MSE 227 Materials Engineering Fall 2012. Overview Websites Textbook Syllabus Highlights –Homework...

-

Upload

harold-simpson -

Category

Documents

-

view

231 -

download

3

Transcript of MSE 227 Materials Engineering Fall 2012. Overview Websites Textbook Syllabus Highlights –Homework...

MSE 227

Materials Engineering

Fall 2012

Overview• Websites• Textbook• Syllabus Highlights

– Homework– Exams– Term Paper– Expectations– Extra Credit

• Introduction to Materials

Lab is in JD1504

Textbook

• Fundamentals of Materials Science and Engineering: An Integrated Approach, 4th Edition, 2012.

William D. Callister, Jr., Univ. of UtahDavid G. Rethwisch, Univ. of Iowa

• ISBN 978-1-1180-6160-2

Syllabus highlights

Grading Policy

• Study Suggestions:• Read the relevant material in the book. • Review and understand the example problems.• Do the assigned homework. Work additional problems if

you are having difficulty with a particular concept. • Review the lecture material (notes, PowerPoints).• Come to office hours/lab.

Term Paper 15 %

(3) Midterm Exams (1.25 hrs) 60 %

Final Exam (2 hrs) 25 %

Last day to drop: Friday, September 14, 2012.

• Do your own work• No cell phones• No music devices• No electronics, other than calculator• Closed book• No notes• If you leave during exam, you are finished with

exam (no “bathroom, smoke or coffee breaks”)

Exam Policy

Extra CreditASM/SAMPE Meetings and LecturesCOST: No charge

Lectures are on Thursdays around 7:00 PM

• September 27, 2012 - Ventura Room (2nd floor USU, above Freudian Sip)

• October 25, 2012 – Northridge Marie Callender’s• November 15, 2012 (student night) - Santa Susana

Room (3rd floor USU, above Freudian Sip)• February 28, 2013 - Ventura Room (2nd floor USU,

above Freudian Sip)• April 25, 2013 (mini-symposium) - Balboa Room

(ground floor across from Wells Fargo/Subway)

Extra Credit:Join a Materials Engineering Society

• SAMPE

• ASM

• NACE

• Material Advantage

http://sampe.org/ • The Society for the Advancement of Material and Process Engineering, SAMPE®, an

international professional member society, provides information on new materials and processing technologies through chapter technical presentations, two journal publications, symposia and commercial expositions in which professionals can exchange ideas. As the only technical society encompassing all fields of endeavor in materials and processes, SAMPE provides a unique and valuable forum for scientists, engineers, designers and academicians.

• Composite materials• Advanced matrix resin development• Advanced reinforcement fiber development• Nano materials• Metal and composite adhesive bonding• Ceramics, carbon-carbon and metal matrix composites• Fire properties of composite materials• Design and analysis of composite structures• Platform design-manned and unmanned air vehicles

Student - A registered student working toward a degree in a materials and processes related field, including all engineering and science disciplines. (USA - $20.00 Canada/Mexico - $26.00; All Others - $26.00)

http://www.sampe.org/chapsociety/studentchapternews.aspx

http://www.sampe.org/membership/newmemberjoin.aspx

SAMPE

ASM Student Memberships $25/yr

For many engineers, a relationship with ASM begins long before the start of their professional careers.

ACerS - The American Ceramic SocietyAIST – Association for Iron & Steel TechnologyASM International

TMS – The Minerals, Metals and Materials Society

Engineering Paper

• Research (finding relevant information)

• Appropriate technical level

• Proper focus (no infommercials)

• Formatting – look at the guidelines and follow them; find examples

• Time Management

• End result: Coherent paper with good technical content

*Outline for Paper*•The outline is to show that you have started working on your paper, that you know what you will discuss (sections/subtopics) and where you can find this information (sources and complete references).

•It is important that you learn how to research and how to find relevant technical information for your paper.

•The topic must be listed on the syllabus. You will not receive credit if it is a topic from a previous semester and has specifically been removed from the syllabus list. I must be able to locate your sources based on your references.

•The information in the next slide provides you with some ideas, examples of possible areas to research for your paper.

•At this point, for the outline you need to give brief statements about what you will include in these specific areas.

•You need to list at least 5 references in the format shown on the next slide.

Basic Outline Format – 1 pageTopic

Abstract

Focus of Paper

Introduction

Theory or Description of Work (if applicable)

Materials

Applications, Examples

Processing

Material Properties

Discussion, Results, Conclusion

References[1] M. Kajiwara, S. Uemiya, T. Kojima and E. Kikuchi, “Hydrogen permeation properties through composite membranes of platinum supported on porous alumina,” Catal. Today 56 (2000), p. 65.

[2] J. H. Arps, B. Lanning and G. Dearnaley, Maximizing a Potentially Significant Energy Source: SwRI researchers develop ultra-thin metal membranes for hydrogen gas separation, Technology Today, Spring 2006.

[3] K. Hou and R. Hughes, “Preparation of thin and highly stable Pd/Ag composite membranes and simulative analysis of transfer resistance for hydrogen separation,” Journal of Membrane Science 214 (2003), p. 43.

[4] J.N. Keuler and L. Lorenzen, “Developing a heating procedure to optimize hydrogen permeance through Pd–Ag membranes of thickness less than 2.2 μm,” Journal of Membrane Science 195 (2002), p. 203.

[5] Y.S. Cheng and K.L. Yeung, Palladium–silver composite membranes by electroless plating technique, Journal of Membrane Science 158 (1999), p. 127.

Guidelines for Formal Term Paper

Basic Format to include:• 1-paragraph Abstract • Introduction (to the topic matter)/Background information • material properties, comparisons with other materials,

applications, processing • Results/Analysis• Discussion & Conclusions • List of references • Single spaced with 1-inch margins. Roughly 8-10 pages long;

content is more important than length.• Include figures and tables. All figures and tables MUST have

appropriate captions.• All references must be appropriately cited throughout the text

and listed at the end of the paper.• You must use at least 5 references from a variety of sources

(text books, reference books, journals, engineering magazines, internet). If you use Callister/Rethwisch, this is in addition to the 5.

Some Resources

Science Direct >Physical Sciences and Engineering > Materials Science

http://www.engineeringtv.com/

https://nanohub.org/newsletters

http://www.wired.com/?mbid=wir_newsltr

http://www.scientificamerican.com/

Topics for the Term Paper

1. Aluminum foam or titanium foam

2. Noise attenuation/reduction/cancellation materials

3. Graphene materials

4. MEMS

5. Thin film materials

6. Ni-based superalloys (shape memory alloys)

7. Silicon carbide

8. High temperature polymers

9. Optical coatings (AR, thermal reduction)

10. Polymer coatings for biosensors

11. Flexible (bendable) metallic glass

12. Titanium diboride

13. Advanced fiber reinforced composite materials

(no concrete/cement materials)

Students are:• Expected to submit original work except in joint

projects where the activities are cooperative and collaborative.

• Expected to attend class except when circumstances are outside the student’s control.

• Responsible for material in the reading assignments, class presentations, discussions, homework and, examples.

• Expected to comply with University regulations governing intellectual property, origin of work, and honesty. Failure to maintain these standards will result in student disciplinary action and a grade of F in the course.

Flexible Thin Films• Transfer printing makes a 10-by-10 array of

gallium arsenide solar cells on flexible plastic possible. Researchers at the University of Illinois at Urbana-Champaign have invented a cheaper way to build devices—including solar cells and infrared cameras—using highly efficient but notoriously costly compound semiconductors. Their method, reported in the journal Nature, involves growing stacks of thin films of semiconductor, peeling off the films one by one, and printing them onto cheaper substrates, such as silicon or glass.

• Silicon is used in computer chips, but if you want to build the fastest transistor or the most efficient LEDs, compound semiconductors— gallium arsenide (GaAs) or gallium nitride —are your best bet.

• Some GaAs solar cells can convert about 40 percent of the sun’s energy into electricity, while silicon cells max out at about 20 percent efficiency.

• The problem is that compound semiconductors are much more expensive than silicon. A 6-inch wafer of gallium arsenide costs about US $200, whereas a 200-millimeter wafer of silicon goes for roughly $40.

Nanowire Thin Film Transistors Impart the Sense of Touch for Artificial Limbs

Optical Coatings

Antireflective surface

Sensimed’s Triggerfish product, using MEMS from STMicroelectronics, is a contact lens that tests for glaucoma.

Photochromic polycarbonate

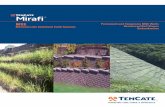

Advanced Fiber Reinforced Composites

Carbon fiber BMW

SEM view of hot-pressed (1600°C, 30MPa) Fast-Sol-Gel-derived carbon-fabric composites: Fibers extending from molten glass

Multiple-mission spacecrafts necessitate reusable heat shields and heat exposed elements. Ceramic Matrix Composite (CMC) are the most suitable structural heat durable materials for these functions, carbon fiber reinforced silicon carbide (C/SiC) in particular.

Polymer Composites: aerospace and automotive Ceramic Matrix Composites: re-entry, hard coating Metal Matrix Composites: friction and thermal properties

Fiber Reinforced Polymer (FRP) Composite Bridge Technology

Electrical Devices

Bio-nanocircuits

RFIDs

Single molecule diode

OTFTs

Stick-on tattoos go electric - a new class of micro-electronics with a technology called an epidermal electronic system (EES) that incorporate miniature sensors, light-emitting diodes, tiny transmitters, receivers and wire filament networks into their designs. University of Illinois at Urbana-Champaign

Graphene

Graphene Electrodes in Organic Solar Cells

2D Graphene Metamaterials and One-Atom-Thick Optical Devices

Graphene Transistor

Graphene thin films

• Nickel Titanium (also known as Nitinol or NiTi) is in the unique class of shape memory alloys.

• How Does Nitinol Work?Nitinol Shape Memory Alloys undergo a thermoelastic phase transformation in their crystal structure when cooled from high temperature Austenite phase to the low temperature phase Martensite. This phase transformation is responsible for its extraordinary properties:

– the shape memory effect,

– superelasticity, and

– high damping capability.

• These technical properties of NiTi shape memory alloys can be modified to a great extent by changes in composition, mechanical working, and heat treatment.

• Applications: catheter shafts, stents, needles, valve frames, distal protection, orthodontic guide wires, occluders, endoscopic guide tubes, retrievers, laproscopes

• For more information on Nitinol properties, visit Nitinol Resource Library.

• Shape Memory

When shape memory alloys are in their martensitic form, they are easily deformed to a new shape. However, when the alloy is heated through its transformation temperatures, it reverts to austenite and recovers its previous shape with great force. This process is knows as Shape Memory.

The temperature at which the alloy remembers its high temperature from when heated can be adjusted by slight changes in alloy composition and through heat treatment. In the Nickel Titanium alloys, for instance, it can be changed from above +100 deg. C to below -100 deg. C. The shape recovery process occurs over a range of just a few degrees and the start or finish of the transformation can be controlled to within a degree or two if necessary.

• Superelasticity

Some shape memory alloys also show a Superelastic behavior if deformed at a temperature which is slightly above their transformation temperatures. This effect is caused by the stress-induced formation of some martensite above its normal temperature. Because it has been formed above its normal temperature, the martensite reverts immediately to undeformed austenite as soon as the stress is removed. This process provides a very springy, "rubberlike" elasticity in these alloys.

Mining and Ore Extraction

• Mining Techniques• Recovered Materials• Chemical Processing• Environmental Impact• Applications for materials• Companies involved in the

industry

en.wikipedia.org/wiki/Mining

http://www.marthamine.co.nz/ore_process.html

Boeing 747 noise reduction; The chevron shapes on both the nacelle and exhaust nozzle reduce the noise of the engines by 30 percent over the older 747 models.

Acoustic Noise Reduction Materials

Bulk metallic glass

A sample of Liquidmetal Technologies’ Zr-based metallic glass.

Baseball bat featuring Liquidmetal Technologies’ ‘Pure Energy Transfer’ technology based on Vitreloy.

Introduction to Materials Science & Engineering

Overview of Course• Course Objective: Basic understanding and

awareness of material behavior.• Learn fundamental concepts.• Chapters 2 & 3 describe the underlying physical

concepts related to the structure of matter.• We will examine the relationships between atoms

(atomic bonding, valence electrons, atomic spacing). Larger structures like unit cells.

• Ch 6 discusses atomic movement (diffusion).

Specifics

• Polymers – Ch 4 - More complicated than metals because of the variety of bonding and chemical structures. Ceramics are also more complicated to explain than metals.

• This leads to Ch 5 (Imperfections). Polymers have many types of defects that affect their behavior. The term “defect” is misleading since much of our ability to manipulate, form or process materials is a result of the “defects”. This is also seen in Ch 8 – Strengthening Mechanisms.

Polymers (aka Gumby and Pokey)Borosilicate Glass

Specific Properties

• Ch 7 – Mechanical

• Ch 12 – Electrical

• Ch 16 – Corrosion and Wear

• Ch 17 – Thermal

• Ch 18 – Magnetic

• Ch 19 – Optical

35

σ = n |e| μeσ = conductivity; n = number of electrons, |e| = charge = 1.6 x 10-19 C, μ = electron mobility

Graphene

Battery materials

Semiconductors: Wed, January 19, 2011

"Nanoscoop" Material Promises 40x Faster Charging of Batteries

http://www.nanosysinc.com/what_we_do/energy_storage/

Corrosion and Degradation of Materials

• Space Shuttle Tiles: --Silica fiber insulation offers low heat conduction.

• Thermal Conductivity of Copper: --It decreases when you add zinc!

THERMAL

40

Invar Elements Composition (% by Weight)

Carbon 0.1 Max.

Manganese 0.3 to 0.6Phosphorus 0.025 Max.

Sulphur 0.025 Max.Silicon 0.35 Max.Nickel 35 to 37Cobalt 0.5 Max.

Chromium 0.5Molybdenum 0.5

Iron Remainder

The expansion of Invar is very low due to the magnetic properties of the material at low temperatures.

• Magnetic Permeability vs. Composition: --Adding 3 atomic % Si makes Fe a better recording medium!

Magnetic FieldMagneti

zati

on

Fe+3%Si

Fe

• Magnetic Storage: --Recording medium is magnetized by recording head.

MAGNETIC

• Transmittance: --Aluminum oxide may be transparent, translucent, or opaque depending on the material structure.

single crystalpolycrystal:low porosity

polycrystal:high porosity

OPTICAL

1. Pick Application Determine required Properties

2. Properties Identify candidate Material(s)

3. Material Identify required Processing

Processing: changes structure and overall shapeex: casting, sintering, vapor deposition, doping, forming, joining, annealing.

Properties: mechanical, electrical, thermal,magnetic, optical, deteriorative.

Material: structure, composition.

The Materials Selection Process

Applications

Materials

Forged and machined Ti alloy fan disk for a large commercial aero-engine.

Cast iron sewer lidExtruded steel tubes

Metal Processing

Effects of Alloying Elements on Steel

47

• Manganese contributes to strength and hardness; dependent upon the carbon content. Increasing the manganese content decreases ductility and weldability. Manganese has a significant effect on the hardenability of steel.

• Phosphorus increases strength and hardness and decreases ductility and notch impact toughness of steel. The adverse effects on ductility and toughness are greater in quenched and tempered higher-carbon steels.

• Sulfur decreases ductility and notch impact toughness especially in the transverse direction. Weldability decreases with increasing sulfur content. Sulfur is found primarily in the form of sulfide inclusions.

• Silicon is one of the principal deoxidizers used in steelmaking. Silicon is less effective than manganese in increasing as-rolled strength and hardness. In low-carbon steels, silicon is generally detrimental to surface quality.

• Copper in significant amounts is detrimental to hot-working steels. Copper can be detrimental to surface quality. Copper is beneficial to atmospheric corrosion resistance when present in amounts exceeding 0.20%.

• Nickel is a ferrite strengthener. Nickel does not form carbides in steel. It remains in solution in ferrite, strengthening and toughening the ferrite phase. Nickel increases the hardenability and impact strength of steels.

• Molybdenum increases the hardenability of steel. It enhances the creep strength of low-alloy steels at elevated temperatures.

• Iron accounts for more than 95 wt% of the alloy material, while the main alloying elements are carbon (between 2.1- 4.5 wt%) and silicon (normally 1-3 wt%).

• From the iron-iron carbide phase diagram, cast iron has a eutectic point at 1153 °C and 4.2 wt% carbon.

• Since cast iron has roughly this composition, its melting temperature of 1150 to 1200 °C is about 300 °C lower than the melting point of pure iron.

• The most common cast iron types are: grey, white, nodular, malleable and compacted graphite.

Ferrous Materials Cast Irons

Temper Designations • F As fabricated. Applies to products in which no thermal treatments or strain-

hardening methods are used to shaped the product.

• H Strain-hardened (wrought products only). Applies to products that have their strength increased by strain-hardening, with or without additional thermal treatments to produce a reduction in strength.

• H1 Strain-hardened only. Applies to products which are strain-hardened to achieve the strength desired without additional thermal treatment.

• O Annealed, recrystallized (wrought products only). Applies to wrought alloys which are annealed to obtain the softest temper, and to cast alloys which are annealed to improve ductility and dimensional stability.

• T Thermally treated to produce stable tempers other than F, O or H. Applies to products which are thermally treated, with or without additional strain-hardening, to produce stable tempers.

• T3 Solution heat-treated and then cold worked. Applies to alloys which are cold worked to improve strength after solution heat treatment, or in which the effect of cold work in flattening or straightening is significant in mechanical property limits.

49http://www.efunda.com/materials/alloys/aluminum/temper.cfm

Materials Processing

51

roll

A o

A droll

• Rolling (Hot or Cold Rolling) (I-beams, rails, sheet & plate)

Ao Ad

force

die

blank

force

• Forging (Hammering; Stamping) (wrenches, crankshafts)

often atelev. T

Forming

ram billet

container

containerforce

die holder

die

A o

A dextrusion

• Extrusion (rods, tubing)

ductile metals, e.g. Cu, Al (hot)

tensile force

A o

A ddie

die

• Drawing (rods, wire, tubing)

die must be well lubricated & clean

Forming operations (forging, rolling, drawing, extrusion) are where the shape of a metal is changed by plastic deformation.

Forming processes are commonly classified into hot-working and cold-working operations.

Flatware

• The Crate and Barrel flatware collection gleams in high-quality 18/8 and 18/10 stainless that never needs polishing, goes right in the dishwasher and costs a fraction of formal sterling.

• Combining 18% chromium for durability and hardness, and 8% or 10% nickel for shine and luster.

• Each piece is hand-forged or stamped. It takes at least 25 steps of hand-forging or stamping steel to create our knives, forks and spoons. The result is substantial construction that’s never light or flimsy.

SUMMARY

• Use the right material for the job.

• Understand the relation between properties, structure and processing.

• Recognize new design opportunities offered by materials selection.

Use Proper Materials