MORONGO CASINO, RESORT SPA Cooling... · 2018. 8. 27. · MORONGO CASINO, RESORT & SPA ... Project...

Transcript of MORONGO CASINO, RESORT SPA Cooling... · 2018. 8. 27. · MORONGO CASINO, RESORT & SPA ... Project...

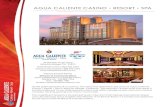

MORONGO CASINO, RESORT & SPA

REQUEST FOR PROPOSAL

COOLING TOWER ADDITION

OCTOBER 21, 2014

Rev. 2

MORONGO CASINO, RESORT & SPA INDEX

REQUEST FOR PROPOSAL

ATTACHMENT A: PROPOSED COOLING TOWER FRAMING AND FOOTING PLAN ATTACHMENT B: EQUIPMENT SCHEDULE

ATTACHMENT C: EQUIPMENT SPECIFICATIONS & CUT SHEETS ATTACHMENT D: CONDENSER WATER PIPING SCHEMATIC ATTACHMENT E: ELECTRICAL SINGLE LINE DIAGRAM

ATTACHMENT F: PROPOSED COOLING TOWER LOCATION

SECTION 1

SECTION 2

SECTION 3

SECTION 4

SECTION 5

SECTION 6

SECTION 7

REQUEST FOR PROPOSAL

SECTION 1

Request For Proposal

Project Description: Provide complete turnkey design‐build and construction cost proposals for the

following solution for adding a dedicated cooling tower to serve the absorption chiller.

All bidders shall perform a detailed walk‐through of the existing facility to assist in generating their firm

fixed‐price bids for the proposed solutions.

Mandatory Site Meeting

Mandatory meeting will be held on November 17, 2014 at 1:00 P.M. All parties are to meet at

the cooling tower yard.

Schedule for the Project

Hard Copy Bids Due – December 12, 2014 at 4:00 p.m. sharp.

Contract Award – TBD, 2014

Project Completion – May 29, 2015

The following attachments are included as a part of this RFP:

Attachment A – Proposed Cooling Tower Footing and Framing Plan

Attachment B – Equipment Schedule

Attachment C – Equipment Specifications & Cut Sheets

Attachment D – Condenser Water Piping Schematic

Attachment E – Electrical Single Line Diagram

Attachment F – Proposed Cooling Tower Location

Project Schedule to be included with contractor submittal package

The following are general requirements that apply to this project:

1. Provide all Structural, Architectural, Mechanical, Plumbing and Control Engineering plans,

specifications, and construction required satisfying the local Authority having jurisdiction. These

codes shall be the minimum quality standard for the work and materials on this proposed

project.

2. Obtain, pay for and comply with all permit requirements as well Building and Seismic,

Mechanical, Plumbing and NEC electrical codes.

3. Comply with all requirements of 2013 California Title 24 Building Energy Efficiency Standards.

Mandatory requirements for Open and Closed Circuit Cooling Towers are listed below:

a. Section 110.2.E Open and Closed Circuit Cooling Towers. All open and closed circuit cooling tower installations shall comply with the following:

i. Be equipped with Conductivity or Flow‐based Controls that maximize cycles of concentration based on local water quality conditions. Controls shall automate system bleed and chemical feed based on conductivity, or in proportion to metered makeup volume, metered bleed volume, re‐circulating pump run time, or bleed time. Conductivity controllers shall be installed in accordance with manufacturer’s specifications in order to maximize accuracy.

ii. Documentation of Maximum Achievable Cycles of Concentration. Building owners shall document the maximum cycles of concentration based on local water supply as reported annually by the local water supplier, and using the calculator approved by the Energy Commission. The calculator is intended to determine maximum cycles based on a Langelier Saturation Index (LSI) of 2.5 or less. Building owner shall document maximum cycles of concentration on the mechanical compliance form which shall be reviewed and signed by the Professional Engineer (P.E.) of Record.

iii. Be equipped with a Flow Meter with an analog output for flow either hardwired or available through a gateway on the makeup water line.

iv. Be equipped with an Overflow Alarm to prevent overflow of the sump in case of makeup water valve failure. Overflow alarm shall send an audible signal or provide an alert via the Energy Management Control System to the tower operator in case of sump overflow.

v. Be equipped with Efficient Drift Eliminators that achieve drift reduction to 0.002 percent of the circulated water volume for counter‐flow towers and 0.005 percent for cross‐flow towers.

4. Provide a full 1 year warranty on all materials and workmanship. Provide all submittals,

operation and maintenance manuals, original equipment manufacturer (OEM) manuals, spare

parts and critical parts list, and As‐Built documentation to the Owner’s representative.

5. Provide 1 full year of service for the new chemical treatment system.

6. The contractor shall work with Todd York (714‐484‐2337) at KDC Systems for HVAC control and

include their design, engineering and construction fee and start‐up commissioning as a separate

line item into the bid.

Description of Cooling Tower Addition:

General Construction

1. Provide foundation, supports and install platform to accommodate a new 4,865 GPM cooling tower.

2. Provide equipment pads for the new condenser water pump and tower filtration system.

3. Epoxy paint the new equipment pads.

4. Provide fencing to match existing and enclose the new cooling tower.

5. Paint new steel platform to match the existing platform.

Mechanical

1. Furnish and install the following equipment:

a. (1) BAC two cell cooling tower

b. (2) new 150 HP Bell & Gossett condenser water pumps.

c. (4) new ABB VFDs with E‐clipse bypass (NEMA 12 Enclosures). Drive to be mounted

inside the existing central plant.

d. (1) new Puroflux centrifugal separator to serve the new tower

2. Provide and install condenser water piping from new cooling tower to the new condenser water

pump.

3. Hot tap existing condenser water supply and return piping and install crossover piping.

4. Provide and install piping from separator and connect to cooling tower basin.

5. Relocate (E) 2‐way control valve on absorption CDW supply.

6. Eliminate (E) 2‐way control valve on absorption bypass and install a new 3 way valve.

7. Provide and install (5) 16” and (2) 10” 2‐way (2 position) control valves.

8. Provide and install new equalizer piping and connect to existing.

9. Provide and install makeup water, drain and overflow for the new cooling tower.

10. Provide passivation of new cooling tower

11. Provide new chemical treatment station with one year of service.

12. Pressure test, flush, fill and ID new piping.

13. Paint new condenser water piping to match the existing piping.

14. Start up and commission new cooling tower.

Electrical

1. Source electrical for CT‐5A and CDWP‐12 from distribution panel DB‐1 Central Plant

2. Source electrical for CT‐5B and CDWP‐13 from distribution panel DB‐2 Cogen Plant

3. Electrical for the centrifugal separator can be sourced from either distribution panel.

4. Breaker, fuse and wire size to be based on equipment submittals and design build drawings.

5. Electrical Metallic Tubing (EMT) to be used inside the central plant. Rigid conduit to be used

outdoors.

Qualifications:

To be considered for this project a bidder must demonstrate knowledge and experience in similar

projects and meet the following qualifications:

Be a licensed Mechanical and General Contractor in the State of California as specified by all applicable laws.

Have a minimum of ten years’ experience providing these services.

Qualified bidders shall have proof and references of minimum five (5) completed cooling tower retrofits/additions of equivalent economic value within the last five (5) years.

Of those five cooling tower retrofits/additions, the contractor must provide proof that the work was completed connecting to live, operating systems without affecting the day to day functionality of the building system and business disruption

Shall propose and present a Method of Procedure ( MOP ) demonstrating the step‐by‐step execution of the project to ensure no disruption to the existing 24/7/365 operating of the Co‐Gen and cooling plants

Demonstrate knowledge of the requirements of codes as relates to mechanical and electrical equipment installation.

Bidder shall have a minimum of one Mechanical Engineer recognized as a Professional Engineer in the State of California employed as a part of their staff.

Provide an organizational chart of employees that will be working on this cooling tower addition and provide current resumes of past project performance for the selected employees.

Have in the bidders employment fully trained and certified technicians capable of providing service and maintenance support for the technologies being implemented.

Provide documentation of in‐house resources and work plan showing proposed man loading and approach to the work, including qualifications of management personnel to successfully execute the work described.

Provide adequate documentation to establish the availability of financial resources to support the range of alternatives anticipated

Be able to provide three references that can attest to the quality of the firm’s past work, and completion of projects of the same magnitude and implementing the same technology as described for installation within the past three years

Document a proven record of on‐time and on budget performance

Provide written documentation of the firms Established Safety program and excellent, verifiable safety record (IIPP)

Provide established records of the firm’s ability to self‐perform the type of work being proposed

Proof of currently employed staff who are Trained and Knowledgeable in all facets of the scope of work as described and technologies being executed.

Proof of Staff capable of providing preventative maintenance and/or four hour emergency, warranty response.

Proof that the bidder has in their direct employment a minimum of (1) one Engineer, Licensed in the State of California as a Professional Engineer.

Ability to effectively communicate with the City as necessary

Morongo Hotel and Casino reserves the right to investigate the qualifications of all firms under

consideration and to confirm any part of the information furnished by a supplier, or to require other

evidence of managerial, financial or technical capabilities that are considered necessary for the

successful performance of the Design‐Build Contract.

Insurance:

Contractor shall, at all times during the term of this Agreement, carry, maintain and keep in full force

and effect, a policy or policies of Comprehensive General Liability Insurance, with minimum limits of

$1,000,000 each occurrence, combined single limits, against any personal injury, death, loss or damage

resulting from the wrongful or negligent acts by the Contractor. Said policy or policies shall be issued by

an insurer rated in A.M. Best’s Insurance Guide with a rating of at least A:X. Contractor shall also provide

comprehensive auto liability insurance covering personal injury and property damage in the amount of a

combined single limit of $1,000,000 covering “Any Auto” utilized by Contractor in performing its services

hereunder.

Contractor agrees to maintain in force, at all times, during the performance of work under this

Agreement, Worker’s Compensation Insurance as required by law of the State of California.

Contractor agrees to maintain in full force and effect during the performance of work under this

Agreement, Professional Liability (Errors and Omissions) insurance in the amount of $1,000,000. Further,

if such insurance is on a claims‐made basis, Contractor agrees to maintain in full force and affect such

insurance for one year after the performance of work under this agreement, including warranty periods,

is completed.

All insurance policies shall provide that the insurance coverage shall not be canceled or reduced by the

insurance carrier without thirty (30) days prior written notice to Morongo Hotel And Casino. Contractor

agrees that he/she will not cancel or reduce said insurance coverage while the contract is in force

through the duration.

Contractor agrees that if it does not keep the aforesaid insurance in full force and effect, Morongo Hotel

And Casino may either immediately terminate this agreement or, if insurance is available at a reasonable

cost, Morongo Hotel And Casino may take out necessary insurance and pay, at Contractor’s expense, the

premium thereon.

Contacts:

Frank A. Bell

Director of Engineering

MorongoCasinoResortandSpa

49500SeminoleDrive

CabazonCA,92230

O:951.849.3080ext.23704

H:702.545.7097

C:951966‐3121

JohnEaston

DirectorofConstructionServices

12700PumarraRoad

Banning,CA.92220

Cell9515203580

Email/jeaston@morongo‐nsn.gov

ATTACHMENT A: PROPOSED COOLING TOWER FRAMING AND FOOTING PLAN

SECTION 2

SEE SEPARATE PDF ATTACHMENT

ATTACHMENT B: EQUIPMENT SCHEDULE

SECTION 3

ATTACHMENT C: EQUIPMENT SPECIFICATIONS & CUT SHEETS

SECTION 4

BAC Cooling Tower:

Model shall be (1) BAC S3E-1222-13R-2 Two-Cell Tower. The cooling tower supplier shall have 25 years of experience in North America manufacturing complete factory

assembled cooling tower units. Each unit shall be designed, manufactured, and business processes are ISO 9001 certified.

The tower shall be constructed of G-235 (Z700 metric) hot-dip galvanized steel. The cold water basin of the tower shall be constructed of Type 304 Stainless Steel. All factory seams in the cold

water basin will be welded to ensure watertight construction and welded seams shall be warranted against leaks for a period of five (5) years.

Each cell of the tower shall have a bottom inlet EASY CONNECT piping arrangement. Each cell of the tower shall have a bottom outlet pump suction connection. Each cell of the tower shall have a bottom equalizer connection and be capable of independent cell operation. The tower water level control shall consist of electronic water level control (EWLC) with solenoid valve and high-

level & low-level alarms. Factory-installed basin sweeper piping shall be provided in each cell of the tower. Each fan shall be provided with a mechanical vibration cutout switch. The hot water basin shall be provided with weir dams to accommodate water flow rates of 50% of the design flow. Hot-dip galvanized steel wire mesh screens shall be factory-installed over the air inlet louvers to prevent debris

from entering the unit. The unit shall include an access door service platform, access ladder (including safety cage), and safety railing

complying with OSHA standards and regulations. The supports for the access door platform shall be constructed of galvanized steel. The access ladder and safety cage shall be provided with an 8’ extension from the bottom of the tower.

The tower shall be provided with an aluminum ladder extending to the top of the unit and perimeter handrails for access to the top of the unit and the water distribution system. The access ladder shall be provided with an 8’ extension from the bottom of the tower.

The tower shall be provided with a Type 304 Stainless Steel walkway in the cold water basin, and an internal platform with aluminum ladder in the upper part of the plenum.

Puroflux Centrifugal Separator

Model shall be a Puroflux PF‐64‐050 Pump Package Separator System

The separator system shall include a centrifugal vortex type separator, integral pump with pre‐strainer, and

Schedule 80 PVC interconnecting piping, all mounted on a steel skid.

The centrifugal separator shall be a Puroflux model PF‐61‐010 consisting of fusion bonded, polyester coated

carbon steel rated for 150 psi, with 0‐160psi gauges and ¼” manual air bleed valve.

The system skid shall be constructed of carbon steel with polyester powder‐coat.

The system pump shall be a close‐coupled CIBF end suction pump rated for 600 GPM @ 60’.

The pump motor shall be a 15 HP, 1750 RPM, standard efficiency TEFC motor rated for 230V/460V.

The pump pre‐strainer shall be constructed of cast iron with a removable stainless steel basket.

The separator system shall have a 6” flange water inlet and a 5” flange water outlet.

The separator system shall be provided with an electrically actuated industrial grade automatic purge valve with

a 1.5” fpt connection.

The separator system shall be equipped with automatic controls consisting of a motor start/stop device with

overload short circuit protection, door‐disconnect switch, step‐down transformer, and purge timer, all mounted

in a NEMA 4X fiberglass enclosure with a single electrical connection point.

ABB Variable Frequency Drives:

Models shall be (2) 150 HP ACH550-BCR-0180A-4+B055 and (2) 60 HP ACH550-BCR-078A-4+B055 ABB variable frequency drives (VFDs).

VFDs shall be provided with NEMA 12 indoor enclosures. VFDs shall include an integral Circuit Breaker Disconnect VFDs shall have E-Clipse Bypass, to include:

o Current transducers to protect the motor from single phase power conditions in bypass o (6) additional inputs and (5) additional relay outputs o 115 VAC contactors to eliminate chatter o Pass-Through I/O communication network which can control inputs & outputs if the drive fails

A 5% Internal Line Reactor shall be provided (VFDs which use optional external reactors are not acceptable). VFDs must be BTL Listed (Communication “gateways” are not acceptable). VFDs must have internal EMI/RFI filter All VFD enclosures shall be UL type approved (self-certified NEMA enclosures not acceptable). VFDs shall be provided with (3) year on-site parts, labor, & travel warranty.

Bell & Gossett Condenser Water Pumps:

Models shall be Bell & Gossett HSC3 (or approved equal), Qty (2). Pump(s) shall meet or exceed the efficiency shown in the pump schedule. The pumps shall be long coupled, base mounted, single stage, double suction, horizontally split case design, in

cast iron bronze fitted construction specifically designed for quiet operation. Suitable standard operations at 225° F and 175 PSIG working pressure or optional operations at up to 250° F and 280 or 400 PSIG working pressures. Working pressures shall not be de-rated at temperatures up to 250F. The pump internals shall be capable of being services without disturbing piping connections or electrical motor connections, and the pump’s internal seals and bearings shall be serviceable without disturbing the upper casing half.

A bearing housing shall supply support for a pair of heavy-duty regreaseable ball bearings designed to circulate in oil. An inboard single row bearing shall absorb thermal expansive forces while an outboard double row bearing shall be clamped in place to absorb both radial and thrust loads and keep the rotating element in proper axial alignment. Bearings shall be replaceable without disturbing the system piping, the upper casing half, and shall be regreaseable without removal of the bearings from the bearing housing.

The impeller shaft shall be a solid 416 stainless steel shaft. Pump shall be equipped with a pair of internally self flushing mechanical seal assemblies in direct contact with the

pump shaft. Seal assemblies shall be a John Crane 21 BF(50) 10(10)1, having a brass housing, Buna bellows and seat gasket, stainless steel spring, and be of a carbon Ni-Resist design with the carbon face rotating against a stationary Ni-Resist face. Mechanical seals shall be replaceable without disturbing the upper casing half and system piping.

Impeller shall be of the enclosed double suction type made of bronze, both hydraulically and dynamically balanced to ANSI/HI 1.1-1.5-1994, section 1.4.6.1.3, figure 1.106, balance grade G6.3, keyed to the shaft and fixed in the axial position.

A flexible type coupling, capable of absorbing torsional vibration, shall be employed between the pump and motor. On variable speed applications the coupler sleeve should be constructed of an EPDM material to maximize performance life.

An OSHA and ANSI rated coupler guard shall shield the coupler during operation. Coupler guard shall be dual rated ANSI B15.1, Section 8 and OSHA 1910.219 compliant coupling guard and contain viewing windows for inspection of the coupling. No more than .25 inches of either rotating assembly shall be visible beyond the coupling guard.

Pump volute shall be of a cast iron (rated for 175 PSIG maximum working pressure) or ductile iron (rated for 280 or 400 PSIG maximum working pressure) axially-split design with flanges (175 PSIG drilled for 125# ANSI companion flanges or optional 280 and 400 PSIG working pressures are drilled 250# flange drilled) and mounting feet integral cast into the bottom half of the casing. Suction and discharge flanges shall be on a common centerline in both the horizontal and vertical planes, and the volute shall include Bronze Casing Wear Rings,

priming port, gauge ports at nozzles, and vent and drain ports. The upper half casing shall be capable of being removed without disturbing piping connections or electrical motor connections.

On pumps rated for 175 PSIG the pump seal flushing shall be internal within the pump casing and shall flush the seal at a rate equal to 25% of the total pump flow. On pumps rated for 280 or 400 PSIG the pump seal flushing shall be external and use flushing lines made of bronze that shall be mounted on the upper half pump casing.

Motors shall meet scheduled horsepower, speed, voltage, and enclosure design. Pump and motors shall be factory aligned, and shall be realigned after installation by the manufacturer’s representative. Motors shall be non-overloading at any point on the pump curve and shall meet NEMA specifications and conform to the standards outlined in EPACT 92.

Pump shall be of a maintainable design and for ease of maintenance should use machine fit parts and not press fit components

Base plate shall be of structural steel or fabricated steel channel configuration fully enclosed at sides and ends, with securely welded cross members and fully open grouting area (for field grouting). The minimum base plate stiffness shall conform to ANSI/HI 1.3.4-1997 for Horizontal Baseplate Design standards.

Pump rotation shall be right-hand or left-hand as viewed from the pump’s motor end and in respect to the discharge flange.

The pump(s) selected shall conform to ANSI/HI 9.6.3.1 standards for Preferred Operating Region (POR) unless otherwise approved by the engineer. The pump NPSH shall conform to the ANSI/HI 9.6.1-1997 standards for Centrifugal and Vertical Pumps for NPSH Margin.

The pump(s) vibration limits shall conform to Hydraulic Institute ANSI/HI 1.1-1.5-1994, section 1.4.6.1.1 for recommended acceptable unfiltered field vibration limits (as measured per H.I. 1.4.6.5.2, Figure 1.108) for pumps with rolling contact bearings.

Pump manufacturer shall be ISO-9001 certified. The seismic capability of the pump shall allow it to withstand a horizontal load of 0.5g, excluding piping and/or

fasteners used to anchor the pump to mounting pads or to the floor, without adversely affecting pump operation. Each pump shall be factory hydrostatically tested per Hydraulic Institute standards and name-plated before

shipment. It shall then be thoroughly cleaned and painted with at least one coat of high grade paint prior to shipment.

Base shall be capable of being field grouted. Where noted on schedule pumps shall be provided as a vertically mounted design with a steel fabricated cradle

base and a vertical solid shaft type P motor. Where noted on schedule pumps shall be provided with internal bronze pump wear rings, special shaft materials,

or special spacer couplers. Where noted on schedule either balanced or unbalanced seals of EPR Carbon/Ni-Resist seals, EPR

Tungsten/Carbide seal, or packing gland material should be used in lieu of the standard seal. Where noted on schedule pumping equipment may require one or all of the following tests: Certified Lab tests

(unwitnessed), Hydraulic Institute Level B tests, or Witnessed Tests.

Baltimore Aircoil Company, Inc.Cooling Tower Selection ProgramVersion: 8.4.0 NAProduct data correct as of: July 29, 2014

Project Name: Morongo CasinoSelection Name: Absorber TowerProject State/Province: CaliforniaProject Country: United StatesDate: August 26, 2014

Optimized Selection ParametersModel & Fan MotorProduct Line: New Series 3000

Model: S3E-1222-13R

Number of Units: 2

Fan Motor per Unit: (1) 60.00 = 60.00 HP

Total Standard Fan Motor Power per Unit: Full Speed, 60.00 BHP

Tower Pumping Head: 8.44 psi

Model AccessoriesIntake Option: None

Internal Option: None

Discharge Option: None

Fan Type: Standard Fan

Maximize Capability, per UnitFlow Rate: 4864.00 USGPM

Hot Water Temperature: 98.60 °F

Cold Water Temperature: 85.00 °F

Wet Bulb Temperature: 78.28 °F

Range: 13.60 °F

Motor Speed: 100.00 % of Full Speed, 60.00 BHP

Thermal performance for this selection is certified by the Cooling Technology Institute (CTI).

END

ELE

VATI

ON (F

ACE

A)

CT-1

CT-2

FRON

TOF

UNI

T

BACK

OF U

NIT

SIDE

ELE

VATI

ON

PLAN

VIE

W

FACE A

FACE BFACE B

FACE A

DATE

:

ORDE

R NO

:B

ALT

IMO

RE

AIR

CO

IL C

OM

PA

NY

RUP

-Q14

0321

1920

1

3000

E Un

it Pr

int

Two

Piec

e Un

its

Q140

3211

9201

8/26

/201

4

L

PLAN

VIE

WEN

D EL

EVAT

ION

CT-1

CT-2

SECT

ION

"A-A

"

P C MO

UNTI

NG B

OLT

L

DATE

:

ORDE

R NO

:B

ALT

IMO

RE

AIR

CO

IL C

OM

PA

NY

RSS

-Q14

0321

1920

1

3000

E Un

it Su

ppor

tSt

anda

rd B

asin

s

Q140

3211

9201

8/26

/201

4

CT-1

CT-2

PLAN

VIE

W

DATE

:

ORDE

R NO

:B

ALT

IMO

RE

AIR

CO

IL C

OM

PA

NY

RIA

-Q14

0321

1920

1

3000

E In

tern

al A

cces

s

Q140

3211

9201

8/26

/201

4

END

ELE

VATI

ON (F

ACE

A)

CT-1

CT-2

PLAN

VIE

W

SIDE

VIE

W

FRON

TOF

UNI

TBA

CKOF

UNI

T

DATE

:

ORDE

R NO

:B

ALT

IMO

RE

AIR

CO

IL C

OM

PA

NY

REA

-Q14

0321

1920

1

3000

E Ex

tern

al A

cces

sTw

o Pi

ece

Units

Q1

4032

1192

01

8/26

/201

4

CT-1

CT-2

C UN

ITC

UNIT

LL

PLAN

VIE

W

DETA

IL B

ELEV

ATIO

N VI

EWBO

TTOM

INLE

T

DETA

IL A

ELEV

ATIO

N VI

EWBO

TTOM

EQU

ALIZ

ER

DETA

IL C

ELEV

ATIO

N VI

EWBO

TTOM

OUT

LET

FACE A

DATE

:

ORDE

R NO

:B

ALT

IMO

RE

AIR

CO

IL C

OM

PA

NY

RBC

-Q14

0321

1920

1

3000

E Bo

ttom

Con

nect

ions

Q1

4032

1192

01

8/26

/201

4

CT-1

CT-2

C UN

ITLL

PLAN

VIE

W

BB

END

ELEV

ATIO

N VI

EW B

-B

C UN

ITL

BB

DATE

:

ORDE

R NO

:B

ALT

IMO

RE

AIR

CO

IL C

OM

PA

NY

RBA

-Q14

0321

1920

1

3000

E Ba

sin

Acce

ssor

ies

Q1

4032

1192

01

8/26

/201

4

Puroflux Corporation • (805) 579-0216 • Fax (805) 579-6005 Rev. E 02/10

P U R O F L U X C O R P O R A T I O N

E N G I N E E R I N G M A N U F A C T U R I N G S E R V I C E

PF64-050 SPECIFICATION SHEET PUMP PACKAGE SYSTEM

SPECIFICATIONS PF64-050

Flow Rate 600 gpm

System Inlet Connection 6” flng

System Outlet Connection 5” flng

Purge Connection 1 1/2” fpt

Separator Model PF61-050

Separator Purge Automatic

Pump Motor 15 hp

Volume 24 gal

Est. Weight, Dry 1045 lbs

Est. Weight, Operating 1245 lbs

Removes particulate as low as 45 microns

150 psi working pressure

Fully assembled skid package

One year limited warranty

SYSTEM COMPONENTS

Separator : PF61-050 - 5” flanged separator

Fusion bonded polyester coated vessel

1/4” Manual air bleed valve

0 to 160 psi gauges on influent / effluent

Electrical Controls : NEMA 4X fiberglass enclosure

Motor overload/short circuit protection

Hand-Off-Auto switches

Pump : Close coupled, end suction centrifugal pump

1750 rpm, TEFC motor

Automatic Purge : Electrically actuated industrial grade ball valve

Adjustable purge timer

Skid : Fusion bonded polyester coated carbon steel

Interconnecting Pipe : Sch.80 PVC piping

Options: Manual Purge, Removable Dome, 22 1/2º profile

Keystone Butterfly Valves - Figure 221/222 2" thru 12"

• 221 - Wafer style resilient seated butterfly valve • 222 - Lugged style resilient seated butterfly valve • Molded-in Seat Design

Features and Benefits • Molded-in resilient seat provides

bubble-tight shutoff to 250 psi.

• Offered in two body styles: wafer and lug. The lugged body is drilled and tapped for isolation and removal of downstream piping at full rated pressure.

• Round, polished disc and hub edge provides 360 degree concentric seating, minimum flow restriction, lower torques and longer seat life.

• Upper and lower inboard bronze bearings ensure longer service life with low operating torques.

• Thru-stem design provides high strength and positive disc control with standardized end connection for operator interchangeability.

• Extended neck allows adequate clearance for flanges and insulation.

• Bidirectional, self-adjusting stem seal, located in the upper journal, is suitable for vacuum and pressure while also preventing external contamination of the stem area.

• Heavy-duty corrosion resistant top bushing, located in the upper journal, absorbs actuator side thrust.

• Cast-in top plate is an integral part of the body and is standardized to allow direct mounting of all Tyco actuators.

• Each valve is factory tested to 110 percent of specified pressure rating.

General Application Heating, ventilation, air conditioning and general industrial services.

Technical Data Size Range: 2" thru 12"

Styles: 221 - wafer style 222 - lug style

Pressure Rating: 250 psi

Bidirectional Dead End Rating: 250 psi

Temperature Rating: -40°F thru +250°F

Flange Accomodation: ASME 125/150

Flow Control

Total Flow Control Solutions™

Keystone is either a trademark or registered trademark of Tyco International Services AG or its affiliates in the United States and/or other countries. All other brand names, product names, or trademarks belong to their respective holders.

Copyright © 2007 Tyco Flow Control. All rights reserved. KEYMC-0029-US-0705

Keystone Butterfly Valves - Figure 221/2222" thru 12"

Copyright © 2007 Tyco Flow Control. All rights reserved. KEYMC-00292

Materials

3

6

7

1

5

2

4

5

Materials

Part Material Material Standards

1. Body Cast Iron ASTM A126 Class B

2. Disc 304 SS

Aluminum Bronze

316 SS

ASTM A351 Grade CF8

ASTM B148 UNS C95200 Grade A

ASTM A743 Grade CF8M

3. Stem 416 SS ASTM A582

UNS S41600

4. Molded-in liner EPDM

NBR

5. Inboard bearings Bronze 6. Upper bushing Polyester 7. Upper stem seal NBR

Keystone Butterfly Valves - Figure 221/222 2" thru 12"

Dimensions

B

221 Wafer 222 Lug

Top Plate Drilling

Size

A

B

C

D

Q

E

F

G

H

Key

Bolt Circle

No. Holes

HoleDiam.

Weight(lbs.)

Adapt.Code

2 21/16 41/8 55/16 111/16 13/8 4 11/4 9/16 3/8 N/A 31/4 4 7/16 7.7 BAB

21/2 29/16 45/8 515/16 113/16 2 4 11/4 9/16 3/8 N/A 31/4 4 7/16 8.8 BAB

3 31/16 53/16 65/16 113/16 25/8 4 11/4 9/16 3/8 N/A 31/4 4 7/16 10.2 BAB

4 41/16 63/8 71/8 21/16 311/16 4 11/4 5/8 7/16 N/A 31/4 4 7/16 16.9 BAC

5 51/16 73/8 711/16 21/4 43/4 4 11/4 3/4 1/2 N/A 31/4 4 7/16 19.9 BAD

6 513/16 81/2 85/16 21/4 59/16 4 11/4 3/4 1/2 N/A 31/4 4 7/16 25.3 BAD

8 713/16 1011/16 91/2 23/8 73/4 6 11/4 7/8 5/8 N/A 5 4 9/16 40.5 CAE

10 913/16 13 107/8 211/16 93/4 6 2 11/8 N/A 1/4 x 1/4 5 4 9/16 61.1 CAF

12 1113/16 1413/16 121/4 31/8 113/4 6 2 11/8 N/A 1/4 x 1/4 5 4 9/16 82.7 CAF

Top Plate Drilling Tapped Lug Data

Bolt No. Hole Bolt No. Weight Adapt. Size A B C D Q E F G H Key Circle Holes Diam. Circle Holes Tap (lbs.) Code

2 21/16 43/4 55/16 111/16 13/8 4 11/4 9/16 3/8 N/A 31/4 4 7/16 43/4 4 5/8-11 UNC-2B 9.0 BAB

21/2 29/16 51/4 515/16 113/16 2 4 11/4 9/16 3/8 N/A 31/4 4 7/16 51/2 4 5/8-11 UNC-2B 10.5 BAB

3 31/16 513/16 65/16 113/16 25/8 4 11/4 9/16 3/8 N/A 31/4 4 7/16 6 4 5/8-11 UNC-2B 11.9 BAB

4 41/16 7 71/8 21/16 311/16 4 11/4 5/8 7/16 N/A 31/4 4 7/16 71/2 8 5/8-11 UNC-2B 21.4 BAC

5 511/16 81/8 711/16 21/4 43/4 4 11/4 3/4 1/2 N/A 31/4 4 7/16 81/2 8 3/4-10 UNC-2B 25.7 BAD

6 513/16 91/4 85/16 21/4 59/16 4 11/4 3/4 1/2 N/A 31/4 4 7/16 91/2 8 3/4-10 UNC-2B 31.0 BAD

8 713/16 117/16 91/2 23/8 73/4 6 11/4 7/8 5/8 N/A 5 4 9/16 113/4 8 3/4-10 UNC-2B 48.0 CAE

10 913/16 137/8 107/8 211/16 93/4 6 2 11/8 N/A 1/4 x 1/4 5 4 9/16 141/4 12 7/8-9 UNC-2B 75.8 CAF

12 1113/16 1511/16 121/4 31/8 113/4 6 2 11/8 N/A 1/4 x 1/4 5 4 9/16 17 12 7/8-9 UNC-2B 106.5 CAF

‘Q’ dimension is the minimum allowable pipe or flange inside diameter at the centered body face to protect the disc sealing edge against damage when opening the valve.

Note

Figure 222 Dimensions (inches)

Figure 221 Dimensions (inches)

Copyright © 2007 Tyco Flow Control. All rights reserved. KEYMC-00293

D

45°

E

EH

KEYSTONE

B

G

F

C

A

Q

D

KEYS TONE

H

Keystone Butterfly Valves - Figure 221/2222" thru 12"

Copyright © 2007 Tyco Flow Control. All rights reserved. KEYMC-00294

Valve Cv

Size (in) Size [mm] 10° 20° 30° 40° 50° 60° 70° 80° 90°

2 50 0 1.3 5 14 26 40 52 59 60

21/2 65 0 1.4 6 21 44 74 107 138 150

3 80 0 1.5 8 29 67 115 175 234 262

4 100 1 15 48 107 196 318 463 589 647

5 125 3 32 99 206 362 579 832 1,045 1,141

6 150 4 47 145 295 510 810 1,160 1,450 1,580

8 200 6 84 239 450 751 1,190 1,754 2,385 2,892

10 250 9 133 360 652 1,064 1,683 2,524 3,596 4,593

12 300 12 192 509 899 1,449 2,288 3,470 5,085 6,682

Cv is the valve flow capacity expressed as the flow rate of 60°F water, in US gallons per minute, which produces a 1 psi pressure drop across the valve.

www.keystonevalves.com

www.tycoflowcontrol.com

Tyco Flow Control (TFC) provides the information herein in good faith but makes no representation as to its comprehensiveness or accuracy. This data sheet is intended only as a guide to TFC products and services. Individuals using this data sheet must exercise their independent judgment in evaluating product selection and determining product appropriateness for their particular purpose and system requirements. TFC MAKES NO REPRESENTATIONS OR WARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO THE INFORMATION SET FORTH HEREIN OR THE PRODUCT(S) TO WHICH THE INFORMATION REFERS. ACCORDINGLY, TFC WILL NOT BE RESPONSIBLE FOR DAMAGES (OF ANY KIND OR NATURE, INCLUDING INCIDENTAL, INDIRECT, OR CONSEQUENTIAL DAMAGES) RESULTING FROM THE USE OF OR RELIANCE UPON THIS INFORMATION. Patents and Patents Pending in the U.S. and foreign countries. Tyco reserves the right to change product designs and specifications without notice.

Note

Keystone EPI2 Electric ActuatorModels E006 to E171

Electric actuator for quarter-turn valves. For output torques to 17,700 lb. in.

Features

Standard

• Standard actuator accepts 24 to 240 Volt DC or AC single phase input, 50 and 60 Hz. Three phase is optional.

• Separate terminal enclosure isolated from the electronics and motor compartment. Only the wiring terminal is exposed during field installation.

• Standard adjustable torque switches, from 40 to 100% of rated torque output.

• Manual override does not require a declutchable mechanism - always engaged.

• NEMA 4/4X/6 enclosure rating with CSA (C-US) and CE.

• Anodized aluminum with epoxy powder coat to protect unit in most aggressive environments.

• Visual mechanical position indicator for accurate visual reference of valve position.

• Direct mounting to Keystone valves or readily adaptable to other quarter-turn valves; minimizes costs associated with adaptation.

• Permanently lubricated self-locking gear train eliminates the need for motor brakes.

• Mechanical travel stops prevent over-travel during hand wheel or motor operation.

• Over temperature motor thermostat.

• Integral speed control independently adjustable in open and closing directions.

Optional Controls

• Analog control modules offer 4 to 20 mA input/output. Complete with additional output relays and monitor relay. Alternate 0 to 10 VDC input/output.

• Communication modules for most standard communication bus protocols. Bluetooth® modules allow for non-intrusive access to the EPI2 for configuration, operation and interrogation via a Bluetooth® enabled handheld PDA or PC.

• Integral local control panel.

General Applications Quarter-turn ball, butterfly, or rotary plug valves, dampers, etc.

Technical Data Temperature : Units available for

-40°F to 158°F [-40°C to 70°C]

Output torque : up to 17,700 lb. in. [2000 Nm]

Voltage : Standard Unit: Universal for - 24 to 240 VAC, 1 phase 60/50 hertz and 24 to 240 VDC

Optional Units for: 208 to 240 VAC, 3 phase 60/50 hertz 380 to 480 VAC, 3 phase 60/50 hertz

575 VAC, 3 phase 60/50 hertz

Flow Control Keystone is either a trademark or registered trademark of Tyco International Services AG or its affiliates in the United States and/or other countries. All other brand names, product names, or trademarks belong to their respective holders.

Total Flow Control Solutions™ Copyright © 2007 Tyco Flow Control. All rights reserved. KEYMC-0275-US-0707

Keystone EPI2 Electric Actuator Models E006 to E171

Copyright © 2007 Tyco Flow Control. All rights reserved. KEYMC-02752

Basic Unit Technical Detail

Voltage Ratings 24 to 240 Volts DC or AC single phase, 50/60 Hz. +/- 10% voltage tolerance

Working Temperature Standard Range: -40°F to 140°F

[-40°C to 60°C]

Optional Ranges Covering From: -40°F to 158°F [-40°C to 70°C]

Environmental Protection Standard Weather Tight Enclosure

NEMA 4/4X/6 according to NEMA ICS6/NEMA 250

IP68 according to EN 60529

Standard unit is CSA (C-US)

Optional Explosion Proof Enclosure

NEMA 4/4X/6 according to NEMA ICS6/NEMA 250

IP68 according to EN 60529

FM/CSA (C-US) NEC 505 (Class 1, Zones 1 & 2)

NEC 500 (Class 1, Div. 2)

Electric motor and universal power supply Innovative POWER SUPPLY MODULE™ to accept 24 V to 240 V DC and AC 1-phase input voltages at 50 and 60 Hz provides flexibility for a broad range of applications.

Over temperature device to protect the motor and electronics is included.

Local Indicator Standard "Window" type located in the cover.

Travel Stops Mechanical stops on the base of the actuator provide +/- 10 degree over/ under travel in each direction (70 degree minimum to 110 degree maximum angular stroke).

Anti-condensation Heater Standard with 10 Watt thermostat will activate the heater when the internal temperature drops below +59°F.

Terminal Enclosure Terminal board is in a separate compartment.

Removal of the actuator’s control cover to do field wiring is no longer required.

Four 1" NPT conduit openings allow flexibility in wiring access.

Electronic Controls “Push-to-Run” 3 wire (Open/Close/Common) remote control signals.

Torque sensing in both directions of travel, adjustable in 10 steps from 40% to 100% of the actuator’s rated torque output.

Absolute encoder is used for position feedback.

Output speed adjustment with ratio of 1 to 9; Speed independently adjustable for the opening and closing directions.

Four SPST (NO/NC) latching contacts are provided for fully Open / fully Closed remote indication. Contact ratings are 5 Amp at 120VAC and 5 Amp at 30 VDC.

Base Unit Default Settings The actuators are provided with the following default values:

- Closing limit by Position

- Opening limit by Position

- Stroking time for closing and opening; 18 seconds for models E006, E013, E025, and E051, 30 seconds for the E091, and 66 seconds for the E171.

- Torque Limiting for closing and opening set at 100% of nominal torque.

AWWA

Unit is tested to, and compliant with AWWA C540.

Main Components Body and Cover

Epicyclical gearing

Output drive

Base Plate

Manual Worm Shaft

Worm Wheel

O-ring

Lubrication

Materials Anodized ESPC aluminum alloy AC-44300

All metal gearing (on most models)

Ductile cast iron grade GJS-500-7

Investment cast iron

High-grade alloy steel

Alloy steel

NBR or Fluorosilicon suitable for ambient temperature range

Grease suitable for ambient temperature range

Easily accessed control panel allows setting of torque, speed, and position quickly and simply. All settings are done from this control panel.

Material of Construction

Keystone EPI2 Electric ActuatorModels E006 to E171

Copyright © 2007 Tyco Flow Control. All rights reserved. KEYMC-02753

New Standards for the Small Electric Quarter-turn Market

Control Panel offers easy setting of all functions from one location

Separate terminal block for safe and easy field wiring terminations

Self-locking, epi-cyclical internal gearing ensures a smooth and reliable operation

KeysModel

Copyrig

Option

OM1 - Retranwith inintrusivAnalog 0 to 10 V

Analog or 0 to 1

Monitor loss of ptemperaloss of a

Motor R

Four adset indealong th

Contactbreak).

Non-inServoaOptionaspecifieconfigurtechnolo

OM2 - Providescontactspower s

stone EPI2 ls E006 to E17

ht © 2007 Tyco Flo

n Modules

Servoamp annsmission Montegral Bluetove ConfiguraPosition INPUTVDC (selectabl

Position OUTP10 VDC (select

Relay Alarm cpower, torque aature of motor oanalog signal.

Running output

ditional SPST ependently at ohe stroke.

ts are configura

ntrusive Confamp/Retransal - OM1 moduld with integral,ration using Bluogy protocol.

Battery Backs power so thas will update wsupply to the ac

Electric A71

ow Control. All rig

nd odule (availaooth® Non- ation) T of 4 to 20 mAle).

PUT of 4 to 20 mable).

ontact to indicaalarm, over or electronics a

contact.

Output Contacne of 10 points

able (make or

figuration of smission

e may be non-intrusive,

uetooth® wirele

kup Module at the remote henever the mactuator is lost.

®

Actuator

ghts reserved.

able

A or

mA

ate

and

cts s

f

ess

ain

OM3IntegLocapushfor lo

OM4ConA motechnconfi

OM1contConvwherthe s

BUSInteOptioallowThes

3 - Local Integral pushbuttonal/Remote Selehbuttons and 2 ocal indication.

4 - Non-intrunfiguration Toodule with Bluenology allows niguration of on-

13 - Three-witrol moduleverts unit to thrre power and dsame.

S Communicarface onal network in

w communicatiose modules are

KEYMC

erface n panel with ector, Open/Clo

LED's (Red/Gr

sive ool etooth® wirelessnon-intrusive -off actuators.

ire interface

ree-wire configdirectional cont

ation - Netwo

nterface moduleon with BUS sye plug and play

C-02754

ose reen)

s

uration trol are

ork

es to ystems. .

O(aNA

ODBCPcocoD

O(aNF

O(aND

1.

2.

3.

4.

5.

OM8 - AS-inteavailable with

Non-intrusiveASi 2.1/2.2 mod

OM9 - PROFIBDPV1 (availabBluetooth® NoConfiguration

ROFIBUS® DPommunication aommunication a

DPV1 extension

OM10 - FOUND

available withNon-intrusive

F interface mod

OM11 - Devicavailable with

Non-intrusiveDeviceNet™ inte

Notes

AS-interface® isAS-Internationa

The Bluetooth wowned by the Bluse of such marunder license.

Foundation™ fietrademark of the

PROFIBUS® is aPROFIBUS Inte

DeviceNet™ is aODVA.

erface® Moduh integral Bl

e Configuratidule.

BUS® DPV0 able with integon-intrusiven) PV0 cyclic and acyclic as per PROFIB

n.

DATION™ fieldh integral Bl

e Configuratidule.

eNet™ Moduh integral Bl

e Configuratierface module.

a registered tradeal.

word mark and logluetooth SIG, Inc.rks by Tyco Flow C

eldbus is a registee Fieldbus Founda

a registered tradeernational.

a registered trade

®

ule uetooth®

on)

and gral

BUS®

bus uetooth®

on)

ule uetooth®

on)

emark of

gos are and any Control is

ered ation.

emark of

emark of

M

SE1a

Dimensions

A

Model Bore Dia

E006 1.125

E013 –

E025 1.875

E051 1.875

E091 2.250

E171 2.250

Notes

Standard Bore - WE013 and E025 a10 mm key. W5above.

A

s (inches)

Actuator Base

Standard Bore

A a. Key

1/4 x 1/4

– 1/2 x 3/8

1/2 x 3/8

1/2 x 3/8

1/2 x 3/8

W1, W2, X1, and Xare 35 mm bore w, W8, and X5 a

e

Depth

Dia.

1.34 1.75

2.12 –

2.12 3.25

2.12 3.25

4.80 5.00

4.80 5.00

X2 on models with 8 mm x

are as listed

C

B

KeystonModels E0

Copyright © 2

Keystone

The same dmarket placeactuators, w

Keystone Vamounting cosystem. Thecustomer or

D

Bol

B Holes

1/4" - 20 UNC

– 3/8" - 16 UNC3/8" - 16 UNC1/2" - 13 UNC1/2" - 13 UNC

Insert - W1, WE051 is 1.625 X5 are as liste

ne EPI2 Ele006 to E171

2007 Tyco Flow C

e Direct Mou

irect mounting e by Keystone

with even more

alve pioneered ompact valve ae EPI2 continueriented system

D

E

t Circle

Dia.

C

C 3.25

3.25

C 5.00

C 5.00

C 6.50

C 6.50

W2, X1, and X2 onwith 3/8 x 3/8 key

ed above.

ectric Actu

ontrol. All rights r

unt System

brought to thefor valves andflexibility.

the direct ctuator

es this with

Shaft In

C Holes

3/8" - 16 UNC 3/8" - 16 UNC 1/2" - 13 UNC 1/2" - 13 UNC 3/4" - 10 UNC 3/4" - 10 UNC

model Model y. W5, W8, and

uator

reserved.

m

e d

additionacustomepurchasebolt circlewith moscoveragewith less

F

serts

Double DD E

0.5 0.

– –

– –

– –

– –

– –

al flexibility aimr more actuatoe. The EPI2 hases and dual shst units. This feae of more valve actuator mode

D Standard Shaf

KeyE F

75 –

– 1.125

– 1.125

– 1.125

– 1.875

– 1.875

KEYMC-02755

ed at allowing tor with every s dual mountingaft acceptanceature allows

e sizes and typeels.

ft Inserts yed

Dep

Key Size

– 1.31/4 x 1/4 2.11/4 x 1/4 2.11/4 x 1/4 2.11/2 x 3/8 4.21/2 x 3/8 4.2

55

the

g e

es

pth

37

12

12

12

25

25

Keystone EPI2 Electric Actuator Models E006 to E171

Copyright © 2007 Tyco Flow Control. All rights reserved. KEYMC-02756

Dimensions (inches)

Models E006, E013, E025, E051, E091

R

W

With optional local interface module OM3

Model

A

A1

B

C

D

D1

E

F

G

H

J

K

L

M

N

P

R1

W2

Weight3

(lbs)

E006 9.4 11.3 10.7 8.3 4.5 6.3 3.3 4.7 2.7 3.1 2.5 1.3 1.4 2.6 2.7 4.9 6.9 1" NPT 19.8

E013 9.4 11.3 10.7 9.0 4.5 6.3 3.3 4.7 2.7 3.1 2.5 1.3 2.1 3.4 3.4 4.9 6.9 1" NPT 20.9

E025 11.6 13.4 13.1 11.3 5.1 6.9 4.3 6.1 2.7 3.7 3.0 1.3 2.5 3.7 3.6 7.1 9.1 1" NPT 34.2

E051 11.6 13.4 13.1 11.3 5.1 6.9 4.3 6.1 2.7 3.7 3.0 1.3 2.5 3.7 3.6 7.1 9.1 1" NPT 37.5 E091 13.4 15.3 13.7 14.3 5.5 7.3 4.3 6.8 2.7 4.1 3.2 1.3 5.5 6.8 6.5 9.5 9.1 1" NPT 57.0

1. Space required for cover removal

2. 4 total conduit connections

3. Add 1.1 lbs. for Option Module OM3 Local Interface

Notes

A1

D1

J

A

H D

B

G F E

P

WK

CW

N M

LH

Keystone EPI2 Electric ActuatorModels E006 to E171

Copyright © 2007 Tyco Flow Control. All rights reserved. KEYMC-02757

Dimensions (inches)

Model E171

With optional local interface module OM3

Weight3

Model A A1 B C D D1 E F G H J K L M N P R1 W2 (lbs)

E171 13.4 15.3 19.9 18.3 5.5 7.3 10.5 6.8 2.7 4.1 3.2 1.3 9.5 10.7 10.4 9.5 9.1 1" NPT 99.2

1. Space required for cover removal

2. 4 total conduit connections

3. Add 1.1 lbs. for Option Module OM3 Local Interface

Notes

A1

D1

B

A J

H D

R

W

N L M C

H

G F E

W

P

W

K K

Keystone EPI2 Electric Actuator Models E006 to E171

Copyright © 2007 Tyco Flow Control. All rights reserved. KEYMC-02758

Torque output at selected setting (lb. in.)

Operating Time at selected setting (sec’s/90)

Performance

Adjustable torque and stroke time offers flexibility in performance and valve protection unsurpassed in the small electric quarter-turn market.

Model 100% 40%

E006 600 560 520 480 440 400 360 320 280 240

E013 1300 1214 1127 1040 954 867 780 693 607 520

E025 2500 2334 2167 2001 1834 1667 1500 1334 1167 1000

E051 5100 4761 4421 4081 3741 3401 3061 2720 2380 2040

E091 9100 8496 7889 7282 6675 6068 5461 4854 4247 3640

E171 17700 16525 15344 14164 12983 11802 10622 9441 8261 7080

Position 9 8 7 6 5 4 3 2 1 0

Output torque is independently adjustable from 40% to 100% in both directions of travel. Adjustments are in increments of 1 from 0 to 9. The default setting is 100%, position 9 on the rotary selector used for configuration.

Model 100% 10%

E006 12 15 18 26 38 48 60 75 85 110

E013 12 15 18 26 38 48 60 75 85 110

E025 12 15 18 26 38 48 60 75 85 110

E051 12 15 18 26 38 48 60 75 85 110

E091 20 24 30 45 60 80 100 120 140 180

E171 44 53 66 100 132 180 220 264 310 400

Position 9 8 7 6 5 4 3 2 1 0

Output speed is adjustable from 10% to 100% in both directions of travel. Adjustments are in increments of 1 from 0 to 9. The default settings are: 18 seconds for the E006, E013, E025 & E051 - 30 seconds for the E091 - and 66 seconds for the E171. The tolerance is +/- 10% of nominal.

Keystone EPI2 Electric ActuatorModels E006 to E171

Copyright © 2007 Tyco Flow Control. All rights reserved. KEYMC-02759

Current Draw

A 7.00 6.50 6.00 5.50 5.00 4.50 4.00 3.75 3.50 3.25 3.00 2.75 2.50 2.25 2.00 1.80 1.60 1.50 1.40 1.30 1.20 1.10 1.00 0.90 0.80 0.70 0.60 0.50 0.40 0.30 0.20 0.10 0.05

Model E006

24 VDC 24 VAC

48 VAC

48 VDC

120 VAC

240 VAC 120 VDC

240 VDC

time (sec/90)

A 7.00 6.50 6.00 5.50 5.00 4.50 4.00 3.75 3.50 3.25 3.00 2.75 2.50 2.25 2.00 1.80 1.60 1.50 1.40 1.30 1.20 1.10 1.00 0.90 0.80 0.70 0.60 0.50 0.40 0.30 0.20 0.10 0.05

Model E013

24 VDC 24 VAC

48 VAC

48 VDC

120 VAC

240 VAC 120 VDC

240 VDC

time (sec/90)

8 12 15 22 30 40 50 60 75 90

8 12 15 22 30 40 50 60 75 90

A

16.00 15.00 14.00 13.00 12.00 11.00 10.00

9.00 8.00 7.00 6.00 5.00 4.50 4.00 3.75 3.50 3.25 3.00 2.75 2.50 2.25 2.00 1.75 1.50 1.25 1.00 0.90 0.80 0.70 0.60 0.50 0.40 0.30 0.20 0.10

Model E025

24 VDC

24 VAC

48 VDC

48 VAC

120 VDC 120 VAC 240 VAC 240 VDC

time (sec/90)

A

19.0 18.5 18.0 17.5 17.0 16.5 16.0 15.5 15.0 14.5 14.0 13.5 13.0 12.5 12.0 11.5 11.0 10.5 10.0

9.5 9.0 8.5 8.0 7.5 7.0 6.5 6.0 5.5 5.0 4.5 4.0 3.5 3.0 2.5 2.0 1.5 1.0

0.75 0.50

Model E051 - E091 - E171

24 VDC 24 VAC

48 VDC 48 VAC 120 VAC 120 VDC 240 VAC 240 VDC time (sec/90)

8 12 15 22 30 40 50 60 75 90

8 12 15 22 30 40 50 60 75 90

Model E051

15 24 30 45 60 90 100 120 150 190

Model E091

33 53 66 100 132 180 220 264 330 400 Model E171

1. A = current draw (Amp) at nominal conditions (output torque 100%)

2. Max current (Amp) at stall conditions - 1.2 x A

3. Current diagrams for VDC supply Current diagrams for VAC/1-phase supply

4. Power factor for VAC supply - 0.60

Notes

Keystone EPI2 Electric Actuator Models E006 to E171

Copyright © 2007 Tyco Flow Control. All rights reserved. KEYMC-027510

Connector L

Connector A

M

L1 L2 L3

Connecto r D

DC

DC

Connector B Connector C

35 36 32 33 34 20 21 22 23 24 25 26 27

Connector M

35

36

32

OP

CL35

36

32

OP

CL

Wiring Diagram

General Arrangement with Base Card

Position Sensor

CLC1 CLC2 OPC1 OPC2 Power and Processor Card

Connector E Connector F

+ – 28 29 30 31 10 11

Notes:

(Note 1) Remote commands (Note 2)

Output contacts (Note 3)

24VOC OV Optional external supply 24VDC

1) Connection L1-L2 for VDC or VAC single phase motor supply from 24 to 240 volt Connection L1-L2-L3 for 3-phase motor supply from 208 to 575V

2) Remote commands options

34 + OP

35 CL

36 –

32 Internal supply 24VDC External supply 24/120VAC External supply 24/120VDC

33

3) Contacts shown in intermediate position CLC1-CLC2 end of travel signalling in CLOSING Contacts shown in intermediate position OPC1-OPC2 end of travel signalling in OPENING

Gro

und

Local Interface (Optional Module 3)

Keystone EPI2 Electric ActuatorModels E006 to E171

Copyright © 2007 Tyco Flow Control. All rights reserved. KEYMC-027511

Model Number Detail

E 006 A 0 W5 00 0

Model (1 digit)

E – EPI2 Quarter-turn Electric

Size (3 digits)

006 – 600 lb. in. 013 – 1,300 lb. in. 025 – 2,500 lb. in. 051 – 5,100 lb. in. 091 – 9,100 lb. in. 171 – 17,700 lb. in.

Local Indicator (1 digit)

A – Standard Window

Voltage ratings (1 digit)

0 – 24 to 240 VDC and 24 to 240 VAC 1-ph 50/60 Hz

1 – 208 to 240 VAC 3-ph 50/60 Hz 2 – 380 to 480 VAC 3-ph 50/60 Hz 3 – 500 to 575 VAC 3-ph 50/60 Hz

Classification & Temperature Rating (2 digit)

W1 – NEMA 4/4X/6 (IP66/68M) Ambient Temp: -13°F to 158°F [-25°C to 70°C] (Motor Pinion Reduction Gear - Reinforced Acetal Resin)

W2 – NEMA 4/4X/6 (IP66/68M) Ambient Temp: -40°F to 158°F [-40°C to 70°C] (Motor Pinion Reduction Gear - Reinforced Acetal Resin)

W5 – CSA 139 (C-US) NEMA 4/4X/6 (IP66/68M) AWWA Ambient Temp: -40°F to 140°F [-40°C to 60°C] (Motor Pinion Reduction Gear - Steel)

X1 – FM/CSA per NEC 505 (Class 1, Zone 1 & 2) NEC 500 (Class 1, Div. 2) NEMA 4/4X/6 (IP66/68M) Ambient Temp: -13°F to 149°F [-25°C to 65°C] (Motor Pinion Reduction Gear - Reinforced Acetal Resin)

X2 – FM/CSA per NEC 505 (Class 1, Zone 1 & 2) NEC 500 (Class 1, Div. 2) NEMA 4/4X/6 (IP66/68M) Ambient Temp: -40°F to 149°F [-40°C to 65°C] (Motor Pinion Reduction Gear - Reinforced Acetal Resin)

X5 – FM/CSA per NEC 505 (Class 1, Zone 1 & 2) NEC 500 (Class 1, Div. 2) NEMA 4/4X/6 (IP66/68M) Ambient Temp: -40°F to 149°F [-40°C to 65°C] (Motor Pinion Reduction Gear - Steel)

Special Option Code (1 digit)

0 – Standard

Option Modules (2 digits)

00 – NONE Standard On-Off Configuration P1 – Servo Amp w/Retransmission (OM1) P2 – Lithium Battery (OM2) P3 – Local Interface (OM3) P4 – Bluetooth® Interface (OM4) P5 – Servo Amp w/Retransmission,

Lithium Battery (OM1 + OM2) P6 – Servo Amp w/Retransmission, Local Interface (OM1+ OM3) P7 – Servo Amp w/Retransmission,

Bluetooth® Communication (OM1-B) P8 – Servo Amp w/Retransmission,Lithium Battery,

Local Interface (OM1 + OM2 + OM3) P9 – Servo Amp w/Retransmission, Lithium Battery,

Bluetooth® communication (OM1-B + OM2) PA – Servo Amp w/Retransmission, Local Interface,

Bluetooth® communication (OM1-B + OM3) PC – Servo Amp w/Retransmission,

Lithium Battery, Local Interface, Bluetooth® communication (OM1-B + OM2 + OM3)

PD – Local Interface, Bluetooth® communication (OM3 + OM4) PF – Local Interface, Lithium Battery,

Bluetooth® communication (OM2 + OM3 + OM4) PJ – Local Interface,Lithium Battery (OM2 + OM3) 3A – ASi 2.1 bus communication (OM8) 4A – ASi 2.1 bus communication, Local Interface (OM8 + OM3) 5A – ASi 2.1 bus communication,

Bluetooth® communication (OM8-B) 6A – ASi 2.1 bus communication, Local Interface,

Bluetooth® communication (OM8-B + OM3) 3D – DeviceNet™ bus communication 4D – DeviceNet™ bus communication,

Local Interface (OM11 + OM3) 5D – DeviceNet™ bus communication,

Bluetooth® communication (OM11-B) 6D – DeviceNet™ bus communication, Local Interface,

Bluetooth® Communication (OM11-B + OM3) 3P – PDP V0/V1 bus communication (OM9) 4P – PDP V0/V1 bus communication,

Local Interface (OM9 + OM3) 5P – PDP V0/V1 bus communication,

Bluetooth® communication (OM9-B) 6P – PDP V0/V1 bus communication, Local Interface

Bluetooth® communication (OM9-B + OM3) 3F – Foundation Fieldbus communication (OM10) 4F – Foundation Fieldbus communication,

Local Interface (OM10 + OM3) 5F – Foundation Fieldbus communication,

Bluetooth® communication (OM10-B) 6F – Foundation Fieldbus communication, Local Interface

Bluetooth® Communication (OM10-B + OM3) PG – 3-wire Interface Card (OM13) PH – 3-wire Interface Card, Lithium Battery (OM13 + OM2)

KeysModel

Copyrig

Also a

KeystoRack anTorques

KeystoRack anTorques

Tyco Flow CoIndividuals usNO REPRESRESPECT TONATURE, INCforeign count

stone EPI2 ls E006 to E17

ht © 2007 Tyco Flo

available for

one 79U Pneund Pinion actuas to 18,100 lb. in

one MRP Pnend Pinion actuas to 18,100 lb. in

ontrol (TFC) provides thesing this data sheet mus

SENTATIONS OR WARRO THE INFORMATION SCLUDING INCIDENTALries. Tyco reserves the r

Electric A71

ow Control. All rig

r Keystone

umatic Actuaator available bn.

eumatic Actuator available bn.

e information herein in gst exercise their indepenRANTIES, EITHER EXPSET FORTH HEREIN O, INDIRECT, OR CONSright to change product

Actuator

ghts reserved.

Direct Mou

ators oth double acti

uators oth double acti

good faith but makes no ndent judgment in evaluaRESS OR IMPLIED, IN

OR THE PRODUCT(S) TEQUENTIAL DAMAGESdesigns and specificatio

unting ...

ing and spring

ing and spring

www.tycoflo

representation as to itsating product selection aCLUDING WITHOUT LI

TO WHICH THE INFORMS) RESULTING FROM Tons without notice.

KEYMC

return.

return.

owcontrol.com

comprehensiveness orand determining producIMITATION ANY WARRAMATION REFERS. ACCOTHE USE OF OR RELIA

C-027512

accuracy. This data shect appropriateness for theANTIES OF MERCHANORDINGLY, TFC WILL N

ANCE UPON THIS INFO

eet is intended only as aeir particular purpose anTABILITY OR FITNESSNOT BE RESPONSIBLE

ORMATION. Patents and

a guide to TFC productsnd system requirements

S FOR A PARTICULAR E FOR DAMAGES (OFd Patents Pending in the

and services. s. TFC MAKES PURPOSE WITH ANY KIND OR

e U.S. and

ATTACHMENT D: CONDENSER WATER PIPING SCHEMATIC

SECTION 5

SEE SEPARATE PDF ATTACHMENT

ATTACHMENT E: ELECTRICAL SINGLE LINE DIAGRAM

SECTION 6

SEE SEPARATE PDF ATTACHMENT

ATTACHMENT F: PROPOSED COOLING TOWER LOCATION

SECTION 7

feetmeters

300100