Mounting and Wiring Variable Air Volume Modular Assembly ...

Transcript of Mounting and Wiring Variable Air Volume Modular Assembly ...

Technical BulletinIssue Date January 7, 2003

© 2003 Johnson Controls, Inc. www.johnsoncontrols.comCode No. LIT-6363125

Mounting and Wiring Variable Air Volume ModularAssembly (VMA) 1400 Series Controllers

Mounting and Wiring VMA1400 Series Controllers............................3

Introduction......................................................................................................... 3

Key Concepts...................................................................................................... 4

VMA Position and Orientation ........................................................................................... 4Damper Actuator Direction to Close.................................................................................. 4N2 Address Switches ........................................................................................................ 4Wiring and Cabling Precautions........................................................................................ 5General Wiring Information ............................................................................................... 6Power Source Wiring ........................................................................................................ 6Phone Jack Polarization.................................................................................................. 10Sensor Interfaces ............................................................................................................ 11

Procedure Overview......................................................................................... 14

Detailed Procedures......................................................................................... 16

Preparing the VMA for Mounting..................................................................................... 16Mounting the VMA1410/1420.......................................................................................... 18Mounting the VMA1430................................................................................................... 19Setting the Damper Position (VMA1410, 1420, or VMA1430 with External Actuator) .... 19Wiring the VMA ............................................................................................................... 21Connecting the N2 Bus ................................................................................................... 24

Reference Information ..................................................................................... 26

VMA Wiring List............................................................................................................... 26VMA Single Duct Application Wiring Diagram................................................................. 28VMA Single Duct Supply/Exhaust Wiring Diagram ......................................................... 29VMA Dual Duct Application Wiring Diagram ................................................................... 30VMA Internal Schematic Diagram ................................................................................... 32Fabricating Your Own Interconnection Cable ................................................................. 34

Troubleshooting ............................................................................................... 35

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

2

Troubleshooting VMA Room Temperature Drift .............................................................. 35

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series ControllersTechnical Bulletin

3

Mounting and Wiring VMA1400Series Controllers

Introduction The integrated VMA1410/1420, which includes a controller, actuator,and pressure sensor, mounts on the Variable Air Volume (VAV)terminal box. The VMA1430 mounts anywhere on the VAV box andis wired to a separate damper actuator.

Note: This document focuses on the VMA1410, 1420, and1430 controllers. The VMA1400 Series also includes the VMA1440,which is a controller used exclusively as part of the Metasys® ZoningPackage. See the Metasys Zoning Package Product Bulletin(LIT-639050) and the Metasys Zoning Package Overview TechnicalBulletin (LIT-639100) for information on this specialized product.

Instructions for wiring the VAV Modular Assembly (VMA) and itsaccessory devices are provided in this section.

This document describes how to:

• prepare the VMA for mounting

• mount the VMA1410/1420

• mount the VMA1430

• set the damper position (VMA1410, 1420, or VMA1430 withexternal actuator)

• wire the VMA

• connect the N2 Bus

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

4

Key Concepts VMA Position and Orientation

Consider the following when positioning and orienting the VMA:

• Mount the VMA on a vertical and flat surface where it functionsbest, such as the side of the VAV box.

• Route or loop the tubing, so a portion of it is lower than thepressure sensor, to create a moisture trap that prevents anycondensation from entering the sensor.

• Do not make any sharp bends in the tubing, as this could collapsethe tube and block the pressure path.

• Verify wiring terminals are accessible.

• Ensure that no extra mounting brackets, linkage, or couplers arerequired for standard mounting.

• Locate the VMA so that it has adequate clearance for futureservicing and is protected from moisture and corrosive fumes.

Damper Actuator Direction to CloseThe damper actuator direction to close establishes upon installation ofthe VMA, using HVAC PRO software. The damper must be manuallypositioned to allow the VMA actuator to fully open and close thedamper. Incorrect damper positions in a zone can lead to misdiagnosedreadings, resulting in unnecessary repetition of setup and diagnostics.

N2 Address Switches It is best, from an accessibility standpoint, to set the N2 switchesbefore mounting the VMA. The switches, located on the side of theVMA, are set to On for the address numbers indicated on the roomschedule or building drawings. Use Addresses 1-253 only.Addresses 0, 254, and 255 are reserved. Refer to the Preparing theVMA for Mounting section in this document for further information.

If software addressing is used, N2 switches must be set to 0 or 255.See the HVAC PRO User’s Guide for details on software addressing.

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series ControllersTechnical Bulletin

5

Wiring and Cabling Precautions

! WARNING: Risk of Electrical Shock or Equipment Damage.To avoid damaging equipment or possible electrical shock, ensure that allpower supplies to the system are disconnected prior to wiring.

! CAUTION: Risk of Equipment Damage.Shorting of Binary Outputs (BOs) while energized will destroy the VMAoutput triac.

Read these precautions before touching the terminals or wiring theVMA and its accessories:

• Make all wiring connections in accordance with the NationalElectrical Code (NEC) and state and local regulations. Fortransformer primaries above 150 VAC, the secondary must beearth grounded at the transformer to meet NEC. Terminal 1 can beearth grounded. Grounding on Terminal 1 results in 24 VAC beingapplied to DCOM with respect to earth.

Note: 24 VAC to 24 VAC isolation transformers are not necessary.The power supply is internally isolated. For specific methods forwiring the VMA to meet UL 864 requirements, refer to the MetasysSmoke Control Wiring Technical Bulletin (LIT-636331).

• Terminal 3 is an earth ground connection (optional).

• Locate equipment and route the wiring so that twisted pair signalwiring is separated from power wiring by at least 150 mm (6 in.).

• Make all wiring connections to the VMA using only copperconductors. To establish tight, reliable electrical connections, usethe correct wire sizes for the terminals. Avoid very thin solidwires, such as 26 AWG or less than 0.6 mm, which tend to break.

• Daisy chain the N2 Bus. The use of Y or T connections without arepeater installed as the T-tap may cause a loss of communications.Make sure that there is at least one End-of-Line termination on theN2 Bus (usually at the Network Control Module [NCM] or N30).

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

6

• Do not run N2 Bus, Zone Bus, Analog Input (AI), Binary Input(BI), Analog Output (AO), or Binary Output (BO) wiring in thesame conduit as line voltage wiring (above 30 VAC), or withwiring that switches power to highly inductive loads such ascontactors, coils, motors, or generators.

• Run Zone Bus, AI, AO, and BI wiring in the same bundle orconduit where convenient. If the BO wiring is not wired throughother switches or contacts, such as actuator end-of-travel switches,bundle it with the other Input/Output (I/O) wiring whereconvenient.

General Wiring Information The following are general wiring considerations:

• The VMA includes isolated N2, isolated binary outputs, andisolated 24 VAC.

• The 24 VAC power input is internally transformer isolated by theVMA. To meet NEC requirements for line voltage greater than150 VAC, Terminal 1 can be earth grounded.

• Up to ten cooling-only controllers (VMA1410) can be poweredfrom one 100 VA low-voltage, power-limited, Class 2 transformer.See Power Source Wiring below for more information. Conduit isnot required by the NEC for Class 2 wiring installations.

• Large insulated spade lugs with a polarizing tab (for high voltage)do not fit on the VMA.

Power Source Wiring To calculate the number of VMAs that can be powered fromone 100 VA unit, use the equation below. In this equation, the valueTotal VA equals the total VA consumed by the VMA, actuator, andoutput loads.

VATotal

100 r TransformeVA 100per VMAs =

Table 1 shows the power rating for each cooling/heating coil valveactuator. The valve power plus the VMA power (1410/1420 = 10 VA;1430 = 3 VA) must not exceed 100 VA. If a device is not listed inTable 1, refer to the product literature for that device.

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series ControllersTechnical Bulletin

7

Table 1: Actuator VA Power RatingActuator Type Power RatingVA-8020 Incremental 4 VAVA-8050 Incremental 6 VAVA-7150 Incremental 2.7 VAVA-7153 Incremental w/feedback 2.7 VAJS/JT Series Electric ZoneValve

On/Off 7 VA

JM Series Electric ZoneValve with JT SeriesActuator

Incremental 1.2 VA

JM Series Electric ZoneValve with JP SeriesActuator

Voltage (0 to 10 VDC) 1.6 VA

VA-8122 Voltage (0 to 10 VDC) 4 VAVA-7152 Voltage (0 to 10 VDC) 4.7 VAVA-7200 Incremental 6.7 VAVA-7203 Incremental w/feedback 6.7 VAVA-7202 Voltage (0 to 10 VDC) 8.7 VAGE RR-7 or Touchplate Lighting relay 42 VA for 50 ms*VA-7450 Incremental 2.5 VAVA-7452 Voltage (0 to 10 VDC) 2.5 VAVA-7040 Thermal (DAO) 3 VAVA-7310 Incremental 2 VAVA-7312 Voltage (0 to 10 VDC) 2 VAVA-7010 On/Off 7 VAVA-4233-BGA-2 On/Off, Spring Return 12 VAVA-4233-AGA-2 Incremental, Spring Return 12 VAVA-4233-GGA-2 Voltage (0 to 10 VDC),

Spring Return12 VA

M9106-AGA-2 Incremental 2.5 VAM9106-GGA-2 Voltage (0 to 10 VDC) 3.2 VAM9206-BGA-2 On/Off, Spring Return 16 VAM9206-AGA-2 Incremental, Spring Return 16 VAM9206-GGA-2 Voltage (0 to 10 VDC),

Spring Return16 VA

M9104-AGA-2N Incremental 3.4 VAM9104-AGA-2 Incremental w/conduit 3.4 VAM9104-AGS-2N Incremental w/DPT-2015 3.4 VAM9104-GGA-2 Proportional 0-10 V 5 VAM9104-GGC-2 Proportional 0-10 V

w/conduit5 VA

* Do not schedule all lights on one transformer to turn on at the same time.The current surge on the transformer could open the circuit breaker.

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

8

When using a single transformer to power multiple VMAs, use a wiregauge large enough to handle the current and minimize the voltagedrop. The voltage drop depends on the current draw, wire gauge, andwire length. On a fully loaded 100 VA transformer, a 120 VACprimary draws only 0.8 amperes, while the 24 VAC secondary draws4 amperes.

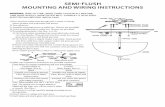

The standard 2.5 mm2 (14 AWG) cable (Example 1 in Figure 1) islimited to 27 m (88 ft) with ten cooling-only VMAs, all at one end ofthe cable. If the transformer is centered (Example 2 in Figure 1) withfive VMAs on the left and five VMAs on the right, the distance ineach direction can be increased. This is because both the currentand voltage drop are halved. In this example, both the left and the rightlegs could be increased to 54 m (176 ft) from the transformer(50 VA from each leg), creating a 108 m (352 ft) total length.

< 88 ft of 14 AWG >

24 VAC

< 176 ft of 14 AWG > < 176 ft of 14 AWG >

100 VA

24 VAC

100 VA

VMA

VM

A

VMA

VMA

VMA

VM

AV

MA

VMA

VMA

VMA

VMA

VMA

VMA

VMA

Example 1: All ten VMAs are at one end.

Example 2: Transformer is centered.V

MA

VMA

VMA

VM

A

VMA

VMA

Cable_lg

Figure 1: Power Cable Lengths There are two ways to connect power and loads to the VMA.Individual spade lugs accept a single 4 mm2 to 0.8 mm(10 to 22 AWG) wire and fit on 6 mm (1/4 in.) tabs, or optional screwterminals can be assembled over the spade lugs. The screw terminalsaccept up to a single 4 mm2 (12 AWG) wire or two 2.5 mm2

(14 AWG) wires. When two wires are crimped into one spade lug, awire nut (to connect two heavy wires to a short 152 mm [6 in.] thinnerwire) or a larger spade lug barrel is needed.

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series ControllersTechnical Bulletin

9

The following tables indicate the relationship between cable lengthand power at the end of wires.

Table 2: Maximum 24 VAC Secondary Cable Length for Given Power/Gauge(U.S. Measurements)

Cable Size8 Gauge 10 Gauge 12 Gauge 14 Gauge 16 Gauge 18 Gauge

Power (VA) atEnd of Wire Cable Length (ft)10 3520 2200 1400 880 550 35020 1760 1110 700 440 275 17530 1173 740 467 293 183 11740 880 555 350 220 138 8850 704 444 280 176 110 7060 587 370 233 147 92 5870 503 317 200 126 79 5080 440 278 175 110 69 4490 391 247 156 98 61 39100 352 222 140 88 55 35

Table 3: Maximum 24 VAC Secondary Cable Length for Power/WireGauge (Metric Measurements)

Cable Size4 mm2 2.5 mm2 1.5 mm2

Power (VA) atEnd of Wire Cable Length (Meters)10 427 268 16820 213 134 8430 142 89 5640 107 67 4250 85 54 3460 71 45 2870 61 38 2480 53 34 2190 48 30 19100 43 27 17

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

10

Phone Jack PolarizationFigure 2 illustrates the polarization of the 6-pin and 8-pin phone jackson the VMA or room sensor (TE-6700 or TMZ1600). Pin 1 is to theextreme left as you face the jack opening, tab notch down.

Note: If you need to create your own cable, refer to FabricatingYour Own Interconnection Cable in the Reference Information sectionof this document. Otherwise, order pre-terminated cables.

8-pin 6-pin

VMA Room Sensor

phonejac

Pin 1

Figure 2: Phone Jack Polarization

Table 4: TE-6700 Phone Jack Pin Identification8-Pin Phone Jack on VMA 6-Pin Phone Jack on TE-6700Pin Signal Pin Signal1 BI-1 Temp Occ 1 Not used2 AI 2 Zone Setpoint 2 +15 VDC3 AI 1 Temperature Sensor 3 COM4 COM for AI-1 4 Not used5 +15 VDC 5 Zone Bus (ZB)6 ZB COM/LED BI COM 6 Not used7 COM for AI-28 ZB+

Table 5: TMZ Phone Jack Pin Identification8-Pin Phone Jack on TMZ 6-Pin Phone Jack on TMZPin Signal Pin Signal1 Not used 1 Not used2 Not used 2 +15 VDC3 AI1, Zone Temperature Sensor 3 COM4 AI1, Sensor Common 4 Not used5 +15 VDC 5 Zone Bus (ZB)6 Supply/Zone Bus Common 6 Not used7 Not used8 Zone Bus

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series ControllersTechnical Bulletin

11

Sensor InterfacesFigures 3, 4, and 5 show interfaces between room sensors and theVMA. For more information on the TE-6700 room sensor (includingDIP switch settings), see the TE-6700 Series 2nd GenerationTemperature Elements Installation Bulletin (LIT-216332).

! CAUTION: Intermittent connections can occur when smallgauge solid wire is crimped into large spade lugs or a when a phone jack ispoorly crimped.

Any of the following situations can cause AI drifting:

• 26 gauge solid wire is crimped in a 18-22 gauge stranded spadeconnector.

• Phone jack is poorly crimped.

• Pliers or something other than crimping tool is used to crimp thespade lug.

• Paint or other material is on phone jack connector.

See the Troubleshooting section for more information.

1

2

3

4

5

6

7

8

1

2

3

4

5

6

BI-1

AI-2 (Setpoint)

AI-1 (Zone Temperature)

AI-1 COM

+15 Volts DC

+15/Zone Bus COM (Not BCOM)

AI-2 COM

Zone Bus/N3+

Sensor

1.6 K ohmSetpoint Potentiometer

6-pin Phone Jack on TE-6700

+15 Volts DC

Zone Bus

COM

8-pin Phone Jack on TE-6700

Screw Terminals

TE6X

4

1

2

5

6

3

7

LED*

ManualOverride

1 K ohm

8

Preferred DIP Switch Position for TE-6700 (LED On)

O N

1 2 3

*

Figure 3: TE-6700 Phone Jack Interface to VMA

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

12

1

8

4

5

AI1AI

COMAI

COM AI2

ZB+ COM 15 VDC

screw term

(18) BI-1(19) COM(20) BI-2(21) COM(22) BI-3(23) COM(24) +15 VDC(25) +15 VDC(26) AI-1(27) COM(28) AI-2(29) COM(30) AI-3(31) COM(32) AI-4(33) COM(34) ZB+(35) ZB-

VMA

BI-1

Preferred DIP Switch Position for TE-6700

O N

1 2 3

Figure 4: TE-6700 Screw Terminal Interface to VMA1400

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series ControllersTechnical Bulletin

13

TE7000

(18) BI-1(19) COM(20) BI-2(21) COM(22) BI-3(23) COM(24) +15 VDC(25) +15 VDC(26) AI-1(27) COM(28) AI-2(29) COM(30) AI-3(31) COM(32) AI-4(33) COM(34) ZB+(35) ZB-

VMA

TE-7000 (Europe Only) Terminal Blocks (TBs)

TB1 TB21 2 3 4 5 6 7 8

Figure 5: TE-7000 (Europe Only)Screw Terminal Interface to VMA1400

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

14

Procedure OverviewTable 6: Mounting and Wiring VMA1400 Series Controllers

To Do This Follow These Steps:Prepare the VMA for Mounting 1. Check that you have the essential equipment and tools.

2. For the VMA1410 and 1420, make certain that the damper shaftprotrudes at least 44 mm (1-3/4 in.) from the VMA mounting surface.

3. Ensure the VMA installation site meets environmental requirements.4. Make sure the VMA mounting location has adequate clearance for

future servicing.5. Set the VMA specific N2 address using the N2 switches or via

VAV Balancing Tool (VBT) or HVAC PRO programs.Use Addresses 1-253 only.

Mount the VMA1410/1420 1. Place the VMA in the desired mounting position on the damper shaftso the wiring terminals are easily accessible. To allow space for VMAmovement during damper rotation, locate the shoulder washer at thecenter of the slot. Make sure the VMA is parallel and mounted flatwith the VAV box.

Note: See IMPORTANT statement in the Detailed Procedures section ofthis document for installations where the air supply to the VAV box isbelow 50°F (10°C)2. Secure the self-drilling No. 10 screw provided into the VMA mounting

slot, using a power screwdriver and socket with a 100 mm (4 in.) extension.3. Alternately, use a punch to mark the position of the shoulder washer,

then drill a hole into the VAV box through the mark, using a 3.5 mm(9/64 in.) bit. Position the VMA so the shoulder washer is over thehole; insert the mounting screw and tighten against the washer.

Mount the VMA1430 1. Place the VMA in the desired mounting position, preferably on avertical surface of the VAV box with the tubing down.

2. Secure the unit at each end with self-drilling No.10 screws, using apower screwdriver, 100 mm (4 in.) extension, and socket.

Set the Damper Position(VMA1410, 1420, or VMA1430with External Actuator)

1. Locate the damper position. Note the direction to close the damper.2. Set the damper position:

• For 90° boxes, grasp the damper shaft firmly with pliers andmanually position it to fully closed (icon perpendicular to airflow).Push down and hold the gear release lever and turn the VMAcoupler until it contacts the mechanical end-stop at the fullyclosed position.

• For 45° or 60° boxes, grasp the damper shaft firmly with pliersand manually position it to fully open. Push down and hold thegear release lever and turn the VMA coupler until it contacts themechanical end-stop at the fully open position.

3. Tighten the set screw to the shaft using an 8 mm (5/16 in.) wrench or10 mm (3/8 in.) 12 point socket wrench. Tighten to 17 to 21 N⋅m[150 to 180 lb⋅in. (14 lb⋅ft)].

4. Push the gear release lever down, and turn the VMA coupler by handto ensure that the damper rotates from full closed to full openpositions without binding.

5. Plug or seal the end of hollow damper shaft to stop cold duct air fromaffecting the circuitry when the VMA is mounted in another enclosure.

6. Attach the pneumatic tubing to the pressure sensor with the HI (red)tubing connected to the inlet or high pressure side. The clear tubeconnects to the LO inlet of the VAV box.

Continued on next page . . .

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series ControllersTechnical Bulletin

15

To Do This (Cont.) Follow These Steps:Wire the VMA 1. Disconnect all power to the VMA.

2. Determine if spade lugs, removable 2- or 3-position screw terminals,or phone cable are to be used.

3. Terminate wiring per engineering drawings.Connect the N2 Bus 1. Set the N2 address of the VMA per engineering drawings before

wiring the VMA (if not already done).2. Connect the N2 Bus wires to the VMA, and continue in a daisy chain

to the next VMA. Repeat this process for each VMA.3. Apply power. Locate and observe the VMA Light-Emitting

Diode (LED). If the LED is on continuously, it is running a 20-secondpower up self test. Continue. If the LED is blinking once per second,then it passed diagnostics, but no N2 messages have been receivedfor this VMA address. Continue. If the LED is irregularly flashingabout four times every second, the supervisory system is polling theVMA.

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

16

Detailed Procedures Preparing the VMA for Mounting

To prepare the VMA for mounting:

1. Check that you have the following equipment:

• VMA

• TE-6700, TE-7000 (Europe only), or TMZ1600 room sensor

• room sensor cable or wire for connecting the room sensor tothe VMA

• separate damper actuator for the VMA1430

2. Check that you have the following tools:

• 8 mm (5/16 in.) square wrench or 10 mm (3/8 in.) 12-pointsocket for actuator collar screw

• pliers to turn the damper shaft (if needed)

• 8 mm (5/16 in.) hex nut driver or 4 in. extension for 5/16 in.socket and power screwdriver for self-drilling screw

• 3.5 mm (9/64 in.) drill bit (optional)

IMPORTANT: The VMA1410, 1420 requires a damper shaft protrusion of atleast 44 mm (1-3/4 in.) from the VMA mounting surface.

3. Ensure the VMA installation site meets the followingenvironmental requirements:

• The VMA location is protected, as much as possible, fromwater caused by leaking pipes, condensation, or drippingsolder from sweating pipe joints.

• The atmosphere is free of explosive vapors or escaping gases.

• The atmosphere is free of exposure to corrosive chemical orsalt vapors, which might damage electrical equipment.

• The temperature is maintained between 0 to 50°C(32 to 122°F), with the relative humidity (noncondensing)maintained between 10 and 90%. These are operating limits.Flow measurement accuracy suffers if the ambienttemperature varies widely within this band.

4. Make sure the VMA mounting location has adequate clearance forfuture servicing.

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series ControllersTechnical Bulletin

17

5. Set the VMA specific N2 address using the N2 switches or viaVBT or HVAC PRO programs. Use Addresses 1-253 only.Addresses 0 and 255 are reserved for software addressing, andAddress 254 may not be used.

For example, if the N2 address is 17 (decimal), the binaryrepresentation is 00010001. Switches 16 and 1 set to theOn position (16 + 1 = 17). See the N2 Address Switches topic inthe Key Concepts section for more information on softwareaddressing.

If using software addressing, set all switches to 00 (all Off) or255 (all On). Use the HVAC PRO program or the VBT program,connected to the Zone Bus, to set the desired address. This mustbe done before connecting the VMA1400 controller to theN2 network.

Note: Make sure the switches are pressed fully to the requiredposition.

N2 Address DIP Switches

Example: 16 + 1 = 17

128

24

816

3264

ON

OFF

DIPSWIT3

Figure 6: Setting the N2 Address Switches on a VMA1410/1420

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

18

Mounting the VMA1410/1420To mount the VMA1410/1420:

1. Place the VMA in the desired mounting position on the dampershaft so the wiring terminals are easily accessible.

To allow space for VMA movement during damper rotation, locatethe shoulder washer at the center of the slot.

Make sure the VMA is parallel and mounted flat with theVAV box. If needed, use a spacer to offset tipping of the VMAcreated by shaft bushings that protrude beyond the box surface.

IMPORTANT: When the air supply to the VAV box is below 50°F (10°C),make sure that any condensation on the VAV box, particularly on the dampershaft, does not enter the electronics. Mount the VMA vertically above thedamper shaft to allow any shaft condensation to fall away from the VMAcontroller. Additional measures may be required in some installations.

2. Secure the self-drilling No. 10 screw (included) into the VMAmounting slot, using a power screwdriver and socket with 100 mm(4 in.) extension.

3. Alternately, use a punch to mark the position of the shoulderwasher, then drill a hole into the VAV box through the mark, usinga 3.5 mm (9/64 in.) bit. Position the VMA so the shoulder washeris over the hole. Insert the mounting screw and tighten against thewasher.

Note: The mounting screw is threaded into sheet metal and thethreads can strip. Do not overtighten. Make sure the screw does notinterfere with full damper rotation.

ShoulderWasher

Mounting Slot

MountingScrew

MTGSCREW

Figure 7: Mounting Screw with Shoulder Washer (VMA1410 andVMA1420)

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series ControllersTechnical Bulletin

19

Mounting the VMA1430To mount the VMA1430:

1. Place the VMA in the desired mounting position, preferably on avertical surface of the VAV box with the tubing down.

2. Secure the unit at each end with self-drilling No. 10 screws, usinga power screwdriver, 100 mm (4 in.) extension, and socket.

Setting the Damper Position (VMA1410, 1420, or VMA1430 withExternal Actuator)

To set the damper position:

1. Locate the damper position, using the typical marking on the endof the damper shaft (Figure 8). Note the direction, Clockwise(CW) or Counterclockwise (CCW), required to close the damper.

DAMPOSIT

Figure 8: Typical Damper Shaft End Icons2. Complete the steps described in Table 7. See Figure 9.

Table 7: Setting the Damper PositionBox Type Steps to Perform90° 1. Grasp the damper shaft firmly with a pliers and manually

position it to fully closed (icon perpendicular to airflow).2. Push down and hold the gear release lever and turn the

VMA coupler until it contacts the mechanical end stop at thefully closed position. If the damper closes CCW, rotate thecoupler to the CCW mechanical limit. If the damper closesCW, rotate the coupler to the CW mechanical limit. Thisprovides a hard stop for this position. The hard stop for theopen position is provided by the VMA.

45 or 60° 1. Grasp the damper shaft firmly with a pliers and manuallyposition it to fully open.

2. Push down and hold the gear release lever and turn theVMA coupler until it contacts the mechanical end stop at thefully open position.

Note: The open end stop is automatically set for 90° boxes.Hard stops must be provided for 45 and 60° boxes at both fullyclosed and fully open damper positions. By installing the VMA atthe fully open position, the VMA provides the open stop for45 and 60° boxes. The closed damper seal provides the fullyclosed stop.

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

20

Gear Release Lever

Damper shaft in fully closed position.

Set Screw

SHLD

Collar rotated to its fully closed position.

(CW to close in this example.)

ENDSTOP2

Figure 9: Positioning the End Stop (VMA1410 or VMA1420)3. Tighten the set screw to the shaft using a 8 mm (5/16 in.) wrench

or 10 mm (3/8 in.) 12-point socket wrench. Tighten to17 to 21 N⋅m [150 to 180 lb⋅in (14 lb⋅ft)].

Note: Default configuration for the VMA is 90° rotation in30 seconds. Autocalibration resets the stroke time, based on the actualrotation between hard stops. This adjustment allows for dampers thattravel 45 or 60° as well as slight variations from 90°, provided thathard stops are available. For example, for 45° rotation, the stroke timeattribute autocalibrates to approximately 15 seconds.

4. Push the gear release lever down, and turn the VMA coupler byhand to ensure that the damper rotates from full closed to fullopen positions without binding.

5. Plug or seal the end of a hollow damper shaft to stop cold duct airfrom affecting the circuitry when the VMA is mounted in anotherenclosure.

6. Attach the pneumatic tubing to the pressure sensor with theHI (red) tubing connected to the inlet or high pressure side. Theclear tube connects to the LO inlet of the VAV box.

Note: It is recommended that tubing is routed as shown below, orthat a loop is taped in the tubing. This provides a low spot forcollecting condensation.

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series ControllersTechnical Bulletin

21

Low Spot for Collecting Condensation

STDMOUNT

Figure 10: Standard Mounting

Wiring the VMANote: Refer to the project engineering drawings for wiring details.All field wiring, with the exception of the N2 Bus, must be kept in thesame room with the controllers, to comply with UL smoke controlrequirements. Refer to the Metasys Smoke Control Wiring TechnicalBulletin (LIT-636331) for details on smoke control requirements.

! CAUTION: Risk of Equipment Damage.Intermittent connections can occur when small gauge solid wire is crimpedinto large spade lugs.

To wire the VMA:

1. Disconnect all power to the VMA.

2. Determine if spade lugs, removable 2- or 3-position screwterminals, or phone cable is used.

2-Position Removable Screw Terminal ConnectorSNAPONS

Figure 11: Optional Removable Screw Terminals2-Position or 3-Position (Accessory)

3. Terminate wiring per engineering drawings.

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

22

Note: AI-5 (velocity pressure) and the damper actuator are notlisted in Tables 8-11 because they are internal points that do notrequire wiring.

Table 8: Terminations for Cooling Only Single Duct Applications(VMA1410)

Name DescriptionAI-1* Zone temperatureAI-2* Zone setpointBI-1* Temporary occupied and LEDBI-2 Comfort (occupied)BI-3 Window, off (shutdown)Zone Bus* User interface bus (commissioning, testing, balancing)* Connected through an 8-pin phone cable from the room sensor.

Table 9: Terminations for Single Duct Cooling with Reheat Applications(VMA1420 and VMA1430)

Name DescriptionAI-1* Zone temperatureAI-2* Zone setpointAI-3 Humidity transmitter or sideloopAI-4 Supply air temperature or sideloopAO-1 and AO-2 Box or supplemental proportional heat or proportional

damper actuator.BI-1* Temporary occupied and LEDBI-2 Comfort (occupied)BI-3 Window, off (shutdown)BO-1, BO-2, BO-3,BO-4, and BO-5

Fan, box heat, supplemental heat, electric heat, lights,humidity, actuator for VMA1430

Zone Bus* User interface bus (commissioning, testing, balancing)* Connected through an 8-pin phone cable from the room sensor.

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series ControllersTechnical Bulletin

23

Table 10: Terminations for Single Duct Supply/Exhaust Cooling withReheat Applications (VMA1420 and VMA1430)

Name DescriptionAI-1* Zone temperatureAI-2* Zone setpointAI-3 Exhaust air velocity pressureAI-4 Supply air temperature or sideloopAO-1 and AO-2 Box or supplemental proportional heat or proportional

damper actuatorsBI-1* Temporary occupied and LEDBI-2 Comfort (occupied)BI-3 Window, off (shutdown)BO-1, BO-2, BO-3,BO-4, and BO-5

Box heat, supplemental heat, electric heat, lights, humidity,actuator for exhaust damper

Zone Bus* User interface bus (commissioning, testing, balancing)* Connected through an 8-pin phone cable from the room sensor.

Table 11: Terminations for Dual Duct Applications (VMA1420 orVMA1430)*

Name DescriptionAI-1 Zone temperatureAI-2 Zone setpointAI-3 Hot deck velocity pressureAI-4 Discharge air temperature or sideloopAO-1 and AO-2 Supplemental heat or proportional damper actuatorsBI-1 Temporary occupied and LEDBI-2 Comfort (occupied)BI-3 Window, off (shutdown)BO-1, BO-2, BO-3,BO-4, and BO-5

Floating/3-wire damper actuators, supplemental heat, lights

* VMA1420 or VMA1430 must be used on Cold Air deck.

Note: AI-5 (velocity pressure) and the damper actuator are notlisted in any of the above tables because they are internal points thatdo not require wiring.

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

24

Connecting the N2 BusNote: A hardware connection between the VMA and the NetworkControl Module (NCM) or N30 is required if the VMA is tocommunicate with the Metasys Operator Workstation (OWS).

To connect the N2 Bus:

1. Set the N2 address of the VMA per engineering drawings beforewiring the VMA (if not already done).

2. Connect the N2 Bus wires to the VMA, and continue in a daisychain to the next VMA. Repeat this process for each VMA.

ToNextN2

Device

N2 REFN2-N2+

NCM200 Series(TB1 or Communicator

Terminal Board)HRDGRD

SFTGRD

N2+

N2-

SFTGRD

REF1

2

36

7

8

NCM300 SeriesPort 1 - N2 Bus

or

REF N2- N

2+

N2+

N2-

REF

SHLD

N2+N2-

N2 REFNCMCONN4

Figure 12: Connecting the VMA to an NCM3. Apply power. Locate and observe the VMA LED. Refer to

Table 12 to interpret the LED indications.

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series ControllersTechnical Bulletin

25

LED

LEDVMA

Figure 13: VMA LED Indicator Location

Table 12: LED IndicationsIf LED is... InterpretationLit continuously LED is running a 20 second power up self test. Allow it to

continue.Blinking once persecond

LED has passed diagnostics, but no N2 messages havebeen received for this VMA address. Check N2 addressand definition in supervisory controller.

Irregularly flashingabout four timesevery second

The supervisory system is polling the VMA.N2 communication is established.

Rapid flashingabout 20 times persecond

Needs code download. Using HVAC PRO software, clickDownload<VMA Code.Note: HVAC PRO software must be attached directly tothe N2 Bus of the controller to perform a code download.You cannot download code from the Metasys system orover the Zone Bus.

Not lit The VMA is not receiving power, or +15 V has shorted.Note: For any unusual conditions, such as fast regular blinking or no LEDindication, refer to the Troubleshooting Variable Air Volume Module Assembly(VMA) 1400 Series Controllers Technical Bulletin (LIT-6363135).

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

26

Reference InformationVMA Wiring List

Note: All field terminals are power limited when powered by aClass 2 transformer.

Table 13: VMA Wiring ListPoint Description

orApplication

Range Input orLoadImpedance

MaximumVoltage

MaximumCurrent

Wire Size inmm2 or mm(AWG)

CableLength inMeters (ft)

1.5 mm2 (18) 150 (500)AI-1* ZoneTemperature

1 K ohmNickel, Pt,or Si

10 K ohm 5 VDC 0.5 mA

0.6 mm (24) 30 (100)

2.25 K ohmNTC

10 K ohm 5 VDC 0.5 mA 0.6 mm to1.5 mm2

(24 to 18)

150 (500)

1.5 mm2 (18) 150 (500)AI-2* ZoneSetpointAuxTemperature

1.6 K ohm1 K ohm Ni,Pt, or Si2-wire Pot.

10 K ohm 5 VDC 0.5 mA

0.6 mm (24) 30 (100)

AI-3* Transmitter;CO2PressureHumidity

0 to 10VDC

1.1 M ohm 16.5 VDC 15 mA 0.6 mm to1.5 mm2

(24 to 18)

150 (500)

1.5 mm2 (18) 150 (500)AI-4* 1 K ohmNickel, Pt,or Si

10 K ohm 5 VDC 0.5 mA

0.6 mm (24) 30 (100)

PerimeterTemperatureor Supply AirTemperature

2.25 K ohmNTC

10 K ohm 5 VDC 0.5 mA 0.6 mm to1.5 mm2

(24 to 18)

150 (500)

AI-5* VelocityPressure(internal)

0 to 1.5 in.W.C.,0.5 to 4.5VDC

250 K ohm 5 VDC 20 mA NA Internal

1.5 mm2 (18) 150 (500)BI-1* TemporaryOccupied

0-5 VDC,2.5 V trig

440 ohm 5 VDC 10 mA0.6 mm (24) 30 (100)

BI-2* Comfort(occupied)

0-15 VDC,2.5 V trig

47 K ohm 17 VDC 0.3 mA 0.6 mm to1.5 mm2

(24 to 18)

150 (500)

BI-3* Window, Off(shutdown)

0-15 VDC,2.5 V trig

47 K ohm 17 VDC 0.3 mA 0.6 mm to1.5 mm2

(24 to 18)

150 (500)

1.5 mm2 (18) 150 (500)AO-1* ProportionalHeat/HumidityDpr. ActuatorFan Speed

0-10 VDC 1 K-10 Mohm

10 VDC 10 mA

0.6 mm (24) 60 (200)

Continued on next page . . .

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series ControllersTechnical Bulletin

27

Point(Cont.)

DescriptionorApplication

Range Input orLoadImpedance

MaximumVoltage

MaximumCurrent

Wire Size inmm2 or mm(AWG)

CableLength inMeters (ft)

1.5 mm2 (18) 150 (500)AO-2* ProportionalHeat/HumidityDpr.ActuatorFan Speed

0-10 VDC 1 K-10 Mohm

10 VDC 10 mA

0.6 mm (24) 60 (200)

100 mA 1.5 mm2 (18) 150 (500)

100 mA 0.6 mm (24) 30 (100)

500 mA 1.5 mm2 (18) 30 (100)

BO-1,2,3,4,5^

FanBox/Supplemental HeatElectric HeatLighting

24 VAC @25-500 mA

48-1000 ohm 30 VAC

500 mA 0.6 mm (24) 6 (20)

SM-1^ Steppermotor(internal)

+ 34 VDC2-phase

72-100 ohm 40 VDC 250 mA NA Internal

N2Bus*^

NetworkingBus

+ 5 Vtransmit,+ 0.2 Vreceive

200 ohm line 5 VDC 100 mA 0.6 mm to1.5 mm2

(24 to 18)

1500 (5000)

ZoneBus*

Local RoomSensor Bus

0 to 5 V or±5 V

>3000 ohm 5 VDC 100 mA 0.6 mm to1.5 mm2

(24 to 18)

150 (500)

RoomSensorCable*

AI-1, AI-2,BI-1, ZoneBus, and+15 VDC

See AI-1,AI-2, BI-1,Zone Bus,and+15 VDC inthis table.

0.6 mm (24)eight conductorphone cable

7.5 (25)15 (50)30 (100*)

1.5 mm2 (18) 150 (500)+15VDC*

DC OutputSupply

13.5-18 VDC

1 K-10 Mohm

18 VDC 35 mA0.6 mm (24) 60 (200)6 mm2 (10) 67 (222)4 mm2 (12) 42 (140)2.5 mm2 (14) 27 (88)1.5 mm2 (16) 17 (55)

24VAC^PowerIn

AC SupplyVoltage

20-30 VAC 12-48 ohm 30 VAC 417 mA for1410/1420;125 mA for1430(100 VAcablelength)

1.5 mm2 (18) 11 (35)

* Isolated from 24 VAC^ Isolated from AI, BI, AO, Zone Bus, 15 VDC

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

28

VMA Single Duct Application Wiring Diagram

(18)

BI-1

(19)

CO

M(2

0) B

I-2(2

1) C

OM

(22)

BI-3

(23)

CO

M

(25)

+15

VD

C(2

6) A

I-1(2

7) C

OM

(28)

AI-2

(29)

CO

M(3

0) A

I-3*

(31)

CO

M*

(32)

AI-4

*(3

3) C

OM

*(3

4) Z

B+(3

5) Z

B-

Prim

ary

24 V

AC

Cla

ss2

Ener

gy L

imite

dTr

ansf

orm

er

3-w

ireIn

crem

enta

lVa

lve

Act

uato

r

2-w

irePr

opor

tiona

lVa

lve

Actu

ator

N2+N2-REFSHLD

* Inc

lude

d on

VM

A142

0/14

30 o

nly.

HI

(Red

)

LO

Pneu

mat

ic T

ubin

g(d

iffer

entia

l pre

ssur

e)

Fan

Rel

ay

open

clos

e

3-w

ireBa

sebo

ard

Hea

t

open

clos

e

(1)

24 V

AC

(2)

24 V

AC

(3)

Earth

Gnd

.(O

ptio

nal)

(4)

BO-1

*(5

) BC

OM

*(6

) BO

-2*

(7)

BCO

M*

(8)

BO3*

(9)

BCO

M*

(10)

BO

-4*

(11)

BC

OM

*(1

2) B

O-5

*(1

3) B

CO

M*

(14)

AO

-1*

(15)

CO

M*

(16)

AO

-2*

(17)

CO

M*

Opt

iona

l N2

Shie

ld

NEC

Cod

e if

Mor

e th

an

150

VAC

Prim

ary

Wiri

ngs

Cou

pler

Bol

tSe

t Scr

ewC

oupl

er

CC

WEn

d St

op

CW

E

nd S

top

CO

M

Act

ion

Afte

r com

mun

icat

ions

est

ablis

hed

Nee

ds c

ode

dow

nloa

dN

o po

wer

or +

15 V

sho

rted

LED

Vis

ual R

espo

nse

Flas

hes

at 1

sec

ond

rate

Irreg

ular

flas

hing

4 ti

mes

per

sec

ond

Rap

id fl

ashi

ng 2

0 tim

es p

er s

econ

dN

ot li

t

On

Solid

20 s

econ

d po

wer

up

self

test

Wai

ting

for N

2 co

mm

unic

atio

n**

Pre

ferre

d D

IP S

witc

h

O

N

1 2

3Po

sitio

n fo

r TE-

6700

Scre

w N

umbe

rs

6 5 1 2 4 73

TB2-

7

TB2-

8TB

1-3

TB1-

4TB

1-2

TB2-

5

8TB

1-1

TE-6

700*

*TE

-700

0 (E

urop

e O

nly)

TB2-

6

3 8 TMZ

Wiri

ng***

56

***

Pin

5 (S

uppl

y) o

f the

TMZ1

600

can

be c

onne

cted

to

eith

er +

15 V

DC

or 2

4 VA

C.

24-1

8 AW

G

To N

CM

N2

Bus

To N

ext

N2

Dev

ice

Figure 14: VMA Wiring Interface

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series ControllersTechnical Bulletin

29

VMA Single Duct Supply/Exhaust Wiring Diagram

Zone

UP

(-) LODPT-2015

OUTGND

IN

Pressure Tubes

Damper

Flow Pickup

Connections to/fromMain Controller (VMA) toActuator/Sensor (M9104)(See detail in Figure 17.)

Cold Airfrom AHU

Supply Airto Zone

Return Airfrom Zone

Return toExhaust Fan

Zone Temperature Sensor to VMA AI1 (26), COM (27)

AP - VMA1420-0(Actuator, Pressure

Sensor, and Controller)

M9104-AGS-2N(Actuator and Pressure Sensor)

sply_exhst

Figure 15: VMA Single Duct Supply/Exhaust Wiring Diagram

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

30

VMA Dual Duct Application Wiring DiagramFigures 16 and 17 are wiring diagrams for dual duct applications.

M9104-AGS-2N(Actuator and Pressure Sensor)

AP-VMA1420-0(Actuator, Pressure

Sensor, and Controller)

Connections to/fromMain Controller (VMA) toActuator/Sensor (M9104)(See detail in Figure 17.)

Cold Airfrom AHU

Hot Airfrom AHU

(Air Handling Unit)

Flow Pickup

Damper

Pressure TubesDischarge Air Temperature to

VMA AI4 (31), COM (32)

Zone Temperature Sensor toVMA AI1 (26), COM (27)

Dual DuctMixing Box

Zone

Mixed Airto Zone

dualductap

UP

(- ) LODPT-2015

OUTGND

IN

Figure 16: VMA Dual Duct Wiring Diagram

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series ControllersTechnical Bulletin

31

CCW COM CW INGNDOUT

BO 1(4)

BCOM(5)

BO 2(6)

+15V(24)

AI Com(31)

AI 3(30)

dualductap2

SHLD

REF N2-

N2+

Pressure SensorUP

(-) LO

OUTGND

INCCW

COMCW

Figure 17: VMA Dual Duct or Single Duct Supply/Exhaust WiringDiagram Detail: Connections to/from Main Controller to

Actuator/Sensor

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

32

VMA Internal Schematic DiagramThe small diagram in Figure 18 is a key diagram showing the differentregions of the larger schematic diagram in Figure 19.

1. Isolated Power Supply2. Earth Ground Connection

3. Airflow and High Temperature Safety Switches

4. Isolated Triacs and Proper Wiring

5. Valve Actuators 6. Zone Busvmadia3

Figure 18: Key to Internal Schematic Diagram (Figure 19)

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series ControllersTechnical Bulletin

33

Primary

Manual Reset

AFS

Earth ground is required by NEC if primary is greater than 150 VAC.

1

2

XFR

Stepper

COM

Water Valve

1

2

4

3

In

N2

VMA

+15 V

+5 V

Triacs

COM COM

AO

15 23

14

OPTO

24 VAC

BCOM

µP AO

CablePRO or CVTPRO

Laptop

R

R

RReheatBO-3

ReheatBO-2

FanRelayBO-1

vmadia2

24 VAC

4

6

8

BI18

AI26

5

= Optical or Magnetic Isolation

30.01 Fµ

HighTemperature

µP = MicroprocessorµF = Microfarad

Figure 19: VMA Internal Schematic Diagram

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

34

Fabricating Your Own Interconnection CableConstruct any fabricated interconnection cable to align the same colorwire on both ends of the cable with Pin 1 in the plug. This provides aconsistent field assembly of the cable. Figure 20 illustrates theinterconnection cables for the TE-6700 and TMZ1600 sensors.

Cblfab_1

Phone Connectors

(Clip Side Out)

TE-6700 Phone Plug

1 2 3 4 5 6 7 8

BI-1

AI-2

AI-1

CO

M fo

r AI-1

+15

VD

C+1

5/ZB

/LED

-BI C

OM

CO

M fo

r AI-2

ZB+

ControllerPhone Plug

12345678

TE-6700 Room Sensor

TMZ1600 Phone Plug

1 2 3 4 5 6 7 8

Not

Use

dN

ot U

sed

AI-1

AI C

OM

+15

VD

C+1

5 C

OM

Not

Use

dZB

+

12345678

ControllerPhone Plug

Phone Connectors

(Clip Side Out)

TMZ1600 Room Sensor

Figure 20: TE-6700 and TMZ1600 Interconnection CablesNote: This is not typical of preassembled phone cables purchasedin retail stores. A telephone system cable is wired opposite of theZone Sensor requirements.

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series ControllersTechnical Bulletin

35

TroubleshootingTroubleshooting VMA Room Temperature Drift

Several job sites have reported that VMA zone temperature readingsrandomly drifted to extremely high values. Such readings cause theVAV box to drive to its full cooling level, resulting in occupantdiscomfort and unnecessary energy expenditure. The primary cause ofthis condition is unreliable field wiring connections either at the VMAor at the sensor.

For any site experiencing temperature drift, do not replace the VMA.It is most likely functioning correctly in response to false readingscaused by faulty field connections. Correcting the faulty connectionseliminates erratic temperature readings.

The following describes the connection problems found and thesuggested solutions.

Problem 1VMAs are wired using 0.40 mm (26 AWG) solid wire. The problemoccurs when 0.51 mm or 0.40 mm diameter (24 or 26 AWG) solidwire is crimped into a 0.82 mm2 or 0.32 mm2 total cross-sectional area(18 to 22 AWG) stranded wire spade terminal.

Note: Spade terminals are designed to accept only stranded wire ofthe correct size.

Solution 1Terminate any small-gauge, solid or stranded (preferred) wire with aplug-on screw terminal at the VMA. Table 14 shows availableterminal blocks.

Table 14: Screw TerminalsProduct Code Number DescriptionAP-TBK1002-0 Removable 2-position screw terminal kit (100 pieces)AP-TBK1003-0 Removable 3-position screw terminal kit (100 pieces)M9000-106 Removable 4-position screw terminal kit (1 piece

each)

Problem 2When pulling phone cable through a conduit or wire tray, the phoneplug is cut off to allow for easier installation. One or more of thereplacement phone plug connections is improperly crimped to the endof the cable.

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

36

Solution 2To ensure a good connection:

• refer to Table 15 for the recommended (not required) phone plugto use with each type of commonly used wire when connecting tothe VMA assembly 8-position modular phone jack

• cut off the defective phone plug and re-crimp a new phone plugonto the lead with the crimp tool recommended by themanufacturer of that plug

Note: Phone plug crimping tools provided with packages of phoneplug connectors are often intended for a very limited number ofapplications. These tools make ineffective connections when usedbeyond the stated limit (typically, 100 uses for the plastic crimpingtool). The tool provided with a package of connectors is compatibleonly with that manufacturer’s connectors.

If the VMA Zone Temperature continues to drift, one or more of thefield connections is still bad.

Typically, phone plugs and jacks are standardized to a FederalCommunications Commission specification (Part 68) and toUnderwriters Laboratories, Inc. (UL) standards, which specifydimensions to ensure that the phone plugs and jacks connect properly.

Table 15 lists the AMP™ plugs that Johnson Controls has identifiedfor use with the 8-position modular phone jack. Other manufacturersproduce phone plugs that also connect properly to the phone jack.Confirm that the correct plug is used for each application and that theplug is manufactured to the universal standard so that properconnection occurs.

Note: When using phone plugs to terminate wire, match the phoneplug with the type of wire used in the application:

• If crimping to solid wire, use a phone plug designed for solid wire.

• If crimping to stranded wire, use a phone plug designed forstranded wire.

Table 16 identifies the AMP Crimp Tool for use with the plugassemblies listed in Table 15.

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series ControllersTechnical Bulletin

37

Table 15: AMP Modular Plug Assemblies (8-Position)AMP PartNumber

Cable Wire Specifications in mm (in.)

5-557315-3* Round Solid Accepts: 0.6 mm (telephone cable) (24 or 26 AWG) solid wireInsulation diameter: 0.74 to 0.99 (0.029 to 0.039)Maximum jacket diameter: 5.08 (0.200)Maximum terminated dimension: 6.15 (0.242)

5-554169-3* Round Stranded Accepts: 26 or 28 AWG stranded wire**Insulation diameter: 0.74 to 0.99 (0.029 to 0.039)Maximum jacket diameter: 5.34 (0.210)Terminated dimension: 6.15 (0.242)

5-554720-3* Oval(also calledFlat or Satin)

Solid Accepts: 0.6 mm (telephone cable) (24 or 26 AWG) solid wireInsulation diameter: 0.89 to 0.99 (0.035 to 0.039)Maximum oval jacket size: 2.54 x 8.89 (0.100 x 0.350)Maximum terminated dimension: 6.15 (0.242)

5-554739-3* Oval(also calledFlat or Satin)

Stranded Accepts: 26 or 28 AWG stranded wire**Insulation diameter: 0.89 to 0.99 (0.035 to 0.039)Maximum oval jacket size: 2.54 x 8.89 (0.100 x 0.350)Maximum terminated dimension: 6.15 (0.242)

* Available in quantities of 100 pieces per box.** No metric equivalent recommended for field use except as prefabricated cable.

Table 16: AMP Crimp ToolAMP PartNumber

Description Specifications Comments

2-231652-1 AMP Crimp Toolspecified for crimpingplugs listed in Table 15to cables

Specified crimp tool crimps allplugs specified in Table 15.Crimp tool consists of twoAMP part numbers:2-231652-0 (tool itself)853400-1 (die)

Since the crimp tool works for avariety of different plug types,order both the tool and die. Thistool is rated for >200,000terminations.

Problem 3The spade terminal connectors at the VMA are crimped using anincorrect or inadequate crimping tool (often pliers).

Solution 3For spade-terminal connectors, it is very important to use the crimpingtool recommended by the connector manufacturer. Many differentspade terminals are available, but each requires a crimping tooldesigned specifically for its application.

If the VMA Zone Temperature continues to drift, one or more of thefield connections is still bad.

Mounting and Wiring Variable Air Volume Modular Assembly (VMA) 1400 Series Controllers Technical Bulletin

38

Problem 4Paint or other material on the phone plug prevents good connectionbetween the temperature sensor (TE-6700 or TMZ1600) and theVMA. Contaminants block conductivity at either or both ends.

Solution 4Carefully inspect each plug and jack, cleaning away all contaminantsbefore making a connection. If still in doubt, install a new phone plug.

If the VMA Zone Temperature continues to drift, one or more of thefield connections is still bad.

Installation GuidelinesFollow these guidelines for reliable wire termination:

• Use the recommended phone plugs with the recommendedcrimping tool.

• Use plug-in screw terminals at the VMA side.

• Use 1.0 or 0.35 mm2 (18 to 22 AWG) stranded wire in a1.0 or 0.35 mm2 (18 to 22 AWG) stranded wire spade terminalwhen connecting to inputs or outputs.

• Crimp spade terminals to wire using the crimping toolrecommended by the terminal manufacturer.

• Use pre-terminated phone cable wire without modification.

• Keep all plugs and jacks clean during the installation process.

Controls Group507 E. Michigan StreetP.O. Box 423 www.johnsoncontrols.comMilwaukee, WI 53201 Published in U.S.A.