More with Less An Introduction to Revolution Fibres.

-

Upload

brendan-fowler -

Category

Documents

-

view

217 -

download

2

Transcript of More with Less An Introduction to Revolution Fibres.

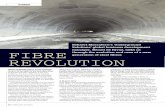

• Based in West Auckland, NZ • Nanofibre Production:

– Design

superior nanofibre products– Manufacture specialised runs

to industrial scale– Deliver revolutionary products

to multiple markets

Design…… functional nanofibre

Develop……. Superior products

Manufacture……. Specialised to Industrial scale

Commercialise……. innovation

Extraordinary Nanofibres

Van der Waals forcesAttractive forces at the molecular level

Non-woven Fibres are created to form a non-woven web of nanofibres

Continuous fibreSmall in diameter, long in length

Negligible weight & ThicknessCompared to traditional materials, nanofibres weigh virtually nothing.

Porous structureA Nanofibre web consists mostly of air

Platform TechnologyA platform to launch new functionality in materials

Electrospinning: The Enabling Technology

Properties: High Surface area Strength Carrier Stability Natural

Materials: Synthetic polymers:

• PVA, PA6, Biopolymers

• Collagen Additives

• Plant extracts• Drug compounds

Applications

Electrospinning

The Missing Link?

Technology Amazing innovation, Lab scale Low/no scale up

available Not concerned with

markets and customers

Industry Market focused Looking for competitive

advantage Only wants tangible

“here and now” Not keen on long R&D

commitments

???

The Delivery: Industrial Scale Production

ES1-A 0.1 grams/hour

Pilot: The Chameleon 100 grams/hour Control and adjust 20+

variables 1000mm wide capable

Sonic Electrospinning Technology

Sonic Electrospinning Technology

2009

2012

2011

Production: The Komodo 800 grams/hour Fully enclosed 2000mm wide capable Variable substrates and multiple layers Additional ES units to increase

production

Winner of NZ Engineering Excellence Award 2012

The next generation of skin care

Skin performance and skin repair dressings

Collagen fibre carrying specifically formulated plant extracts known for skin rejuvenation and cell growth

• High efficiency filtration• Unique, biodegradable air filters• Manuka-infused antibacterial fibres• In 120,000 New Zealand homes

Nanofibre Air Filters

Opportunities in Biotech From “Advanced Healthcare Materials 2012”:

“Electrospinning is a remarkably simple, robust, and versatile technique capable of generating fibers with diameters down to the nanoscale.

A non-woven mat of electrospun nanofibres possesses high porosity and spatial interconnectivity well-suited for nutrient and waste transport and cell communication.

A scaffold based on electrospun nanofibers also has a large specific surface area for loading of bioactive molecules to facilitate efficient and selective cellular responses.

Electrospinning has been applied to more than 100 different types of polymers.

Naturally occurring matrix proteins including collagen, elastin, and fibrinogen and synthetic polymers such as poly( ε - caprolactone) (PCL) and poly(lactic- co -glycolic) acid (PLGA) can all be prepared as nanofibers by electrospinning.”

Unique Opportunities for NZ in Biotech• Multitude of uses for nanofibre in biotech – many well researched

and in need of commercialization• Nanofibres very similar to structures in the body – from skin to

cellular scaffolds• Revolution Fibres: One of few nanofibre producers with industrial

scale manufacturing capabilities and product development services• A good country to innovate and trial unique treatments• Good supporting research infrastructure – IIB, Auckland Uni, etc.• A unique opportunity for NZ to embrace and champion a platform

technology in the biotech space – generate new IP and new healthcare products.

• Required: innovators, sector leaders, manufacturing partner, routes to market

Current technology platforms in NZ

• A family of polyaniline related polymers

• Thermally stable

• Supports growth of mammalian cells

• Anti-microbial, anti-oxidant, anti-static, barrier

properties, etc.• Conductive – capable of picking up and

transferring signals across the fabric• Useful for wound dressings, tissue / bone

scaffolds

Current technology platforms in NZ

• Chitosan – sourced from squid pen• Naturally antibacterial – proven to work against

dermatological infections• Proof of concept work with Otago University

• Collagen – sourced from hoki• Readily absorbable in water and on skin• Excellent carrier of active ingredients (drug

compounds, bioactives, etc)

Areas of interest?

• Tissue regeneration: Skin repair, tendon-bone connection, bone/tendon/ligament repair, skin substitutes

• Encapsulation of drugs, antioxidants and enzymes: Known benefits of extending shelf-life, targeted release

• Controlled release: Topical skin applications, alternatives to pills ointments and injections (repeated doses)

• Oral / epidermal fast-dissolving delivery systems

• Biodegradable carrier systems for plant / human / animal protection products: Continual release, slow-release, encapsulation, weather resistant

9a Corban Ave, Henderson, Auckland, New [email protected] 835 4805www.revolutionfibres.com

Address:

EmailPhone:Website: