MSRP-I04

-

Upload

daniel-morales-vargas -

Category

Documents

-

view

38 -

download

0

Transcript of MSRP-I04

Association of American Railroads

MANUAL OF STANDARDSAND

RECOMMENDED PRACTICESSECTION I

SAFETY AND OPERATIONS

INTERMODAL EQUIPMENT MANUAL

Published by

The Association of American Railroads50 F Street, N.W., Washington, D.C. 20001-1564

© Copyright Association of American Railroads

Printed in U.S.A.

ISSUE OF 2004Effective February 1, 2004

Compiled under the direction of the Committees responsible for the subjects shown herein.

(See copyright statement next page)

2/1/04

Copyright © 2004 by the Association of American Railroads (AAR)Safety and Operations

50 F Street, N.W.Washington, D.C. 20001-1564

All rights reserved, including the right to reproduce this book in any form. It is the AAR’s intention that this publication be used to pro-mote the objectives of the AAR and its members for the safe, efficient, and uniform interchange of rail equipment in North America. To this end, only excerpts of a rule or specification may be reproduced by the purchaser for their own use in promoting this objective. No portion of this publication may be displayed or otherwise made available to multiple users through any electronic distribution media including but not limited to a local area network or the Internet. No portion may be sold or used for advertisement or gain by any entity other than the AAR and its authorized distributor(s) without written permission from the AAR.

2/1/04

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual2/1/04

Part 1

ORDERING INFORMATIONCopies of the various sections of this manual can be obtained as follows:

ORDERS FORPUBLICATIONS

Publications DepartmentTransportation Technology Center, Inc.P.O. Box 1113055500 DOT RoadPueblo, CO 81001Email: [email protected]: Toll-free 877-999-8824, Direct 719-584-0538Fax: 719-584-7157TTCI Web page: www.ttci.aar.com

CIRCULARLETTERSUBSCRIPTIONS

Subscriptions to Circular Letters of the AAR Safety and Operations’ Technical Services are available in hardcopy or electronic format (online access via AAR’s Web page at www.aar.org). Circulars are issued at least monthly and include industry letter ballots and results, arbitration decisions, notification of rules and standards revisions, industry early warning and maintenance advisories, and other information related to mechanical rules and standards. Annual subscriptions commence on July 1 and terminate on June 30 of each year.For ordering information, contact the following:Phone: Toll-free 877-999-8824, Direct 719-584-0538Fax: 719-584-7157Email: [email protected] Web page: www.aar.orgTTCI Web page: www.ttci.aar.com

TECHNICALQUESTIONS

For technical questions regarding this manual, contact the following:Technical Committee CoordinatorTransportation Technology Center, Inc.P.O. Box 1113055500 DOT RoadPueblo, CO 81001Email: [email protected]: 719-585-1880Fax: 719-585-1895

2/1/04 I–i

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual2/1/04

THIS PAGE LEFT BLANK INTENTIONALLY

I–ii 2/1/04

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual2/1/04

TO THE USERSection I—Intermodal Equipment Manual, Manual of Standards and Recommended Practices,

Association of American Railroads (AAR), covers many aspects of intermodal systems. There arestandards, specifications, and requirements for containers; chassis and trailers; trailer hitches andhitch lubrication; and intermodal cars. In addition, there is a standard operating procedure (SOP)that includes procedures for securement practices, inspections, reporting, and corrective actions.

USER’S GUIDE

Section I consists of the following:• Preface: a listing of the subjects covered in all sections (the volumes making up this man-

ual). This preface is part of each section.• Table of Contents in Alphabetical Sequence: a generalized subject listing that indi-

cates applicable specifications, standards, and recommended practices.• Table of Contents in Numerical Sequence: a listing of the specifications (M prefix),

standards (S prefix), and recommended practices (RP prefix).• Specifications, Standards, and Recommended Practices: the body of this volume

deals specifically with designation of intermodal service freight cars, containers, trailers, and securement systems.

• Appendix A: Revised Page Dates: the latest revision date of each page in Section I.

RELATED SECTIONS

Section I—Intermodal Equipment Manual, can be considered to stand alone. Other sectionsand the AAR Interchange Rules may require that components be stencilled with inspection and/orperiodic maintenance data.

RESPONSIBILITY

The coverage of Section I—Intermodal Equipment Manual, is the responsibility of the AAR In-termodal Committee, unless otherwise specified.

2/1/04 I–iii

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual2/1/04

PREFACEThe Manual of Standards and Recommended Practices of the Technical Services Division, As-

sociation of American Railroads, is issued by authority of the Management Committee of the Divi-sion and includes all regularly adopted specifications, standards, and recommended practices of theAssociation of American Railroads.

The manual is composed of the following sections:• Section A, Part I—Table of Contents, Alphabetical and Numerical Index of Sections A

through N inclusive• Section A, Part II—Miscellaneous Specifications, Standards (010 Series), and Recom-

mended Practices (010 Series)• Section A, Part III—Vacant• Section B—Couplers and Freight Car Draft Components (100 Series)• Section C—Car Construction—Fundamentals and Details (200 and 2000 Series)• Section C, Part II, Volume 1—Specifications for Design, Fabrication, and Construction of

Freight Cars, M-1001• Section C, Part II, Volume 2—Appendices M-1001• Section C, Part III—Specifications for Tank Cars, M-1002• Section D—Trucks and Truck Details (300 and 3000 Series)• Section D, Part II—Code for Designating Design Features for Side Frames and Truck Bol-

sters (300 and 3000 Series)• Section E—Brakes and Brake Equipment (400 and 4000 Series)• Section E, Part II—Electronically Controlled Brake Systems• Section F—Vacant• Section G—Wheels and Axles (600 Series)• Section G, Part II—Wheel and Axle (Shop) Manual (600 Series)• Section H—Journal Bearings and Lubrication (700 Series)• Section H, Part II—Roller Bearing (Shop) Manual (700 Series)• Section H, Part III—Lubrication (Shop) Manual (700 Series)• Section I—Intermodal Equipment Manual• Section J—Specification for Quality Assurance, M-1003• Section K—Railway Electronics• Section K, Part II—Railway Communications• Section L—Lettering and Marking of Cars (900 Series)• Section M—Locomotives and Locomotive Equipment• Section N—Multi-Level ManualSpecifications are designated with an “M” prefix (e.g., M-900). Standards are prefixed “S” (e.g.,

S-900). Recommended Practices carry the prefix “RP”( e.g., RP-900). The prefix “S” or “RP” will befollowed by a three- or four-digit number. The first digit, 0 through 9, indicates the section in whichthe standard or recommended practice can be found, as shown in parentheses above.

I–iv 2/1/04

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual2/1/04

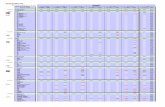

TABLE OF CONTENTS INALPHABETICAL SEQUENCE

Subject Standard PageBad Order Device for Identification of Defective Hitches . . . . . . . . . . . . . . . . . . . . M-985 I–167Car Owner’s Manual for the Inspection and Maintenance of Double-Stack Container Cars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RP-899 I–175Closed Van Containers for Domestic Intermodal Service . . . . . . . . . . . . . . . . . . . . M-930 I–17Double-Stack Container Cars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RP-851 I–169Grease for Lubrication of Trailer Hitches on Flatcars. . . . . . . . . . . . . . . . . . . . . . . M-929 I–15Highway Trailer Hitches for Freight Cars with 90,000-lb Maximum Gross vehicle Weight Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-928A I–8Highway Trailer Hitches for Freight Cars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-928 I–1Intermodal Container Support and Securement System for Freight Cars. . . . . . . M-952 I–153Intermodal Equipment Cars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RP-852 I–172Remanufacture of TOFC Trailers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-962 I–161Standard Operating Procedures for Intermodal Securement . . . . . . . . . . . . . . . . . SOP I–195TOFC Portable Bridge Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-966 I–164Trailers for Intermodal Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-931 I–71

2/1/04 I–v

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual2/1/04

TABLE OF CONTENTS INNUMERICAL SEQUENCE

Standard Subject PageM-928 Highway Trailer Hitches for Freight Cars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–1M-928A Highway Trailer Hitches for Freight Cars with 90,000-lb Maximum Gross vehicle

Weight Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–8M-929 Grease for Lubrication of Trailer Hitches on Flatcars . . . . . . . . . . . . . . . . . . . . . . I–15M-930 Closed Van Containers for Domestic Intermodal Service . . . . . . . . . . . . . . . . . . . I–17M-931 Trailers for Intermodal Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–71M-952 Intermodal Container Support and Securement System for Freight Cars . . . . . . I–153M-962 Remanufacture of TOFC Trailers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–161M-966 TOFC Portable Bridge Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–164M-985 Bad Order Device for Identification of Defective Hitches . . . . . . . . . . . . . . . . . . . I–167RP-851 Double-Stack Container Cars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–169RP-852 Intermodal Equipment Cars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–172RP-899 Car Owner’s Manual for the Inspection and Maintenance of Double-Stack

Container Cars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–175SOP Standard Operating Procedures for Intermodal Securement . . . . . . . . . . . . . . . . I–195

I–vi 2/1/04

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-9282/1/04

HIGHWAY TRAILER HITCHES FOR FREIGHT CARS

SpecificationM-928

Adopted: 1969; Revised: 1987, 2004

1.0 SCOPE

1.1 This specification became effective January 1, 1988.

1.2 This specification covers the mechanical characteristics, structural adequacy, and testingrequirements of highway semitrailer hitches of 65,000-lb maximum gross vehicle weight capacitythat will be approved for application to freight cars. This specification also applies to new hitchdesigns put into service after the effective date of the specification.

1.3 The means by which a highway trailer is secured to a freight car will not subject the hitchstructure or the trailer kingpin to a longitudinal force greater than 240,000 lb at any impact speedup to and including 10 mph.

2.0 CONSTRUCTIONHitches shall be built to include all items necessary to satisfy the functional requirements of thisspecification and to provide efficient operation, even if some details are not mentioned in this spec-ification.

2.1 A lock must be provided that prevents a hitch’s trailer-retaining feature from losing its gripon the kingpin until unloading operations are put into motion.

2.2 Each lock that is essential to securing the hitch in an upright position and to securing thetrailer to the hitch must indicate, by visual inspection from the ground and from both sides of thecar, if and when the locking mechanism is positively locked and the kingpin is properly seated inthe kingpin-retaining mechanism.

2.3 The kingpin-retaining mechanism, whether manually or automatically operated, must be of adesign that can be manually unlocked and can remain in the unlocked position until the next load-ing operations are put into motion.

2.4 The kingpin-retaining mechanism must be specifically designed for use with the standardconfigurations of the trailer kingpin, S.A.E. J700, and must engage a minimum of 50% of the avail-able area of the top surface of the kingpin collar. The mechanism must be capable of pulling aloaded trailer, with its pneumatic or mechanical brakes applied, into the locked position whererequired by the kingpin-retaining mechanism design.

2.5 Lateral and longitudinal loads shall be applied to the major diameter of the kingpin as closeto the base of the trailer as possible.

2.6 The hitch’s trailer-support member must provide adequate bearing, 550 in.2 minimum, to pre-vent damage to the trailer during transit and loading/unloading operations. The top of the hitch’strailer-support member must be flat for a minimum width of 23.5 in. The top of the trailer-supportmember must be flat within ±1/16 in. over the entire bearing area.

2.7 Cushioned hitches must be designed so as to return a trailer, having its parking brakesapplied, to the hitch-neutral position within a tolerance of ±10% of the fore and aft hitch-headtravel.

2.8 The height of a trailer-support member’s top surface shall be 47 in. ±3/8 in. above the tirerunway surface, measured vertically at each side of the trailer-support member with the hitchlocked upright. The trailer support member’s top surface shall be level within ±1/8 in. above a flat

2/1/04 I–1

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-9282/1/04

level base plate measured vertically at each side of the trailer support member with the hitchlocked upright.

2.9 All pins that connect structural members must be provided with plate retainers welded to thestructural members.

2.10 The trailer hitch kingpin locking jaws will have a hardness of 330–370 BHN.

3.0 TEST CONDITIONSThe hitch must withstand test loads without damage to any part of the hitch. For this purpose,damage will be defined as any permanent deformation, unless specifically defined, or any condi-tion that prevents continued service of the hitch. Damage will be determined by visual inspectionand by operation with a loaded trailer.

3.1 Impact Test

3.1.1 Hitches with built-in cushioning must not exceed 240,000 lb of kingpin force at any impactspeed up to and including 10 mph when tested on a car equipped with standard draft gear. Hitcheswithout built-in cushioning must meet the requirements of this specification when tested on a carwith car body cushioning that provides a kingpin force not exceeding 240,000 lb at a 10-mphimpact.

3.1.2 Hitch cushioning must be qualified on each type of car on which the hitch is intended to beapplied.

3.1.2.1 The hitch manufacturer shall furnish for inspection and evaluation of the hitch applica-tion and for impact test purposes the car complete with the hitch installed in accordance with theproduction application design.

3.1.2.2 In the case of cars having multitrailer capability, a hitch must be installed at each trailerlocation.

3.1.3 The car equipped with hitches under test shall be the hammer car (moving car). Unless thecar is equipped with a cushioning device (other than standard draft gear) that is considered part ofthe cushioning system, it is to be equipped with 24 5/8-in. standard pocket draft gears that are ingood condition and that meet AAR Specification M-901E.

3.1.4 The anvil (standing cars) shall consist of three nominal 70-ton-capacity open top cars, eachloaded with sand or other granular material to a minimum gross rail weight of 220,000 lb. Thehandbrake is to be set tightly on the third (non-struck) car in the string. Free slack between cars isto be removed without compressing the draft gears. No restraint other than the handbrakes on thelast car is to be used. All anvil cars are to be equipped with AAR standard draft gears meetingAAR Manual of Standards and Recommended Practices, Section B, Specification M-901E.

3.1.5 The test car shall be loaded with a trailer at all hitch locations. Trailers must comply withAAR Manual of Standards and Recommended Practices, Section C, Part II, Specification M-1001,paragraph 4.1.3.4.1 (for 40-ft trailers). Trailer lading shall be of a rigid material such as concreteblocks or steel billets rigidly secured to the trailer body. Trailer service brakes shall be released(which automatically applies the parking brake). The test car is to be impacted into the anvil carsat speeds of 4, 6, 8, and 10 mph (in this order) in both directions. Additional impacts may be madeat the option and expense of the manufacturer. (See “Design and Test Requirements for Trailer/Container Transport Cars” in MSRP Specification M-1001 for coupler force requirements at10 mph.)

3.2 Static Tests

3.2.1 Static tests shall be performed on one hitch, applied either to the test car or to a test standin a manner representative of an average commercial application.

I–2 2/1/04

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-9282/1/04

3.2.2 A vertical downward load of 54,000 lb shall be applied to the support member of the hitchfor a period of at least 1 minute.

3.2.3 A lateral load of 27,000 lb shall be applied to the hitch on a plane with and through thekingpin in position. This loading shall be applied for at least 1 minute.

3.2.4 A vertical downward loading of 150,000 lb must be applied to the kingpin collar by a jackingbeam arrangement that will simultaneously apply a vertical reaction force at one side of thetrailer support member. The jacking beam arrangement and the jacking force must develop theminimum 150,000-lb force on one side of the kingpin collar. This loading shall be applied for aduration of at least 10 minutes. For hitches having nonsymmetrical securement to the kingpin,this test must be performed on both sides of the hitch.Angular rotation between the top surface of the hitch support member and the jacking beam mustnot exceed 5° during this test. Upon completion of the test, any permanent deformation of thehitch’s trailer support member that exceeds 1/8 in. will be considered a failure.

4.0 INSTRUMENTATION

4.1 All instrumentation must comply with the AAR Manual of Standards and RecommendedPractices, Section B, Specification M-901F, and must be approved by the Transportation Technol-ogy Center, Inc., prior to testing.

4.2 During static tests, only the applied loads shall be measured.

4.3 During impact tests, the impact velocity and the longitudinal horizontal kingpin force shallbe measured during each impact and at both kingpins.

5.0 SERVICE PERFORMANCEA conditional Certificate of Approval shall carry a stipulation limiting the number of applicationsto 3,000 hitches that may be placed in service during the first 2 years. During the time the certifi-cate is conditional, a record of all service failures shall be reported semiannually to the Manager—Intermodal Committee. After the expiration of the 2-year service period, at least 10 hitches mustbe inspected by representatives designated by the AAR. If the condition of the hitches on thesecars is satisfactory, an unconditional Certificate of Approval may be granted.

2/1/04 I–3

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

APPENDIX A M-9282/1/04

APPENDIX AINSTRUCTIONS REGARDING THE APPLICATION FOR CERTIFICATE OF

APPROVALThe following instructions will govern the Intermodal Car Performance Subcommittee’s applica-tion and approval of highway semitrailer hitches for freight cars.

1.0 The manufacturer is to make application to the Chief—Technical Standards, TransportationTechnology Center, Inc., 55500 DOT Road, P.O. Box 11130, Pueblo, CO 81001.

2.0 A separate application shall be made for each different type of hitch for which approval isdesired.

3.0 Each application shall be accompanied by four sets of drawings that provide the followinginformation:

3.1 Drawings shall show the general arrangement, overall dimensions, and type of materials forthe hitch and the installation of the device to the actual car submitted for the test.

3.2 In the case of the car construction, drawings shall show details of the hitch’s supportingstructure and parts that house the hitch as to design, material used, and tolerances provided for.

3.3 Twenty additional sets of the application and general arrangement drawings shall be fur-nished for distribution to the members of the Committee.

4.0 All tests of hitches must be made at an approved test site. The manufacturer’s facility may beapproved by the AAR if it contains facilities for meeting all test requirements.

5.0 The AAR shall provide an official observer when the hitch is tested in accordance withparagraph 3.0 of this specification. Upon completion of individual impacts made in accordancewith paragraph 3.0, the official observer shall be provided with data as outlined in paragraphs 4.2and 4.3 of this specification. These data shall be considered tentative until such time as they arechecked and a final report on the tests is made. Charges covering the time and expenses of theofficial observer will be rendered to the manufacturer.

6.0 The manufacturer’s representative may discontinue the test at any time and withdraw themanufacturer’s device if desired.

7.0 Representatives of any other hitch manufacturer will not be permitted to be present duringthe tests except by permission of the manufacturer of the device under test.

8.0 No exemptions to these specifications will be made unless presented in writing and approvedby action of the Committee prior to any testing under the specification.

9.0 Following completion of all tests as required by paragraph 3.0 of this specification, themanufacturer shall submit four copies of the test data to the Intermodal Car PerformanceSubcommittee. A report will be issued by the Intermodal Car Performance Subcommittee andshall contain all required test data and copies of oscillogram records showing the kingpin forcesmeasured during the impact tests as required under paragraph 3.0 of this specification. Copies ofthe AAR report shall be distributed to the Committee.

10.0 A conditional Certificate of Approval will be issued after all the requirements of thisspecification have been met as evidenced by the report of the Intermodal Car PerformanceSubcommittee and after the concurrence of the Committee.

11.0 Unconditional approval will be issued by the Committee in accordance with paragraph 5.0 ofthis specification.

12.0 After a conditional Certificate of Approval is issued, if a manufacturer desires to make anychanges that significantly affect the cushioning, structural adequacy, or trailer securementfeatures of the hitch or if a change is made in identifying specifications for the purpose of

I–4 2/1/04

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

APPENDIX AM-9282/1/04

clarification or correction, the Intermodal Car Performance Subcommittee shall be advised. TheCommittee will decide in each case what action is to be taken on these changes.

13.0 At its own expense, the Committee may make complete specification tests of an averagecommercial installation of a hitch in order to establish that standards are being maintained.Failure to pass this test may cause revocation of the manufacturer’s certificate at the discretion ofthe Committee. The test shall be conducted at an AAR test site or the manufacturer’s facility. Themanufacturer shall make its facility available to the AAR upon request or shall waive therestriction of conducting tests only at an AAR test site or the manufacturer’s facility.

14.0 After a Certificate of Unconditional Approval has been granted for a design of a hitch, theCommittee may, at any time, check the service performance of any device of this type. Evidence ofunsatisfactory performance or discovery of undesirable conditions may cause revocation of thecertificate at the discretion of the Committee.

15.0 Manufacturers shall advise the Manager—Intermodal Car Performance Subcommittee of allsales of hitches during the 2 years following the issuance of a conditional Certificate of Approval.These reports must be submitted every 6 months.

16.0 Use of a certified noncushioned hitch must be limited to cars having car body cushioningequal to or better than the cushioning utilized on the test car at the time of certification.

17.0 A change in car weight of more than 7.5% will require reapplication and retest. Otherchanges in car design will be reviewed on an individual basis.

2/1/04 I–5

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

APPENDIX B M-9282/1/04

APPENDIX BTRACTOR DIMENSIONS AND CLEARANCE ENVELOPE FOR FLATCARS

Fig. B.1 Recommended tractor dimensions for use with tractor-operated hitches

Fig. B.2 Trailer clearance envelope for flatcars

I–6 2/1/04

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

APPENDIX CM-9282/1/04

APPENDIX CAPPROVED CUSHION UNITS

The following cushion units are approved for the indicated car/hitch combinations:

Cushion Unit Type of Hitch Approved Type of CarKeystone 6-in. unit

Part No. 9976ACF 5C 89-ft flatcar

Keystone 8-in. unitPart No. 10929

ACF 5C Santa Fe modifieda/ flatcar from boxcar

a/ Pending car approval by the Equipment Engineering Committee

Miner TCU-40 ACF 5C Single platform flatcarMiner TCU-5 ACF 5C 89-ft flatcarOleo WX-2269 (HC-506) ACF 5C 89-ft flatcarOleo WX-2063 (HC-508) ACF 5C 89-ft flatcarOleo Wx-2202 (HC-908F) ACF 6H TG Railway modified flatcar from boxcarOleo WX-2202 (HC-908F) ACF 5C Santa Fe modifieda/ flatcar from boxcarOleo WX-2569 (HC-906S) ACF 5C 89-ft flatcar

2/1/04 I–7

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-928A2/1/04

HIGHWAY TRAILER HITCHES FOR FREIGHT CARS WITH 90,000-LB MAXIMUM GROSS VEHICLE WEIGHT CAPACITY

SpecificationM-928A

Adopted: 2003

1.0 SCOPE

1.1 This specification became effective September 1, 2003.

1.2 This specification covers the mechanical characteristics, structural adequacy, and testingrequirements of highway trailer hitches of 90,000-lb maximum gross vehicle weight capacity(MGVWC) that will be approved for application to both free/unrestricted interchange and con-trolled/restricted interchange freight cars. This specification also applies to new hitch designs putinto service after the effective date of the specification.

1.3 It is the intent under this specification that the securement means of a highway trailer to afreight car will not subject the hitch structure or the trailer kingpin to a longitudinal force greaterthat 240,000 lb. For free/unrestricted interchange freight cars, any impact speed up to and includ-ing 10 mph must not exceed the 240,000-lb maximum longitudinal kingpin force. For controlled/restricted interchange freight cars, the 240,000-lb maximum longitudinal force is validatedthrough a static test.

2.0 CONSTRUCTIONHitches shall be built to include all items necessary to satisfy the functional requirements of thisspecification and to provide efficient operation, even if some details are not mentioned in this spec-ification.

2.1 A lock must be provided that prevents a hitch’s trailer-retaining feature from losing its gripon the kingpin until unloading operations are put into motion.

2.2 Each locking mechanism that is essential to securing the hitch in an upright position and tosecuring the trailer to the hitch must indicate, by visual inspection from the ground and from bothsides of the car, when the locking mechanism is positively locked and the kingpin is properlyseated in the kingpin-retaining mechanism. The standard convention is to have the yellow button(barrel) extend beyond the hitch when unlocked and retracted flush or slightly recessed whenlocked.

2.3 The kingpin-retaining mechanism, whether manually or automatically operated, must be of adesign that can be manually unlocked and can remain in the unlocked position until the next load-ing operations are put into motion.

2.4 The kingpin-retaining mechanism must be specifically designed for use with the standardconfigurations of the trailer kingpin, S.A.E. J700, and must engage a minimum of 50% of the avail-able area of the top surface of the kingpin collar. The mechanism must be capable of pulling aloaded trailer, with its pneumatic or mechanical brakes applied, into the locked position whererequired by the kingpin-retaining mechanism design.

2.5 Lateral and longitudinal loads shall be applied to the major diameter of the kingpin as closeto the top surface of the trailer-support member of the trailer as possible.

2.6 The hitch’s trailer-support member must provide adequate bearing, 550 in.2 minimum, to pre-vent damage to the trailer during transit and loading/unloading operations. The top of the hitch’strailer-support member must be flat for a minimum width of 28 1/2 in. The top of the trailer-sup-port member must be flat within ±1/16 in. over the entire bearing area.

I–8 2/1/04

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-928A2/1/04

2.7 Cushioned hitches must be designed so as to return a trailer, having its parking brakesapplied, to the hitch’s neutral position within a tolerance of ±10% of the fore and aft hitch-headtravel.

2.8 The height of a trailer-support member’s top surface of shall be within ±3/8 in. of the designheight of the trailer hitch. Compliance is determined by measuring the distance from the tire sup-port surface to the trailer support surface (hitch head). This is a vertical measurement taken ateach side of the trailer-support member with the hitch locked in an upright position. The trailersupport member’s top surface shall be level within ±1/8 in. above a flat level base plate measuredvertically at each side of the trailer support member with the hitch locked upright.

2.9 All pins that connect structural members must be provided with plate retainers welded to thestructural members. The use of pins with heads is recommended so that only one pin retainer isrequired per pin. Additionally, it is recommended that the pin retainer be located in an area that iseasily inspected; the outside surfaces are recommended.

2.10 The trailer hitch kingpin locking jaws will have a hardness of 330–370 BHN.

3.0 TEST CONDITIONSThe hitch must withstand test loads without damage to any part of the hitch. For this purpose,damage will be defined as any permanent deformation, unless specifically defined, or any condi-tion that prevents continued service of the hitch. Damage will be determined by visual inspectionand by operation with a loaded trailer.

3.1 Impact Test

3.1.1 Hitches with built-in cushioning that are designed for free/unrestricted interchange servicemust not exceed 240,000 lb of kingpin force at any impact speed up to and including 10 mph whentested on a car equipped with standard draft gear. Hitches without built-in cushioning that aredesigned for free/unrestricted interchange service must meet the requirements of this specificationwhen tested on a car with car body cushioning that provides for a kingpin force not exceeding240,000 lb at any impact speed up to and including 10 mph. Hitches that are designed for con-trolled/restricted interchange service are not required to be impact-tested but are required to meetthe static test requirements.

3.1.2 Hitches with built-in cushioning that are designed for free/unrestricted interchange servicemust be qualified on each type of car on which the hitch is intended to be applied. Hitches withoutbuilt-in cushioning that are designed for free/unrestricted interchange service must be qualified ona typical car type, to be determined by the hitch manufacturer and agreed upon by the AAR, toverify the structural adequacy of the hitch.

3.1.2.1 Hitch manufacturer shall furnish, for inspection and evaluation of the hitch applicationand for impact test purposes, the car complete with the hitch installed in accordance with the pro-duction application design.

3.1.2.2 Cars having multi-trailer capability must have a hitch installed at each trailer location.

3.1.3 The car equipped with hitches under test shall be the hammer car (moving car). Cars withhitches designed to provide cushioning for the trailer are to be equipped with 24 5/8-in. standardpocket draft gears that are in good condition and that meet AAR Manual of Standards and Recom-mended Practices, Section B, Specification M-901E. Cars with hitches not designed to providecushioning for the trailer are to be equipped with a suitable cushioning device (other than stan-dard draft gear) that will be considered part of the cushioning system.

3.1.4 The anvil (standing cars) shall consist of three nominal 70-ton-capacity open top cars, eachloaded with sand or other granular material to a minimum gross rail weight of 220,000 lb. Thehandbrake is to be set tightly on the third (non-struck) car in the string. Free slack between cars isto be removed without compressing the draft gears. No restraint other than the handbrakes on the

2/1/04 I–9

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-928A2/1/04

last car is to be used. All anvil cars are to be equipped with AAR standard draft gears meetingMSRP Specification M-901E.

3.1.5 The test car shall be loaded with a trailer at all hitch locations. Trailers must comply withAAR Manual of Standards and Recommended Practices, Section C, Part II, Specification M-1001,paragraph 4.1.3.4.1. Trailer lading shall be of a rigid material such as concrete blocks or steel bil-lets rigidly secured to the trailer body. Trailer service brakes shall be released (which automati-cally applies the parking brake).

3.1.6 The test car that is designed for free/unrestricted interchange service is to be impacted intothe anvil cars at speeds of 4, 6, 8, and 10 mph (in this order) in both directions. The test car that isdesigned for controlled interchange service is to be impacted into the anvil cars at speeds in 2-mphincrements from 2 mph up to a speed at which the 240,000-lb kingpin force is reached. Additionalimpacts may be made at the option and expense of the manufacturer. (See MSRP SpecificationM-1001 for coupler force requirements at 10 mph.)

3.2 Static Tests

3.2.1 Static tests shall be performed on one hitch, applied either to the test car or to a test standin a manner representative of an average commercial application.

3.2.2 For controlled/restricted interchange freight cars only, a longitudinal load of 240,000 lbshall be applied to the hitch on a plane with and through the kingpin in position. This loadingshall be applied for at least 10 minutes.

3.2.3 A vertical downward load of 75,000 lb shall be applied to the support member of the hitchfor a period of at least 1 minute.

3.2.4 A lateral load of 37,500 lb shall be applied to the hitch on a plane with and through thekingpin in position. This loading shall be applied for at least 1 minute.

3.2.5 A vertical upward loading of 150,000 lb must be applied to the kingpin collar by a jackingbeam arrangement that will simultaneously apply a vertical reaction force at one side of thetrailer support member. The jacking beam arrangement and the jacking force must develop theminimum 150,000-lb force on one side of the kingpin collar. This loading shall be applied for aduration of at least 10 minutes. For hitches having nonsymmetrical securement to the kingpin,this test must be performed on both sides of the hitch.Angular rotation between the top surface of the hitch support member and the jacking beam mustnot exceed 5° during this test. Upon completion of the test, any permanent deformation of thehitch’s trailer support member that exceeds 1/8 in. will be considered a failure.

4.0 INSTRUMENTATION

4.1 All instrumentation must comply with the AAR Manual of Standards and RecommendedPractices, Section B, Specification M-901F, and must be approved by the Transportation Technol-ogy Center, Inc., prior to testing.

4.2 The applied loads shall be measured only during static tests.

4.3 During impact tests, the impact velocity and the longitudinal horizontal kingpin force shallbe measured during each impact and at all kingpins.

5.0 MARKINGApproved hitch and hitch components will be labeled as approved for 90,000 service.

6.0 SERVICE PERFORMANCEA conditional Certificate of Approval shall carry a stipulation limiting the number of applicationsto 3,000 hitches that may be placed in service during the first 2 years. During the time the certifi-cate is conditional, a record of all service failures shall be reported semiannually to the Manager—

I–10 2/1/04

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-928A2/1/04

Intermodal Car Performance Subcommittee. After the expiration of the 2-year service period, atleast 10 hitches must be inspected by representatives designated by the AAR. If the condition ofthe hitches on these cars is satisfactory, an unconditional Certificate of Approval may be granted.

2/1/04 I–11

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

APPENDIX A M-928A2/1/04

APPENDIX AINSTRUCTIONS REGARDING THE APPLICATION FOR CERTIFICATE OF

APPROVALThe following instructions will govern the Intermodal Car Performance Subcommittee’s applica-tion and approval of highway trailer hitches for freight cars.

1.0 The manufacturer must be an approved M-1003 facility.

2.0 The manufacturer is to make application to the Chief—Technical Standards, TransportationTechnology Center, Inc., P.O. Box 11130, Pueblo, CO 81001.

3.0 A separate application shall be made for each different type of hitch for which approval isdesired.

4.0 Each application shall be accompanied by four sets of drawings that provide the followinginformation:

4.1 Drawings shall show the general arrangement, overall dimensions, and type of materials forthe hitch and the installation of the device to the actual car submitted for the test.

4.2 In the case of the car construction, drawings shall show details of the hitch’s supportingstructure and parts that house the hitch as to design, material used, and tolerances provided for.

4.3 Twenty additional sets of the application and general arrangement drawings shall be fur-nished for distribution to the members of the Committee.

5.0 All tests of hitches must be made at an approved test site. The manufacturer’s facility may beapproved by the AAR Intermodal Car Performance Subcommittee if it contains facilities formeeting all test requirements.

6.0 The AAR shall provide an official observer when the hitch is tested in accordance withparagraph 3.0 of this specification. Upon completion of individual impacts made in accordancewith paragraph 3.0, the official observer shall be provided with data as outlined in paragraphs 4.2and 4.3 of this specification. These data shall be considered tentative until such time as they arechecked and a final report on the tests is made. Charges covering the time and expenses of theofficial observer will be rendered to the manufacturer.

7.0 The manufacturer’s representative may discontinue the test at any time and withdraw themanufacturer’s device if desired.

8.0 Representatives of any other hitch manufacturer will not be permitted to be present duringthe tests except by permission of the manufacturer of the device under test.

9.0 No exemptions to these specifications will be made unless presented in writing and approvedby action of the Committee prior to any testing under the specification.

10.0 Following completion of all tests as required by paragraph 3.0 of this specification, themanufacturer shall submit four copies of the test data to the Intermodal Car PerformanceSubcommittee. A report will be issued by the Intermodal Car Performance Subcommittee andshall contain all required test data and copies of oscillogram records showing the kingpin forces

I–12 2/1/04

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

APPENDIX AM-928A2/1/04

measured during the impact tests as required under paragraph 3.0 of this specification. Copies ofthe AAR report shall be distributed to the Committee.

11.0 A conditional Certificate of Approval will be issued after all the requirements of thisspecification have been met as evidenced by the report of the AAR representative (observer) andafter the concurrence of the Committee.

12.0 Unconditional approval will be issued by the Committee in accordance with paragraph 6.0 ofthis specification.

13.0 After a conditional Certificate of Approval is issued, if a manufacturer desires to make anychanges that significantly affect the cushioning, structural adequacy, or trailer securementfeatures of the hitch or if a change is made in identifying specifications for the purpose ofclarification or correction, the Intermodal Car Performance Subcommittee shall be advised. TheCommittee will decide in each case what action is to be taken on these changes.

14.0 At its own expense, the Committee may make complete specification tests of an averagecommercial installation of a hitch in order to establish that standards are being maintained.Failure to pass this test may cause revocation of the manufacturer’s certificate at the discretion ofthe Committee. The test shall be conducted at an AAR test site or the manufacturer’s facility. Themanufacturer shall make its facility available to the AAR upon request or shall waive therestriction of conducting tests only at an AAR test site or the manufacturer’s facility.

15.0 After a Certificate of Unconditional Approval has been granted for a design of a hitch, theCommittee may, at any time, check the service performance of any device of this type. Evidence ofunsatisfactory performance or discovery of undesirable conditions may cause revocation of thecertificate at the discretion of the Committee.

16.0 Manufacturers shall advise the Intermodal Car Performance Subcommittee of all sales ofhitches during the 2 years following the issuance of a conditional Certificate of Approval. Thesereports must be submitted every 6 months.

17.0 Use of a certified noncushioned hitch must be limited to cars having car body cushioningequal to or better than the cushioning utilized on the test car at the time of certification.

18.0 A change in car weight of more than 7.5% will require reapplication and retest. Otherchanges in car design will be reviewed on an individual basis.

2/1/04 I–13

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

APPENDIX B M-928A2/1/04

APPENDIX BRECOMMENDED TRAILER DIMENSIONS AND TRAILER CLEARANCE

ENVELOPE

Fig. B.1 Recommended tractor dimensions for use with tractor-operated hitches

Fig. B.2 Trailer clearance envelope for flatcars

I–14 2/1/04

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-9292/1/04

GREASE FOR LUBRICATION OF TRAILER HITCHES ON FLATCARS

SpecificationM-929

Adopted: 1969; Revised: 1975, 2004

1.0 SCOPEThis specification covers grease suitable for lubricating retractable trailer hitches, stanchions, orother screw-type or knockdown-type devises used in securing highway trailers to flatcars.

2.0 PROPERTIES AND TESTS—GENERAL

2.1 Soaps and FillersThe grease shall be a homogeneous combination of well-refined mineral oil, lithium soap, andmolybdenum disulphide compounded so as to obtain a minimum of separation of the constituentsover long periods of time. It shall contain no fillers such as clay, talc, mica, or gypsum.

2.2 Mineral Oil

2.2.1 ContentThe grease shall contain a high-quality, solvent-refined mineral oil as determined by ASTMMethod D-128.

2.2.2 The petroleum oil, extracted in accordance with ASTM Method D-128, shall conform to thefollowing properties:

3.0 PHYSICAL PROPERTIES AND TESTS

3.1 General

3.1.1 This grease shall be of uniform consistency and free from lumps and shall not harden withage or exposure.

3.1.2 Samples taken from well-mixed contents of a container shall conform to the followingrequirements:

3.2 PackingLubricant for trailer hitch on flatcars shall be put up in 5-lb friction-top cans or in metal drums orcontainers, according to the purchasers’ requirements as specified on the orders.

Requirements Method of AnalysisSaybolt Univ. viscosity at 210 °F Min. 78 seconds ASTM D-445Viscosity index Min. 80 seconds ASTM D-2270

Requirements Method of AnalysisWorked consistency at 77 °F MM/10 265–295 ASTM D-217Dropping point, °F Min. 360 ASTM D-566Oxidation stability, psi drop in 100 hours Max. 12 ASTM D-942‘Moisture, percentage Max. 0.20 ASTM D-95Corrosion test Must pass Fed. Test Method 791

Method 5304Molybdenum disulfide (300-mesh maximum size) percentage by weight Min. 3.0Lithium hydroxy stearate soap, percentage by weight 4.0–9.0

2/1/04 I–15

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-9292/1/04

3.3 MarkingThe seller shall mark each can, drum, or container as follows:

3.4 Place of Making TestsTests governing the acceptance or rejection of lubricant for trailer hitch on flatcars will ordinarilybe made at the laboratory of the purchaser and at purchaser’s expense.

3.5 CertificationThe purchaser may, if he or she so elects, request the seller to furnish a certified copy of seller’slaboratory test report showing that the lubricant furnished fully meets the requirements of thisspecification. The request for the certified report must accompany the order for any lot of grease sopurchased.

3.6 RejectionLubricant for trailer hitch on flatcars that fails to conform to the requirements of this specificationwill be rejected, and the seller will be notified.

3.7 RehearingSamples tested in accordance with this specification that represent rejected material shall be heldfor 14 days from the date of the test report. In case of dissatisfaction with the results of the test,the seller may make claim for rehearing within that time.

LUBRICANT FOR TRAILER HITCH ON FLATCARSAAR Spec. M-929

I–16 2/1/04

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-9302/1/04

CLOSED VAN CONTAINERS FOR DOMESTIC INTERMODAL SERVICE

SpecificationM-930

Adopted: 1972; Revised: 1998, 2004

CONTENTS

Paragraphor Appendix Topic Page1.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–202.0 Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–203.0 Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–204.0 General Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–214.1 Handling Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–214.2 Exterior and Interior Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–214.3 General Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–224.4 Gooseneck Container Tunnel Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–224.5 Maximum Gross Weight Ratings (MGWR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–234.6 Special Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–234.7 Marking, Identification, and Coating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–245.0 Design Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–255.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–255.2 Dynamic Load Factors for Loads Acting through Handling Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–265.3 Design Requirements for Specific Parts of the Container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–276.0 Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–306.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–306.2 Dimensional Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–316.3 Stacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–316.4 Lifting from the Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–316.5 Strength for Side or Straddle Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–326.6 Restraint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–326.7 Front End Wall Strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–326.8 Rear End Wall Strength. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–326.9 Side Wall Strength. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–326.10 Roof Strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–326.11 Floor Strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–326.12 Racking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–336.13 Weatherproofness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–336.14 Acceptance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–347.0 Center of Gravity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–348.0 Certification Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–349.0 Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–3410.0 Oversight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–34

2/1/04 I–17

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-9302/1/04

LIST OF FIGURES

11.0 Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–3412.0 Repair Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–34Appendix A Closed-Van, Dry-Cargo, Domestic Container, 28 ft Long . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–60Appendix B Requirements for Containers Equipped with Electrical Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–65Appendix C Thermal Domestic Container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–70

Fig. Number Caption PageFig. 13.1 Extreme dimensions for 8-ft 0-in.-wide × 20-ft and 40-ft containers only . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–35Fig. 13.2 External dimensions for 8-ft 6-in.-wide closed van containers longer than 40 ft . . . . . . . . . . . . . . . . . . . . . . I–36Fig. 13.3 External dimensions for 8-ft 6 3/8-in.-wide high-cube, closed van containers longer than 40 ft . . . . . . . . . . I–37Fig. 13.4 Top corner fittings on 20-ft and 40-ft containers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–38Fig. 13.5 Bottom corner fittings on 20-ft and 40-ft containers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–39Fig. 13.6 Top intermediate fitting for 8-ft 6-in.-wide containers longer than 40 ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–40Fig. 13.7 Top intermediate fitting for 8-ft 6 3/8-in.-wide, high-cube, closed van containers longer than 40 ft . . . . . . . . I–41Fig. 13.8 Bottom intermediate fitting for 8-ft 6-in.-wide containers longer than 40 ft . . . . . . . . . . . . . . . . . . . . . . . . . . . I–42Fig. 13.9 Bottom intermediate fitting for 8-ft 6 3/8-in.-wide, high-cube, closed van containers longer than 40 ft . . . . . I–43Fig. 13.10 Bottom corner fitting for 8-ft 6-in.-wide containers longer than 40 ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–44Fig. 13.11 Front aperture for high-cube units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–45Fig. 13.12 Dimensions of gooseneck tunnel for standard cube containers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–46Fig. 13.13 Dimensions of gooseneck tunnel for 8 ft 6 3/8-in.-wide high-cube, closed van containers longer than 40 ft . I–47Fig. 13.14 Top rail protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–48Fig. 13.15 Lift pads (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–49Fig. 13.16 Maximum gross weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–50Fig. 13.17 Maximum legal DOT weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–50Fig. 13.18 Dynamic strength requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–51Fig. 13.19 Stacking requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–51Fig. 13.20 Top lift requirement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–52Fig. 13.21 Straddle lift requirements (45-ft, 48-ft, 53-ft units only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–52Fig. 13.22 Straddle lift requirements (20-ft and 40-ft units only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–53Fig. 13.23 Longitudinal restraint requirement (20-ft to 40-ft unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–53Fig. 13.24 Longitudinal restraint requirement (compression and tension) (45-ft, 48-ft, and 53-ft units) . . . . . . . . . . . . . I–54Fig. 13.25 Longitudinal end fitting compression restraint requirement (45-ft, 48-ft, and 53-ft units) . . . . . . . . . . . . . . . . I–54Fig. 13.26 Transverse restraint requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–55Fig. 13.27 Front and rear strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–55Fig. 13.28 Side wall strength. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–56Fig. 13.29 Roof strength (anywhere on the roof) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–56Fig. 13.30 Ultimate floor strength (distributed load) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–57Fig. 13.31 Ultimate floor strength (centered load) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–57Fig. 13.32 Floor deflection requirement (uniformly distributed load) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–57Fig. 13.33 Longitudinal racking requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–58

I–18 2/1/04

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-9302/1/04

Fig. 13.34 Transverse racking requirement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–58Fig. A.2 External dimensions for 8-ft 6-in.-wide × 28 ft long closed van containers . . . . . . . . . . . . . . . . . . . . . . . . . . I–62Fig. A.3 Upper handling fittings for a 28-ft closed van container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–63Fig. A.8 Dimensions of gooseneck tunnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–64Fig. B.1 Type I electrical connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–68Fig. B.2 Type II electrical connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–69

2/1/04 I–19

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-9302/1/04

CLOSED VAN CONTAINERS FOR DOMESTIC INTERMODAL SERVICE

SpecificationM-930

Adopted: 1972; Revised: 1998, 2004

1.0 SCOPE

1.1 This specification defines the design, testing, inspection, and performance requirements fordomestic, closed, van-type, cargo containers that are demountable from railway cars and highwaychassis and are interchangeable between the rail and highway modes of transport.

1.2 For specifications of special-purpose containers, refer to the appendices following this basespecification. If the containers are also to be used in the marine mode, reference the ISO 1496series standards for additional requirements.

1.3 The provisions of this specification are effective for containers ordered after July 1, 2003.

1.4 Containers certified under this specification must meet all applicable federal, state, and AARregulations.

2.0 OBJECTIVESThis specification is intended to provide minimum standards for the purchase and construction ofcontainers to be used in the rail and highway modes of transport. The specification will identifythe design and test parameters required for new domestic containers to ensure a minimum15 years of useful service life and to facilitate ease of maintenance. Cubic capacity should be maxi-mized within the physical constraints of this specification. It is not the intent of this specificationto place restrictions on the structural design methods or the use of any materials.

3.0 DEFINITIONS

Term DefinitionDouble stack Well-type railcar that can transport two levels of intermodal contain-

ers.Intermodal container

Unit of equipment for carrying cargo in multiple modes of transportation; is supported by a container chassis during highway transport and a railcar during rail transportation.

Handling fitting Box-shaped device with uniquely shaped holes (apertures) used to secure or lift containers.

Load factor Usually the maximum gross weight rating (MGWR) or payload; used to relate a dynamic force to a static weight; may be used interchangeable with “G” (acceleration).

Maximum gross weight rating (MGWR)

Maximum weight of a unit and its payload based on its structural capability.

Side lifting Lifting a container with a device located to the side of the container. A side-lifting device may lift the container at the top with twistlocks or from the bottom with lifting arms.

Straddle lifting Lifting a container with a lifting device such as an overhead crane or straddle carrier that straddles over the top of the containers. (A straddle carrier is a crane designed to lift containers and move them relatively long distances longitudinally along a track at relatively high speeds.)

Tare weight Weight of an empty unit.

I–20 2/1/04

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-9302/1/04

4.0 GENERAL REQUIREMENTS

4.1 Handling FittingsRefer to Fig. 13.1 for positioning dimensions and manufacturing tolerances of lifting/stackingaperture faces and openings. See Fig. 13.2 for aperture locations. Design must provide for secure-ment at the lower fitting locations to industry standard roadway chassis, flatbeds, COFC railcars,TOFC railcars, and double-stack railcars equipped with deck-mounted, low-profile, AAR-approvedtwist lock or pin locks. Handling fittings must be capable of utilizing manual, semiautomatic, andfully automatic interbox connectors when stacked in double-stack railcars as well as low-pro-file-type (3.375-in. maximum height cone) COFC pedestal and twist-lock devices.

4.1.1 Corner Fittings for 20-ft and 40-ft Containers 8 ft WideThe container must be equipped with four top and four bottom corner fittings as shown inFigs. 13.4 and 13.5.

4.1.2 Handling Fittings for Containers 8 ft 6 in. Wide or High-Cube Containers8 ft 6 3/8 in. Wide and Longer Than 40 ftThe container may be equipped with ISO or wide-top pick (WTP) handling fittings, subject to thepurchaser’s specification and agreements with handling railroads.

4.1.2.1 The ISO container must be equipped with four top and four bottom handling fittings asshown in Figs. 13.6 and 13.8 or 13.9. These fittings must be located at the 40-ft intermediate loca-tions as shown in Fig. 13.2 and located by the “S” dimension. ISO containers must have additionalhandling fittings as shown in Fig. 13.10 and located as shown in Fig. 13.2 at extreme bottom ends.

4.1.2.2 The WTP container must be equipped with four top and four bottom handling fittings asshown in Figs. 13.7 and 13.9. These fittings must be located at the 40-ft intermediate locations asshown in Fig. 13.3 and located by the “S” dimension. WTP containers must have additional han-dling fittings as shown in Fig. 13.11 and located as shown in Fig. 13.3 at extreme bottom ends.Note that side and end face apertures are not required at the rear of the container. Additionalapertures may be provided at other locations as required by the user.

4.1.3 Unit NumbersThe unit number shall be stamped into the roadside lower front fitting and the curbside lower rearfitting.

4.2 Exterior and Interior DimensionsThe unloaded container must conform to the dimensions and tolerances shown below and illus-trated in Figs. 13.1, 13.2, and 13.3.

2/1/04 I–21

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-9302/1/04

4.3 General DimensionsGeneral dimensions must be as follows:

4.4 Gooseneck Container Tunnel DimensionsGooseneck container tunnel dimensions shall be as specified in Fig. 13.12 for standard containersand Fig. 13.13 for high-cube containers.

Table 4.1 Exterior dimensions of an unloaded containerNominal Exterior Actual Exterior Tolerance Interior Minimum

Length20 ft 19 ft 10 1/2 in. +0 in. –1/4 in. 19 ft 2 3/4 in.40 ft 40 ft 0 in. +0 in. –3/8 in. 39 ft 4 1/8 in.45 ft 45 ft 0 in. +0 in. –3/8 in. 44 ft 4 1/8 in.48 ft 48 ft 0 in. +0 in. –3/8 in. 47 ft 4 1/8 in.48 ft high cube 48 ft 0 in. +0 in. –3/8 in. 47 ft 6 in.53 ft 53 ft 0 in. +0 in. –3/8 in. 52 ft 4 1/8 in.53-ft high cube 53 ft 0 in. +0 in. –3/8 in. 52 ft 6 in.

Width8 ft 8 ft 0 in. +0 in. –3/16 in. 7 ft 7 13/16 in.8 ft 6 in. 8 ft 6 in. +0 in. –3/16 in. 8 ft 1 13/16 in.8 ft 6 in. high cube 8 ft 6 3/8 in. +0 in. –3/16 in. 8 ft 3 in.

Height8 ft 8 ft 0 in. +1/16 in. –3/16 in. 7 ft 2 5/16 in.8 ft 6 in. 8 ft 6 in. +1/16 in. –3/16 in. 8 ft 8 5/16 in.9 ft 0 in. 9 ft 0 in. +1/16 in. –3/16 in. 8 ft 2 5/16 in.9 ft 6 in.a/

a/ Must be equipped with tunnel sections at the front end of their structure for use with gooseneck-type chassis for legal highway height limits (13 ft 6 in. in most states). See Fig. 13.12 for standard containers and Fig. 13.13 for high-cube containers.

9 ft 6 in. +1/16 in. –3/16 in. 9 ft 8 5/16 in.9 ft 6 in. high cubea/ 9 ft 6 1/2 in. +1/16 in. –3/16 in. 9 ft 1 3/8 in.

4.3.1 Clear Door Height For standard containers, minimum outside height minus 12 in. For high-cube containers, the floor boards may be sloped downward with the understructure, as required, nominal 6 ft from door end, to provide nominal 9 ft 1 3/8 in. clear door opening.

4.3.2 Clear Door Width For standard and high-cube containers, minimum outside width minus 4 in.

4.3.3 Upper Handling Aperture Fitting Encroachment

At the intermediate handling frames, some encroachment of the cargo space at the upper handling fitting may be expected. Encroachment shall be limited to 6 in. down from the underside of the intermediate header.

I–22 2/1/04

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-9302/1/04

4.5 Maximum Gross Weight Ratings (MGWR)(See Figs. 13.16 and 13.17.)

4.6 Special Features

4.6.1 AccessAccess to the inside of the container by the door must be from at least one end.

4.6.2 Weatherproof RequirementThe containers must be weatherproof as determined by the applicable test in paragraph 6.1.3. Riv-eted or mechanically fastened components must be assembled with waterproofing barrier materi-als. Assembly of the container must incorporate waterproofing barrier materials at all locationssubject to ingress of water and environmental contamination. In addition, all closed-box and tubu-lar sections must be equipped with 5/8-in. minimum drain holes.

4.6.3 Base Structure DeflectionWhen the container is loaded to the maximum gross weight with the cargo evenly distributed overthe surface of the floor, its base structure must not deflect below the bottom of the lower handlingfittings.

4.6.4 Base Plane Clearance of ContainersThe base plane of the container shall be the plane defined by the bottom of the primary lower han-dling fittings. When the container is in the unloaded condition, the bottom plane of the cross mem-bers (including the end sills) or of the corresponding substructure plane must be 1/2 in. (+3/16 in.,–1/16 in.) above the base plane. Corner fittings on containers over 40 ft must be 1/4 in. (±1/4 in.)above the base plane.

4.6.5 Clearance ProfileNo part of the container may project beyond the permissible overall external dimensions when thecontainer is in an unloaded condition.

4.6.6 Upper Handling Fitting ProjectionThe top of the upper handling fittings must project a minimum of 1/8 in. above any other part ofthe container structure except the intermediate frame header and reinforcement described inparagraph 5.2.6.1.

4.6.7 Recessing of FastenersThe side sill configuration must provide for fasteners to be recessed inside the overall width of thecontainers.

4.6.8 Manifest ReceptacleWhen specified, one weather-tight manifest receptacle shall be provided. The minimum pocket sizeshall be 13 in. high, 6 1/2 in. wide, and 5/8 in. deep. The receptacle shall not protrude beyond theoverall external dimensions of the container.

Table 4.2 Maximum gross weight ratingsNominal Length

(ft)Maximum Gross Weight Rating (MGWR

(lb) (lading plus tare)53 67,20048 67,20045 67,20040 67,20020 52,900

2/1/04 I–23

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-9302/1/04

4.6.9 Top Rail Protector (Optional)For containers subject to side lift, a nominal 9-ft-long top rail protector is to be applied to each sideof the top rail, centered between the intermediate frames, as shown in Fig. 13.14. The design is toprovide protection of the top rail and roof edge from damage by the center mast area of side-lifting,container-handling equipment. Designs incorporating integral protection are acceptable.

4.6.10 Lift Pads (Bottom Rail Protectors) (Optional)

4.6.10.1 When lift pads are provided, to accommodate lift shoes, a clear, unobstructed 8-in.-wide× 5-ft-long surface shall be provided, starting within 2 ft of the end frames, on each side of the con-tainer. Containers longer than 40 ft are an exception; their surfaces shall start within 2 ft of the40-ft handling fittings and extend toward the center of the container. See Fig. 13.15.

4.6.10.2 Horizontal surfaces of lifting pads shall extend inward a minimum of 6 in. from the out-side vertical plane of the container. The vertical surface of the lift pads shall extend upward a min-imum of 2 1/4 in. from the bottom side rail.

4.6.10.3 Lift pads shall be fastened to the container in a manner that prevents damage to lift padattachments by lifting machine lift shoes.

4.6.11 Roof Arch (Optional)The roof structure may be arched upward in the center by 1/4 in. to 3/8 in. to facilitate drainage.

4.6.12 Miscellaneous ConsiderationDesign should optimize maintenance-free operation with minimal wind resistance. Design shouldincorporate industry standard components and parts to provide ease of maintenance and repair.

4.7 Marking, Identification, and Coating

4.7.1 MarkingEach container shall have a two- to four-digit alpha reporting mark, ending in “U,” that is assignedin accordance with the provisions of ISO Standard 6346. This code, which represents the vehicle’sowner or lessee, shall be followed by a maximum six-digit number, which shall be determined inaccordance with the AAR Code of Trailer and Container Service Rules and shall be located on allfour sides of the container, as indicated in ISO 6346. Also, the tare and maximum gross weightsshall be shown on the curb-side (right-hand) rear door. In addition, the following shall be indicatedon the containers:

• Manufacturer’s name plate• Manufacturer’s data plate• Exterior dimensions• Interior dimensions• Certification plate (see paragraph 8.0)• Floor rating (to be stenciled on the interior wall, curb side, top one third of container and

on the nose at mid-height)• Repair decal—When components require special weld or repair procedures, such as pre-

heat or other than E70 equivalent electrodes, a special decal must be affixed to the con-tainer advising repair companies of such. Manufacturer-approved repair procedures must be made available through printed manuals or Internet access.

These markings are the minimum markings required. If a check digit or other marking be desired,refer to ISO 6346.

4.7.2 Intermediate Handling FittingsIntermediate handling fittings (lift points) may be marked by a contrasting color from the remain-der of the container to assist the lift operator in alignment while stacking or unstacking. If the con-

I–24 2/1/04

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-9302/1/04

tainer is equipped with wide top pick (WTP) position upper fittings, the exposed castings are to bepainted blue (Pantone 293), and WTP decals must be positioned close to each casting on the sides.

4.7.3 Automatic Equipment Identification Tag (Optional)An automatic equipment identification (AEI) tag may be placed on each container. If applied, thetag must perform and be programmed and positioned in accordance with the AAR Manual of Stan-dards and Recommended Practices, Section K, Standard S-918.

4.7.4 PlacardingHazardous material placards must be located to be visible when carried in intermodal dou-ble-stack cars (bottom or top position). Nominal dimensions are to be 72 in. from the bottom siderail and 60 in. inboard from ends, all four sides.

4.7.5 UndercoatingUnderside shall be coated with a protective coating to include the floor bottom side and the insideof the tunnel. Coatings must provide 15 years of service.

4.7.6 Recommended Application Criteria for Coatings

4.7.7 Test Requirements for Coating Systems

5.0 DESIGN REQUIREMENTS

5.1 General

5.1.1 When loaded to MGWR, containers will be subjected to dynamic forces resulting fromimposed accelerations acting through the securement. The following minimum load factors andthe test requirements as outlined in paragraph 6.0 will apply.

5.1.2 The designer must determine the amount, if any, by which the container should exceed theminimum design requirements. Allowances should be made for the physical and chemical proper-ties of the materials of construction (fatigue, corrosion, galvanic action, and similar consideration)and for normal wear and tear of engaging parts during the expected life of the container. Particu-lar consideration must be given to the possible adverse effects of galvanic action at the mating sur-faces of dissimilar materials.

5.1.3 All materials for construction must perform within a temperature range of –40 °C to 80 °C.

Criteria Minimum Acceptable StandardBlast profile, SSPC-6 2.0 – 2.5 milPrimer, zinc epoxy, 65% dry weight 2.0 – 2.5 mil dryFinish, poly, isocyanate 9approved) ≤3.5 VOC 2.0 – 2.5 mil dry

Criteria Minimum Acceptable StandardX-hatch adhesion (ASTM D-3359) 5BImpact resistance (ASTM D-2794) Direct: 60 in.·lb (no crazing)

Reverse: 40 in.·lb (no crazing)Spray salt resistance (ASTM B-117) 2000 hours

<1/8 in. scribe creepvery slight rust run-down

no field blistersArtificial weathering (ASTM G-53/QUVA) 3000 hours

80% at 60° specular gloss retentioncolor accuracy ∆E ≤ 4.0

2/1/04 I–25

AAR Manual of Standards and Recommended PracticesIntermodal Equipment Manual

M-9302/1/04

5.1.4 Unless otherwise noted, all structural design requirements must be met without exceedingthe minimum yield strength of any portion of the structure. This requirement will be referred to asan “elastic” case. Equipment builder must be prepared to demonstrate through analysis and testthat this requirement is met.

5.2 Dynamic Load Factors for Loads Acting through Handling Fittings(Reference Fig. 13.18.)

5.2.1 Static LoadsThe static loads for design purposes are obtained by multiplying the load factors in paragraph 5.2by the maximum gross weight of the containers as listed in paragraph 4.5.

5.2.2 Load PathsLoads are to act through handling fittings that attach the container to the railcar, highway chas-sis, and upper fittings of the bottom container in a double-stack operation. The directions of theforces are to be applied along the three principal axes of the container in both directions. Attach-ment of the container to the railcar is at the end frame locations of 20-ft and 40-ft containers andat the 40-ft intermediate frame locations on containers over 40 ft.

5.2.3 Multiplicity of ForcesDesign loads so obtained are assumed to act singly or simultaneously in any combination of thevertical, longitudinal, and lateral directions.

5.2.4 Support and RestraintWhen carried on railcars, containers will be supported and/or restrained through the handling fit-tings as defined in paragraph 5.2.2. When carried on a highway vehicle, support and restraint willbe primarily the same as on the railcar, except that containers with intermediate frames can berestrained at the extreme frame ends. Additional support and restraint will be achieved by frontlower sill and end fittings and/or tunnel area, real sill, and floor cross members.

5.2.5 Loads for Both Rail and Highway Modes

5.2.5.1 Containers must be capable of taking longitudinal restraint loads in either direction bythe lower pair of handling fittings defined in paragraph 5.2.2 on either end of the containers.

5.2.5.2 Containers with intermediate frames must also be capable of withstanding longitudinalcompressive restraint loads by the lower pair of handling fittings located at either extreme end ofthe container.

5.2.5.3 Containers must be capable of taking lateral restraint loads in either direction by anylower pair of handling fittings on either side of the containers.