Monthly-Annual Inspection Repair Checklist

-

Upload

tess-michaels -

Category

Documents

-

view

87 -

download

1

description

Transcript of Monthly-Annual Inspection Repair Checklist

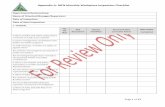

Appendix A – Monthly/Annual Playspace Health, Safety & Maintenance Inspection Checklist

Instructions: The entire playspace should be checked by a staff member (or suitably qualified individual who has an understanding of the playspace and maintenance required) and their observations recorded on the attached report form.

Have all previously reported problems been rectified? (Yes/No) If NO what maintenance/repairs need to be carried out and when are they to occur?

................................................................................................................................................................

................................................................................................................................................................

................................................................................................................................................................

................................................................................................................................................................

Have accident /incidents records been reviewed to identify problems? (Yes/No) What maintenance/repairs need to be carried out and when are they to occur?

................................................................................................................................................................

................................................................................................................................................................

................................................................................................................................................................

................................................................................................................................................................

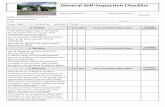

General Assessment of playspace

Is the site clean and secure? (Yes/No)

Is the playspace clear of litter and dangerous objects? (Yes/No)

Is access to the site in good condition and clear of obstruction? (Yes/No)

Occupational Health and Safety and Personal Protection Equipment (PPE)

If gardening and or maintenance is to be performed by staff and children do you have the appropriate tools (including children’s tools, gloves, and masks)? (Yes/No)

Have staff/children been instructed in the correct and safe use of tools materials? (Yes/No)

Is the turf cleaned of rubbish and debris regularly? (Yes/No) Turf

Has the turf established itself? (Yes/No)

Has the turf been watered regularly? (Yes/No)

Is there adequate drainage (e.g. no pooling of water in heavy rain)? (Yes/No)

Has the surface beneath the turf become compressed and require decompaction? (Yes/No)

Has the turf developed bald spots, does it require patching, fertilising or top dressing? (Yes/No)

P a g e | 2 Is the grass well maintained does it need mowing? (Yes/No)

Are weeds removed or is the turf sprayed before weeds can establish themselves? (Yes/No)

Does the turf show any sign of pests that may require the use of a pesticide spray? (Yes/No)

Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

Artificial turf

Is the surface cleaned of rubbish and debris regularly? (Yes/No)

Is the surface secure, free from rips, tears or split seams? (Yes/No)

Has the sub base beneath the surface “settled” requiring infilling? (Yes/No)

Is the surface turf stained with any contaminants that require cleaning or patching? (Yes/No)

Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

Plants Are any of the plants or trees showing signs of disease, distress or failure to thrive? (Yes/No)

Do any of the plants or trees require spraying with pesticides/fungicides? (Yes/No)

Are any of the plants or trees dead, requiring removal/replacement? (Yes/No)

Do any of the plants or trees require mulching/weeding? (Yes/No)

Do any of the trees that are staked require adjustments to the stakes or bindings? (Yes/No)

Are all the plants trees receiving adequate water/fertiliser? (Yes/No)

Are the trees free from potential falling deadwood, pointed or broken branches? (Yes/No)

Are all trellis’ and garden string lines secure? (Yes/No)

Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

P a g e | 3 Timber Are all timber playspace components free from damage from sunlight, moisture and insect infestation? (Yes/No)

Are all nails and screws in timber playspace components flush with the surface or countersunk? (Yes/No)

Are all bolts in timber playspace components in place and secure? (Yes/No)

Are all joints and connections in timber playspace components firm (not loose)? (Yes/No)

Are chains and ropes in timber playspace components secure and in good condition? (Yes/No)

Are all components in timber playspace components in place, (none missing)? (Yes/No)

Are all timber playspace components free of cracks and splinters? (Yes/No)

Are all timber playspace components free of warping or twisting? (Yes/No)

Are the access ramps and entrances for timber playspace components free of slipping and tripping hazards? (Yes/No)

Are all rails around decks above 500mm secure? (Yes/No)

Are all rails coming down from egress points of all decks above 750mm secure? (Yes/No)

Are the vertical fences around all decks and landings above 1200mm secure? (Yes/No)

Is all timber garden edging secure and not posing a tripping hazard? (Yes/No)

Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

Blackboards/Chalkboards

Are all timber components of the blackboard/chalkboard free from damage from sunlight or moisture? (Yes/No)

Are all nails and screws in the blackboard/chalkboard timber playspace flush with the surface or countersunk? (Yes/No)

Are all bolts in the blackboard/chalkboard surround in place and secure? (Yes/No)

Are all timber components of the blackboard/chalkboard free of cracks and splinters? (Yes/No)

Are all timber components of the blackboard/chalkboard free of warping or twisting? (Yes/No)

Does the blackboard/chalkboard surface require repainting? (Yes/No)

Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

P a g e | 4 Surfaces

Are all structures above 500mm in height surrounded with an approved soft fall surface extending 1.9 metres in circumference? (Yes/No)

Have any hard surfaces/items (e.g. concrete, pavers, gravel) been moved within this zone since it was constructed? (Yes/No)

Are loose fill areas regularly inspected for debris and hazards (e.g. rocks, toys, glass bottles and syringes), raked to ensure decompaction, topped up or refilled when required? (Yes/No)

Is the loose fill surface material checked weekly to ensure a depth of at least 300mm? (Yes/No)

Is there adequate drainage (e.g. no pooling or water/shifting of surfaces in heavy rain)? (Yes/No)

Is their weekly checking to ensure that loose fill surface material that may shift under platforms and other structures is removed and spread to main areas of impact? (Yes/No)

Are unitary surfaces (wet pour/artificial grass) clean and intact, free from subsidence or damage to its composition/joints that may require patching or repair? (Yes/No)

Are all edging materials for wet pour/artificial grass free of splinters, exposed nails and bolts? (Yes/No)

Are all concrete areas free of cracking, crumbling composition/edges, water pooling, loose expansion joints, exposed reinforcing? (Yes/No)

If the concrete has been treated with an acrylic surfacing is there any evidence of degradation or uneven wear? (Yes/No)

Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

Permeable paving

Maintenance completed by.................................................................. Completed Date: / /

Has the surface been the subject of vehicular traffic that has caused damage to the surface? (Yes/No)

Are all paved surfaces in good order, no shifted, tilted or sunken pavers/cobblestones that may present a tripping hazard, no broken or degraded edging that may lead to further shifting? Is there adequate drainage (e.g. no pooling of water in heavy rain)? (Yes/No)

Are paved/cobbled areas and flagging raked to remove leaves and vegetation that may pose a slipping hazard Have any weeds (including roots) growing in paved/cobbled areas been removed or sprayed? (Yes/No)

Is there any movement or rocking in paved/cobbled areas or sandstone flagging? (Yes/No)

Have any depressions formed in the decomposed granite that may pose hazards to pedestrians or equipment? (Yes/No)

Items requiring maintenance:

1..............................................................................................................................................................

P a g e | 5 Sandpit Has the sandpit been fitted with a strong permeable UV resistant cover that can be secured on a daily basis against removal by wind or entry by animals? (Yes/No)

Is there adequate drainage in the sandpit (e.g. no pooling of water in heavy rain)? (Yes/No)

Is the sand raked on a daily/weekly basis to remove foreign matter that may cause injury or illness? (Yes/No)

Is the sandpit regularly checked and appropriately treated for animal fouling? (Yes/No)

Has the sandpit been turned over monthly to aerate it? (Yes/No)

Has the depth of the sand been maintained to a minimum of 500mm? (Yes/No)

Is the sand replaced or replenished when necessary? (Yes/No)

Is the boundary of the pit free of splinters, nails or loose border material? (Yes/No)

Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

Digging patch

Is there adequate drainage in the digging patch (e.g. no pooling of water in heavy rain)? (Yes/No) Is the soil/sand raked on a daily/weekly basis to remove foreign matter that may cause injury or illness? (Yes/No) Has the digging patch been turned over monthly to aerate it? (Yes/No) Has the depth of the soil/sand been maintained to a minimum of 500mm? (Yes/No) Is the soil/sand replaced or replenished when necessary? (Yes/No) Are the boulders in the boundary of the pit secure in their bedding material free from any movement or rocking? (Yes/No) Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

Shade sails

Are all posts, connectors, eyelets and tensioning attachment/points secure and in good order? (Yes/No) Is the canopy securely connected and are all cables taunt? Are there any signs of tearing at the seams or connection points? Is the canopy free of any vegetation, algae or moss build-up? (Yes/No) Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

P a g e | 6 Screening /fencing Does screening display any damage from sunlight, moisture and insect infestation? (Yes/No) Have all cracks or splits to screening material been filled and sanded? (Yes/No) Does the screen require rejuvenation with oil or lacquer? (Yes/No) Are the post and railing sections secure and free from corrosion? (Yes/No) Have any damaged sections of fencing been removed (and replaced with a new section)? (Yes/No) Does the new section comply with the current regulations and local council ordinance? (Yes/No) Are the gate hinges, latching and self closing mechanisms functional and in good order? (Yes/No) Is the Perspex shielding around the latch cracked or broken? (Yes/No) Is there vegetation, branches, or play equipment placed or stored against fences/gates that could be used by a child to climb over the fence ? (Yes/No) Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

Stones/Rocks/Boulders Are stones/rocks/boulders secure in their bedding material free from any movement or rocking? (Yes/No) Are stones/rocks/boulders free from fractures splits or sharp edges? (Yes/No) Are stones/rocks/boulders regularly cleaned to remove leaves and vegetation that may pose a slipping hazard? (Yes/No) Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

Stepping stones Are stepping stones secure in their bedding material free from any movement, rocking or subsidence? Are stepping stones free from fractures splits or sharp edges? (Yes/No) Are they regularly cleaned to removed leaves and vegetation that may pose a slipping hazard? (Yes/No) Is there adequate drainage around the stepping stones to avoid liquefaction of the bedding layer? (Yes/No) Is there weekly checking to ensure that loose fill surface material around the stepping stones has not shifted creating tripping hazards? (Yes/No) Items requiring maintenance: 1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

P a g e | 7 Concrete sleepers Are the concrete sleepers secure in their bedding materials, free from any movement or rocking? (Yes/No) Are the concrete sleepers free from fractures splits or sharp edges? (Yes/No) Is there adequate drainage (e.g. no pooling of water) above retaining walls or in raised garden beds? (Yes/No) Are all fasteners in place and secure? (Yes/No) Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

Teepees Do the bamboo/timber supports display any signs of damage from sunlight, moisture and insect infestation? (Yes/No) Have any cracks or splits to the bamboo/timber supports been filled and sanded? (Yes/No) Do the bamboo/timber supports require rejuvenation with oil or lacquer? (Yes/No) Are all the bamboo/timber supports secure in their foundations? (Yes/No) Is the apex secure or in need of rebinding to cover the metal flanges? (Yes/No) Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

Slides Are all slide components free from damage from sunlight, moisture and insect infestation? (Yes/No) Are all nails, screws and bolts in the slides frame/platform/surface secure and/or flush with the surface or countersunk? (Yes/No) Are all joints and connections in all slide components firm (not loose)? (Yes/No) Are all slide components free of perishing, cracks or splinters and warping or twisting? (Yes/No) Are the joints and fastenings on parts such that there are no “catch” points? (Yes/No) Are all access ramps, steps or entrances to the slide in good order and free of slipping and tripping hazards? Is the sliding surface clear of obstructions? (Yes/No) Is the gel-coat surface of any fibreglass slides intact and free from glass fibre protrusions? (Yes/No) Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

P a g e | 8 Swings Is there a certified fall zone extending 1.9 metres from the furtherest extension point of the swing (Yes/No) Is the material within the fall zone regularly inspected for debris and hazards? (e.g. rocks, toys, glass bottles and syringes), Is it raked to ensure decompaction, topped up or refilled when required? (Yes/No) If the material within the fall zone is a loose fill surface material (e.g. certified soft fall mulch), is it checked weekly to ensure a depth of at least 300mm? (Yes/No) Is the certified soft fall mulch checked weekly to ensure that any that may have shifted is raked back to the main areas of impact? (Yes/No) If the material within the fall zone is a unitary surface (wet pour/artificial grass) is it clean and intact, free from subsidence or damage to its composition/joints that may require patching or repair? (Yes/No) Is there adequate drainage (e.g. no pooling or water/shifting of surfaces in heavy rain)? (Yes/No) Are all edging materials surrounding the fall zone free of splinters, exposed nails and bolts? (Yes/No) Are all chain/ropes swing components secure and in good condition? (Yes/No) Are all bolts and fasteners holding chains/ropes secure? Are locknuts in place? (Yes/No) Have the covers or guards over all points that can pinch, crush or entrap been maintained? (Yes/No) Is the swing seat free of perishing, cracks or splinters? (Yes/No) Are all footings of the framework of the swing secure and free of movement when the equipment is in use? (Yes/No) Are all footings of the framework holding of the swing in place covered? (Yes/No) If the swing framework is metal are the components free from damage from sunlight, moisture and (e.g. rusting supports, chains, pivot points)? (Yes/No) If the swing framework is timber are the components free from damage from sunlight, moisture and insect infestation (e.g. warping/twisting)? (Yes/No) Are all nails, screws and bolts in timber swing framework flush with the surface or countersunk? (Yes/No) Are all bolts in the timber swing framework in place and secure? (Yes/No) Are all joints and connections in the timber swing framework firm (not loose)? (Yes/No) Have all the timber swing framework components been treated/painted when necessary to prevent rotting or splintering? (Yes/No) Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

P a g e | 9 Scramble Nets and Rope climbers

Is the framework of the scramble net/rope climber free of damage from sunlight, moisture and insect infestation? (Yes/No) Has all the timber work in the framework of the scramble net/rope climber been treated/painted when necessary to prevent rotting or splintering? (Yes/No) Is all the timber work in the framework of the scramble net/rope climber free of cracks and splinters? (Yes/No) Are all footings of the framework of the scramble net/rope climber secure and free of movement when the equipment is in use? (Yes/No) Are all footings of the framework holding the scramble net/rope climber in place not visible? (Yes/No) Are all joints and connections in the framework of the scramble net/rope climber firm? (Yes/No) Is the framework of the scramble net/rope climber free of warping or twisting? (Yes/No) Are all nails and screws in the framework of the scramble net/rope climber flush with the surface or countersunk? (Yes/No) Are all bolts in the framework of the scramble net/rope climber in place and secure? (Yes/No) Are chains/ropes in the framework of the scramble net/rope climber secure and in good condition? (Yes/No) Are all ropes secure and have all frayed ends been trimmed and repaired? (Yes/No) Have ropes and chains been re-tensioned and securely fastened? (Yes/No) Have the covers or guards over all points that can pinch, crush or entrap been maintained? (Yes/No) Are all bolts and fasteners secure? Are locknuts in place? (Yes/No) Are the access ramps, landings ladders and swing bridges in the framework of the scramble net/rope climber free of slipping and tripping hazards? (Yes/No) Are all rails around decks above 500mm secure? (Yes/No) Are all rails coming down from egress points of all decks above 750mm secure? (Yes/No) Are the vertical fences around all decks, landings and bridges above 1200mm secure? (Yes/No) Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

P a g e | 10 Garden arbours/arches Do the footings of the arbour appear to be secure and stable? (Yes/No) Are all foundation fastening devices secure (Yes/No) Are all arbour components secure? Are there any screws, bolts or nails visible that may pose “catching “ hazards? (Yes/No) Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

Water features & pumps Are the children supervised whilst using the pump? (Yes/No) Are all the screws and connecting bolts on the pump tight? (Yes/No) Are the bearings and steel on steel contact points lubricated? (Yes/No) Are there any broken or worn parts that require re-fastening or replacing? (Yes/No) Are there any unusual noises coming from the pump during use? (Yes/No) Is the pump-stand secure and have any fastenings become loose? (Yes/No) Does the pump display any signs of rust or corrosion? (Yes/No) Is the water/channel/bowl /rill cleaned of vegetation, leaves algae regularly? (Yes/No) Items requiring maintenance: 1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

Rainwater tanks Are all house and shed roofs in the rain catchment area free of asbestos, lead-based paints, chemically treated timbers, lead flashing and bitumen- based materials? (Yes/No) Do any overflow or discharge pipes from roof mounted appliances such as evaporative air conditioners or hot water systems discharge into the roof catchment area or gutters? (Yes/No) If your tank is fitted with a first-flush device is it functional and has it been cleaned? (Yes/No) Is the roof catchment area and guttering regularly inspected and cleared of leaves and debris? (Yes/No) Are there tree branches overhanging the catchment area that need to be removed? (Yes/No) If screens/guards are in use are they cleaned regularly? (Yes/No) Is the tank structurally secure? Is the lid firmly closed? Are there any holes or gaps? (Yes/No) Is piping firmly fastened and draining correctly? (Yes/No) Is there any water “Ponding” in gutters that may lead to mosquito breeding? (Yes/No)

P a g e | 11 Has your tank been examined for sludge accumulation and algal growth in the last 2-3 years? (Yes/No) If it exists, is your tank pump in working order? Have filters/strainers been cleaned? Is all piping watertight? (Yes/No) If your tank has a back-flow prevention device has it been checked and certified by a qualified plumber? (Yes/No) Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

Creek beds Is the creek bed draining freely (e.g. no pooling of water in heavy rain)? (Yes/No) Is the creek bed regularly cleaned to removed leaves and vegetation that may block any stormwater drain? (Yes/No) Are there areas where water has “ponded”, where mosquito breeding may occur? (Yes/No) Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

Seats

Are the seats inspected regularly to ascertain structural stability? (Yes/No) If made from timber does the seat show any damage from sunlight, moisture and insect infestation? (Yes/No) If made from timber has the seat been treated/painted when necessary to prevent rotting or splintering? (Yes/No) If made from timber is the seat been free of cracks and splinters? (Yes/No) Are all footings of the seat secure and free of movement? (Yes/No) If made from timber is the seat free of warping or twisting? (Yes/No) Are all nails and screws in the seat flush with the surface or countersunk? (Yes/No) Are all bolts in the framework of the seat in place and secure? (Yes/No) Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

P a g e | 12 Edible gardens Have the foundations of the bed have not shifted? (Yes/No) Are all the sleepers free from damage from moisture or insect infestation? (Yes/No) Have any of the sleepers cracked or warped? (Yes/No) Are all nails, bolts or screws flush with the surface of the timber or countersunk? (Yes/No) Does the pre moulded corrugated steel show any signs or rust? (Yes/No) Are all fasteners tight and have faulty or broken components been replaced? (Yes/No) Is the plastic seal that covers the upper steel edge secure and in good condition? (Yes/No) Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

Garden and edible garden mulch covering Is the mulch at 75 mm depth in all garden areas and at a depth of 300mm around play structures? Has it been topped up if required in Autumn and Spring? (Yes/No) If wind or water has moved mulch out of garden beds have drainage solutions been implemented or heavier mulch used as a replacement? (Yes/No) Is mulch regularly raked to avoid compaction? Is the garden edging secure and functional? (Yes/No) Have all weeds been regularly removed from the mulch by hand or herbicide? Has the mulch been removed from contact with plant stems/trunks?

P a g e | 13 If any of your answers indicate your playspace requires maintenance or repair, detail below what problems exist and what corrective action needs to be taken to avoid their reoccurrence?

MAINTENANCE REQUIRED

Items requiring maintenance:

1..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

2..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

3.............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

4..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

5..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

6..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

7.............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

8..............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

9.............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

10............................................................................................................................................................

Maintenance completed by.................................................................. Completed Date: / /

Director/Principal/Coordinator............................................................ Completed Date: / /

P a g e | 14 REPAIRS REQUIRED (refer to each section of maintenance required)

1) Item requiring repair..........................................................................................................................

Cause of Damage.................................................................................................................................

Description of Damage & Repair required..............................................................................................

................................................................................................................................................................

................................................................................................................................................................

................................................................................................................................................................

Repair completed by............................................................................. Completed Date: / /

Director/Principal/Coordinator............................................................ Completed Date: / /

2) Item requiring repair..........................................................................................................................

Cause of Damage.................................................................................................................................

Description of Damage & Repair required..............................................................................................

................................................................................................................................................................

................................................................................................................................................................

................................................................................................................................................................

Repair completed by............................................................................. Completed Date: / /

Director/Principal/Coordinator............................................................ Completed Date: / /

3) Item requiring repair..........................................................................................................................

Cause of Damage.................................................................................................................................

Description of Damage & Repair required..............................................................................................

................................................................................................................................................................

................................................................................................................................................................

................................................................................................................................................................

Repair completed by............................................................................. Completed Date: / /

Director/Principal/Coordinator............................................................ Completed Date: / /