n2k - N2K - November 2015

-

Upload

black-press -

Category

Documents

-

view

218 -

download

1

description

Transcript of n2k - N2K - November 2015

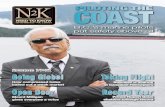

Safe StrategySafe StrategyVanderhoof’s New Gold Vanderhoof’s New Gold celebrates safety milestonecelebrates safety milestone

Pipeline PlanningPipeline PlanningTransCanada looking TransCanada looking to new technologyto new technology

New ArrivalNew ArrivalMaersk Line makes fi rst Maersk Line makes fi rst call at Fairview Terminal call at Fairview Terminal

Going GreenGoing GreenLake Babine Nation Lake Babine Nation

bets on biomassbets on biomass

NOVEMBER 2015 • VOL. 2, ISSUE 7

Irene Mills Rosa Miller Herb Pond

You aboutasked

To learn more about the North Coast Cetacean Sightings Network and other programs we support through theVancouver Aquarium (including the AquaVan and Marine Speaker Series), visit www.princerupertlng.ca/socialinvestment. BG Canada is proposing an LNG facility on Ridley Island near Prince Rupert, BC. Stay informed by signing up for our email updates using the form on our Contact Us page.

The local community has told us that environmental protection is important - it is to us too. We’re doing what we can now to help expand the existing level of ocean knowledge and research in Northwest BC. We believe by doing this, wewill be able to reduce impacts in the ocean environment.

ENVIRONMENTALPROTECTION

5500sightings reported

in 2014

6200sightings reported

in 2015 (so far)

BG Canada is proud to support the BC Cetacean Sightings Network (BCCSN). The BCCSN is a community-based research program led by the Vancouver Aquarium.

If you see a whale, dolphin, porpoise, or sea turtle, call 1-866-472-9663 orvisit www.wildwhales.org/sightings.

Brett Jeffrey | [email protected] | 250.641.2441Terrace Vancouver Calgary Edmonton Fort McMurray Bonnyville Lethbridge

DESIGN-BUILD GENERAL CONTRACTORPRE-ENGINEERED STEEL BUILDING EXPERTS

INDUSTRIAL COMMERCIAL WAREHOUSING MANUFACTURING TRANSPORTATION AVIATION

ENTREC CRANES - BEAR CREEK INDUSTRIES INC. ENTREC CRANES - TERRACE

ENTREC CRANES - BEAR CREEK INDUSTRIES INC.ENTREC CRANES - TERRACE

ENTREC CRANES - TERRACE

METAL BUILDINGS

A U T H O R I Z E D B U I L D E R

With less than 60 days to go until the calendar turns to 2016, people across the Northwest are gearing up for a very bright future as industry continues to turn its attention to the region.

Th e possibilities are, frankly, endless when it comes to what the future holds. Between proposals for liquefi ed natural gas in Prince Rupert and Kitimat, mining along the Highway 37 corridor and in the northern interior, biomass and clean energy projects planned in various communities and increased export capacity coming to the North Coast in the near future, the economic future of the region is much more than a one-trick pony.

And while residents and local governments are getting ready to take advantage of the opportunities presented by industrial growth, as evidenced by the $2.1 million program to train more than 200 Nisga’a members outlined by Rod Link on Page 10, industry itself is preparing to ensure it can develop in a way that benefi ts the people who call this beautiful part of the province home.

In this issue of N2K, Vivian Chiu looks at how New Gold is expanding the focus of safety well beyond its own borders. While the company can boast more than two years without a reportable accident at its Blackwater Project, New Gold wanted to do more for its workers and the place they call home by donating $5,000 to the Nechako Valley Search and Rescue team. Th at donation will ensure the volunteers of the group have the resources they need in order to save lives in the area.

Meanwhile, TransCanada is turning to high-tech methods to ensure its Coastal GasLink project meets the stringent environmental demands of working in the region. As outlined by Cameron Orr, the company is looking to use towers and cranes to prevent damage on steep slopes and is considering drilling under rivers using the pipeline itself to prevent the project’s footprint from being any larger than it needs to be.

It is this type of eff ort that has led to substantial support from local governments and organizations in the community, support such as that off ered to the Prince Rupert Gas Transmission Project outlined on Page 17.

While it is impossible to tell what the future holds, many people in the Northwest and the companies looking to do business here are ready to work together to ensure the best future possible. Th at is something people around the province need to know.

Todd HamiltonN2K [email protected]

PublisherTodd Hamilton

Editor-in-ChiefShaun Thomas

Prince RupertEd Evans, Sales

Melissa Bouti l ier, SalesKevin Campbell, Reporter

TerraceRod Link, Editor

Brian Lindenbach, Sales Bert Husband, SalesErin Bowker, Sales

KitimatLouisa Genzale, Sales Cameron Orr, Editor

SmithersGrant Harris, SalesNick Briere, Sales

Chris Gareau, EditorCecile Favron, Reporter

HoustonMary-Anne Ruiter, Sales

Burns LakeLaura Blackwell, Sales Flavio Nienow, EditorFort St. James/

VanderhoofPam Berger, Sales

Vivian Chiu, ReporterHaida Gwaii

Quinn Bender, Sales

N2K CONTACT INFO:Vanderhoof • 250-567-9258Fort St. James • 250-567-9258Burns Lake • 250-692-7526Houston • 250-845-2890Smithers • 250-847-3266Terrace • 250-638-7283Kitimat • 250-632-6144Prince Rupert • 250-624-8088Haida Gwaii • 250-559-4680

N2K is a Black Press publication mailed or delivered by carrier to 31,500 homes and businesses

throughout Northwest B.C.Our Head Office is located at:

737 Fraser Street, Prince Rupert, B.C., V8J 1R1

250-624-8088Fax: 250-624-8085

View our e-version for free at:

www.thenorthernview.com/eeditions

Out-of-area subscriptions now availablee-mail: [email protected]

Volume 2 • Issue 7 November 2015

16

37

37

16

Granisle

New Hazelton

Hazelton

Cranberry Junction

Port Edward

SKA

Burns La

SmithersTelkwa

Houston

Terrace

Kitimat

Prince Rupert

SAFE PLANNINGNew Gold supports community safety 7

NEW ARRIVALArrival of weekly Maersk vessel highlights continued growth of Fairview Terminal 12

FINDING SUPPORTTerrace, Metlakatla and Port Edward back Prince Rupert Gas Transmission pipeline 17

HELP WANTEDCheck out the jobs in the career section 22

INSTALLATION TECHNOLOGYTransCanada turns to the latest technology to construct Coastal GasLink pipeline 14

THINKING GREENLake Babine First Nation plans for new biomass plant and clean energy future 18

SAVING SALMONHatchery ensures future of stocks 20

LNG PREPARED$2.1 million to train Nisga’a members 10

NORTHWEST’S LARGEST VOLUME DEALER FOR A REASON!!

www.smprv.ca

D5631

Located on Highway 16, Houston, BC • Phone 250-845-2244 • Toll Free 1-800-665-3151

www.sullivangm.com

Lightweight, aff ordable, quality-built travel trailers, fi fth wheelsand campers.

BRITISH COLUMBIA'S

LARGESTHD DEALER

FOR 2014

CHECK OUT OUR LINE UP OF 2015 HEAVY DUTY TRUCKSWhether you plan on purchasing a fl eet of vehicles or need a lease, let us help you meet your commercial needs.

We can deliver your new vehicle today.

SEE OUR GREAT SELECTION OF NEW & USED RVS

This space is a collaborative promotional venture by LNG Canada and N2K Editor Cameron Orr

Joan Goldhawk, Senior Advisor for Local Content, says the company’s approach includes reaching out to employment agencies directly to ensure LNG Canada is connecting with individuals looking for work.

“What we’re really trying to do is have conversations with different groups and organizations to understand how best to connect with local jobseekers,” she says.

Goldhawk believes conversations with employment service providers give LNG Canada a great deal of insight into what information jobseekers want, how they want to receive that information, and even how they want to contact prospective employers.

“This information has been extremely helpful, and we really want to take this feedback to heart. In fact, we’re looking to bring employment support services groups together in a more formal setting, to determine how best to work together,” says Goldhawk.

The company will begin by hosting focus group sessions with local employment agencies. From there, Goldhawk says if the organizations want to work more

commitment,” says Goldhawk.

LNG Canada is also involved in a Pathways to Success program. Pathways is a $1.2 million job development and readiness program for First Nations, which Goldhawk says has placed 108 people into jobs since it started earlier this year. Of the 108 people, 103 have maintained those jobs.

The company also recently announced the LNG Canada Trades Training Fund. The fund was established to support employers, particularly small to medium enterprises that employ, sponsor and train apprentices in the construction and related trades. More information is available atwww.bccassn.com.

““What we’re really trying to do is have conversations with different groups and organizations to understand how best to connect with local jobseekers”

closely together, LNG Canada will host a strategic workshop to identify partnership opportunities and determine how best to deliver services to meet the needs of local jobseekers.

Taking the time to listen to the needs of the community is a long-term process, but short-term efforts are already underway. Goldhawk says LNG Canada has already mandated that all contractors post all available jobs, to ensure that people are aware of the opportunities.

“To support our ‘hire local’ priority, we have made it a contractual requirement for every company to post every available job, with all the employment service providers,” she says.

LNG Canada is already seeing positive results fi lling local opportunities. For example, the company has leased a number of beds at Civeo’s Sitka Lodge in Kitimat. Civeo, through its contract, has hired approximately 40 local area people for the facility.

“It’s a wonderful example of two companies that have a very strong local content

LNG Canada is taking a unique approach to discover the best ways to connect local communities to job opportunities resulting from the LNG industry.

Understanding local employment needs

7

Three years of mining exploration for the Blackwater Project has yielded no lost-time incidents, including two years of no reportable

accidents for New Gold.Celebrating the safety milestone with employees and

contractors on Oct. 6, along with a $5,000 donation to the Nechako Valley Search and Rescue (NVSR), project director Tim Bekhuys said it’s an opportunity to show appreciation for the 500,000 work hours in the past three years from staff — 70 per cent of whom were locally hired.

“We try to make sure that we walk the talk and hire locally. Along with that comes the responsibility of making sure that those people are safe as well,” said Bekhuys.

Located 110 kilometres southwest of Vanderhoof, the Blackwater Project will be an open-pit gold and silver mine with an estimated 17-year lifespan and the potential to produce 485,000 ounces of gold per year for the first nine years, according to New Gold.

As the project takes place in a potential wildfire location, with a short-term evacuation in 2014 that did not harm workers or structures, the camp team had provided ongoing camp services such as housing and meals to wildfire crews, helicopter pilots and engineers as well.

“Certainly in New Gold, we see it as our responsibility to get every worker home safe,” Bekhuys said.

“So we take safety very seriously, and we monitor the safety in all of our sites very closely on a daily basis.”

See Page 8

“In New Gold, we see it as our responsibility to get every

worker home safe.”

- Tim Bekhuys

By Vivian Chiu

New Gold puts focus on safety at the site and in the community

Safety is

According to New Gold, the Blackwater mine will employ between 1,200 and 1,500 workers during its construction, and 500 workers during operations.

As the project shuts down for the winter and continues its environmental assessment process, New Gold is looking to meet with the community through a series of open house sessions before Christmas, Bekhuys said.

Mine-building at Blackwater is expected to start in early 2018, after the company finishes construction of the Rainy River mine in northwest Ontario in mid-2017.

“Our goal right now is to have the project shovel-ready over the next year or so,” Bekhuys said.

“We have great support from the community and we want to make sure that jobs and contracts are going to local people…and partnerships with the First Nations in the area as well.”

New Gold’s $5,000 donation to NVSR will furnish the team’s new location on Burrard Avenue and make it into a training centre, as their recent grant application failed, said president Chris Mushumanski.

It is now the mining company’s third donation to NVSR, as the fi rst in 2012 contributed to a First Aid stretcher with a wheel attachment and another donation in January of this year went into more fi rst aid and swift water rescue equipment, Mushumanski added.

“It’s been a tremendous opportunity for us to be acknowledged by them and we are really grateful for

the support that New Gold has provided over the years to the search and rescue team,” he said.

The BC Search and Rescue Association is currently proposing an alternative support model that would provide stable funding for the 80 SAR groups in B.C., said Mushumanski, who is also the association’s Bulkley Nechako regional director.

Including three proposals that will be presented to the B.C. government, the model will remove the annual burden of grant writing and fundraising, he said.

“Otherwise we really don’t have any predictable sources of funds for capital projects and training, and equipment purchases that we needed.”

“Our goal right now is to have the project shovel-ready over

the next year or so.”

- Tim Bekhuys

15 Cardlock Locations: Fort St. James To Quesnel,

Terrace To Valemount. Fuel Tanks Sales & Rentals, Bulk Fuel

and Oil Deliveries: Vanderhoof Toll Free: 1-888-545-2667,

Quesnel: 1-888-992-2667,

Prince George: 1-866-309-2667

Houston: 1-800-848-6347,

Terrace: 250-635-9595

VANDERHOOF and DISTRICTS CO-OPERATIVE ASSOCIATION

Keller thrives on challenges and excels where others struggle. Backed by the largest and most comprehensive independent ground engineering specialist in the world, and with over 30 years of local on-site experience, Keller Canada provides the largest variety of piling and geotechnical solutions in the country.

Couunnnnntttt uus in.

Investing in BC LNG

Contact us: Leanne Enns, Keller CanadaTel: 250-615-3844 • Fax: 250-622-2886

716 Fraser Street, Prince Rupert, BC V8J 1P9email: [email protected]

10

Nisga’a citizens in Terrace, Prince Rupert and the Nass Valley are to benefi t from a $2.1 million training program over the next three years.

Th e goal is to train 215 Nisga’a for jobs within the liquefi ed natural gas industry, but skills learned can also apply elsewhere said Gary Patsey of Nisga’a Employment Skills and Training (NEST), the Nisga’a Lisims Government agency which is to administer the program.

“Th is training targets those who require assistance with requisite skills enhancement before attaining industry or trades training and certifi cations. For these individuals, the training is foundational to further training in any other sector as well,” he said.

Already more than 50 people have applied for training to earn a driver’s licence, considered one of the key fi rst steps toward employment.

“We forecast that as clients work their way up to trades or industry training and gainful or demand driven employment, their quality of life will improve, their family or personal income will improve and acquiring

transportation will be a viable option to them,” said Patsey.Th e money comes from a provincial government skills

training program and was announced in Terrace on Oct. 19. Patsey said child care support will be provided to participants who need it.

NEST anticipates an early November start-up by fi rst hiring people to administer the program.

See Page 11

By Cameron Orr

$2.1 million to train more than 200 Nisga’a for LNG jobs

“The participants will be provided opportunities to

apply their newly-acquired skills .... in work that benefi ts

the community”

- Gary Patsey

PREPARING THE NATIONPREPARING THE NATION

PRETIVM IS ADVANCING ITS HIGH-GRADE GOLD BRUCEJACK PROJECT IN NORTHERN BC.

It will contract out for services it cannot directly provide.Part of the training will also involve work experience at

projects in Nisga’a communities.“Th e participants will be provided opportunities to apply

their newly-acquired skills, training and strategies in work that benefi ts the community while enhancing the experience and resume of the clients,” said Patsey.

Training planned so far includes fi rst aid/CPR, road safety and dealing with hazardous materials.

Nisga’a Lisims Government president Mitchell Stevens called the training program an important step toward economic development.

“Th e program adds to the capacity of our people to participate in the major developments that are coming soon to our region,” he said.

As it is, the Lisims government has signed a series of agreements with mining, pipeline and other companies providing business and employment opportunities on their projects. Th at list includes the Brucejack gold mine now under construction near Stewart by Pretivm Resources of Vancouver and TransCanada’s planned natural gas pipeline to feed the proposed Pacifi c Northwest LNG project on Lelu Island near Port Edward.

“The program adds to the capacity of our people.”

- Mitchell Stevens

12 13

The New ArrivalThe New Arrival

First Maersk vessel sails into Fairview TerminalFirst Maersk vessel sails into Fairview TerminalBy Shaun Th omas

It was a vessel not unlike the hundreds that have made their way into Fairview Terminal since it opened in 2007, but when the MSC Rania berthed at Fairview

Terminal on Oct. 1 it was seen as a major milestone.For the first time ever, the name Maersk appeared on a

ship in the harbour. But as the newest weekly call for the Prince Rupert terminal came, it is certainly not the last time the line will visit Prince Rupert.

The 2M Allice of Mediterranean Shipping Company and Maersk Line, a unit of Copenhagen-based A.P. Moller-Maersk Group, added the Port of Prince Rupert as the first North American port of call as part of its TP8

Transpacific Service.Prince Rupert Port Authority president and CEO

Don Krusel said the addition of the cargo service will only serve to support further growth and expansion for Fairview Terminal, which continues to see increased volumes.

“The addition of the 2M Alliance as a dedicated marine carrier service is another milestone in the unprecedented growth we’ve achieved at Fairview Container Terminal since it began operation in 2007,” he said.

“This new service is a validation of the advantages our port has brought to transpacific trade, and we look

forward to building relationships with MSC and Maersk — and the many new customers that will benefit from the supply chain solution offered through our gateway.”

The new shipping line arrived at the same time as a $200 million project is underway to increase the capacity of Fairview Terminal from 500,000 TEUs (twenty foot equivalent units) to 1.3 million TEUs.

Through to the end of September, Fairview Terminal had moved 592,152 TEUs compared to 457,132 TEUs during the first nine months of 2014. Imports through the terminal are up 23 per cent to sit at 330,888 TEUs, while exports are up 39 per cent to sit at 261,265 TEUs. As

with the year-over-year numbers, the number of loaded containers leaving Prince Rupert is down, falling from 120,325 TEUs to 114,342 TEUs so far this year.

“This new service is a validation of the advantages our port has brought to transpacifi c trade.”

- Don Krusel

14

Northwest British Columbia is perhaps as far away from the landscape of Mexico as you can get, but there are some similarities, at least

when it comes to building natural gas pipelines.For instance, the challenges of running a pipe up

the side of a mountain is the same in Canada as it is in Mexico.

It’s a challenge TransCanada has had to face, but it’s also one they’ve overcome.

To do so they follow a process that winter sport enthusiasts might recognize: a sort of ski lift-type contraption.

Of course it’s not actually a ski lift. The company uses a tower-based hoist system that can bring materials and pipe up the side of a steep mountain. Such a process not only saves time, but potentially saves lives.

Coastal GasLink project director Greg Cano says the process of using tower hoists is not new to the pipeline industry. TransCanada used the system when it built the

Tamazunchale Extension Pipeline Project in Mexico.It’s a process that’s used in Europe too, said Cano.“We have identified at least one place on Coastal

GasLink that we will be using this cable-crane system,” he said.

“Depending on which contractor we select, some of them have actually identified up to five additional areas where we could use a cable crane.”

The one sure place they plan to use this crane hoist system is the area where the pipeline comes back up out of the Kitimat River valley.

See Page 15

By Cameron Orr

TransCanada turns to new technology for Coastal GasLink

Hoisting the Hoisting the PIPELINEPIPELINE

“They do provide us a real advantage in safety and for us that is the absolute focus.”

- Greg Cano

Using the crane system not only makes the process safer, but is better for the environment.

“What that allows us to do is keep the right of way very narrow going up that steep slope down to the river valley. There will be very minimal disturbance on that long slope up out of the valley,” he said.

While the system in Mexico used three towers, Cano says Kitimat’s may be a five-tower system.

He said using the process in Mexico was a great template for other projects.

“It really showed its worth down there in increasing the safety and reducing the environmental footprint in these large, long hills. We intend to investigate it on all our projects where it makes sense,” he said.

“They do provide us a real advantage in safety and for us that is the absolute focus on this project. Especially in the steep slopes on the mountain.”

A ski-lift for pipelines isn’t the only novel approach to contrustrion the company has. River crossings may see approaches that have also been used in Mexico.

Cano said the typical standard of crossing under a river is through a process called horizontal directional drilling, which is well-used and is effective for larger crossings.

See Page 16

“In a lot of respects, we think it is a better process for

river crossings.”

- Greg Cano

s

16

But in some areas they’ll be investigating a different way.

“What we have done in the past is something called horizontal directional drilling, and in Canada that is very standard. What that is is they drill a small pilot hole first then they attach a bigger bit and make the hole larger ... so eventually you’ve got a fairly big open tunnel and then we pull the pipe through that,” said Cano.

An alternate system is to attach a drill bit to the end of the pipe itself and have the pipeline pushed through the hole as it’s drilled. That leaves no open hole during the process.

“In a lot of respects we think it is a better process for river crossings,” he said, adding it is very dependent on the type of geology and distance it has to cross.

Now, what does the company do post-construction?There are a few processes the company is either

investigating or planning to further improve on the line’s safety and efficiency.

One plan is to have a heat waste recovery power plant installed on their compressor stations.

For Coastal GasLink’s first phase they will have one compressor station and with a potential of two running turbines at their stations (with a third as a spare) they can generate potentially up to 10 megawatts of power.

Cano said about 10 per cent of that power can be used on the system itself while the remainder will feed

in to the provincial power grid.Meanwhile, on the safety, front the pipeline would

be monitored 24 hours a day, he said, with information either being fed by satellites in remote areas or through fibre optics and cellular services.

There is a regular maintenance schedule of the pipeline’s equipment and regular tests, and aerial patrols up to four times a year.

That could potentially increase if the company adopts the use of drones for monitoring too.

“We’re actually looking at the technology for pipeline surveys and pipeline patrols,” he said.

“If you don’t have to bring a helicopter up ... you can probably do that more often.”

The company is still eyeing a construction start date for 2016, should the LNG Canada project in Kitimat get the green light.

“Obviously it does rely on the final investment decision coming from our client, but our planning is still on that schedule,” he said.

“We’re actually looking at the technology for pipeline

surveys and pipeline patrols.”

- Greg Cano

Piping & Plumbing Structural Steel & Fabrication Flat Roofing

Sheet Metal & CladdingMachining

Metal WorkingMillwrighting

245 - 3rd St. KitimatTel. 250-632-6859

Toll Free 1•877•632•6859 [email protected]

www.101industries.com

EXPERTS IN

COMMERCIAL - INDUSTRIAL - RESIDENTIAL

Quality Through Craftsmanship

Serving the Northwest for Over 47 years

PRINCE RUPERT’S OWN AIRLINEPROUDLY SERVING THE NORTH

COAST SAFELY SINCE 1981

DAILY SCHEDULED SERVICE TO MASSET AND SURROUNDING

COMMUNITIES

WHEN EXPERIENCE COUNTSFLY WITH INLAND AIR

Prince Rupert: 250-624-2577 • Queen Charlotte: 250-559-4222Masset: 250-626-3225 • Toll Free: 1-888-624-2577

www.inlandair.bc.ca

16

37

37

16

97

Granisle

New Hazelton

Hazelton

Cranberry Junction

Port Edward

HudsoHope

Prince Rupert Gas Transmission

ALA

SKA

Fort St. James

Mackenzie

Tumbl

Prince GeorgeVanderhoofFraser Lake

Burns Lake

SmithersTelkwa

Houston

Terrace

Kitimat

Prince Rupert

Chetwynd

orrrortrtrtt EEEEdwdwdwd ara d

FrFrFrFrFrFrFrFrraaaasasasasasasasasasasasassssssereeerererererrrrrrrreeeee LLLLLLLLLLLLLLLakakakakkkkkkkkkkkkkeeeeeeeeeeeFFFrraa asssssseeaaaaaaaaa eee

Burnrnnssss LaL kekeLakKiKiKiKitititititimammmm tttFindingFinding SupportSupportT

he Prince Rupert Gas Transmission Project, a TransCanada pipeline that would bring liquefi ed natural gas from Northeastern B.C. to Pacifi c

NorthWest LNG’s Lelu Island terminal, has been fi nding major backing in the past few months.

On Sept. 29, councillors in the City of Terrace voted to write a letter of support for the pipeline and the terminal.

“It’s a wholesale endorsement. You can’t have a pipeline if you’re not going to have an upstream and downstream. It wouldn’t make sense to support just a pipeline,” said

Mayor Carol Leclerc.Th e next day, the company announced it had reached a

project agreement with the Metlakatla First Nation. “We are confi dent that TransCanada will work diligently to

ensure our way of life and the environment, and in particular Lelu Island, will not be negatively aff ected by the project,” said Chief Harold Leighton.

Finally, on Oct. 7, the District of Port Edward sent a letter signed by Mayor Dave MacDonald expressing their support of the project.

By Shaun Th omas

18

Lake Babine Nation (LBN) is betting on the construction of a biomass plant to provide clean energy to its members and create a steady revenue stream.

Expected to be on the grid by 2017, the biomass plant will burn wood chips to sell heat to government organizations, private homes in Woyenne and community buildings in Fort Babine.

Chief Wilf Adam said negotiations are still taking place and it is still undetermined how much revenue the plant will generate for LBN once completed.

The project’s phase one, which is still ongoing, includes an engineering feasibility study, engineering design, crew training and work experience for the firewood program.

During phase one, seven local First Nations people received on-the-job training through a government-funded program. During the 47-week program, which wrapped up in June 2015, participants built 67 firewood storage sheds for LBN in Tachet and Fort Babine, as well as two timber bridges.

Lake Babine Nation’s biomass project manager, Bernard Patrick, said this job creation partnership has impacted the community “in positive ways,” saying the seven locals received “fantastic job experience”.

Chief Adam said he is still unsure how long phase one will take.

Phase two will include the construction of an underground distribution system in Fort Babine, a community of approximately 200 members.

See Page 19

“Investing in First Nations clean energy ... supports First Nations to achieve economic

self-suffi ciency.”- John Rustad

By Flavio Nienow

Lake Babine Nation turns its attention to clean energy

Phase 3 of the construction project, which is expected to wrap up in 2017, will see the construction of an energy centre in Woyenee, as well as a business set-up and operation training.

Once completed, the biomass plant is expected to create five full-time and eight part-time permanent jobs.

John Rustad, Minister of Aboriginal Relations and Reconciliation, said the provincial government is “very supportive” of First Nations exploring energy options for their communities.

“Investing in First Nations clean-energy projects and capacity building supports First Nations to achieve economic self-sufficiency,” said Rustad.

The province provided $40,000 to LBN for a feasibility study for the project in 2013, and more than $110,000 for the skills training program.

According to the provincial government, biomass resources in B.C. provide cheaper and more sustainable energy to remote communities.

The province has committed itself to maintain a share of at least 90 per cent of its electricity generation from clean and renewable energy sources, and to mandate that all new facilities will have net zero greenhouse gas emissions. Biomass, as a carbon neutral renewable resource, can make a major contribution towards this goal.

The ministry of forests, lands and natural resource operations estimates Northern B.C. has the

largest availability of wood biomass in the country, with approximately 3.1 million cubic meters of potential forest tenure available for use as biomass for energy.

Alora S. Griffin Phone: (250)627-1777 Architect AIBC, MRAIC, LEED AP Email: [email protected] 983, Prince Rupert, BC, V8J 4B7 Website: aloragriffinarchitect.ca

We specialize in sustainable site, building & interior design, heritage restoration & project management.

alora griffin architect

Custom Homes Town Houses Condos Float Homes

Commercial Industrial Cultural Recreational

20

They are tasked with maintaining the only endangered salmon stock in the Northwest watershed, but Toboggan Creek Fish Hatchery’s place near the

farming community of Evelyn goes beyond conservation measures.

Th e hatchery is managed by community members from the area near Smithers through the Toboggan Creek Salmon and Steelhead Enhancement Society on a contract from the Department of Fisheries and Oceans Canada (DFO). Now celebrating their 30th year of operation, the hatchery has outlived most other local-based facilities in the region.

“One of the best things about the community hatcheries is you are working at arms length in your community, for your community,” said manager Mike O’Neill, a Smithereen who has been with the operation since it began in 1985.

With static funding for their work, the hatchery has had to scale back the numbers they raise to just 50,000 fry compared to 150,000 at its peak. But their work to enhance Chinook stocks on the Upper-Bulkley River and record data on Toboggan Creek Coho for almost 30 years has made them indispensable.

Bulkley Chinook have adapted to survive the warmer waters of the river, which has little mountain run-off , and that has made them an exceptional species to the DFO.

“Th ey’ve adapted [to the freshwater environment] and it shows in their DNA – their DNA is not similar to any other Chinook stock in British Columbia,” explained O’Neill.

“And that’s why we have to make sure that some of them are still around because, being from a warm water watershed, over time if we continue to see warming trends then this may be one of the only stocks that can withstand that.”

Toboggan Creek Coho are a self sustaining species, but the small hatchery has managed to make room in the budget to focus on the fi sh and provide federal authorities with a good picture of the health of the watershed.

“For the Toboggan Coho it is more for science, to learn about timing and harvest and exploitation – we count every fi sh back,” said O’Neill.

“In this day in age, to have almost 30 years of continuous data that’s pretty rare, there’s not many facilities that survive that long.”

To fund these endeavours, the DFO’s Stock Assessment Division has backed trapping and sampling of Coho stock at the hatchery’s “fence” in Toboggan Creek.

“Assessment is probably the most important aspect of fi sheries management,” O’Neill explained.

By Cecile Favron

Smithers’ Tobbogan Creek Hatchery sustains the stocks

“To have almost 30 years of continuous data, that is

pretty rare.”

- Mike O’Neill

Saving NorthwestSaving Northwest

SALMONSALMON

Th e realization of the community’s gem began when the government built the facility in the 1980s and then looked to contract out the running of the operation. Involved members in Evelyn stepped up to become board directors – many of them not previously knowing about hatching fi sh.

But they quickly came to understand the conservation measures as well as the economic benefi ts of managing the resource well. Today’s board is down to only seven members, some from neighbouring Smithers, and O’Neill said they are looking to get more young people involved.

Th e mention of Steelhead in the society’s name stems from the provincial government’s early stake in the project to determine the cause of low Steelhead returns.

“We used to raise hundreds of thousands of Steelhead fry,” explained O’Neill.

“But I think over time [the provincial government] realized that there wasn’t a problem with Steelhead – it was that anglers were killing virtually every Steelhead that they caught and that drove the numbers down. So then [the province] backed out of it, now we concentrate on salmon,” he said.

Th e exploitation factor in a species decline is something that Toboggan Creek Hatchery helps the DFO measure in other species now.

Each fi sh leaving their facility is tagged with a tiny code embedded in their head and the adipose fi n is clipped. Fisheries and fi shermen then turn in the fi sh heads so that DFO can determine how many fi sh are caught along their journey to spawn which starts off the coast of Alaska. It also helps determine more broadly how well the stocks are doing.

“Right now Chinook is in a bit of a down-cycle, this year looks better but the previous fi ve we were in quite a low cycle and Coho on the other hand are on a high cycle,” O’Neill explained from the data complied by the DFO.

Th e hatchery brings in student and community help through paid positions to manage the tagging and releasing of fi sh and also the counting of fi sh as they return to spawn near the end of the summer.

Each year the egg-take happens over that period and the eggs are fertilized and then incubated in the controlled environment of the hatchery over the winter months, which leads to higher survival rates over wild-rearing. Once out of incubation, the fi sh are kept inside for fi ve months and then moved outside in May to a channel in Toboggan Creek until they reach smolt size and are ready to head to the ocean.

Th e whole process takes approximately 18 months and has kept tourists captivated over the years.

“I don’t know how many thousands of people we’ve had through here over the years,” O’Neill laughed.

“Th ey’ve got a lot of positive feedback because people like to see their tax dollars spent in something that they can actually see the benefi ts. It’s quite rewarding to release a coho, like the ones we released this May; they’ll be back going through our counting fence in August of next year.”

22

Heavy Equipment OperatorsStart date: ImmediatelyExperienced Heavy Equipment Operators required for high-quality camp. We offer excellent Pay Rate. Location in Northern BC, working 12 hour days on a 15 day in rotation and a 14 day off.Your return transportation to camp will be provided from Hazelton, Kitwanga, Smithers, or Terrace. We are looking for experienced Heavy Equipment Operators for: Excavator, Dozer, Grader, Loader and Rock Truck Drivers.The nature of camp work requires that this person have excellent interpersonal skills, handle stress well, and be able to live and work as a member of a team.Minimum requirements:

Experience is a must, minimum of two yearsExperience in other areas of Heavy Equipment would be an asset Excellent communication skills, able to follow directions and provide assistance as needed Self-motivated and able to work independently while maintaining high stan-dards of service

Daily Functions:Ensures that the “Trucking Operations” are run with the attitude that we are here to provide “service” for our customersOperates the vehicle in a safe and economical manner to insure the lowest possible operational and maintenance costMaintains current DOT personnel records with the Administrative AssistantAlerts Equipment Maintenance Manager of any needed repairs and their priorityShow a willingness to learn job site goals and company wide goalsPerform any other related duties as may be required

Please Email your applications toGeorge & Darlene Simpson: [email protected]

Fax: George & Darlene: 250-842-5615

Two construction projects in October have pushed the value of Terrace building permits issued to date to more than $50 million, a 10-year record.

One is the first phase of a large multi-family residential development on the bench now breaking ground and the other is an addition and renovation of a business on Park Ave. downtown.

Seven townhomes in two duplexes and one triplex now under construction by Vancouver developer SwissReal carry a value of $1.4 million while an expansion to Park Ave. Optometry has a value of $1 million.

The permit value of more than $50 million is more than double last year’s total for the same time period and triple the 10-year average of just under $16 million.

In terms of commercial construction building permit values this year, the Sunshine Inn development

adjacent to city hall tops the list at $15.041 million followed by a warehouse expansion at Bandstra Transportation amounting to $1.3 million, the Great Canadian Oil Change project at $709,000 and a $200,00 project for the Andrew Sheret plumbing and heating business.

The Northwest Regional Airport expansion project valued at $15.709 million comes under the institutional construction category.

As of the end of August, 24 permits for single residential construction were issued for a total value of $5.914 million.

In addition to the Sunshine Inn development, a second hotel past Canadian Tire heading west along Hwy16, a Comfort Inn, is also under construction.

Its building permit of approximately $10 million was issued in the fall of 2014.

By Rod Link

Terrace sees building permits top $50 million

The Prince Rupert Northern View, Northern Connector, N2K and North Coast Outdoors is now accepting resumés for a full-time journalist/photographer.The Northern View is an award-winning newspaper and publication company situated in Prince Rupert, B.C. on the beautiful shores of the Pacifi c Ocean. Prince Rupert is a city now fi rmly in the national spotlight because of its blossoming world-class deep harbour import/export port facility, LNG proposals and its long-standing, incredible tourism opportunities. Qualifi cations: Independent, self-starter; Superior writing and strong news judgment; A degree or diploma in journalism or related experience; Willingness to adapt to new trends in online reporting and publications; Demonstrated experience in desktop layout programs, such as Adobe InDesign; Above all things, a team-player.We require all applicants to have a valid driver’s licence and own a reliable vehicle. This position requires evening and weekend work. Salary is commensurate with experience. Please send resumés, cover letters, clippings, portfolios — something to get our attention — BY EMAIL ONLY, phone calls will not be accepted.

Todd Hamilton, publisher, N2K & Prince Rupert Northern ViewE-mail: [email protected]

Web address: http://www.thenorthernview.com

PRINCE RUPERT

Trade is building stronger communities.The Port of Prince Rupert is growing opportunities and prosperity by connecting the communities of northern BC.

Last year, port activity was directly responsible for the equivalent of 3,060 permanent full-time jobs. Watch and

share our video tribute to the workers and families of BC’s gateway industry: youtube.com/rupertport.

rupertport.com | @rupertport