MSME-DI, KOLKATA GOVT. OF INDIA MINISTRY OF MSME 111 ...

Transcript of MSME-DI, KOLKATA GOVT. OF INDIA MINISTRY OF MSME 111 ...

1

REPORT ON

INDUSTRIAL POTENTIALITY SURVEY

OF HOOGHLY

(WEST BENGAL) 2015-2016

MSME-DI, KOLKATA

GOVT. OF INDIA

MINISTRY OF MSME

111 & 112, B. T. ROAD, KOLKATA –108

2

FOREWORD

The Industrial Potentiality Survey Report on Hooghly district has been

prepared under the Action Plan, 2015-16. The present survey report includes

comprehensive analysis of existing resources, infrastructure, industrial activities,

status and their problems emphasizing MSMEs. Based on these analysis, the scope

and further expansion for MSMEs are found out and highlighted. Ten prospective

schemes on MSME sector are annexed.

Necessary data and suggestions for preparation of this report have been

collected from various Govt. offices, Financial Institutes, Local Bodies and NGOs. I

would like to express my sincere thanks to all of them specially General Manager,

DIC, Hooghly; Lead bank Manager and other Govt. &Non-Govt. organization of the

district.

I hope this report will be very useful to all promotional agencies, NGOs and

overall the MSMEs of Hooghly district.

I appreciate the efforts provided by Mrs. Senjuti Dutta, Investigator under guidance

of Sri D. Banerjee, Asstt. Director (Stat) for successfully conducting the survey and

having completed the report.

Place- Kolkata.

Date-31st December, 2015. ( K.L.RAO )

Director.

3

CONTENTS

Chapter No. Subject Page No.

District at a glance 4-6

Map 7

I. Objective, Scope & Methodology 8-9

II. General Characteristics of the district 10-12

III. Resources 13-22

IV. Infrastructure 23-33

V. Present Industrial Structure 34-46

VI. Central Govt. Schemes & Incentives 47-49

VII. State Govt. Policies & Incentives 50-54

VIII. Sample Project Profiles 55-93

4

Hooghly - DISTRICT AT A GLANCE

(A) AREA, POPULATION AND LITERACY

1) Geographical Area : 31.49 sq km

2) 2011 Census Total Population (Provisional)

i) Male Population : 2814653

ii) Female Population : 2704492

iii) Urban Population : 2128499

iv) Rural Population : 3390646

3) Density of Population per sq. Km (in No.) : 1753

4) Sex Ratio per thousand person : 961

5) Total No. of Literates

i) Male Literates : 2,211,777

ii) Female Literates : 1,866,611

iii) Male Literacy rate : 87.03%

iv) Female Literacy rate : 76.36%

v) Rural Literacy rate : 78.53%

vi) Urban Literacy rate : 86.91%

vii) Literacy rate for the : 81.80%

district as a whole

(B) ADMINISTRATIVE SET UP

1) District Headquarters : Chinsura

2) No. of Sub-Divisions : 4

3) No. of blocks : 18

4) No. of Mouzas : 1915

5) No. of Police Stations : 22

5

6) No. of Villages : 1842

7) No. of Panchayat Samities : 18

8) No. of Gram Panchayats : 207

9) No. of Municipalities : 12

(C) AGRICULTURE AND ALLIED ACTIVITIES

1) Gross Cropped Area : 313.38 thousand hect.

2) Net Cropped Area : 212.09 thousand hect.

3) Area under non-agricultural use : 96.99 thousand hect.

4) Forest : 0.53 thousand hect.

5) Barren & Uncultivable Land : 0.13 thousand hect

6) Permanent pasture and other grazing land : 0.02 thousand hect

7) Cultivable waste land : 0.92 thousand hect

8) Current fallow : 0.67 thousand hect

9) Fallow land other than current fallow : 0.42 thousand hect

10) No. of Agricultural Research Institute : 1

11) No. of Agricultural Training Centre : 1

14) No. of Block Seed Farm : 4

15) Major Crops : Rice,Wheat,Other cereals

(D) INFRASTRUCUTRE

1) Total State Highway : 176 Kms

Total National Highway : 55 Kms

2) No. of registered Motor Vehicles : 431787

3) No. of Sub-Stations (Power) : 25

4) No. of Mouzas electrified( upto 2012) : 1904

5) No. of Bank Branches : 240

6) Lead Bank : UCO

6

(E) INDUSTRIES 1) No. of Registered Enterprises EM-II : 6383

(Since 2006-07 to 2014-15)

2) No. of Employment

(Since 2006-07 to 2014-15) : 68236

3) Udyog Aadhar Memorandum(UAM)

Registration 2015-16 (Since October,15)

i) Micro : 235

ii) Small : 35

iii) Medium : 2

Total- 272

=-=-=-=-=-=-=-

7

8

CHAPTER - I

OBJECTIVE, SCOPE AND METHODOLOGY

Hooghly is one of the advanced districts of West Bengal. The district is advanced both in

agriculture and industry. It lies on the bank of the Hooghly river of south Bengal. The different

districts of West Bengal have been classified into three different categories viz. ‘A’, ‘B’, ‘C’ and

‘D’ – ‘A; comprising the most industrially advanced districts of the state and ‘D’ the least. The

Hooghly district comes under category ‘B’.

Objectives :

The main objectives of the present report of Industrial Potentiality Survey are to assess the

resources both human and materials available in the district; to appraise the existing infrastructural

facilities; to evaluate the status of existing industries and to identify various prospects and

problems. The report also aims at identifying prospective industries/MSME units. Moreover, the

importance of entrepreneurial talents and skills of the people which are basic to industrialization is

attempted to give due recognition.

Scope:

Although the present report is emphasized on the small scale industries, village and cottage

industries, tiny , repairing and servicing enterprises but the scope of the report is vast.

In the various Chapters , developments aspects of the district are analyzed and assessed to

highlight the various developmental scope. In the resource Chapter, human and material resources

are analyzed in detail. Human resource includes accounts on the literacy rate, occupational pattern

of people, etc. Whereas material resources includes the agricultural produce, land utilization,

cropping pattern, forest resource, livestock resources, sericulture, etc

For analyzing infrastructures, a separate Chapter covers the physical and social

infrastructures available in the district. Physical infrastructure cover the land, factory,

accommodation, water, power , railways, road transport, communication, air transport, etc. and

social infrastructure covers the entrepreneurship, marketing potential, lending facilities, incentives,

growth centers , etc.

Present industrial scenario on large and medium scale industries, small scale industries, etc

has been discussed in the present industrial climate Chapter.

In the District Planning Chapter, the target of the concerned district authority and

promotional agencies are studied for scope for various development aspects including industries.

Methodology:

The office of the Development Commissioner, Micro Small and Medium Enterprises, New

Delhi has issued guidelines for preparation of this report. The latest guidelines has been followed

for preparing this report.

9

Study data has been collected from two sources viz. primary and secondary sources, for

preparation of this report. In the initial stage, questionnaires were prepared and dispatched to

various Government and Semi- Government Departments like Directorate of MSME, Govt. of

West Bengal, District Industries Centre, District Planning, Banks, Agriculture, Forest, Animal

Recourse etc.

A separate questionnaire was also designed and ‘Stratified Random Sample’ method was

applied for generation primary data. During field visits, the team interacted with existing SSI units,

entrepreneurs, traders, industry associations, NGOs, etc for eliciting necessary response.

Finally, collected data has been compiled and analyzed in depth to prepare and shape the

report.

========XXX========

10

CHAPTER – II

GENERAL CHARACTERISTICS OF THE DISTRICT

The economy of Hooghly district is admixture of predominant agriculture and industry. It

lies on the bank of the Hooghly river and about 15 Km. Away from Kolkata. So, the district enjoys

the proximity of Kolkata Metropolitan city and the Hooghly river. Numbers of large and medium

scale industries have been set up along the bank of the Hooghly river. Besides, a large number of

MSEs has also been set up along the bank of Hooghly river as well as other parts of the district. The

remaining part of the district is under agricultural activities. At present, multi-national companies

are showing interest in setting up of industries in the district and some closed large scale units re-

opened. Thus, industry is growing fast in the district.

Location :

The district has a geographical area of 31.49 sq. km. The district is surrounded by Nadia in

the east, Burdwan in the north, Bankura in the west and Paschim Midnapore in the south. The

district lies between 230

.01’20’’N and 220

.39’32’’N latitude and 800

.30’15’’E and 870

.30’20’’E

longitude. The geographical location of the district is shown in Table 2.1

Table 2.1

Geographical location of the Hooghly district and its HO.

Name of the

district

Latitude Longitude

North South East West

Hooghly 230 .01’20’’N 220 .39’32’’N 800 .30’15’’E 870 .30’20’’E

Chinsurah 220 .55’N - 88

0 .29’E -

Climate Of Hooghly:

Hooghly has a tropical savanna climate. The annual mean temperature is 26.8°C, although

monthly mean temperatures range from 16°C to 33°C and maximum temperatures in Hooghly often

exceed 38°C. The main seasonal influence upon the climate is the monsoon. Maximum rainfall

occurs during the monsoon in August and the average annual total is above 1,500mm. Moderate

northwesterly to northeasterly winds prevails for most of the year with a high frequency of calms.

Summer is dominated by strong southwesterly monsoon winds. Winters are comfortable with

temperatures lying between 11 to 17°C.

Soil :

The soil of the district is deep alluvial. The topography indicates a predomination of flat

and plan surface with a storage of high moisture. The district is divided into three soil groups viz.

(1) Gangetic Alluvium, (2) Alluvium deposit in Damodar and Dwarkeshwar Valley and (3) Red

Soli Region. Gangetic alluvium belt comprises an area of 59150 hectares and it is rich in calcium

and fertile contained high level of potash, medium nitrogen and phosphate. The vindhya alluvium

soo; comprises the major are of 248950 hectares and this soil is less fertile and slightly acidic. In

this soil, nitrogen content is high, phosphate is available andpotash is medium. The red soil

11

comprises of an area of 68000 hectares and is infertile with low in organic carbon, calcium

with phosphate and potash. The red soil covers in the western parts of the Goghat block but in rest

of the district mostly is under Gangetic Alluviom and Vindhya Alluvium. Gangetic Alluvium belt

in eastern and south eastern parts of the district.

Rivers :

There are many rivers and rivulets in the Hooghly district. The Hooghly, the Dwarkeshwar,

the Damoder and the Rupnarayan are the main rivers of the district. The other rivers and rivulets

are the Sarashwati, the Kunti, the Jhumi-Jhelika, the Behula, the Kunnatal, the kadarmati, the

Tarakjala and the Amadar. Many of these rivers are navigable.

Forests :

Tropical forests are found in the district. So, the forests are deciduous in nature. In these

forests, timbers, fuel woods, thatches, etc. are available.

Income :

Collection of revenue from different sources is an indicator for assessing the economic

prosperity of a district. The table below shows a clear picture of revenue collected from different

sources over 3 years.

Table 2.2

Revenue collected from different sources in the district of Hooghly

( Thousand Rupees ) Categoty wise of Revenue Collection 2010-11 2011-12 2012-13

Land Revenue 120106 174829 252828

Stamp Revenue & Registration Fees 1161545 1392914 1744288

Excise Revenue 1679541 514714 158791

Sales Tax 1116030 1019484 692184

Taxes on Vehicles 361224 373379 508581

Entertainment Tax 5089 9822 4617 (I)

Electricity Duty 34016 18279 15824

Agri. Income Tax .. .. ..

Professional Tax 123592 132055 130845

Other Taxes 395547 11 32158

Total 4996690 3635487 3540116

Source- District Statistical Handbook, 2013

Bureau of Applied Economics & Statistics

Government of West Bengal

Administrative set up of Hooghly district:

The district with an area of 31.49 sq. km . has 4 Sub-divisions, 18 Blocks, 24 Police

Stations, 18 Panchayat Samities, 207 Gram Panchayats, 1 Municipal Corporation and 12

Municipalities. The district headquarters is at Chinsura. The details of administrative set up of the

district are given in the following table.

12

Table 2.3

Administrative Set-up

Sub-

Division

Police Station C.D.Block/

M.C./ M

Panchayat Municipal

Corporation

Municipality Inhabited

Village

Samity Gram Gram

Sansad

No

Ward

No Ward

Sadar

Sub-Div.

9 5/ 0/ 2 5 69 1101 - - 2 52 741

Dhaniakhali

Gurap

Dhaniakhali 1 18 264 - - - - 214

Pandua Pandua 1 16 247 - - - - 153

Balagarh Balagarh 1 13 183 - - - - 129

Chinsurah

Chinsurah

(Women)

Hooghly-

Chinsurah(M) - - - - - 1 30 -

Chinsurah (P)

&Mogra

Chinsurah-

Mogra

Bansberia(M)

1 10 196 - - 1 22 52

Polba & Dadpur Polba & Dadpur - - - - - - - -

Chandan-

nagar

Sub-Div.

5 3/ 1/ 3 3 41 592 - - 3 59 193

Tarakeswar Tarakeswar

Tarakeswar(M) 1 10 144 1 33 - - 339

Haripal Haripal - - - - - 1 15 89

Singur

Bhadreswar(P) Singur 1 15 208 - -

-

-

-

- -

Bhadreswar Bhadreswar(M) 1 16 240 - - 1 22 152

Bhadreswar (P) Champdani(M) - - - - - 1 22 98

Bhadreswar (P)

Chandannagar

Chandannagar

(MC.) - - - - - - - -

Serampur

Sub-Div.

6 4/ 0/ 6 4 34 574 - - 6 137 208

Jangipara Jangipara 4 34 574 - - - - 128

Chanditala Chanditala-I 1 10 177 - - - - 47

Chanditala (P)

Dankuni (P) Chanditala-II 1 9 148 - - - - 20

Dankuni Dankuni (M) 1 9 132 - - 1 19 -

Serampur (P)

Dankuni (P)

Uttarpara (P)

Serampur-

Uttarpara - - - - - - - 13

Uttarpara Uttarpara-

Kotrung(M) 1 6 117 - - 1 24 -

Uttarpara(P) Konnagar(M) - - - - - 1 20 -

Serampur Serampur(M) - - - - - 1 29 -

Serampur (P)

Baidyabati(M)

- - - - - 1 22 -

Rishra

Rishra(M) - - - - - 1 23 -

Aram-

bagh

Sub-Div.

4 6/ 0/ 1 6 63 924 - - 1 18 554

Goghat Goghat-I

Goghat-II

1

1

7

9

107

121

-

-

-

-

-

-

-

-

97

110

Arambagh

Arambagh

Arambagh(M)

1

-

15

-

221

- - -

-

1

-

18

152

-

Khanakul Khanakul-I

Khanakul-II

1

1

13

11

192

145

-

-

-

-

-

-

-

-

93

52

Pursurah Pursurah 1 8 138 - - - - 50

Total- 4

24

18/ 1/ 12

18 207 3191 1 33 12 266 1842

Source- District Statistical Handbook, 2013

Bureau of Applied Economics & Statistics

Government of West Bengal

========XXX========

13

CHAPTER - III

RESOURCES

Resources in the form of land, entrepreneur, skill and raw material determine the growth and

expansion of industry in a place. Resources comprising of human and material are considered to be

the most vital factors.

A) HUMAN RESOURCE:

Human resources comprising of entrepreneur, skill and un-skill personnel are primary need

for setting up of industrial units. So, elaboration of human resources is very important for

promotional agencies, planners and entrepreneurs for the growth of industries in the district. The

details of human resource in the district are analyzed in the following paragraphs.

Population :

As per 2011 Census the district of Hooghly had a population of 5519145.

Table 3.1

Population distribution by sex

Year Total

Population

No. of

Male

No. of

Female

Urban

Population

Rural

Population

1901 1075872 542697 533175 160723 915149

1911 1115390 569509 545881 176775 938615

1921 1105565 575566 529999 204763 900802

1931 1141517 607567 533950 230855 910662

1941 1416013 759848 656165 321186 1094827

1951 1604229 852143 752086 394839 1209390

1961 2231418 1179267 1052151 579283 1652135

1971 2872116 1514874 1357242 760270 2111846

1981 3557306 1863782 1693524 1050529 2506777

1991 4355230 2271792 2083438 1358251 2996979

2001 5041976 2589625 2452351 1687749 3354227

2011 5519145 2814653 2704492 2128499 3390646

Literacy :

As per 2011 census, the literacy rate of Hooghly district is shown in the following table:-

Table 3.2

Literacy Rate by sex in rural and urban areas in the district of Hooghly, 2011

Sub-Division/

C.D.Block/ M.C./ M

Rural % Urban % Total %

Male Female Total Male Female Total Male Female Total

Sadar Sub-Div. 82.39 69.46 75.99 90.08 81.87 86.05 84.84 73.37 79.17

Dhaniakhali 82.51 68.79 75.66 - - - 82.51 68.79 75.66

Pandua 81.75 68.25 75.04 84.71 75.56 80.18 82.22 69.41 75.86

Balagarh 81.85 70.38 76.23 85.97 77.84 81.99 82.36 71.30 76.94

Hooghly- - - - 93.81 88.39 91.10 93.81 88.39 91.10

14

Source- District Statistical Handbook, 2013

Bureau of Applied Economics & Statistics

Government of West Bengal

Total literacy rate of the district is 81.80 which is at a very higher position. The male and

female literacy rate is 87.03 and 76.36 percent respectively.

Block level population of the district as per 2011 Census is given below:

Table 3.3

Block level population (2011 census):

Sl No. Name of the Municipality/Corporation/

/C.D Block/ Urban Town

Population

Total Male Female

1 Hooghly-Chinsurah 137409 73164 64245

2 Bansberia 74611 42910 31701

3 Chandannagore 126860 68840 58020

4 Bhadreswar 78702 46510 32192

Chinsurah(M)

Chinsurah-Mogra 87.65 76.35 82.11 88.52 78.23 83.49 88.22 77.57 83.01

Bansberia(M) - - - 89.78 79.97 85.05 89.78 79.97 85.05

Polba-Dadpur 81.57 68.55 75.14 - - - 81.57 68.55 75.14

Chandannagar

Sub-Div.

86.28 74.70 80.57 90.43 82.13 86.42 88.03 77.76 83.01

Tarakeswar 86.52 73.11 79.96 - - - 86.52 73.11 79.96

Tarakeswar(M) - - - 87.50 80.00 83.90 87.50 80.00 83.90

Haripal 84.36 72.59 78.53 86.95 76.37 81.83 84.41 72.66 78.59

Singur 88.25 78.36 83.37 90.96 82.98 87.06 88.77 79.24 84.07

Bhadreswar(M) - - - 91.17 81.33 86.51 91.17 81.33 86.51

Champdani(M) - - - 87.60 75.31 81.89 87.60 75.31 81.89

Chandannagar(M.C.) - - - 92.38 86.90 89.66 92.38 86.90 89.66

Serampur Sub-Div. 86.46 75.90 81.23 90.95 84.67 87.90 89.78 82.31 86.13

Jangipara 85.18 73.34 79.33 88.98 77.19 83.20 85.47 73.63 79.62

Chanditala-I 87.59 78.23 82.93 89.17 80.75 84.93 88.24 79.29 83.76

Chanditala-II 88.46 80.08 84.28 88.37 81.59 85.01 88.40 81.13 84.78

Serampur-Uttarpara 87.77 77.86 82.96 92.29 84.95 88.69 91.21 83.28 87.33

Uttarpara-

Kotrung(M)

- - - 92.93 88.28 90.65 92.93 88.28 90.65

Konnagar(M) - - - 93.59 88.01 90.84 93.59 88.01 90.84

Serampur(M) - - - 91.77 85.48 88.73 91.77 85.48 88.73

Baidyabati(M) - - - 90.15 86.23 88.26 90.15 86.23 88.26

Dankuni(M) - - - 87.21 80.82 84.13 87.21 80.82 84.13

Rishra(M) - - - 91.46 83.78 87.89 91.46 83.78 87.89

Arambagh

Sub-Div.

85.66 71.90 78.94 86.96 75.00 81.03 85.73 72.07 79.05

Goghat-I 85.64 71.41 78.70 - - - 85.64 71.41 78.70

Goghat-II 84.15 70.02 77.24 - - - 84.15 70.02 77.24

Arambagh 85.51 72.19 79.01 - - - 85.51 72.19 79.01

Arambagh(M) - - - 86.96 75.00 81.03 86.96 75.00 81.03

Khanakul-I 84.41 70.66 77.73 - - - 84.41 70.66 77.73

Khanakul-II 86.12 71.96 79.16 - - - 86.12 71.96 79.16

Pursurah 88.63 75.28 82.12 - - - 88.63 75.28 82.12

District Total 84.78 72.09 78.53 90.51 83.12 86.91 87.03 76.36 81.80

15

5 Baidyabati 85545 46326 39219

6 Serampore 153058 85958 67100

7 Champdani 69323 43115 26208

8 Rishra 84252 49503 34749

9 Konnagore 58125 31766 26359

10 Uttarpara-Kotrang 119734 65148 54586

11 Tarakeswar 20335 11681 8654

12 Arambagh 36972 20991 15981

13 Chinsurah-Mogra,C.D. 76473 43509 32964

14 Goghat-I C.D. 76563 45123 31440

15 Goghat-II C.D. 85419 50396 35023

16 Dhaniakhali C.D. 173640 99729 73911

17 Pandua C.D. 149088 84972 64116

18 Balagarh C.D. 127466 72451 55015

19 Polba-Dadpur C.D. 137638 78421 59217

20 Haripal C.D. 148250 82856 65394

21 Singur C.D. 164803 89925 74878

22 Serampore-Uttarpara C.D. 36861 20529 16332

23 Tarakeswar C.D. 106549 61275 45274

24 Arambagh C.D. 157264 91728 65536

25 Chanditala-I C.D. 108375 57832 50543

26 Chanditala-II C.D. 83953 45826 38127

27 Pursurah C.D. 104014 60094 43920

28 Jangipara C.D. 123397 69855 53542

29 Knanakul-I C.D. 133428 77556 55872

30 Khanakul-II C.D. 98617 55597 43020

31 Pandua 18267 9889 8378

32 Bandhagachi 3317 1807 1510

33 Kodalia 5618 3137 2481

34 Raghunathpur 10537 6176 4361

35 Madhusudanpur 5164 2928 2236

36 Amodghata 5355 2876 2479

37 Shankhanagar 4082 2399 1683

38 Khamarpara O.G. 323 181 142

39 Bandel Thermal Power P. Town O.G. 57 39 18

40 Barakhejuria O.G. 1539 947 592

41 Chak Bansberia 3588 2239 1349

42 Kulihanda 8988 5047 3941

43 Naldanga O.G. 9590 5447 4143

44 Simla 9809 5337 4472

45 Dharampur 3797 2074 1723

46 Singur 14783 8066 6717

47 Dakshin Rajyadharpur 7131 3911 3220

48 Purba Tajpur 4480 2316 2164

49 Kharsarai 3934 2185 1749

50 Begampur 7146 3805 3341

51 Chikrand 5801 3207 2594

52 Pairagachha 3492 1858 1634

53 Rishra 9743 5239 4504

54 Nabagram Colony 26997 14540 12457

55 Kanaipur 5109 2703 2406

56 Bamunari 4977 2748 2229

57 Mohanpur 15013 8290 6723

16

58 Barijhati 5099 2741 2358

59 Garalgachha 3848 2072 1776

60 Krishnapur 4613 2472 2141

61 Raghnathpur 5867 3293 2574

62 Mrigala 12822 7048 5774

B) MATERIAL RESOUCES

Material resources are basic need to the growth of industrial unit. On the other hand, the

growth of resource-based industry depends on the available quantum of material resources.

Material resources consist of agricultural produce, forest produce, live-stock resources and so

on. The material resources available in the district are elaborated in the following paragraphs:-

Agriculture:

Though the district of Hooghly is predominantly an industrial district of West Bengal with

numerous industries situated on the bank of the Hooghly river, it still retains its rural character

with its rural population to the extent of about 60 percent depends on agriculture. Since all the

cultivated land of the district has long been brought under cultivation, the margin for further

extension of agriculture has naturally been reduced to a considerable extent. For better

production, farmers are adopting improved scientific agricultural technology using chemical

fertilizer, hybrid seeds and pesticides etc. As a result the cropping intensity of the district at

present is very high. Though rice is the main crop of the district, the agricultural economy

greatly depend on potato, jute, vegetables and orchard etc.

Land Utilisation :

In spite of the fact that Hooghly is one of the most important industrial districts of West

Bengal, about 70% of its population depend on agriculture and represents an important and

remarkable place in the field of agriculture in West Bengal.

Due to massive population explosion and continuous increase of pressure on land, the

farmers of this district are engaged in cultivation of all the major crops utilising the fullest

potentiality of land and natural resources. Though rice is the prime crop of the district the

agricultural economy largely depends on potato, jute, vegetables and orchard and the cropping

intensity of the district has been escalated to 220%.

Vegetable is a prige crop in the blocks of Haripal, Singur, Chanditala, Polba and

Dhaniakhali being grown in a relay system throughout the year. Though potato is cultivated in all

the blocks of this district Dhaniakhali, Arambagh, Goghat, Pursurah, Haripal, Polba-Dadpur,

Tarakeswar, Pandua and Singur contributed much of its production of this district. Dhaniakhali,

Haripal, Pandua, Arambagh and Pursurah have maximum number of cold storages for potato in this

district.

Table 3.4

Classification of Land Utilisation Statistics in the district of Hoogh

(Thousand hectares)

Reporting Area 313.38

Forest Area 0.53

Area under Non-agricultural use 96.99

17

Barren & uncultivable land 0.13

Permanent pastures & other grazing land 0.02

Land under misc. tree groves not included in Net area sown 1.61

Cultivable waste land 0.92

Fallow land other than Current fallow 0.42

Current fallow 0.67

Net area sown 212.09

There is an Agricultural Training Center at Chinsurah for Krishi Prajukti Sahayaks (Pre-

Service and In-Service). This Training Center may be utilised as training centre for farmers from

time to time.

Table 3.5

Agricultural Research Institute 1 (One) no.

Training Center for farmer Nil

Seed farm no. and location

Rice Research Farm 1 (Chinsurah)

Coconut Development Farm 1 ( Chandernagor)

Model Farm 1 (Dhaniakhali)

Block Seed Farms 4 (Balagarh)

Sub-divisional Adaptime Res. Farm 3 (Polba,Singur,Pursurah)

No. of big farmers 12 No.

No. of Small farmers 55592 No.

No. of marginal farmers 361418 No.

No. of agricultural labourers 348502 No.

No. of bargadars 115027 No.

Land under big farmers 166 ha.

Land under Small farmers 75745 ha

Land under marginal farmers 138494 ha.

Land under bargadars 27371 ha.

Source- District Statistical Handbook, 2013

Bureau of Applied Economics & Statistics

Government of West Bengal

Cropping pattern:

Like other districts in West Bengal, the cropping pattern of Hooghly district is more or less

same. Almost all cultivable lands are multi – cropped. Thus, crops are produced throughout the

year. However, the farmers follow the following cropping pattern.

1) Kharif crops followed by potato, vegetable and other rabi crops.

2) Jute followed by kharif paddy/vegetable.

3) Rabi crops followed by summer paddy/crops.

4)

The agricultural production in the district during 2010-11 to 2012-13

18

Area Cultivated:

Pre-kharif 70650 ha.

Kharif 211500 ha.

Rabi/Boro 213950 ha.

Table 3.6

Production of Principal Crops in Hoogly

Area in thousand hectres

Production in thousand tones

Crops 2010-11 2011-12 2012-13

Area Production Area Production Area Production

Rice 292.4 904.2 277.2 806.8 273.4 793.0

Wheat 0.3 0.9 0.2 0.4 0.1 0.3

Other Cereals 0.3 0.5 0.3 0.5 0.2 0.4

Total Cereals 293.0 905.6 277.6 807.7 273.8 793.7

Pulses 0.3 0.5 0.2 0.2 0.3 0.3

Total Food grains 293.4 905.8 277.8 807.9 274.1 794.0

Oilseeds 52.6 59.4 51.2 60.0 56.1 71.1

Jute(C) 26.9 573.2 26.9 444.5 26.7 526.4

Potato 100.4 3530.6 94.4 2439.9 100.2 3246.4

Source- District Statistical Handbook, 2013

Bureau of Applied Economics & Statistics

Government of West Bengal

Size of land holding:

Pattern of cultivation of an area also depends on size of land. If the size of land is large;

tractors, sewing machine, harvesting machine could be used for cultivating purpose and

consequently production would be more. In the following table shows the distribution of land

holding.

Table 3.7

Distribution of operational holding according to size class in the district of Hooghly

(Area in hectares)

Size of land 2012-12

No of Holdings Area of holdings

Marginal 297969 131036

Small 40474 62345

Semi-medium 6299 17106

Medium 1166 5485

Large - -

Total 345908 215972

Source- District Statistical Handbook, 2013

Bureau of Applied Economics & Statistics

Government of West Bengal

19

Note:- Marginal: Below 1.0 hectares, Small: 1.0 hectares and above but less than 2.0 hectares, Semi-

medium: 2.0 hectares and above but less than 4.0 hectares, Medium: 4.0 hectares and above but less than

10.0 hectares, Large:10.0 hectares and above.

Agricultural Marketing :

The main objective of analyzing agriculture marketing system in the district is to determine

how the various agricultural products are marketed in the district. In other words how the

agricultural produces reach the ultimate consumers. As the district is devoid of modern and

organized marketing infrastructure which is needed to help the growers/farmers to get a fair price

for their produce. Middlemen like Beparies, Aratdars, Fariahs,etc play a very vital role in the

activities of marketing various agricultural products in the district. The total markets in the district

are 223. There are 3 Regulated Market Committees in Saoraphuli and Pandua. They have 142 sub-

market yards. Besides, 36 wholesale markets, 187 daily and weekly markets/hats are spread over

the district. Agricultural Markets is given below:-

Table 3.8

Sub-division wise wholesale/ main markets in Hooghly district.

Sub-Division Name of Wholesale/Main Markets Principal commodities

Chinsua(sadar) Mogra,Pandua Potato,Rice

Serampore Sheoraphuly, Champadanga Jute, rice, Potato, paddy

Arambagh Tarakeshwar,Haripal,Kalipur Rice

Table 3.9

Block wise markets/hats in Hooghly district.

Name of the block No. of markets No. of hats

Pandua 7 7

Balagarh 11 -

Jangipara 5 5

Chanditala-I 14 -

Chanditala-II 13 -

Tarakeshwar 6 2

Serampore-Uttarpara 33 -

Polba-Dadpur 3 3

Arambagh 19 -

Khanakul-I 18 -

Khanakul-II 9 -

Goghat-I 8 -

Goghat-II 7 -

Pursurah - -

Table 3.10

Warehousing and Cold Storage Facilities available to Cultivators in the district of Hooghly

20

Year Warehouses Cold Storages No. of

Cultivators

benefitted No. Capacity(MT) No. Capacity (MT)

2010-11 25 59562 132 1662900 815000

2011-12 36 70502 142 1768000 1000000

2012-13 29 71848 144 1751429 1015000

Source : Asstt. Director of Agri. Marketing (Administrative), Hooghly

There are 29 warehouses with 1015000 MT capacity and 133 running cold storages with

1624000 MT capacities. Potatoes are stored in the cold storages. Other infrastructure like link road,

transport, shed, etc .are more or less available in all parts of the district. The surplus agro-produces

are cereals-25 percent vegetables-10 percent and fibre (jute)-100%.

Horticulture:

Horticulture produce in Hooghly district are yet to be raised commercially. Among these

produce, vegetables are surplus. Fruits are mainly grown in orchid. The production of horticulture

produce is given in the following table:-

Table 3.10

Area covered under Horticulture (Sector wise):

Fruit Crops 11743 ha.

Floriculture 817 ha.

Medicinal Plant Nil

Table 3.11

Area and production of Fruits and Vegetables in the district of Hooghly 2012-13.

Name of Fruits/

Vegetables

Area (Thousand hectares) Production (Thousand

tonnes)

Fruits

Mango 5.64 40.50

Banana 5.21 108.80

Pineapple 0.05 0.71

Papaya 0.74 18.65

Guava 0.22 4.15

Jackfruit 0.12 2.27

Litchi 0.21 1.88

Mandarin Orange - -

Other Citrus 0.21 2.21

Sapota 0.11 1.35

Others 0.11 1.00

Total 12.62 181.52

Vegetables

Tomato 1.07 20.40

Cabbage 2.95 67.10

Cauliflower 3.73 96.82

Peas 0.71 7.05

Brinjal 7.83 136.19

21

Onion 2.67 58.50

Cucurbits 12.26 142.05

Ladies Finger 3.88 41.60

Radish 1.45 19.75

Others 17.49 94.33

Total 54.04 683.79

Source- District Statistical Handbook, 2013

In the district, fruits are grown by traditional method. Mango, banana and papaya are the

major frits and some fruit processing unit may be set up based n this fruits. The district is also rich

in production of vegetable. During peak season, vegetables are surplus and whole the year, various

vegetables grow in the district. So, vegetable based industries may also set up.

Sericulture :

There is no significant activity in Sericulture in the district.

Forest :

Forest is another important resource for economic development. But Hooghly district has

only 299.41 hectares forest land which is only negligible in compare to the total are of the district.

Category wise forest are in the district is given below :-

Table 3.12

Category wise forest are in Hooghly district 2012-13

Sl No. Status of forest Area (Hect)

1 Reserved Forest 211.93

2 Protected Forest 77.26

3 Un classed state Forest 10.22

Total 299.41

Source- District Statistical Handbook, 2013

Bureau of Applied Economics & Statistics

Government of West Bengal

Forest in the district mainly comes under social forest. In these forest, mango, sal, teak,

simul, eucalyptus, jamrul, akashmani, neem, bamboo, subabul, babul, etc. are grown The main

forest produce are timber, fuel wood, pole etc. The production of forest resource is given below:-

Table 3.12

Major forest production in Hooghly district for 2012-13

Produce Production

Timber 79.62 Thousand cu metre

Fuel 23.36 Thousand cu metre

Pole 108 Nos.

Revenue Rs.634000/-

Source- District Statistical Handbook, 2013

Bureau of Applied Economics & Statistics

Government of West Bengal

22

Live-Stock :

Livestock is another input for economic development. It helps in the development in both

agriculture and industry. Farmers in the district rear domestic animals for cultivation of their land

as well as for secondary income. In Arambagh sub-division, a sizeable numbers of people adopted

poultry as their profession. Arambagh Hatchery has been set up at headquarter of Arambagh Sub-

division. Livestock population is given in the following table:-

Table 3.13

Livestock population in Hooghly district

Category 2007

(As per last Census)

1. Cattle

Cows 451252

Bulls and Bullocks 75123

Young Stock 434460

Total Cattle 960835

2. Buffaloes

Cows 18225

Bulls and Bullocks 13076

Young Stock --

Total Buffaloes 31301

3. Sheep 5497

4. Goats 759716

5. Horses and ponies 16

6. Pigs 29060

7. Other Live-stock 79260

Total Live-stock 1865685

8. Poultry

Fowls 2202538

Ducks 890064

Others 23468

Total Poultry 3116070

Source- District Statistical Handbook, 2013

Bureau of Applied Economics & Statistics

Government of West Bengal

Diary Development

Dairy activities have been developed significantly in the district. All the leading dairy units

in the State have set up their one or two units in the district. The units are as under:-

1) Mother Diary, Dankuni

2) Amul Dairy (two units), Chanditala & Makalpur

========XXX========

23

CHAPTER-IV

INFRASTRUCTURE

Hooghly being situated adjacent to the industrially advanced district of Howrah, the

industrial saturation of Howrah has give rise to a natural trend of industrial extension to this

contiguous district of Hooghly. The industrial development of the district displays imbalance

between the narrow riparian strip along the River Bhagirathi from Uttarpara to Tribeni and the rest

of the district. While the former bristles with modern factories, the industrial progress in the other

part is indicated at the best by Cold Storages, Rice mills and the Brick fields. Remaining parts of

the district still exhibit a strong agricultural bias with very limited sign of industrial development.

Infrastructure is pre-requisite for laying the foundation of rapid industrialization and

economic growth of a place. Development of infrastructure helps the industrial growth and

development in many ways as it reduces capital cost, increases labor productivity and makes

available the required information at lesser costs. Infrastructures are classified into two categories

viz. Physical Infrastructure and Social Infrastructure: These are discussed below:-

Physical Infrastructure

Land :

Availability of land for industrial use is a burning question now, in the district, it is already

stated that Hooghly is most congested comprising of towns, industries, fertile agricultural land and

thick population. In spite of this congestion, the district authority is very keen to arrange land for

appropriate industries because of eagerness of industrialization of the authority. In the north and

west part of the district land is available. There is 88.78 hectare of land consisting of non-

agriculture use, barren and uncultivated, permanent pastures, waste, fallow etc. These land could

be used for industrial purpose.

Water :

In Hooghly district the question of water does not pose any problem as the sources are

numerous rivers like the Hooghly, the Damodar, the Dwarkeshwar, the Rupnarayan. These rivers

are perennial in nature. Besides, underground water is available in whole district.

24

Power :

Power is one of the important input for speedy industrialization. WBSEDCL is responsible

to supply power in the district. It is reported that power supply is better in the district. The district

of Hooghly had the following consumption of electricity during the last three years.

Table 4.1

Category wise consumption of electricity in Hooghly district (000KWH)

2010-11 2011-12 2012-13

Domestic 505430 539470 593922

Commercial 100565 113405 124663

Industrial 759718 745940 772839

Public Lighting 6548 6351 6190

Agricultural Irrigation & Dewatering 102477 102328 97809

Public Water Works & Sewage Pump 16359 16017 15137

Railway Traction & Non-traction 1183 1131 1084

Miscellaneous 19097 16519 31360

Total 1511377 1541161 1643004

Source- District Statistical Handbook, 2013

Bureau of Applied Economics & Statistics

Government of West Bengal

Table 4.2

Mouzas Electrified in the district of Hooghly

(Number)

Sub-Division/ C.D.Block 2011 2012 2013

Sadar Sub-Div. 756 756 756

Dhaniakhali 214 214 214

Pandua 157 157 157

Balagarh 135 135 135

Chinsurah-Mogra 56 56 56

Polba-Dadpur 194 194 194

Chandannagar Sub-Div. 352 352 352

Tarakeswar 90 90 90

Haripal 154 154 154

Singur 108 108 108

Serampur Sub-Div. 229 229 229

Jangipara 129 129 129

Chanditala-I 56 56 56

Chanditala-II 25 25 25

Serampur-Uttarpara 19 19 19

Arambagh Sub-Div. 567 567 567

Goghat-I 99 99 99

Goghat-II 112 112 112

Arambagh 159 159 159

25

Khanakul-I 94 94 94

Khanakul-II 53 53 53

Pursurah 50 50 50

Total 1904 1904 1904

In the above table, the major consumers of power are domestic people, industrial units,

commercial establishments and so on. The power supply is more or less satisfactory in the district.

All 1904 Mouzas of the district are electrified. So power is available in all parts of the district. This

facility is hardly available in other districts except a few.

There are many power distribution sub stations with power grid and under them 25 sub

stations spread all over the district. The location of the sub stations are given below:

Table 4.3

Name and location of the sub stations :

Sl.No Name of the Sub-Stations (in K.V)

1 AdiSaptagram 132/33/II

2 Rishra 132/33/II

3 Hindusthan Glass 33/II

4 Sheorphuli 33/II

5 Singur 33/II

6 Kaikala 33/II

7 Raghunathpur 33/II

8 Dunkuni Coal Complex 33/II

9 Jangipara 33/II

9 Shiakhala 33/II

10 Dasghara 33/II

11 Belmuri 33/II

12 Chanpadanga 33/II

13 Mayapur 33/II

14 Khanakul 33/II

15 Arambagh 33/II

16 Tarui 33/II

17 Dunlop 33/II

18 Taldanga 33/II

19 Kalitala 33/II

20 Talandu 33/II

21 Bansberia 33/II

22 Pandua 33/II

23 Inchura 33/II

24 Boinchee 33/II

25 Khanyan 33/II

26

Railways :-

The railway is under Howrah Division. The first train of ER started its journey from Howrah to

Hooghly. Hooghly station was announced as the heritage station. The railway communication of

the district, especially at the suburban area, is very developed. Bandel Junction is the district

railway headquarters and is the largest and the busiest rail station and a vital junction station of

India. There are four junction stations in Hooghly:

• Bandel

• Dankuni

• Kamarkundu

• Seoraphuli

Distribution of railway lines

1. Eastern railway Howrah-Burdwan main line

2. Howrah-Burdwan cord line

3. Howrah-Tarakeswar main line

4. Howrah-Katowa main line

Total no of railway station : 69

Roads:

The district of Hooghly is having a good network of road communication connecting he

district headquarters as well as with the nearest city of Kolkata through the following road network:

Table 4.4

National Highway

National Highway No.- 2 55

Total 55

Table 4.5

State Highway

In KMs

SH -2 1. Bankura - Khatra

2. Khatra more - Taldangra - Chenchuria

3. Chenchuna - Bishnupur 4. Bishnupur By-pass

5. Bishnupur - Kotulpur - Arambagh

6. Kotulpur- Arambagh

7. Arambagh - Pursurah - Champadanga

8. Champadanga - Tarakeswar - Baidyabati

9. Baidyabati - Uttarpara

10. Uttarpara - Dakshineswar - Dunlop - Bkp

11. Barrackpore - Barasat

12. Barasat - Basirhal - Hasnabad

13. Hasnabad - Chaital - Maiancha

(0 - 30)

(30 - 52)

(52 - 76) (76 - 81)

(81 - 117)

(117 - 135)

(135 - 156)

(156 - 196)

(196 - 214)

(214 - 226)

(226 - 239)

(239 - 301)

(301 - 323)

27

SH- 6 1. Rajnagar - Sun

2. Sun - Ahmedpur

3. Ahmedpur - Kirnahar - Ramjibanpur

4. Ramjibanpur - Kelugram - Katwa

5. Stkk road Burdwan part

6. Stkk road Hooghly pari

7. Saptagram - Uttarpara gt poad

8. Uttarpara - Howrah - B. Garden gt road

9. B garden - Alampur

(0 - 26)

(26 - 47)

(47 - 76)

(76 - 99)

(99 - 169)

(169 - 202)

(202 - 242)

(242 - 255)

(255 - 266)

SH- 7 1. Rajgram - Nalhafi

2. Nalhati - Moregram via nh60

3. Moregrarn - Alinagar

4. Almagar - Kulee

5. Kulee – Ramjibanpur

6. Ramjibanpur - Palita - Palitpur - Natunhat

7. Natunhat - Muraiipur - Karjona

8. Karjona- Burdwan

9. Burdwan - Arambagh Burdwan Portion 10. Burdwan - Arambagh Hooghlv Portion

11. Arambagh - Goghat - Ramjibanpur

12. Ramiibanpur - Khirpai

13. Chandrakona- Keshpur

14. Keshpur - Midnapore

(0 - 31)

(0 - 0)

(31 - 51)

(51 - 71)

(71 - 100)

(100 - 129)

(129 - 148)

(148 - 163)

(163 - 196) (196 - 205)

(205 - 226)

(226 - 244)

(244 - 265)

(265 - 289)

SH-13 1. Mollarpui maghipara - Bolpur - Vedla br

2. G.t road - Palsu (via nh-2)

3. Vedia br - Guskara

4. Guskara - Burdwan

5. G.t road Burdwan town

6. Palsit - Mogra - Dankuni

(0 - 66)

(0 - 0)

(66 - 82)

(82 - 111)

(111 - 121)

(121 - 203)

SH-15 1. Dainha t - Manieswai k m

2. Tarakeswar - Champadanga (via sh2)

3. Eksora - Battikuri (via nh6)

4. Manteswar - Memari

5. Memari - Chqkdlghi

6. Chakdighi - Tarokeswar

7. Champadanaa - Chandilala

8. Chanditala - Eksara

9. Baltikuri - Bargachia - Amta

10. Amta - Bagnan

11. Bagnan - Shvarnpur - Gadiara

(0 - 30)

(0 - 0)

(0 - 0)

(30 - 62)

(62 - 93)

(93 - 106)

(106 - 142)

(142 - 156)

(156 - 192)

(192 - 205)

(205 - 242)

Total 176

Table 4.6

Metalled Road

No. Name In K.M.

(approx.

)

Sub-

Division

Secton

1 Chandenagore-Nasibpur Road 11.620 Hooghly Chinsurah

2 Anandanagore health centre- Link Road 2.660 Hooghly Chinsurah

3 Bhadreswar Rly.Stn. to Chandenagore-Nasibpur

Road

5.880 Hooghly Chinsurah

4 Polba-Keswara Road 5.140 Hooghly Chinsurah

5 Pawnan-Onchai Road 3.000 Hooghly Chinsurah

6 Barunapara link Road 2.900 Hooghly Chinsurah

28

7 Saniya-Pawnan Road 3.300 Hooghly Chinsurah

8 Jayer-Dwarbasini-Sanihati Road 10.820 Hooghly Chinsurah

9 Mogra-Sultangacha Road 5.000 Hooghly Kunti

10 Sultangacha-Khanpur-Dasghara Road 36.230 Hooghly Kunti,

Gurap

11 Pandua-Polba Road 16.600 Hooghly Kunti.

Pandua

12 Mogra-Polba Road 8.650 Hooghly Kunti

13 G.T.Road to Kola village- Link Road 0.450 Hooghly Pandua

14 Naksa-Digsui Road 2.950 Hooghly Pandua

15 STKK to Dumurdaha Rly.Stn.- Link Road 1.000 Hooghly Kunti

16 Khanyay-Itachuna Road 4.080 Hooghly Pandua

17 G.T.Road to Talandu Rly.Stn.- Link Road 1.430 Hooghly Pandua

18 Pandua-Kulti Road 6.020 Hooghly Pandua

19 Boinchee-Horal Road via Bilsora 5.600 Hooghly Pandua

20 Dakshina Kali Temple from Pandua-Polba- Link Road

0.500 Hooghly Kunti

21 Dakshina Kali Temple from Mogra-Khanpur-

Link Rd.

1.280 Hooghly Kunti

22 Pandua-Kamtai Road to Simlagarh 5.800 Hooghly Pandua

23 Marshit-Basantaburitala Road 1.350 Hooghly Pandua

24 Boinchee-Bastara-Majinan-Belmuri Road 20.600 Hooghly Gurap

25 Mogra-Khanpur to Kanthalgoria health centre 1.330 Hooghly Gurap

26 Kaspastikiri-Meria Road 3.720 Hooghly Kunti

27 Mogra-Dasghara Road at Gurup 2.000 Hooghly Gurap

28 Jaugram-Khanpur Road 10.270 Hooghly Gurap

29 Dasghara-Rathtala Road 0.229 Hooghly Gurap

30 Roads under Dhaniakhali CD Blocks 1.300 Hooghly

31 Belmuri-Bhandarhati to Bagnan health centre 0.180 Hooghly Gurap

32 Chinsurah-Dhaniakhali to Belmuri Rly.Stn 2.670 Hooghly Chinsurah

33 Bhanderhati-Kumrul Road 13.810 Hooghly Chinsurah

34 Olipur to Chandapur Road 7.200 Hooghly Gurap

35 Jejur-Chandanpur Road 2.100 Hooghly Gurap

36 Narayanpur on Trakeswar-Dasghara Road to

Jiara Ferry Ghat- Link Road

3.180 Hooghly Chinsurah

37 Tarakeswar-Kanariaghat Road 5.300 Hooghly Chinsurah

38 Tarakeswar bazar to Tarakeswar health centre

Road

0.700 Hooghly Chinsurah

39 Nandankuthi-Samserpur Road 5.450 Hooghly Chinsurah

40 Singur-Ugly Road 9.660 Hooghly Chinsurah

41 Kamakundu-Bejemelia Road 3.226 Hooghly Chinsurah

42 Nalikul on BTC Road to Bandipur bazar to Gaja

Bakultala- Link Road

6.000 Serampore Seakhala

43 Nalikul-Seakhala Road 6.180 Serampore Seakhala

44 Singur-Banamalipur Road 7.500 Serampore Serampore

45 Singur High School to Durgapur Expressway via

Dhirgangi Road

2.800 Serampore Serampore

46 Tarakeswar-Mujpur-Peasara Road 10.800 Serampore Seakhala

47 Tarakeswar-Keshabchawk Road 5.760 Serampore Seakhala

29

48 Furfura-Sarif-Jangipara Road 16.000 Serampore Jangipara

49 Bora-Seakhala-Jangipara Road 23.400 Serampore Serampore,

Seakhala,

Jangipara

50 Jagjibanpur-Autpur-Jangipara Road 9.400 Serampore Jangipara

51 Rahimpur-Rajbalhat-Tararmore Road 8.100 Serampore Seakhala

52 Bokpotaghat-Rahimpur-Jangipara Road 9.500 Serampore Jangipara

53 Bokpotaghat-Ichanagori Road 11.420 Serampore Jangipara

54 Jagatballavpur-Sitapur-Jangipara Road 9.800 Serampore Jangipara

55 Jangipara-Boral Road 3.420 Serampore Jangipara

56 Ujalpukur-Rampara-Toralpur Road 3.950 Serampore Seakhala

57 Furfura-Aniya-Dakshindihi-Bargachia Road 8.770 Serampore Jangipara

58 Bandhpur-Ichapasara Road 5.100 Serampore Seakhala

59 Sitapurhat-Mundalika Road 2.200 Serampore Jangipara

60 Kalachara-Bhagabatipur Road 7.200 Serampore Serampore

61 Janai-Baksa-Krishnarampore Road 3.780 Serampore Serampore

62 Maternity hospital Link Road 0.420 Serampore Serampore

63 Janai-Adambazar-Janai Rly.Stn. to

Panchabatitala Road

3.200 Serampore Serampore

64 NH-2 byepass to Naity Road via Gobra Rly.Stn. 4.400 Serampore Serampore

65 Jangalpara-Gangadharpur Road 4.140 Serampore Serampore

66 Kotalpara-Khusiganj Road via Pursurah 11.500 Arambagh Khanakul

67 Balarampur-Chatrasal Road 8.840 Arambagh Khanakul

68 Pursuah-Radhanagar Road 17.800 Arambagh Khanakul

69 Pursuah-Radhanagar to Tantisal health centre-

Link Road

2.300 Arambagh Khanakul

70 Jagatpur-Dharampota to Pursurah-Radhanagar-

Link Road

3.300 Arambagh Khanakul

71 Jagatpur-Dharampota Road 24.600 Arambagh Khanakul

72 Rajhati-Bandar to Ramchandrapur health centre

Road

2.400 Arambagh Khanakul

73 Khanakul health centre- Link Road 1.960 Arambagh Khanakul

74 Kabulia-Tilakchawk Road 10.430 Arambagh Khanakul

75 Kabulia-Tilakchawk with a link to Narayanpur

health centre

0.400 Arambagh Khanakul

76 Sodepur-Khushigunj Road 11.840 Arambagh Arambagh

77 Kabley to Moloypur health centre Road 8.200 Arambagh Arambagh

78 Banamalipur-Fatepur-Gotan Road 5.540 Arambagh Arambagh

79 Muthadanga-Batanal-Pahalanpur Road 10.200 Arambagh Arambagh

80 Muthadanga-Krishnaballvpur upto R.K.Mission

a steel bridge

0.450 Arambagh Arambagh

81 Arambagh-Gourhati Road 13.000 Arambagh Arambagh

82 Gourhati-Bandar Road 12.000 Arambagh Arambagh

83 Gourhati-Baradangal Road 2.310 Arambagh Arambagh

84 Khanakul-Gourhati Road 7.554 Arambagh Khanapur

85 Arambagh-Tirol Road 8.000 Arambagh Arambagh

86 Kalipur-Udayrajpur Road 9.300 Arambagh Kamarpukur

87 Madhubati-Bengai Road 5.800 Arambagh Kamarpukur

88 Kamarpukur- Link Road 2.000 Arambagh Kamarpukur

89 Jayrambati-Kamarpukur Road 5.000 Arambagh Kamarpukur

90 Kotolpur-Kamarpukur Road 14.000 Arambagh Kamarpukur

91 Jayrambati Link Road 5.000 Arambagh Kamarpukur

30

92 Jayrambati-Kamarpukur Road to Jayrambati

Matri Mandir- Link Road

0.370 Arambagh Kamarpukur

93 Jayrambati-Punnyapukur Road 0.300 Arambagh Kamarpukur

94 Kamarpukur-Anur Road 2.830 Arambagh Kamarpukur

95 Darakeswar Bridge approach Road 0.900 Arambagh Arambagh

96 Khandighi-Jitarpur health centre Road 6.290 Arambagh Kamarpukur

Total Length (Matalled) 622.839

Road Transport :

There is good network of road communication in the district. Thus, the principal mode of

transportation of goods and movement of people within and outside the district is road. The mode

of transportation is bus, truck, mini bus, taxi, car, trekker, auto-rickshaw, rickshaw, etc. The vehicle

population of the district is given in the following table:-

Table 4.7

Vehicle population in Hooghly district as on 31.03.2013

Sl No Categories of vehicles No. of vehicles

1 Goods Vehicles 25528

2 Motor car & Jeep 26313

3 Motor cycle & Scooter 359799

4 Taxi & Contract Carriage 1410

5 Auto Rickshaw 7041

6 Mini Bus 338

7 Stage Carriage 4460

8 Tractor & Trailer 4590

9 Others 2308

Total 431787

Air Transport :

There is no airport in the district. The nearest airport is Netaji Subhash Chandra Bose

International Airport, Dum Dum which is about 40Kms away from district headquarter Chinsurah.

Water Transport :

The river Hooghly is the main source of water transport of the district. All kinds of vessels

except big ship run in this river and the distance of Kolkata from Chinsurah through waterways is

about 20kms. Thus, till day this waterway plays an important role for transportation of

goods.Regarding water transport, the district has 52 ferry services plying on the river Hooghly and

other rivers. The table shows the major ferry services in the district.

31

SOCIAL INFRASTRUCTURE

Entrepreneurship :

Availability of efficient entrepreneurs is one of the essential qualities of a well developed

economy. An entrepreneur is a person who can efficiently determine an optimum risk taking

decision so that production as well as growth is maximized. To build up and channelize the

entrepreneurial skill of a person , a high level of standard education is to be imparted to the

prospective entrepreneurs. The presence of large, medium, small and micro enterprises is also

necessary to encourage the new entrepreneurs. The local educated youths are unaware about the

industrial activities and they are coming forward to adopt an enterprise as their profession.

Various promotional agencies like DIC, financial institutions, NGOs, MSME-DI, etc. are

engaged to convert the educated and skilled youths into entrepreneurs through conducting ESDP,

EDP, MDP, Skill Development Training, Awareness Campaigns, etc. As a result, it is found that at

present, the local educated unemployed youths are showing their interest in MSE sector. It is

expected that more youths will adopt MSE as their profession in near future.

Market Potential :

The market potential of a district depends on the existence of well developed market

locally as well as in its surrounding areas and also on the purchasing power and consumption

pattern of the population. It also depends on the standard of living of the local people, the stage of

growth attained by the district and the income levels of individuals.

The district has 223 daily/weekly markets in its various blocks and municipalities. The

main markets are Sheoraphuly, Pandua, Champadanga, Pandua, Champadanga, Arambagh,

Chinsurah, Baidyabati, Konnagar, Khanakul, Pursurah, Balagarh, Mogra, Haripal, Bhadreshwar,

Champdani and so on. Main marketing activities are performed in these markets. The existing MSE

units sell their products in these markets. Besides, the units enjoy the proximity of metropolitan

city, Kolkata. With minimum effort, the units bring their products in wholesale markets in Kolkata.

Kolkata is the key market in the State and NE region of the country as well as south East Asia. This

potential is available for the units in the district.

The population of the district is 55.19 lakh. The populace makes a considerable size of

demand as most of the people either middle income group or lower income group. The new

entrepreneur may target these consumers for setting up of their units.

In the service sector, Mobile phone repairing, computer servicing centre, agro-servicing

centre, auto-mobile servicing centre, electrical gadgets servicing centre, etc. are found increasing

demand.

Lending Institution:

Finance is indispensable for industrial activities. Finance is to be made available to

industries at the right time and amount for their growth. It is, therefore, essential to have a sound

network of financial institutions to mobilize saving from the people and meet the financial

requirements to the industries within the area.

32

Table 4.8

Block wise distribution of Commercial and Gramin Banks in Hooghly district:

Sl.No

.

Name of Block Number of Bank offices

Commercial

Bank

Gramin

Bank

1 Dhaniakhali 25 1

2 Pandua 14 3

3 Balagarh 12 2

4 Chinsurah-Mogra 16 -

5 Polba-Dadpur 12 3

6 Tarakeswar 10 1

7 Haripal 16 5

8 Singur 26 4

9 Jangipara 13 2

10 Chanditala-I 12 1

11 Chanditala-II 16 -

12 Serampur-Uttarpara 7 1

13 Goghat-I 6 2

14 Goghat-II 9 1

15 Arambagh 10 2

16 Khanakul-I 10 1

17 Khanakul-II 5 3

18 Pursurah 9 2

Total 228 12

Source: Lead Bank Office, Hooghly

Table 4.9

CD Ratio of Lead bank in Hoogly District

Sl.

No.

Name of

District

Lead

Bank

CD Ratio March 2014 CD Ratio Ratio June 2015 (Amount in crore)

Deposit Advance CD Ratio

1 Hooghly UCO 24 27456.29 5719.90 21

Source: Lead Bank Office, Hooghly

Table 4.10

Co-operative Banks in Hoogly

Name of the bank Address

Baidyabati Sheoraphuli co-op. Bank ltd., Head office : 6, Kalahata lane ,Post Office Sheoraphuli

Hooghly Co-Operative Credit Bank Ltd Raj Bahadur S C Mukherjee Road,Post Office Hoogly

Hooghly district central co-op. Bank ltd Netaji Subhash Road,P. O. Chinsurah

Konnagar Samaboya Bank Ltd 66, G. T. Road (west),Post Office Konnagar

Nabagram peoples co-op. Credit bank ltd 11, Vivekanand Road P. O. Nabagram,

Uttarpara co-operative bank ltd 8, Sridhar Chakrabarty Street,Post Office Uttarpara

Technical Skill & Training facilities:

There is no dearth of skill in the district. As per Live register of Employment Exchange

539314 persons registered their names as unemployed. Out of which 1531 persons were industrial,

33

6374 skilled and semi-skilled, 195625 clerical etc as on 2013. These skilled persons are

available for various industrial units.

There are various training facilities in the district. The details of facilities are given below :-

Table 4.11

A) Polytechnic

Sl no Name & address Courses offered

1 Hooghly Institute of Technology,

P.O. & Dist-Hooghly

Chemical, civil, electrical, mechanical,

computer application.

2 Women’s Polytechnic,

Chandannagar , Hooghly

Architecture electronic &

telecommunication, computer application,

computer science & technology, pharmacy

B) Part-time Evening (4years) Diploma courses for industrial persons

Sl No. Name & address Courses offered

1 Hooghly institute of Technology,

P.O. & Dist- Hooghly

Mechanical, civil & electrical

Besides, Hooghly Institute of Technology and Women’s Polytechnic have community

Polytechnic Cell to provide vocational training. Technical persons may also be obtained from

textiles Engineering College at Serampore.

Apart from above, there are number of private training institutes providing training in

computer, gold and silver ornaments, handicraft items, repairing and servicing of various items, etc.

========XXX========

34

CHAPTER-V

PRESENT INDUSTRIAL STRUCTURE

The study of existing industries is important because the present industrial structure forms

the base for building up future development. This development can be better achieved if the same is

related to the existing industries in the district. Besides, the analysis of the industrial sector as a

whole keeping the above perspective in view, an effort has been made in this Chapter to depict the

present industrial scenario of the district.

The industrial scenario of the district comprises an admixture of large, medium, small and

traditional village industries. In view of creating favorable conditions in the economy for self

sustaining growth of industries specially MSMEs, the following parameters viz. (1) General

Industrial Climate, (2) Large Scale Industries, (3) Medium Enterprises, (4) Small Scale Enterprises,

(5) Khadi & Village Enterprises, (6) Handicrafts, (7) Handloom and (8) Problems faced by the

existing industries have been taken into consideration.

1) General Industrial Climate

Hooghly is one of the leading industrial districts in the State. Better resources and

infrastructural facilities encouraged the all categories of entrepreneurs to set up industrial units in

the district. Thus, industrialization was started from pre-independence and it is still continued. At

present, entrepreneurs are more interest in setting up their industrial units. Almost all large and

medium scale units are running well. The MSEs are also functioning well. New industrial units in

all sectors like large, medium, small and micro are being set up in every year.

Hooghly district has one Food Park in the district.

Sl.

No. Name of Ind. Area Land acquired (In Acre) Land developed (In Acre) No. of Units

in Production

Modular Food Park, Dankuni 500 acre 500 acre 215

Source:- WBSIDC & WBIIDC

The existing industrial growth centers are located in the region comprising Uttarpara,

Rishra, Serampore, Shoraphully, Chandernagore, Mogra, Chinsurah and Pandua.

The proposed growth centers will cover Sheakhala (Chanditala 1), Makla (Serampore-

Uttarpara), Khalisani (Singur),Sugandha (Polba-Dadpur), Tribeni (Chinsurah-Mogra),

Jirat(Balagarh),Khanyan(Pandua),Champadanga(Tarakeswar),Arambagh(Arambagh),Kamarpukur(

Goghat-II ) and Jangipara(Jangipara).

Hooghly is one of the most economically developed districts in West Bengal. It is the main

jute cultivation, jute industry, and jute trade hub in the state. The jute mills are along the banks of

the river Hooghly in Tribeni, Bhadreswar, Champdani and Sreerampur.

35

List of some Jute Mills in Hooghly district:

Sl. No. Name of Jute Industries

1 North Brook Jute Co. Ltd., Champdani

2 Dalhousi Jute Mill, Champdani

3 Breathwait & Co., Angus

4 Gondalpara Jute Co. Gondalpara

5 Victria Jute Mill, Telenipara, Bhadreswar

6 Baleaius India Ltd., G.T. Road, Bhadreswar

7 Angus Jute Workers, Angus

8 Lagon Jute Machinery Ltd., Angus

9 North Shyamnagore Jute Mill Ltd. Bhadreswar

10 Bellis India Ltd., Bhadreswar

Existing Major Industrial Units in Hooghly district:

Existing Major Industrial Units Sl.No Name of the Industry Product Manufacturing

1 Bhushan Steel Galvanised Steel Sheets

2 Black Diamond Beverages Coca Cola Bottling Plant

3 Multi Serve Rolls SG Iron Rools

4 Quality Steel Wire Products Steel Wire

5 Ganesh Steel & Alloys Steel Ingots

6 Longlast Pipes Pipes

7 North Eastern Metal Metal Processing

8 Om Forging Steel Forging

9 B.B. Forging Steel Forging

10 Modern Steel Hot Rolling Mill Plant

11 Jasmine Agro Food Products Agro Processing

12 Hindustan Development Corporation Steel Castings

13 Orient Steel Industries Steel Castings/Ingots

14 Agarwal Steel Complex Steel Ingots

15 Saraf Iron Foundry Iron Castings

16 Assam Tubes Steel Ingots

17 Ganga Valley Foods Food Processing

18 Cans & Closures Cans

19 Anmol Biscuits Bakery Products

20 Modular Food Park Industrial park for food

processing industries

Industrial Projects in Pipeline;

Sl. No. Name of the Company Product

1. Bajrangbali Rolling Mills (P) Ltd. Steel Ingots

2. Indian Rayons Ltd. Rayon

3. Star Battery Ltd. Components including battery plates

4. Nanda Forging Pvt. Ltd. Audio-Parts

5. Ma Bhairavi Cold Storage Pvt. Ltd. Cold Storage

6. Modular Ind. Infrastructure Ltd. Food Park

7. Modern India Steel Rolling Mill (P) Ltd. Hot Rolled Steel

8. Nezone Strips Ltd. Plastic Injection Moulded crates

36

9. Orient Steel & Industries Ltd. Hot Rolled Products

10. Kusum Products Ltd. Vegetable Oils

11. Hope Cardamom Estate Ltd. Hot Rolled Products

12. Opec Innovations Ltd. Pham Products

13. B.B. Forgings (P) Ltd. Casting of Iron and Steel

14. Mohan Bakers Biscuits

15. Shivashakti Agro (India) Ltd Poultry Feed

2) Large Scale industries

There are as many as 171 large and medium scale industrial units in the district. Most of

them are years old. The large scale units are manufacturing different products like jute products,

pharmaceuticals products, iron and steel casting, rolling mills, rubber products, wheat products,

computer pants, motor bike, car, paints, iron and steel alloy and ingot, textile products, etc. The list

of major large scale units given below.

Sl No. Name of Industries

1 Bandel Thermal Power Plant, Bandel

2 Dankuni Coal Complex, Dankuni

3 Mother Dairy, Dankuni

4 Aditya Birla Insulators

5 B. D. Castings Ltd.

6 Calcutta Springs Ltd.

7 Down Stream Units of HPL( 2 Units)

8 Himadri Chemicals & industries ltd. (Mahistikry unit)

9 Himadri Chemicals & industries ltd.

10 Himadri Chemicals & industries ltd. (HaripalUnit)

11 IFB Agro Industries Ltd.

12 J.P Flour Mills Pvt. Ltd.

13 Jute Mills ( 6 Units)

14 Kessoram Rayon

15 J.K. Steel

16 Tribeni Tissues

17 Hindustan Development Corpn. Ltd.

18 ICI India Ltd.

19 Indian Rayon & Industries Ltd.

20 India Foils Ltd.

21 Kusum Industries

22 Hyderabad Industries Ltd.

23 Tirupati Ferro Alloy Udyog(P) Ltd.

24 Arcvac Forge Casting Pvt. Ltd.

25 Ascon Agro Products Exporters & Buildingers Pvt. Ltd.

26 Bio-caps India Ltd.

27 Brand Alloys Ltd.

28 Global Automobiles Pvt. Ltd.

29 Himadri Chemicals & Industries Ltd.

30 Hooghly Alloy & Steel Ltd.

31 JP Flour Mill Pvt. Ltd.

32 Jayashree Textiles

33 Xenitis Infotech Pvt. Ltd.

37

LIST OF MEDIUM SCALE INDUSTRIES IN HOOGHLY DISTRICT

Sl

No.

Name of Industries Item of Production

1 Hindusthan Motors Ltd., Hind Motor, Automobile Mfg.

2 Jaya Sree Textile & Industries, Rishra Textile Goods

3 Kessoram Rayon, Kuntighat Rayon Pulp.

4 J. K. Steel, Rishra Iron & Steel Industries

5 Tribeni Tissues, Tribeni Tissue Paper

6 Hindusthan National Glass Ltd., Rishra Glass bottles, Sheetglass, Tubes etc.

7 Angus Works, Baidyabati Rly Wagon Components

8 Kusum Industries, Rishra Hydrogenerated Vegetable Oils

9 Nelco Chemicals, Rishra Chemicals

10 Window Glass, Tribeni Glass Tubes and GlassProducts

11 Eastern Paper Mill, Adconagore, Tribeni Paper

12 Lagan Jute Machinery, Bhadreswar Jute Machineries and Components

13 Durgapur Maliabe Casting,

Khanyan, Pandua

Iron Castings

14 Light Machinery, Khanyan, Pandua Aluminum Foils

15 East India Four Mills (P) Ltd., Delhi Road,

Serampore

Wheat

16 High Rise Roller Flour Mill P. Ltd.,

Sugandhya

Wheat

17 Hindustan Develop. Corpn. Ltd., Bamunari Foundry Items

18 Panchanan Cold Storage (P) Ltd., Arambagh Cold Storage

19 Hyderabad Industries Ltd., Hindmotor Indus. & Agri Machinery

20 ICI India Ltd., Rishra Rubber based chemical

21 Indian Rayon & Industries. Ltd., Rishra

Processing & Printing of Fabric,

Textile & Synthetic Wool

22 SWIL Ltd.,

Uttarpara

Copper & Copper Alloy wire

23 The General Industrial Society Ltd.,

Baidyabati

Cotton Blended yarn

24 India Foils Ltd., Hoera, Khanyan Aluminium foils

25 SS Brick Industries (P) Ltd. Fly Ash Brick

26 Pashupati Seohung Ltd.

Chapsara, Serampur

Rubber Contraceptive

27 Pulver Ash Ltd., BTPS,

Bandel

Fly Ash Brick

28 The Phosphate Co. Ltd,

Rishra,

SSP, Sulphuric Acid

29 Tirupati Ferro Alloy Udyog (P) Ltd. Niala,

Khanyan

Steel Fabrication

30 Lead Stone Energy Ltd.,

Sugandhya

Lead alloys

31 Bishnu Potato Storage (P) Ltd.

Pursurah

Cold Storage

32 R.S.Ispat (P) Ltd, Dankuni Ingot ,Hot rolled steel products

33 Ruia Chemicals & Industries Ltd.

Raghunathpur

Calcium Carbonate

34 Adhunik Steel (P) Ltd.,

Serampur

Alloy Steel

38

35 Eastern Jute Wool Tex (P) Ltd. Jute Yarn

36 Ganesh Steel & Alloys Limited M.S.I. ongts

37 Keshavilal Khandewal Properties Ltd. HDPE Woven Sacks

38 Premier Mettaurgical (P)Ltd. Steel Ingots

39 Anmol Biscuits (P) Ltd.,

Dankuni

Biscuits

40 Khanakul Himghar (P) Ltd.,

Khanakul

41 Multi Serve Rolls (P) Ltd. Cast iron/Steel iron

42 Nezone Tubes Ltd.,

Dankuni

Steel Tube

43 Tol India Ltd. M.S. Angles, Rods, Rounds etc

44 Walter Craven Ceramic Project India Ltd. Fly Ash Brick Mfg. Machine

45 Brand Alloys Ltd. Steel Products

46 Jainex Metallics Ltd. Ingot Casting

47 Star Battery, Chakundi,

Dankuni

Lead Acid Battery

48 Hooghly Ispat Ltd Ductile Iron Casting

49 Paceman Sales Promotion Pvt. Ltd. Refined Vegetable Oils

50 Vikrant Alloys & Forgings Ltd.

Dankuni,Delhi Road

Forging or Stamped but not further

Worked

51 Bhusan Industries Ltd. Bangihati,

Delhi Road, Serampore

Cold Rolled Steel Sheets

55 Hindustan Seals Ltd. Printing inks, Lacquers, Varnishes

53 Leadstone Energy Pvt. Ltd. Red Lead & Calcium Lead Litharge

54 Mukund Foods Pvt. Ltd.

Maitypara, Dankuni

Food Products

55 Ravi Timber & Allied Products, Durgapur

Expressway, Panchgram, Dankuni

Plywood

Small Scale Industries

Small Enterprises(SEs) are also flourishing like other enterprises. Availability of agro products in

the district and availability of infrastructure, proximity of Kolkata metropolis are encouraging and the SEs to

set up units in the district. Thus, both resources based units like food products and demand based units have

been set up.

The SEs are concentrated in and around of handannagar, Dankuni, Konnagar, Baidyabati,

Arambagh, Bandel, pandua, Chinsurah, tarakeshwar, Singur, Balagarh, Serampur, Uttarpara, Polba-Dadpur,

Chanditala, etc. The resource based products of Ses are ricemill, cold storage, cattle feed, biscuits, milk

products, noodles, breads, jute products, edible oil, etc. and demnd based products are metal products, fiber

glass products, printed circuit board, glass products, insecticides, electrical products, FRP molded products,

apparel, plastic, products, chemical products, etc. Most of the units are running well.

Number of Small Scale Industrial Units Filed Entrepreneur Memorandum to the Directorate

of Micro and Small Scale Enterprises in Hooghly District

Ministry of Micro, Small and Medium Enterprises(MSME) has notified the Udyog Aadhaar

Memorandum(UAM) under the MSMED Act, 2006 vide gazette notification [SO No. 2576(E)]

dated 18-09-2015 in order to promote ease of doing business for MSMEs.

Prior to the introduction of the Udyog Aadhaar, to obtain MSME or SSI Registration, two

filing namely Entrepreneur Memorandum-I (EM-I) and Entrepreneur Memorandum-II (EM-II) had

39

to be filed. With the introduction of Udyog Aadhaar, the process of obtaining SSI or MSME

registration has been

drastically simplified.

Total number of EM-II issued by District Industries Centre,Hooghly since 2006-07 to 2015-16 is

given below.

Udyog Aadhaar Memorandum(UAM) registration in respect of Hooghly district since

September,2015 is given below:

Year Micro Small Medium Total

2015-16

(Since October,15)

235 35 2 272

The MSME sector comprises of vast range of productive activities. The small units consists

of Rice Mills, Cold Storages, Brick fields, Rolling Mills, Cattle/Poultry feed, Ice Block/Ice Candy,

Paints and Varnish, Plastic products, Rubber mounded items, Bakery, Wire drawing, Casting of

non-ferrous/ferrous, PVC rigid pipe, Computer, Hatchery, Rice bran oil, Mustard Seed crushing,

Spice grinding, Electronic items etc.

Potential area for New MSMEs Manufacturing Industry

Micro , Small ,Medium Enterprises

Due to enhancement of investment limit after implementation of MSMED Act, 2006, most

of the erstwhile SSI units come under ME Sector. These sectors are expanding fast in the district.

They are producing both resource and demand based products like SEs and they are also

concentrated in the area of SEs sector.

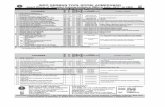

Years No. of Regd

Units

Employment Inv in Plan &

Machinery

( in Lakh)

2006-07 639 7869 7681.00

2007-08 595 8227 7292.00

2008-09 647 7973 7088.59

2009-10 565 6036 5476.65

2010-11 478 5846 5011.53

2011-12 516 5842 8830.98

2012-13 333 4573 5801.97

2013-14 630 5022 4523.43

2014-15 973 6297 7913.66

2015-16 (upto sept) 1007 10641 9657.843

Total 6383 68326 69277.653

40

Micro and Small Enterprises Sl.No 5 Digit NIC-

2004

Description

1 15138 Potato chips/powder

2 15139 Vegetable process

3 21021 Jute twine/cloth/bag

4 21021 Jute particle board

5 21021 Jute particle board

6 21021 Jute stick powder

7 15319 Puffed rice

8 15441 Macaroni products

9 15204 Milk products

10 15114 Poultry meat processing

11 15209 Dairy plant

12 15332 Poultry feed

13 15411 Mechanised bakery

14 15205 Ice candy/cream

15 15312 Rice mill

16 15142 Edible oil mill

17 15311 Flour mills

18 15314 Paddy husking

19 15314 Wheat grinding

20 15499 Noodles

21 15412 Bakery products

22 15499 Vinegar/synthetic vinegar

23 15499 Instant breakfast food

24 15315 Squash & syrup

25 15543 Mineral water

26 15203 Dalia (wheat grits)

27 18105 Readymade Garments/apparels/cotton blended shirts

28 19121 School/office bag

29 18102 Cotton knitwear/knitted socks

30 17213 Nylon mosquito net

31 21021 Jute spinning/diversified jute products

32 17141 Dyeing & bleaching

33 17125 Jute sacks

34 19202 Leather shoes and chappals with PVC/Micro cellur sole

35 18209 Industrial hand gloves

36 25199 Rubber molded products

37 25199 Automobiles and other gaskets

38 19202 Hawai chappals

39 25209 PVC hose pipe

40 33112 Disposable syringes

41 25114 Tyre retreading

42 18209 Hand gloves

43 25203 Moulded plastic products

44 25243 Detergent powder

45 24241 Washing soap

41

46 24119 Phenyl and acid for toilet cleaning (lavatory chemical)

47 24222 Paints and varnish

48 17236 Conveyor belt

49 24246 Cosmetic

50 24241 Low cost toilet soap

51 24239 Pharmaceutical formulation

52 24113 Red lead, lethargy and lead sub-oxide

53 04101 Distilled water for vehicle

54 21012 Paper products

55 21024 Corrugated paper for packaging

56 25209 Paper box for packaging

57 22212 Exercise book/note book etc.

58 26921 Ceramic frit, glazes and pacifiers

59 28994 Sanitary ware

60 26921 Refractory insulation brick

61 26101 Glass pressed and hallow wares

62 26921 Vitreous glazed roofing tiles

63 26109 Glass shell of electric bulb & tubes

64 26921 Mosaic floor tiles

65 26921 Bone china crockery and novelty wares

66 33201 Ophthalmic lens block

67 26101 Toughened glass/laminated safety glass

68 21093 Sand/emery paper

69 26105 Decorative glassware

70 27110 Alloy Casting

71 27141 Steel/Iron ingot

72 34109 Motor parts

73 27151 Building hardware (MS)

74 28996 S.S. utensils

75 36102 Steel furniture

76 28111 Gate & grill/laminated gate & grill

77 28991 Machine bolts & nuts

78 25199 Metal gasket

79 29229 Loom spares (for jute Mills and Handloom)

80 28997 Pressure Cookers

81 29308 Insecticide duster & sprayers

82 27152 C.I/G.I pipes/pipe fitting

83 36101 Wrought iron furniture

84 35923 Rickshaw assembly

85 30006 Computer Monitor

86 30007 CPU assembly

87 30007 U P S

88 33121 Constant voltage transformer

89 72292 Software development

90 72902 Desktop publishing

91 33121 Electronic regulator

92 52603 Assembly of colour T.V.

42

93 31300 PVC cables

94 31503 GLS lamp/Tube light

95 31101 Electric motor

96 31501 Emergency light

97 29303 Electric fan

98 31102 Distribution transformer

99 31506 Electric fitting

100 31503 Tube light fitting