Nanolithography Techniques MSE 505 / MSNT...

Transcript of Nanolithography Techniques MSE 505 / MSNT...

Ou

tlin

e

•W

hat

Is N

ano

tech

no

log

y?

•T

he

Mo

tiva

tio

n F

or

Go

ing

Sm

all

•N

ano

fab

rica

tio

n T

ech

no

log

ies

�B

asic

Tec

hn

iqu

es

�N

ano

Lit

ho

gra

ph

y

NA

NO

TE

CH

NO

LO

GY

�N

ano

tech

no

log

yis

th

e d

esig

n a

nd

en

gin

eeri

ng

of

com

po

nen

ts o

r st

ruct

ure

s th

at h

ave

at le

ast

on

e p

hys

ical

d

imen

sio

n t

he

size

of

100

nan

om

eter

s o

r le

ss.

�F

or

per

spec

tive

, th

e d

iam

eter

of

a h

um

an h

air

is

rou

gh

ly 1

00,0

00 n

ano

met

ers.

A s

ing

le w

alle

d c

arb

on

n

ano

tub

eh

as a

dia

met

er o

f ab

ou

t o

ne

nan

om

eter

.

�F

or

the

mic

roel

ectr

on

ics

ind

ust

ry, d

evic

e st

ruct

ure

d

imen

sio

ns

are

bei

ng

red

uce

d u

sin

g “

top

do

wn

” m

eth

od

s –

scal

e d

ow

n m

inim

um

fea

ture

siz

e.

�T

rue

nan

ote

chn

olo

gy

is w

hen

dev

ices

or

stru

ctu

res

are

craf

ted

by

usi

ng

“b

ott

om

up

” m

eth

od

s i.e

., b

y b

uild

ing

str

uct

ure

s u

p m

ole

cule

by

mo

lecu

le.

Ch

arac

teri

stic

fea

ture

siz

es t

hat

lie

in t

he

inte

rmed

iate

ran

ge

bet

wee

n

iso

late

d a

tom

s an

d b

ulk

mat

eria

ls (

on

e to

100

nan

om

eter

s) o

ften

dis

pla

y p

hys

ical

att

rib

ute

s su

bst

anti

ally

dif

fere

nt

fro

m t

ho

se d

isp

laye

db

y ei

ther

at

om

s o

r b

ulk

mat

eria

ls.

Dev

elo

pm

ent

Tim

e

Device Size (nm)

NA

NO

TE

CH

NO

LO

GY

Mo

tiva

tio

n T

o G

o S

mal

l

�T

o m

ake

no

vel d

evic

es t

hat

leve

rag

e th

e sp

ecia

l pro

per

ties

of

nan

osc

ale

bu

ildin

g b

lock

s co

nsi

stin

g o

f a

smal

l co

llect

ion

of

ato

ms.

�In

co

ntr

ast

to b

ulk

mat

eria

ls, h

avin

g p

rop

erti

es t

hat

are

d

om

inat

ed b

y n

ove

l qu

antu

m p

hen

om

ena

and

/or

the

effe

cts

of

surf

ace

ener

gy.

�W

hat

has

bee

n g

ain

ed in

th

e la

st 5

0 ye

ars

wit

h d

evic

e sh

rin

kag

e w

ill b

e su

rpas

sed

by

the

ben

efit

s o

f n

ano

mat

eria

lsan

d t

hei

r ar

ran

gem

ent

into

dev

ices

.

�S

up

erio

r se

lect

ivit

y fo

r in

tera

ctio

n, e

nh

ance

d s

ensi

tivi

ty t

o

det

ecti

on

, an

d n

ove

l pro

gra

mm

abili

ty f

or

add

ed s

tru

ctu

ral a

nd

fu

nct

ion

al c

on

tro

l (i.e

. bio

sen

sors

).

�R

evo

luti

on

ary

new

pro

du

cts

usi

ng

new

mat

eria

ls a

nd

su

bst

ance

s n

ot

acce

ssib

le w

ith

oth

er t

ech

no

log

ies

Nan

ote

chn

olo

gy

(Dip

Pen

Nan

olit

ho

gra

ph

y)

(Nan

o-i

mp

rin

t lit

ho

gra

ph

y)

(E-b

eam

an

d X

-ray

N

ano

lith

og

rap

hy)

Nan

oas

sem

bly

Tec

hn

iqu

esL

ayer

-by-

Lay

er A

ssem

bly

Mo

lecu

lar

Rec

og

nit

ion

-Bas

ed S

elf-

Ass

emb

lyS

elf-

Ass

emb

led

Mo

no

laye

rs(S

AM

)N

ano

asse

mb

lyb

y S

tep

-Wis

e P

oly

mer

izat

ion

Nan

op

atte

rnin

gT

ech

niq

ues

X-r

ay L

ith

og

rap

hy

E-b

eam

Lit

ho

gra

ph

yN

ano

imp

rin

tL

ith

og

rap

hy

Mo

lecu

lar

Imp

rin

tin

g

Ele

ctro

less

Dep

osi

tio

n T

ech

niq

ues

Wit

h C

har

ged

Nan

op

arti

cles

Pro

tein

Nan

oen

gin

eeri

ng

Tec

hn

iqu

esC

om

pu

ter-

Aid

ed P

epti

de

Des

ign

Au

tom

ated

Ab

ioti

cP

epti

de

Syn

thes

isB

ioti

c P

epti

de

Syn

thes

is in

Ho

st O

rgan

ism

Nan

om

anu

fact

uri

ng

•N

ot

Just

an

En

gin

eeri

ng

Pro

cess

–F

or

Ato

mic

Sca

le p

reci

sio

n a

nd

co

ntr

ol,

fun

dam

enta

l pri

nci

ple

s o

f p

hys

ics

and

ch

emis

try

mu

st b

e ap

plie

d.

•N

ano

scal

eM

anu

fact

uri

ng

is

Mu

ltid

isci

plin

ary

–In

volv

ing

bu

t n

ot

limit

ed t

o m

ech

anic

s, e

lect

rica

l en

gin

eeri

ng

, ph

ysic

s, c

hem

istr

y, b

iolo

gy,

an

d

bio

med

ical

en

gin

eeri

ng

.

•N

ano

man

ufa

ctu

rin

gis

th

e In

teg

rati

on

o

f E

ng

inee

rin

g, S

cien

ce a

nd

Bio

log

y

Nan

om

anu

fact

uri

ng

Nan

ofa

bri

cati

on

* L

ith

og

rap

hy

InG

ener

al T

erm

slit

ho

gra

ph

y ca

n b

e vi

ewed

as

a p

hys

ical

p

roce

ss in

volv

ing

imag

e tr

ansf

er o

r p

atte

rnin

g in

to v

ario

us

typ

es o

f m

edia

usi

ng

……

……

…

•V

isib

le a

nd

UV

Lig

ht

•E

lect

ron

Bea

m

•Io

n B

eam

•L

aser

•X

-ray

s

•P

reci

sio

n M

ach

inin

g

•P

rin

tin

g

* F

or

Nan

oF

abri

cati

on

A k

ey c

on

sid

erat

ion

is R

eso

luti

on

Pro

cess

Bia

s

Eve

ry p

roce

ss s

tep

cr

eate

s an

op

po

rtu

nit

y to

lose

info

rmat

ion

or

dis

tort

th

e d

esir

ed

pat

tern

.

Info

rmat

ion

Flo

w in

th

e O

pti

cal L

ith

og

rap

hic

Pro

cess

Op

tica

l Lit

ho

gra

ph

y

Wav

elen

gth

s fo

r o

pti

cal l

ith

og

rap

hy.

Res

olu

tio

n W

min

use

s k 1

= 0.

3 an

d D

OF

use

s k 3

= 1

, ass

um

ing

NA

= 0

.9 f

or

all w

avel

eng

ths

exce

pt

EU

V, w

hic

h a

ssu

med

NA

= 0

.25.

rep

rese

nts

th

e re

lati

ve im

pro

vem

ent

in m

ovi

ng

to

th

e n

ext

gen

erat

ion

wav

e le

ng

th

J. V

ac. S

ci. T

ech

no

l. B

, Vo

l. 21

, No

. 6, N

ov/

Dec

200

3

Op

tica

l Lit

ho

gra

ph

y

Fu

nd

amen

tal L

imit

s to

go

ing

bel

ow

193

nm

•F

or

157

nm

-S

ing

le c

ryst

al c

alci

um

flu

ori

de

len

ses

req

uir

ed

-O

xyg

en a

nd

wat

er v

apo

r ab

sorb

at

this

wav

elen

gth

-C

ost

est

imat

es a

re in

th

e ra

ng

e o

f $2

0 m

illio

n p

er s

can

ner

•F

or

EU

V

-M

ult

i co

ated

ref

lect

ive

mir

rors

req

uir

ed –

up

to

40

laye

rs

-R

efle

ctiv

e m

asks

are

req

uir

ed a

nd

mu

st h

ave

a su

rfac

e

flat

nes

s o

f 5

0 n

m o

r le

ss f

rom

ed

ge

to e

dg

e

-M

ask

surf

aces

can

be

dam

aged

by

oxi

dat

ion

.

-C

ost

est

imat

es a

re f

rom

$40

to

$70

mill

ion

per

sca

nn

er

Vecto

r

scan

Sp

ot

4n

m (

10

0 k

V)

7n

m (

50

kV

)

10

0 k

V /

50

kV

ZrO

/W

(S

ch

ott

key)

JB

X-9

30

0FS

Vecto

r

scan

Varia

ble

50

kV

LaB

6 s

ing

le

crysta

lJB

X-9

00

0M

V

Vecto

r

scan

Sp

ot

5n

m2

5 k

V a

nd

50

k

VLaB

6 s

ing

le

crysta

lJB

X-6

00

0FE

/E

Vecto

r

scan

Sp

ot

8n

m2

5 k

V a

nd

50

k

VLaB

6 s

ing

le

crysta

l JB

X-5

00

0LS

/E

Vecto

r

scan

Varia

ble

25

kV

an

d 5

0

kV

LaB

6 s

ing

le

crysta

lJB

X-3

03

0M

V

Defl

ecti

on

Beam

S

hap

eM

in.

Beam

S

ize

Accele

rati

ng

V

olt

ag

eE

mit

ter

Ele

ctro

n B

eam

Sys

tem

s

Ele

ctro

ns

hav

e a

fin

ite

qu

antu

m m

ech

anic

al w

avel

eng

th:

λ=

1.2

Vb-1

/2

Wh

ich

giv

es a

dif

frac

tio

n li

mit

ed b

eam

siz

e ex

pre

ssed

as:

dd

=0.

6αλ

Ad

d a

ll co

ntr

ibu

tio

ns

to c

alcu

late

th

eore

tica

l min

imu

m b

eam

siz

e:

dd

= (

dg

2+

ds2

+ d

c2+

dd

2 ) 1/

2

Ele

ctro

n B

eam

Siz

e L

imit

s

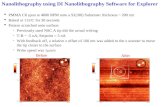

15 n

m w

ide

go

ld p

alla

diu

m li

nes

, 50

nm

per

iod

icit

y,

PM

MA

res

ist,

fab

rica

ted

by

lift-

off

on

a t

hin

sili

con

n

itri

de

mem

bra

ne

IBM

1. R

ES

. DE

VE

LOP

. V

OL.

32

NO

. 4 J

UL

Y 1

988

Ele

ctro

n B

eam

Nan

olit

ho

gra

ph

y

27 n

m p

erio

d li

nes

exp

ose

d in

30

nm

HS

Q r

esis

t o

n

Si;

(a)

ove

rall

gra

tin

gs

and

(b

) h

igh

er m

agn

ific

atio

n

view

of

ind

ivid

ual

lin

es in

th

e 27

nm

per

iod

gra

tin

g

exp

ose

d a

t a

do

ub

le-p

ass

line

do

se o

f 16

50 n

C/c

m.

30 n

m p

erio

d g

rati

ng

exp

ose

d in

30-

nm

-th

ick

HS

Q r

esis

t o

n S

i; (

a) o

vera

ll g

rati

ng

s, a

nd

(b

) h

igh

er m

agn

ific

atio

n v

iew

of

~10

nm

lin

es a

t 30

nm

per

iod

exp

ose

d a

t 22

00 n

C/c

m.

E-B

eam

Exp

osu

res

in H

ydro

gen

Sils

esq

uio

xan

eR

esis

t

J. V

ac. S

ci. T

ech

no

l. B

21,

No

6.,

No

v/D

ec 2

003

Nan

om

eter

Gra

tin

gs

by

E-b

eam

lith

og

rap

hy

J. V

ac. S

ci. T

ech

no

l. B

, Vo

l. 21

, No

. 6, N

ov/

Dec

200

3

Wid

th o

f in

div

idu

al li

nes

vs

do

se f

or

30, 4

0, a

nd

50

nm

per

iod

icit

y g

rati

ng

s ex

po

sed

in 3

0 n

m o

f H

ydro

gen

Sils

esq

uio

xan

ere

sist

.

Plo

t o

f lin

ewid

thva

riat

ion

fr

om

no

min

al (

i.e.

dev

elo

ped

fo

r th

e ti

me

req

uir

ed t

o c

lear

fea

ture

s)

for

up

to

50%

o

verd

evel

op

men

t. Is

ola

ted

fe

atu

res

stay

wit

hin

a +

/-10

% p

roce

ss w

ind

ow

fo

r fe

atu

res

as s

mal

l as

30 n

m.

Den

se (

line:

spac

era

tio

of

1:3

or

gre

ater

) fe

atu

res

rem

ain

in t

he

pro

cess

w

ind

ow

fo

r fe

atu

res

as

smal

l as

45 n

m.

Nan

olit

ho

gra

ph

yP

roce

ss W

ind

ow C

on

stra

ints

Nan

ofa

bri

cati

on

Ele

ctro

chem

ical

ly G

row

n W

ires

fo

r S

enso

r A

rray

Ap

plic

atio

ns

Nan

oL

ett.

, Vo

l. 4,

No

. 3, 2

004

Sch

emat

ic d

iag

ram

of

a st

ruct

ure

use

d f

or

the

elec

tro

chem

ical

wir

e g

row

th.

(a)

Ele

ctro

dep

osi

ted

wir

e co

nn

ecte

d b

etw

een

ele

ctro

des

. (b

) C

ross

-sec

tio

nal

vi

ew o

f th

e S

isu

bst

rate

, sili

con

nit

rid

e (1

um

), A

u c

on

tact

s, a

nd

th

erm

ally

ev

apo

rate

d S

iO. C

han

nel

s fo

r th

e el

ectr

oly

te s

olu

tio

n a

re f

orm

ed b

etw

een

el

ectr

od

es b

y e-

bea

m p

atte

rnin

go

f th

e S

iO.

Sca

nn

ing

ele

ctro

n m

icro

gra

ph

s o

f d

evic

e p

atte

rns

wit

h f

eatu

re

size

s le

ss t

han

40

nm

ach

ieve

d

by

x-ra

y n

ano

lith

og

rap

hy

follo

wed

by

lifto

ff. T

he

x-ra

y m

ask

is s

ho

wn

on

to

p a

nd

th

e lif

ted

-off

pat

tern

is o

n t

he

bo

tto

m.

Nan

o-p

atte

rnin

g b

y X

-ray

Lit

ho

gra

ph

y

Nan

o-m

ach

inin

g

By

usi

ng

su

b-n

ano

met

er c

on

tro

l aff

ord

ed b

y A

FM

tec

hn

olo

gy

the

nm

1300

em

plo

ys a

su

btr

acti

ve

ph

oto

mas

kre

pai

r te

chn

iqu

e. T

he

curr

ent

syst

em is

fo

cuse

d o

n m

eeti

ng

req

uir

emen

ts f

or

the

130-

nan

om

eter

des

ign

ru

le n

od

e, b

ut

the

tech

niq

ue

is e

xten

dab

le t

o t

he

100

nm

no

de

and

bey

on

d.

RA

VE

LL

C

Pro

cess

seq

uen

ce o

f m

ech

anic

al A

FM

lith

og

rap

hy,

lift

-off

an

d p

atte

rn t

ran

sfer

Mec

han

ical

Lit

ho

gra

ph

y b

y A

FM

J. V

ac. S

ci. T

ech

no

l. B

, Vo

l. 16

, No

. 5, S

ep/O

ct 1

998

Th

e s

am

ple

is t

he s

urfa

ce o

f a g

old

crysta

l (A

u(1

11

)) c

overed

wit

h a

self

assem

ble

d

mo

nola

yer (

SA

M) o

f d

ecan

eth

iol

(C

H3

(C

H2

)9

SH

).

Im

ag

ing

was d

on

e u

nd

er

liq

uid

in

a s

olu

tion

con

tain

ing

octa

decan

eth

iol(C

H3

(C

H2

)1

7S

H).

Th

e

lith

og

rap

hy w

as d

on

e b

y a

pp

lyin

g a

n

ap

proxim

ate

ly 1

0X

hig

her f

orce d

urin

g

writ

ing

. Th

is d

isp

laced

th

e d

ecan

eth

iol

mole

cu

les,

wh

ich

were t

hen

rep

laced

in

th

e S

AM

by t

he lon

ger o

cta

decan

eth

iol

mole

cu

les.

Th

e s

urfa

ce is h

igh

er w

here

writ

ten

becau

se t

he t

ails o

f th

e

octa

decan

eth

iol

mole

cu

les s

tick u

p a

bove

the a

verag

e h

eig

ht

of

the S

AM

. Tota

l siz

e

of

the s

pir

als

is 6

20

nm

. A

verag

e lin

e

sp

acin

g is 4

0n

m a

nd

averag

e lin

e-w

idth

s

(FW

HM

) a

re 1

5 t

o 2

0n

m.

Nan

olit

ho

gra

ph

yA

FM

Nan

og

raft

ing

of

Th

iols

on

a A

u(1

11)

Su

rfac

e

M. L

iu a

nd

G. L

iu, U

C D

avis

Nan

olit

ho

gra

ph

y u

sin

g A

no

dic

Oxi

dat

ion

Wh

en t

he

AF

M t

ip is

bro

ug

ht

clo

se t

o t

he

surf

ace,

wat

er f

rom

th

eam

bie

nt

hu

mid

ity

form

s a

dro

ple

t b

etw

een

th

e ti

p a

nd

th

e su

bst

rate

. To

dri

ve t

he

ano

dic

oxi

dat

ion

pro

cess

, a v

olt

age

(5 t

o 1

5 vo

lts)

is a

pp

lied

bet

wee

n t

he

tip

an

d t

he

sub

stra

te. T

he

hig

h e

lect

ric

fiel

d io

niz

es t

he

wat

er d

rop

let

and

th

e O

H-

ion

s p

rod

uce

d p

rovi

de

the

oxi

dan

t fo

r th

e ch

emic

al r

eact

ion

.

Th

e N

otr

e D

ame

log

o s

ho

ws

2nm

th

ick

oxi

de

gro

wn

on

a T

i film

. O

xid

atio

n is

per

form

ed b

y ap

ply

ing

a p

ote

nti

al t

o a

co

nd

uct

ing

AF

M t

ip

and

usi

ng

th

e co

nd

ense

d w

ater

dro

ple

t at

th

e ti

p a

s an

ele

ctro

chem

ical

ce

ll. T

he

oxi

diz

ed r

egio

n g

row

s, r

esu

ltin

g in

rai

sed

su

rfac

e fe

atu

res.

Nan

olit

ho

gra

py

–A

no

dic

Oxi

dat

ion

EE

Dep

artm

ent

Un

iv. o

f N

otr

e D

ame

Nan

olit

ho

gra

ph

y u

sin

g A

FM

An

od

ic O

xid

atio

n o

n T

i Su

bst

rate

Wid

th a

t th

e b

ott

om

o

f th

e tr

ench

is a

bo

ut

80n

m

EE

Dep

artm

ent

Un

iv. o

f N

otr

e D

ame

Th

e w

idth

at

the

top

of

the

lines

is

abo

ut

70n

m

EE

Dep

artm

ent

Un

iv. o

f N

otr

e D

ame

Nan

olit

ho

gra

ph

y u

sin

g A

FM

An

od

ic O

xid

atio

n -

Ti S

ub

stra

te

Nan

olit

ho

gra

ph

y u

sin

g a

n S

TM

Sch

emat

ic d

iag

ram

of

the

exp

erim

enta

l set

-up

fo

r si

lico

n o

xid

e re

mo

val b

y fi

eld

em

itte

d e

lect

ron

bea

m ir

rad

iati

on

at

an e

leva

ted

te

mp

erat

ure

usi

ng

a S

can

nin

g T

un

nel

ing

Mic

rosc

op

e (S

TM

).

(1)

Th

e o

xid

e la

yer

wit

hin

th

e e-

bea

m-e

xpo

sed

ar

ea is

dec

om

po

sed

an

d r

edu

ced

(2)

Th

e re

du

ced

SiO

is

chan

ged

to

vo

lati

le S

iOan

d e

vap

ora

ted

fro

m

the

surf

ace

at e

leva

ted

te

mp

erat

ure

s.

Nan

ote

chn

olo

gy

14 (

2003

) R

55–R

62

Th

e q

uan

tum

yie

ld f

or

imp

act-

ind

uce

d S

iO2

dec

om

po

siti

on

as

a fu

nct

ion

of

the

e-b

eam

ki

net

ic e

ner

gy

wit

h b

eam

cu

rren

ts o

f 10

nA

(◦),

20

nA

(♦),

30

nA

(), 4

0 n

A()

an

d 5

0 n

A(×

). T

he

solid

cu

rve

rep

rese

nts

th

e su

bst

anti

al y

ield

.

Nan

olit

ho

gra

ph

y o

n S

iO2

usi

ng

an

ST

M

Nan

o-f

abri

cati

on

of

pat

tern

s b

y P

C

con

tro

l of

the

ST

M t

ip p

osi

tio

n.

Sm

alle

st li

new

idth

= 25

nm

Nan

ote

chn

olo

gy

14 (

2003

) R

55–R

62

ST

Mim

age

of

a p

oly

pro

pyl

ene

mo

lecu

le o

n g

rap

hit

e.

Nan

ofa

bri

cati

on

on

th

e M

ole

cula

r S

cale

(a)

Sch

emat

ic d

iag

ram

of

the

dev

ice.

Th

e su

spen

ded

bri

dg

e co

nsi

sts

of

har

d b

aked

ph

oto

resi

sto

r S

iO2,

an

d e

vap

ora

ted

Si(

or

SiN

). (

b)

Sca

nn

ing

-ele

ctro

n-

mic

rosc

op

e (S

EM

) im

age

of

the

dev

ice

that

h

as a

co

nta

ct a

rea

of

400

nm

2. F

or

clar

ity

in S

EM

imag

ing

, sam

ple

s w

ere

tilt

ed 4

5°. (

c) S

EM

imag

e th

at s

ho

ws

that

th

e to

p s

urf

ace

is f

ar a

way

fro

m t

he

sub

stra

te (

> 50

0 n

m)

and

th

at t

he

sup

po

rtin

g

mid

dle

laye

r fe

atu

res

a la

rge

un

der

cut.

Th

us,

we

can

mea

sure

th

etr

ansp

ort

pro

per

ties

of

the

dev

ices

wit

ho

ut

a lif

toff

ste

p in

th

e fa

bri

cati

on

.N

ano

Let

t., V

ol.

3, N

o. 2

,200

3

Th

e el

ectr

on

ic t

ran

spo

rt

char

acte

rist

ics

of

self

-ass

emb

led

m

on

ola

yers

of

ph

enyl

ene-

bas

ed ð

-co

nju

gat

ed m

ole

cule

s w

ere

mea

sure

d in

a t

hre

e t

erm

inal

dev

ice

geo

met

ry. T

he

sho

rt (

1 n

m)

mo

lecu

les

wer

e co

nn

ecte

d b

etw

een

tw

o g

old

ele

ctro

des

wit

h a

nea

rby

Al 2

O3/

Al g

ate

elec

tro

de.

It w

as

po

ssib

le t

o f

abri

cate

wo

rkin

g

dev

ices

usi

ng

th

ree

of

the

five

m

ole

cule

s in

vest

igat

ed. T

he

oth

er

two

typ

es o

f m

ole

cule

s le

d t

o

dev

ices

wh

ere

the

Au

ele

ctro

des

w

ere

sho

rted

to

get

her

. Fo

r d

evic

es

wit

h 1

,3-b

enze

ned

ith

iol,

a w

eak

gat

e ef

fect

was

ob

serv

ed.

Nan

ofa

bri

cati

on

SA

M o

f P

hen

ylen

e-B

ased

Co

nju

gat

ed M

ole

cule

s in

an

FE

T g

eom

etry

In t

he

con

stan

t tu

nn

elin

g c

urr

ent

mo

de

of

op

erat

ion

, a v

olt

age

Vz

is

app

lied

to

th

e Z

pie

zoel

ectr

ic e

lem

ent

by

mea

ns

of

the

con

tro

l un

it C

U t

o

keep

th

e tu

nn

elin

g c

urr

ent

con

stan

t w

hile

th

e ti

p is

sca

nn

ed a

cro

ss t

he

surf

ace

by

alte

rin

g V

xan

d V

y. T

he

trac

e o

f th

e ti

p, a

y-s

can

, gen

eral

ly

rese

mb

les

the

surf

ace

top

og

rap

hy.

Ele

ctro

nic

inh

om

og

enei

ties

als

o

pro

du

ce s

tru

ctu

re in

th

e ti

p t

race

, as

illu

stra

ted

on

th

e ri

gh

tab

ove

wit

h

two

su

rfac

e at

om

s h

avin

g e

xces

sive

neg

ativ

e ch

arg

e.

Sca

nn

ing

Tu

nn

elin

g M

icro

sco

pe

Nan

op

atte

rnin

go

n t

he

Ato

mic

Sca

le

Usi

ng

a S

can

nin

g T

un

nel

ing

Mic

rosc

op

e (S

TM

)

IBM

199

0X

eno

n A

tom

s

Ult

rah

igh

Den

sity

DN

A A

rray

s

So

l Gel

Str

uct

ure

s

Pro

tein

Nan

oar

rays

Sm

all O

rgan

ic M

ole

cule

s

100

nm

4µm

Co

nd

uct

ing

Po

lym

ers

290

nm

Dip

-Pen

N

ano

lith

og

rap

y

Pro

toty

pe

Pro

be

Arr

ays

1 µm

65 n

m

Sin

gle

Nan

op

arti

cle

Lin

es

290

nm

Sili

con

Nan

ost

ruct

ure

s

Bo

tto

m-U

p N

ano

fab

rica

tio

n v

ia

Dip

-Pen

Nan

olit

ho

gra

py

Bu

ildin

g B

lock

s

DP

N-G

ener

ated

Su

rfac

e T

emp

late

sA

dd

ress

able

Mat

eria

ls w

ith

Wel

l-D

efin

edS

up

erst

ruct

ure

s an

d O

rien

tati

on

s

Lif

e S

cien

ces

Mic

roel

ectr

on

ics

(Bio

)sen

sor

Dev

ices

•si

ng

le m

ole

cule

stu

die

s•

stru

ctu

re/f

un

ctio

n•

dru

g d

isco

very

•u

ltra

-hig

h d

ensi

ty g

ene

chip

s•

pro

teo

mic

s/p

epti

de

arra

ys•

cell

pro

cess

es (

adh

esio

n)

•vi

rus/

pro

tein

cry

stal

lizat

ion

scie

nce

& t

ech

no

log

ysc

ien

ce &

tec

hn

olo

gy

•m

ole

cula

r el

ectr

on

ics

•n

ano

scal

esu

rfac

e p

hen

om

ena

•o

rgan

ic e

tch

res

ists

•p

rin

ted

nan

oca

taly

sts

•co

mb

inat

ori

al m

ater

ials

dis

cove

ry•

CN

T, n

ano

wir

ed

evic

es•

add

itiv

e p

ho

tom

ask

rep

air

•ci

rcu

it e

dit

•sp

intr

on

icd

evic

es•

gas

/ch

emo

sen

sors

DP

N:

A V

ersa

tile

To

ol F

or

Nan

ofa

bri

cati

on

CO

NV

ER

GE

NC

E o

f fi

eld

s fr

om

th

e “

BO

TT

OM

UP

”

Tw

o F

un

dam

enta

l Typ

es o

f D

ip-P

en

Nan

olit

ho

gra

ph

y M

eth

od

s

•D

irec

t W

rite

–w

rite

th

e m

ole

cule

of

inte

rest

dir

ectl

y o

nto

th

e su

rfac

e as

th

e in

k•

Tem

pla

tin

g–

wri

te o

ut

an in

k p

atte

rn in

ord

er t

o

fab

rica

te o

r at

tach

so

met

hin

g e

lse

Dip

-Pen

Nan

olit

ho

gra

ph

y / S

AM

16-m

erca

pto

hex

adec

ano

ic

acid

(M

HA

)

Pro

ced

ure

fo

r p

rep

arin

g f

un

ctio

nal

ized

DP

N-g

ener

ated

nan

ost

ruct

ure

s u

sin

g t

hio

l-co

nta

inin

g m

ole

cule

s

Dip

-Pen

Nan

olit

ho

gra

ph

y / S

AM

AF

M t

op

og

rap

hic

imag

es o

f th

e et

ched

MH

A/A

u/T

i/SiO

x/S

in

ano

stru

ctu

res,

lin

es (

A)

and

do

ts (

B),

bas

ed o

n t

he

DP

N o

f M

HA

o

n a

go

ld s

urf

ace

AF

M t

op

og

rap

hic

imag

es o

f in

div

idu

al A

u n

ano

par

ticl

esad

sorb

ed o

n H

S-S

AM

-mo

dif

ied

nan

op

atte

rns

of

lines

(A

, wit

h h

igh

-res

olu

tio

n im

age

inse

rted

) an

d d

ots

(B).

Dip

-Pen

Nan

olit

ho

gra

ph

y / S

AM

ME

GA

ped

e-

DP

NS

tam

per

™

Flu

ore

scen

t ar

rays

dep

osi

ted

by

a M

EG

Ap

ede

DP

NS

tam

per

ME

GA

ped

ep

rob

e ar

ray

Nan

ofa

bri

cati

on

Usi

ng

Sel

f A

ssem

bly

Th

e su

bst

rate

is f

un

ctio

nal

ized

w

ith

org

anic

mo

lecu

les

to

pro

du

ce p

ola

r an

d n

on

-po

lar

reg

ion

s. C

arb

on

nan

otu

bes

in

solu

tio

n a

re a

ttra

cted

to

th

e p

ola

r re

gio

ns

and

sel

ecti

vely

se

lf a

ssem

ble

on

th

e su

bst

rate

fo

llow

ing

th

e lit

ho

gra

ph

ical

ly

def

ined

pat

tern

s.

Mas

s p

rod

uct

ion

of

carb

on

n

ano

tub

eb

ased

cir

cuit

st

ruct

ure

s is

po

ssib

le

Su

rfac

e F

un

ctio

nal

izat

ion

SW

CN

T S

elf

Ass

emb

ly

Po

lar

Mo

lecu

lar

Pat

tern

sN

on

-Po

lar

Reg

ion

SW

CN

T S

usp

ensi

on

Su

bst

rate

Fab

rica

tio

n s

equ

ence

fo

r th

ree

dif

fere

nt

vari

etie

s o

f im

pri

nt

lith

og

rap

hy.

Imp

rin

t L

ith

og

rap

hy

Nan

ofa

bri

cati

on

Usi

ng

Ste

p-a

nd

Fla

sh

Imp

rin

t L

ith

og

rap

hy

1.U

sin

g a

pre

cise

pie

zo-d

rive

n d

isp

ense

h

ead

, a s

ilico

n-r

ich

, lo

w-v

isco

sity

, p

ho

tocu

rab

le, m

on

om

er s

olu

tio

n is

d

isp

ense

d o

nto

th

e su

bst

rate

in t

he

reg

ion

wh

ere

the

pat

tern

is t

o b

e p

rin

ted

.

2.T

he

tem

pla

te is

th

en p

ress

ed in

to c

on

tact

w

ith

th

e w

afer

usi

ng

ver

y lo

w p

ress

ure

s (<

1psi

) to

sp

read

th

e liq

uid

acr

oss

th

e fi

eld

an

d f

ill t

he

tem

pla

te's

rel

ief.

3.U

V li

gh

t is

irra

dia

ted

th

rou

gh

th

e b

ack

of

the

tem

pla

te, c

uri

ng

th

e m

on

om

er.

4.T

he

tem

pla

te, p

re-c

oat

ed w

ith

a

flu

oro

carb

on

rel

ease

ag

ent,

is r

emo

ved

, le

avin

g t

he

cure

d, p

atte

rned

res

ist

laye

r b

ehin

d.

5.F

inal

ly, a

bre

akth

rou

gh

etc

h p

assi

ng

th

rou

gh

th

e re

sid

ual

etc

h b

arri

er a

nd

a

tran

sfer

laye

r (a

ny

org

anic

sp

in-c

oat

ed

resi

n s

uch

as

an a

nti

refl

ecti

ve c

oat

ing

, A

RC

) tr

ansf

ers

the

hig

h a

spec

t ra

tio

pat

tern

to

th

e su

bst

rate

.

So

lid S

tate

Tec

hn

olo

gy

Feb

ruar

y 20

04

100,

60,

30,

an

d 2

0 n

m f

eatu

res

def

ined

usi

ng

th

e IT

O-b

ased

pro

cess

.

Tem

pla

te p

atte

rn t

ran

sfer

seq

uen

ce f

or

30 n

m f

eatu

res.

Ste

p a

nd

Fla

sh N

ano

-Im

pri

nt

Lit

ho

gra

ph

y

J. V

ac. S

ci. T

ech

no

l. B

, Vo

l. 21

, No

. 6, N

ov/

Dec

200

3

Pri

nte

d f

eatu

res

in t

he

acry

late

-bas

ed e

tch

bar

rier

. (a)

To

p-d

ow

n S

EM

s.

(b)

Cro

ss-s

ecti

on

al im

ages

of

bo

th s

ing

le t

ier

and

mu

lti-

tier

ed f

eatu

res.

Ste

p a

nd

Fla

sh N

ano

-Im

pri

nt

Lit

ho

gra

ph

y

J. V

ac. S

ci. T

ech

no

l. B

, Vo

l. 21

, No

. 6, N

ov/

Dec

200

3