MSF Safety Flash 2012 #43

-

Upload

syukry-maulidy -

Category

Documents

-

view

217 -

download

0

Transcript of MSF Safety Flash 2012 #43

-

8/13/2019 MSF Safety Flash 2012 #43

1/2

The information available on this Safety Flash and our associated web site is pr ovided in good faith and only for the purposes of enhancing safety and best practice. For theavoidance of doubt no legal liability shall be attached to any guidance and/or recommendation and/or statement herein contained.

- 1 -

Marine Safety Forum Safety Flash 12-43Issued: 9thNovember 2012

Subject: Gearbox Lub Oil Cooler leak

Recently on one of our vessels an issue was reported regarding a Gearbox Lub Oil Cooler leak.The vessel was berthed in harbour after completing a dry docking programme.This programme included the overhaul of the main engine and all associated coolers.The vessel had been carrying out engine tests and trials in port prior to a scheduled sea trial. As part ofthese trials the engine was started and run for short periods of time. The engineers onboard had beenchecking oil levels and noticed the gearbox oil level had dropped slightly. They investigated and as part ofthat investigation checked the overboard discharge. They identified that oil had made its way overboard andsubsequently into the harbour.

On discovering this, the engine was immediately stopped. The vessels crew rapidly laid absorbent bundsinto the harbour in way of the oil. Harbour authorities were contacted and their duty officer attended thevessel. The appropriate regulatory authorities were also made aware of the incident. An environmentalrecovery company was contacted and they attend the vessel, they assessed the situation and due to thesmall quantity of oil (10- 20 litres approx) considered there was no need to deploy any equipment other thanfurther absorbent booms. They returned later that day to check and evaluate. The booms were then removedfrom the water and disposed of.

Due to the change in the gearbox oil level the gearbox lubricating oil cooler was suspected as the most likelysource of the oil leak. The cooler was removed from the vessel by shore side contractors and delivered backto the Test house for retest. The cooler was retested and found to be leaking, it was then dismantled and oncloser inspection the face on the cooler end cover was found to be pitted. This would have the effect ofallowing oil to seep into the water side of the cooler and hence the contaminated water was dischargedoverboard. A new cooler end cover was supplied and fitted, the cooler was reassembled, retested andrefitted, engine trials carried out once more and found to be successful.

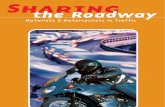

Gearbox Lub Oil Cooler end cover face pitted under gasket, allowing oil to seep into water side of cooler

-

8/13/2019 MSF Safety Flash 2012 #43

2/2

The information available on this Safety Flash and our associated web site is pr ovided in good faith and only for the purposes of enhancing safety and best practice. For theavoidance of doubt no legal liability shall be attached to any guidance and/or recommendation and/or statement herein contained.

- 2 -

Thanks to the vigilance and prompt action of ships staff this matter was identified and addressed, howeverthe potential for a more serious outcome was present.

One of the recommendations of the investigation was that when test running engines for the first timefollowing major overhaul works that a watch keeper observes the cooling water outlet when the engine is firststarted.

We will also include a generic engine procedure for commissioning, test and first operation of new/repairedequipment in the next revision of the Integrated Management System

Your assistance in ensuring your safe working environment is appreciated.