by any mammal; goats, camels, buffalo, sheep and moose to name a few. Raw cow milk ranges from 3.6-5.2% milkfat depend-ing upon the breed. The breeds most commonly used for milk production in the U.S include Jersey, Guernsey, Brown Swiss, Ayrshire, Milking Shorthorn and Holstein.

MSNF, milk solids non fat, also known as serum solids or non fat dry milk, is another standard component of milk. About 8.5% of raw milk is comprised of non fat milk solids, of which 5.3% is carbohydrates and 3.2% is protein. All of the carbohydrates are dairy sugar or Lactose, not to be confused with the section on sugars, but rather taken into consideration when determining the intended sweetness of the mix. MSNF is used in dairy formulation to build total solids and protein levels in the mix, which have functional attributes; the natural emulsification of fat, as an aid in creat-ing air cell structure critical to maintaining overrun and heat shock protection.

Sugars, come in many shapes and sizes and since Ameri-cans have a “sweet” tooth compared to other countries, we know them well! Their main objective is to create a targeted sense of sweetness in the finished product, while at the same time depressing the freezing point of the mix. They have a relatively high usage rate and comprise 17-24% of dairy fro-zen dessert mixes. Sucrose, Lactose, Glucose, Fructose and Dextrose are among the most utilized forms and are primarily derived from sugar beets, corn and dairy milk. Surprisingly, most of the “table” sugar or granulated sugar used in the U.S. does not come from the traditional and well known sugarcane grass, but rather from sugar beets. Yes, sugarcane is a grass believe it or not! Corn syrup, another highly used sweetener in the U.S, acts as a replacement to sucrose due to its signifi-cant economic benefit on cost and similar sweetening charac-teristics to sucrose. However, too much corn syrup may lead to an undesirable gummy or chewy texture in ice cream.

Stabilizers, do not contribute to taste, but are a highly spe-cialized set of functional raw materials that maintain product consistency during production and after packaging. Relative cost per pound compared to other ingredients is extremely high, but remains an economical and useful addition since it is only (.2 - .5%) of the total mix formula. In most cases they are actually comprised of one stabilizing and one emulsifi-cation agent; stabilizers are specifically targeted to control water and emulsifiers focus on fat. Common characteristics that warrant control are; freezing properties, churning, over-run, hardening, melting, separation and heat shock. Cellulose gum, locust bean gum, guar gum and carrageenan are com-mon stabilizers while egg yolks, polysorbates and mono- &

2 NICRA February 2010

CALL YOUR NICRA SUPPLIER MEMBERS FIRST

http://www.nicra.org

diglycerides are examples of emulsifiers.

Total Solids, while not an ingredient for a mix recipe, but rather a result, needs to be targeted for the particular frozen dessert application. Think of total solids as putting the ice cream mix in a microwave, evaporating all of the water and being left with the resulting powder. To begin, let’s say you have an ice cream product without any defects right after processing, freezing and packaging, the retailers’ utopia. The primary threat to product integrity would be tempera-ture fluctuation or heat shock as ice crystal size is directly related to the amount of temperature fluctuation and length of time. Larger fluctuations in temperature and longer periods of time will grow large ice crystals leading to coarseness, which is not a desirable result. Now, take two mixes of the same butterfat and sugar levels. Formulate one mix to have 37% total solids and the other 41%, expose them to the same levels of heat shock. Each product is experiencing the same environment, but the mix with more total solids has “less” water. Less water means proportionally less ice crystals in the finished product diminishing the affects of heat shock.

Commercially Available Ingredients to the dairy are too numerous to mention completely, but a few are; 40% cream, 36% cream, 4% whole milk, skim milk, condensed skim milk, non fat dry milk, whey, sucrose, corn syrup and various stabilizers. Based upon the region and availability, plants can

make the same finished products, but with different raw ma-terials and production formula’s. One location may use butter for its fat source, but another may use 36% cream and skim milk to obtain the required butterfat level.

For most of the ice cream retailers, mix formulation may never be a part of your business plan, but knowing the sci-ence behind your mix or finished product may help you pin-point the issues and solutions in a sea of infinite possibilities! Enjoy the winter and let the mad scientist in you formulate some new creations for the 2010 season.

NEW ACTIVE MEMBERS

Brics, Inc.5719 Winthrop Ave.Indianapolis, IN 46220317/590-5855Fax: 317/344-7412David Vonnegut-GabovitchNonie Vonnegut-GabovitchDavid DuBow1 FD

Fairchild’s Ice Cream3301 Veterans Memorial Blvd., #78JMetairie, LA 70002504/352-2071Charles Mouille

Amy & Daniel Feldman2196 E. Green Oaks Ln.Greenwood Village, CO 80121303/220-7846Fax: 303/694-7846

John Nygard4069 Aidan CircleCarlsbad, CA 92008305/753-6054Fax: 305/753-60551 FD, SS

NEW SUPPLIER MEMBER Leiby’s Ice Cream116 Mountain Dr.Tamaqua, PA 18252570/573-1871Fax: 570/668-6005www.leibysicecream.com Jack RiegelKeith ZimmermanBill ParksHard ice cream, yogurt, soft serve mixes, probiotic yogurt soft serve, custom manufacturing, co-packing

4 NICRA February 2010

CALL YOUR NICRA SUPPLIER MEMBERS FIRST

http://www.nicra.org

Since 1918New and Improved Innovations• Yellow Cake Batter;

Eggless, Low Micro Dry Mix and Eggless, Low Micro Base

• European Style Enrobing Chocolate

• Gelato BasesincludingPistachio and Mixed Berry

A Division of Concord Foods, Inc.10 Minuteman Way, Brockton, MA 02301Tel: 508-580-1700 Fax: 508-584-9425Email: [email protected]

ACTIVE MEMBER SPOTLIGHT

BUSINESS PLANS AND THE REASONS WE NEED THEM

By Jim RossFlat Pennies Ice Cream

Without a doubt the road to a successful business requires a high quality well detailed road map. That is exactly what a business plan is. It allows you and your business to have a physical copy of how you plan to achieve the business goal(s).

The components of the plan should be simple and easy to read. A clear and concise plan allows you to refer to the origi-nal format if you find yourself struggling.

Outlines for business plans should cost you only time not money. No one knows your business as you do so it’s best if you take the time and draft the plan. Once complete it should be for your use and only those with a need to know.

Many great ideas for templates may be found on the web at

www.sba.gov link to business plans. Other information can be found from NICRA, the ideas folder has a section on busi-ness plans. Consider data from local newspapers (they often know population counts and per capita incomes) and census bureau data from your region. Don’t forget to determine the spending habits of your clientele, this can be found at your local Chamber of Commerce or like minded civic groups. The library supplies a wealth of information for your area as well.

Networking is key. It’s important to know what is happen-ing within your area. Furthermore, you may learn that others have tried to operate a business similar to what you have planned, but have failed, this is useful information, We can always learn from the mistakes of others and work towards a meaningful solution.

If your strategy is to host events, be sure to include those ideas into your business plan. The details you plan early on will take the pressure off when you are busy. It always gives the business a perceived sense of planning, you will appear (and will be) organized. Many great ideas are shared at the annual convention for NICRA. Perhaps the energy that surrounds us will spark a new idea or improve on one you already have.

Remember uniqueness sells. If you can create a “one of kind” store or even an event customers take notice and appreciate being a part of something special. That said, give the com-pany plenty of time to succeed. The more details you know the better!

Finally, a business plan offers vision. Visualize on paper what you want others to see with you. If your business is yet to be started or has been going for years, a business plan will guide you to a successful future. Best Planning!

SCHOLARSHIP WINNER SAYS THANKS

I want to sincerely thank you again for awarding me the Bryce Thomson Scholarship Award for the second time. I am so honored that you would consider me the first time, but this second time was completely unexpected. I just wanted to let you know, I’m entering my second year at Georgia Tech, progressing towards a Civil Engineering degree. This scholarship has provided so much support for me to attend this school, take classes and even continue my technologi-cal degree overseas in China this summer. Thank you for supporting my parents and their small business ventures with the ice cream industry, and thanks for helping out with my education. Happy New Year!Kinzie RieckmannBlue Ridge Ice Creams Georgia Institute of TechnologyCivil Engineering

6 NICRA February 2010

CALL YOUR NICRA SUPPLIER MEMBERS FIRST

http://www.nicra.org

SUPPLIER MEMBER SPOTLIGHT

HOW TO SUCCEED AND FAIL IN THE ICE CREAM BUSINESS

By Mark EnglandDolce Gelato

Since I am new to NICRA I wasn’t sure exactly what I could contribute to the other members that they didn’t already know. So, I decided to make a list of all the things I wish I had known before I got into the ice cream business. Hopefully, it might give veterans of the business some new ideas and help people who are just starting avoid some costly mistakes. I am an artist by training so running a business is not my first choice of occupation. I married into this business five years ago and have been trying to juggle my art career and run our gelato business at the same time. That leads to my first lesson.

Don’t do what you don’t know how to do. If you are not a business person who has a mind and skill for business, don’t do it. It doesn’t matter how much you like ice cream or gelato, if you don’t have the skill and determination to run a business it will only be a matter of time before you fail. I love making the best gelato in Utah and get a lot of personal satisfaction from doing it, but if I can’t be a good business person, then I won’t be able to make it. Too many people think that if they love gelato and making people happy then they will naturally succeed. It doesn’t matter how good your ice cream is, or how much you love it, if you don’t also have business sense, then you will fail and you won’t be able to make people happy any longer.

Don’t buy used equipment that has a direct impact on the quality of your product unless you are absolutely sure it is functioning properly. A typical gelato cabinet will cost between 11 and 20 thousand dollars. We had a chance to buy a used one that wasn’t a major brand for a third the price. It did not hold our gelato at the proper temperature and we replaced it within a month. If you are concerned about quality, don’t take shortcuts. It will show in your product or be unreliable and cost more money in the long run.

Check references and be very careful of workers who don’t need to work or live at home. If they live at home there is a higher chance they don’t need the job and therefore will not care as much about performing well enough to keep their job.

Don’t expand faster than you are able to. We opened a second store in anticipation of finding a manager to run it. We didn’t so we had to manage two stores which suffered until we did. Having a second location is not twice as much work, it is three times as much work if you don’t have good managers.

Be extremely careful of long term leases that lock you in and make your whole business as well as personal savings vulnerable. Basically, if you go through a difficult patch and don’t have enough flexibility, they will take everything. Give yourself a lot of reserve in terms of money and time.

Be careful of locations that may have cheap rent and high turnover. They are like that for a reason. I have seen some locations change hands every year or two. It doesn’t matter what the store is. Bad Karma sticks to a location.

Here are things I strongly recommend: Put something unique in your store. Whether it is pictures, posters, objects, or lighting, make it a unique experience. We have a glass topped table that holds about 300 little objects in it. Kind of like an “eye spy” table. It is a perfect conversation starter. We have watched nervous couples on dates look at the table when they didn’t know what to say to each other. Kids love to find new objects. If they find the new object we put in each week they get a free serving of gelato.

Twitter and email lists. The cheapest and most effective way of advertising your product is through the internet. Gather emails when people buy a cup. Tell them “Would you like to sign up for free ice cream coupons?” That way they are more willing to sign up. When we make a new flavor we twitter and email out that the first five people to come in and order that flavor get it free. We send out announcements of parties, concerts, specials, and new products. This will create a whole group of followers who are connected to your business because you are rewarding them for being regular customers. Create “private” clubs for special promotions. Send out email blasts that tell them that all gelato is free between 4:30 and 5:00 as a “customer appreciation”. We also have worked with websites that do revues of local restaurants. They spread the word and coupons for our store, which encourages them to get on our mailing list.

Catering, catering, catering. It is the cheapest way to make money. We have been doing catering for four years now. The cost per serving is lower and you get to advertise your product as well. Here is an example. We did a wedding last August for 700 people. We used 20 pans of gelato and charged them $4 a serving including waffle cones that we made on location. Total bill came to $2900. We had four workers serve for three hours. Our total labor costs came to $120. Cost of gelato about $200. Profit came to over $2500. A week later I did an event for fifty people in the park. The bill came to $190. Labor came to $19 and gelato costs were $30. Profit of $140. Last month I did a business lunch for 130 people for $3.50 each. The bill came to $550. Labor was $19, and gelato was $50. Profit was over $470. At each of these events we also gave out business cards, which brought people in to our store. The last two events were only possible because of the next piece of advice.

I got tired of hauling a heavy, expensive, dipping cabinet

Gelato System

TM

Introducing Simplé.Flavor intensive, not labor intensive.

Available in aVARIETYofFLAVORS

Fabbri North America, LLC 57-01 49th Place, Maspeth, NY 11378 Ph: 718-764-8311 e-mail: [email protected]

Now, all the pre-measured ingredients you need to make delicious, artisan gelato are in one,convenient tin. Simplé by Fabbri.

For almost 100 years, the Fabbri company has been innovating the art of making fine gelatos.Still family owned, we think we have comeup with our finest gelato system yet. It is soeasy, anyone in your establishment canmake it.

Imagine rich, flavorful gelatos thatno longer require long hours of training to create.

There is no second-guessing, no fussing with recipes.All that's required is four easy steps to make gelato or sorbetthat is unsurpassed in taste and texture.

We did the work so you can take the credit.

1 2 3 42

Simplé_singlead_B&W 4/2/08 8:34 AM Page 1

8 NICRA February 2010

CALL YOUR NICRA SUPPLIER MEMBERS FIRST

http://www.nicra.org

around that made it expensive and time consuming. So I designed a portable dipping cabinet that doesn’t use power that has tripled our catering business. If I could, I would close the store and just do catering with it.

The best way to advertise your catering is at bridal shows. We just did two bridal shows and gave out a combined total of 3,500 samples. The booth charges were half the regular rate because we shared the cost with a local cookie company which we distribute. People want something special at their wedding. We dress up our gelato with waffle cones we make on location, pizzeles, cookies, or crepes. If you give brides samples they will remember what you make and keep you in mind when they plan their summer weddings. Encourage them to sign your email list for free coupons, and offer them a five percent discount if they commit to catering that day. It is also a great opportunity to go around to all the other vendors, photographers, reception centers, etc., and bring them samples so they get to know your product and will refer brides to you or put you on their preferred vendor list. Send them a $25 gift card when they do.

Do something different. There are a million ice cream stores out there. Gelato stores are becoming more common as well. Unless you are the only game in town the only way to set yourself apart is to do something better or different than everyone else.

ICE CREAM UNIVERSITY & FABBRI ANNOUNCE PARTNERSHIP

Ice Cream University & Fabbri North America have joined a partnership to present four new seminars in 2010 at the Fab-bri North America Culinary Center in Maspeth, New York.

They are Seminar 103 – It’s All About Gelato, a one day seminar, February 8, 2010 and October 14, 2010. Seminar 107 – The Gelato Experience, The Art of Making Gelato and Ice Cream, a two day seminar will be held March 16-17, 2010 and November 18-19, 2010.

This training experience will bring together the student’s passion for gelato and ice cream with our expertise in frozen dessert education. Starting with passion to theory to appli-cation to artistry, the classes offer unparalleled educational experience focused on building a culinary and business foundation for anyone who wants to produce a true authentic Italian gelato, sorbet and ice cream using Fabbri ingredients. For the last 17 years Ice Cream University has been using the Fabbri product line to train thousand of students. The classes offer personalized hands-on training and interaction.

For more information contact Malcolm Stogo at 973/669-1060 or send an e-mail to [email protected].

SIX WAYS TO MANAGE YOUR OWN ANXIETY, CALM DOWN YOUR EMPLOYEES...AND SAVE YOUR COMPANY

by Jeffrey Miller

Elevated systemic anxiety can have severe repercussions, and in the 21st century most organizations are at risk. The good news, says Jeffrey Miller, is that it takes only one person to break the cycle and turn the whole company around.

If you’re a leader, you feel it in your gut: Stress is at an all-time high. No wonder. The uncertain economy keeps everyone, even those who work for successful companies, slightly off-balance. Doing more with less has become a way of life: fewer dollars, fewer employees, and what feels like fewer hours in the day. (The only thing there seems to be more of is competition!) And now that working virtually is de rigueur and globalization has truly taken hold, we must collaborate with people at the proverbial four corners of the earth. It all adds up to anxiety overload, that can be deadly for an organization.

“Helping your organization manage excessive, chronic anxiety is your number one job,” asserts Miller, author of The Anxious Organization, 2nd Edition: Why Smart Companies Do Dumb Things (Facts on Demand Press, January 2008, ISBN-13: 978-1-8891505-2-9, ISBN-10: 1-8891505-2-5, $19.95). “Why? Because it means ensuring that employees operate on principles rather than emotions. When people stay in low-grade panic mode, they can no longer think clearly, creatively, and flexibly. They make irrational decisions. When the irrational decisions start adding up, the company isn’t long for this world.”

Of course, some anxiety in the workplace is normal and even desirable, points out Miller. It goes back to our primitive survival instincts. All organizations face threats, both internal and external, and anxiety is an instinctive response to any threat to one’s survival. But when the natural chronic anxiety in an organization rises to an excessive level, employees become like a herd of stampeding wildebeests. They start operating on “fight or flight” instinct rather than thinking clearly, creatively, and in a flexible manner.

Furthermore, anxiety is contagious. Here’s how it infects your company: In order to relieve your anxiety, you unwit-tingly pass it on to a coworker. She passes it on to someone else, who passes it on to yet another employee. Before long, the entire organization is trapped in a cycle of anxiety that seems to have no clear starting point. And all the while, the underlying cause goes unaddressed.

“What happens next is rarely pretty,” Miller says. “Perhaps the anxious employees succumb to wildebeest-like group-think and run their company off the proverbial cliff. Or one

10 NICRA February 2010

CALL YOUR NICRA SUPPLIER MEMBERS FIRST

http://www.nicra.org

person is unfairly singled out as a scapegoat. Or employees can’t take the stress any longer and start leaving the compa-ny. A very common scenario is one where people are fired to ‘solve the problem,’ which only reappears later with the new employee because the system that caused the problem hasn’t really changed.”

Dismal as this scenario sounds, there is some good news. Rather than accepting the cost of excessive anxiety as a way of life, you can change your organization for the better. That’s right. It takes only one person-that could be you!-to break the destructive cycle of anxiety. Miller offers the fol-lowing suggestions:

Strive to be a predictable leader. The least stressful compa-nies to work for are those in which the rational system-the officially stated goals, values, policies, procedures, job roles, and so forth-is a fairly accurate description of what actu-ally transpires on the average workday. This means that the rational system and the emotional system are reasonably well aligned. What the leaders of such companies have in common is their predictability. If you want to guess what the leader will do in any given situation, check out the company’s mission statement, current objectives, policy manuals, and reporting structure. The leader’s behavior is consistent with what the rational system of the company would lead you to expect.

When there is a conflict between the rational system of an organization and its emotional system, the latter will usu-ally prevail. Employees tend to disregard the rational system when the emotional system contradicts it. They will, for instance, ignore their written job descriptions if the emotional system rewards them for doing something else, and disregard policies and procedures that conflict with the interpersonal ecology. The emotional system of an organization is simply more compelling than the rational system. People apprehend it with their entire bodies. It’s personal.

Map the anxiety in your situation. Because anxiety feels uncomfortable, we tend to play “Hot Potato” with it: We dilute the pain by passing it on to someone else. When you understand this mechanism, it’s possible to figure out where your anxiety originated. Draw a circle that represents you and other circles labeled with the names of those around you. Use arrows to indicate where anxiety is coming from and where it is going. Interestingly, you may find that some of your anxi-ety is coming from a family member or even a figure from your childhood. Once you’ve mapped your anxiety, you can use the following techniques to help you defuse it.

Learn to take an “I-position.” When you have to solve a prob-lem, it’s tempting to worry about how your decision will af-fect the feelings of other people. But keep in mind that you’ll never please everyone. It’s impossible! Trying to control the reactions of other people is anxiety-driven behavior, and it results in only more anxiety. To take an I-position, you need to make a principle-based decision rather than one based on

feelings and personalities. It’s true that taking an I-position may temporarily cause anxiety to rise...but in the long run, the entire system will be able to calm down.

Calm yourself with a six-second vacation. When you are in a situation that makes you feel anxious, you must distance yourself from it before you can think clearly. If you’re in the middle of a meeting, conversation, or other incident that is triggering your anxiety, try taking a six-second vacation:

Inhale for two seconds, sending the air where you need a little help. It can be sent to any part of your body, mind, or spirit, or you can direct it to a troubling idea, a present worry, a concern, even a recurring theme.

Exhale for two seconds, releasing all muscle tension in your body, starting at the head and moving to the toes. Think of yourself as a boneless chicken.

Do NOTHING for two seconds.

“Detriangle” yourself. Did you know that any relationship between two people seeks to stabilize itself by pulling in one or more third parties? This process is called “triangling.” Suppose you have a conflict with a coworker (let’s call him Mike). Because the two of you can’t reach an agreement, anxiety builds up. You decide to draw in a third coworker (let’s call her Mary) to get her “on your side” and relieve your anxiety. You have created a triangle: you and Mary against Mike.

Triangles are perfectly natural, but they can sometimes create even more anxiety. The good news is that you can “detri-angle” yourself. Here’s how:

1. Look for the objective cause of the anxiety that has led the triangle to rise.

2. Take sides with issues, not with people. Take an “I-position” and state it clearly.

3. Maintain an independent one-on-one relationship with each of the other members of the triangle.

Correct an overfunctioning/underfunctioning relationship. Overfunctioners take over responsibilities that belong to another person. Underfunctioners allow this to happen. It is a reciprocal relationship-neither can exist without the other-and both parties are reacting to anxiety. Needless to say, too much of this type of behavior is unhealthy for both people and for the organization as a whole.

Fortunately, either party can break the cycle by taking the all-important I-position. If you are an overfunctioner, realize that you are not responsible for someone else’s success or failure. You cannot do his job for him, even if he is a subordi-nate. If he fails, he fails (but he probably won’t). On the other hand, if you are the underfunctioner in the relationship, you

11NICRA February 2010

CALL YOUR NICRA SUPPLIER MEMBERS FIRST

http://www.nicra.org

The National DipperThe only magazine that keeps you up-to-date in the retail frozen dessert industry.

Call or write for a subscription today!1028 West Devon Avenue • Elk Grove Village, IL 60007-7226

Phone: (847) 301-8400 • Fax: (847) 301-8402e-mail: [email protected]

Subscribe on-line at: www.nationaldipper.com

Regular columns include:• New Products • Industry News • Calendar of Events • Classified

Special features include:• Equipment Reviews • Management Articles

• Association Events • Employee Training • Promotions • Annual Source Book

Also Available:• Dipping Tips Training Posters • Manuals for Costing Products

• Employee Training Posters • Point of Sale Posters • Magazine Binders

®

®

Subscribe to

must realize that your long-term passive approach serves to maintain the other person’s overfunctioning behaviors (mi-cromanaging, controlling, etc.). Get clear on your responsi-bilities and take actions that will reverse the overfunctioning/underfunctioning cha-cha.

Of course, the above tips represent only a few of the tech-niques Miller teaches his clients. Because anxiety is a very complex phenomenon, many companies need professional help in identifying its many permutations and sorting out its root causes. But don’t despair. When you make an effort to rise above your own anxiety, you may start a “ripple effect” that transforms your entire organization.

“I never cease to be amazed by the power one person can possess,” says Miller. “Because everyone in an organization is connected, you can’t change your own behavior without changing the entire system. It’s impossible! Sometimes these changes are subtle; sometimes they’re profound. For exam-ple, I had one client who learned to manage his own anxiety and, as a result, averted a strike, saved his company $6 mil-lion, and earned a major promotion.

“Taking responsibility for yourself-giving up the need to blame or control others-actually requires a tremendous amount of courage,” he adds. “That’s the stuff leaders are made of. And when enough people are able to manage their anxiety and find this kind of courage, well, that’s the formula for a stunningly successful organization.”

Jeffrey A. Miller through his company, Jeffrey Miller + As-sociates, helps businesses attain key goals and objectives by increasing their organizational effectiveness. He has experi-ence as a family therapist, management consultant, and coach to top executives in corporate and not-for-profit settings. For over 20 years, organizations across a wide range of industries and business functions have called on his support and guid-ance. Mr. Miller has a BA from the University of Texas, a Masters of Social Work from Loyola University of Chicago, and has completed a two-year post-graduate program in hu-man/natural systems theory and intervention. He is certified as a Level III Organizational Engineer.

BUTTER PRICES

December 24, 2009 - Grade AA Butter finished at $1.3275. The weekly average was $1.32688.

December 31, 2009 - Grade AA Butter finished at $1.3275. The weekly average was $1.3275.

January 8, 2010 - Grade AA Butter finished at $1.3450. The weekly average was $1.3325. (2009 price was $1.3300)

January 15, 2010 - Grade AA Butter finished at $1.5250. The weekly average was $1.4020. (2009 price was $1.1115)

January 22, 2010 – Grade AA Butter finished at $1.4675. The weekly average was $1.4844. (2009 price was $1.1006)

12 NICRA February 2010http://www.nicra.org

2010 NICRA OFFICERSPresidentBob Turner, Dairy Corner, Urbana, OhioPresident ElectLynn Dudek, Ruth Ann’s, No. Muskegon, MichiganVice President Dan Messer, Eskamoe’s Frozen Custard, Monroe, La. Secretary/TreasurerDavid Zimmermann, Royal Ice Cream, Bonita Springs, Fla.Immediate Past PresidentVince Giordano, Sno Top, Manlius, New YorkExecutive DirectorLynda Utterback, Elk Grove Village, Illinois

2010 BOARD OF DIRECTORSTerms Ending Annual Meeting 2010Nanette Frey, Frey’s Tasty Treat, Inc. East Amherst, New YorkMary Leopold, Leopold’s Ice Cream Savannah, GeorgiaJeff Myers, The Double Dip Lebanon, OhioCharles Page, Page Dairy Mart Pittsburgh, Penn.Kasia Wilk, Lucks Food Decorating Tacoma, WA

Terms Ending Annual Meeting 2011Terry Michels, Queen City Creamery & Deli, LLC

Cumberland, MarylandRod Oringer, Concord Foods Brockton, MassachusettsRick Pizzi, Pizzi Farm Ice Cream Waltham, MassachusettsJim Ross, Flat Pennies Ice Cream Bay City, Wisconsin

Terms Ending Annual Meeting 2012Carl Chaney, Chaney’s Dairy Barn

Bowling Green, KentuckyCliff Freund, Cliff’s Dairy Maid Ledgewood, New JerseyJuergen Kloo, Joy Cone Co. Hermitage, PennsylvaniaJohn Pitchford, JP’s Custard Cart, Albuquerque, New MexicoJoe Venuti, Bedford Farms Ice Cream Bedford, Massachusetts

2010 SUPPLIER OFFICERSPresidentMargaret Anderson, Taylor Freezer of New England Norwood, MassachusettsVice PresidentTom Zak, Concord Foods, Brockton, MassachusettsSecretary/TreasurerMary Kircher, Dingman’s Dairy, Paterson, New JerseyChairmanRich Draper, Ice Cream Club, Inc., Boynton Beach, Fla.

MISSION STATEMENT FOR NICRAThe mission of the National Ice Cream Retailers Association (NICRA), a non-profit trade association, is to be the leader in the frozen dessert industry that others look to for help, support and education. NICRA will promote business growth and development throughout the industry.

VISION OF THE ASSOCIATIONNICRA will associate with similar associations dedicated to the same interests. NICRA will facilitate communication and education that both newcomers and veterans in the industry desire to be successful. NICRA will maintain a feeling of family within the association as it grows, and be dedicated to responsibly managing the association while maximizing value to the members.

NONDISCRIMINATION POLICYNICRA is committed to a policy of nondiscrimination in all of its endeavors. To that end, NICRA shall not tolerate any words or acts of discrimination, harassment or any inappropriate behavior in general against any person affiliated with NICRA, including its members and guests, with regard to race, sex, color, creed, religion, age, national origin, disability, marital status or sexual orientation.

This Bulletin is published by: National Ice Cream Retailers Association1028 West Devon AvenueElk Grove Village, IL 60007-7226847/301-7500 - Fax: 847/301-8402e-mail: [email protected] - Web: www.nicra.orgBob Turner, Chairman Publications CommitteeLynda Utterback, Editor©2009 National Ice Cream Retailers AssociationVol. 31, No. 2This issue of the NICRA Bulletin is now available online at http://www.nicra.org. Click on the Members Only button and enter your Username and Password. If you cannot find your Username and Password, call the NICRA office at 866-303-6960 or send an e-mail to [email protected] requesting the information.