Molecular orientation in non-Newtonian flow Jeffrey A. Odell ...

Transcript of Molecular orientation in non-Newtonian flow Jeffrey A. Odell ...

Introduction

The motion of spheres in non-Newtonian liquids is ofwidespread and fundamental importance to manycomplex industrial processes. In the oil, paint, deter-gent and cosmetic industries, for example, there is theproblem of controlling the settling and suspension ofparticles in non-Newtonian media. Study of the flowaround a sphere can also benefit the understanding ofcomplex cyclic flows such as flow through porousmedia, which are usually modelled experimentally bypacked beds of spheres. This aspect of flow around

spheres has relevance to gel permeation chromatogra-phy (GPC), filtration of polymer solutions, and en-hanced oil recovery (EOR).

The specific case of a sphere settling under gravityalong the axis of a cylindrical tube of twice the radiusof the sphere has been chosen as a benchmark problemin viscoelastic flow (Leal et al. 1988). However, thetransience of this experiment (including a slow ap-proach to steady state), difficulties with experimentalreproducibility and a severely limited range of possibleflow regimes (due to the reliance on gravity to generatethe flow field) are some of the main reasons why

Simon J. Haward

Jeffrey A. OdellMolecular orientation in non-Newtonian flowof dilute polymer solutions around spheres

Received: 16 April 2003Accepted: 17 November 2003Published online: 4 February 2004� Springer-Verlag 2004

Abstract A novel approach is pre-sented to study the benchmarkproblem of flow around spheres inmodel dilute solutions of monodis-perse samples of atactic polystyrenein di-octyl phthalate. Spheres areheld ‘‘stationary’’ on flexible canti-levers of known spring-constant, k,while the polymer solutions arepumped past at controlled flowrates, allowing access to a widerange of Deborah number. In thisway the non-Newtonian forcesexperienced by the spheres can bemeasured as a function of Deborahnumber, while detailed observationsand measurements of birefringenceare made, enabling assessment ofmacromolecular strain and orienta-tion. In addition the flow fieldaround a sphere has been measuredin an a-PS solution. Experimentshave been performed on a single

sphere and on two spheres axiallyaligned in the direction of flow. Theextensional flow around the down-stream stagnation point of the singlesphere is found to play a pivotal rolein the development of molecularstrain and stress, resulting in flowmodification and subsequent non-Newtonian behaviour. The flowbirefringence in the wake is found tomodify severely the flow around asecond, downstream, sphere, affect-ing the non-Newtonian forcesencountered by the second sphere.This provides an explanation for thetime interval dependent terminalvelocity often observed when twospheres follow the same paththrough viscoelastic liquids.

Keywords Birefringence Æ Polymersolution Æ Extensional flow ÆSphere Æ Stagnation point

Rheol Acta (2004) 43: 350–363DOI 10.1007/s00397-003-0350-7 ORIGINAL CONTRIBUTION

S. J. Haward Æ J. A. Odell (&)H.H. Wills Physics Dept.,University of Bristol,Tyndall Avenue,Bristol, BS8 1TL, UKE-mail: [email protected]

understanding of the physics of the problem hasremained limited.

In this paper a new experimental approach isdescribed, in which the flow of polymer solutions aroundspheres can be studied in steady state, allowing moredetailed observations to be made of non-Newtonian floweffects. Flow cells have been constructed in which spheresare held on fine flexible cantilevers of measured springconstant. This allows the forces experienced by thespheres to be measured as a function of the flow rate ofthe polymer solution, while simultaneous measurementsof birefringence and/or the flow field can also be made.

Dilute solutions of monodisperse atactic polystyrene(a-PS) in di-octyl phthalate (DOP) have been studied inthe flow cells. Use of such model solutions allowsaccurate determination of molecular parameters such ascontour length and relaxation time, which in turn en-ables accurate definition of the Deborah number, De, ofthe flow regime. Use of a viscous solvent (DOP) meansthat shear thinning of the solutions should be negligibleand also that inertial effects should be minimal due tothe resulting low Reynolds number. Also, since the a-PSmolecule has a high intrinsic birefringence, estimates ofthe molecular strain can be made even at high dilutions.

Background

The falling ball has been found to provide a reliabletechnique for measuring the shear viscosity of non-Newtonian liquids in the low shear rate limit, with acalculation based on the assumption of Stokes’ law(Gottlieb 1979; Chhabra and Uhlherr 1979). However,as detailed below, experiments at higher shear rates haverevealed a host of largely unexplained non-Newtonianphenomena that, in many cases, make the acquisition ofreproducible experimental results a virtual impossibility.

Bisgaard (1983) used laser-Doppler velocimetry tomeasure the fluid velocity along the axes of spheres fall-ing through a 1% solution of polyacrylamide in glycerol.Spheres of various sizes and materials were used toprovide a variety of sphere terminal velocities. It wasfound that to get reproducible results in the experimentsa long time interval was required between droppingspheres through the solution. More specifically, releasingballs every 10 min resulted in a gradual increase in theterminal velocity of each successive ball until subsequentspheres fell up to 30% faster than the first. Releasing oneball every hour resulted in a velocity increase of up to 9%and an interval of 2.5 h was required before the velocityincrease reached less than 2%. Bisgaard noted that vis-cous heating of the test fluid by the spheres is unlikely toexplain a 30% increase in velocity.

Cho et al. (1984) assessed the use of the falling ball asa viscometer for non-Newtonian liquids in the interme-diate shear rate range. In aqueous polyacrylamide

solutions at concentrations 0.2%, 0.35%, 0.5% and 1%it was found that the terminal velocity was sensitive tothe time interval between the dropping of successiveballs. When balls were dropped at 30-s intervals in a 1%solution the terminal velocity increased by �50%. Aninterval of over 30 min was required to eliminate theeffect. Cho et al. pointed out that 30 min was far longerthan any usual measure of the relaxation time of thesolution.

Jones et al. (1994) found a terminal velocity increaseof >30% for spheres dropped at 15-min intervals in a0.19% solution of polyisobutylene (PIB) in polybutene(PB), a non-shear thinning Boger fluid. A period of 24 hwas required before the solution recovered its originalbehaviour. The authors did not discover the reason forthe velocity increase but stated that it obviously involvessome changes in the polymer configuration and thatsuch a possibility could involve the production of ex-tended chain configurations by the passage of the balls.The extended configurations then return to their equi-librium state over a long time period.

Using the same Boger fluids as Jones et al. (1994),Degand and Walters (1995) studied flow around asphere using a novel approach. A single sphere was heldstationary inside a tube as the fluid was driven past usingeither a pump or a pressure drive or gravity to generatethe flow. With this method the authors could access a fargreater range of Deborah numbers than with fallingballs as the flow velocity could be easily increased anddecreased as required. Measurements of the pressuredifference across the sphere as a function of flow rateallowed the authors to calculate the drag coefficient. Theobservation of a sudden increase in the drag coefficientat an onset Deborah number was considered to be cer-tainly due to extensional viscosity effects. It should benoted that this experiment was performed for the specialcase of the sphere fitting very tightly inside the tube (theratio of sphere radius to tube radius was 0.88). In thissituation there will have been a large component ofsimple shear in the flow around the sides of the sphere;however the use of Boger fluids should have obviatedany effects of this, and the authors observed little shearthinning in their experiments.

Arigo et al. (1995) used laser-Doppler velocimetry tomeasure the axial velocity along the axis of spheresfalling in PIB/PB-based Boger fluid for a range ofDe. They found that the axial velocity profiles remainedsymmetric in front of and behind the sphere at lowDe. As De was increased the upstream velocity profileremained independent of De; however downstream ofthe sphere a wake developed that increased in spatialextent with increasing De. At De�7.5 the wake extendednearly 30 sphere radii behind the sphere, measured to thepoint where the velocity reached zero; however off axismeasurements indicated that, radially, the wake onlyextended to �1.1 sphere radii away from the centreline.

351

The work of Solomon and Muller (1996) involved thesettling of spheres in monodisperse polystyrene basedBoger fluids. A polystyrene sample of Mw=20·106 wasprepared in 0.16% solutions in mixtures of DOP/oligo-meric polystyrene and tricresyl phosphate/oligomericpolystyrene to produce solutions of ‘‘poor’’ and ‘‘good’’extensibility, respectively. The Deborah number of theexperiment was varied by using spheres of various den-sities and sizes. The two fluids showed drag increases of>300% for De>1, an effect considered by the authorsto be purely elastic since the Reynolds number was<0.01.

Fabris et al. (1999) used digital particle image ve-locimetry to perform measurements of the flow fieldaround falling spheres in the solution of ‘‘good’’ exten-sibility studied by Solomon and Muller (1996). Fabriset al. found that the radial part of the flow field remainedsymmetric as De increased and was very similar to theflow field observed in glycerol. The axial component,however, remained constant in front of the ball butdeveloped an increasingly long trailing wake withincreasing De. A large increase in the drag coefficientwas observed with increasing De, and both this and theobserved flow field modification were attributed to anincrease in extensional viscosity along the centreline ofthe trailing wake.

The computational work of Chilcott and Rallison(1988) concerning the flow of a suspension of FENE-CRdumbbells past a rigid sphere showed that, for high De,the polymer became highly stretched in thin regions offluid close to and downstream of the rear stagnationpoint.

Harlen (1990) modelled the steady flow of a polymersolution past a sphere falling at high De but low Reusing the birefringent strand technique developed byHarlen et al. (1990). The presence of a thin strand ofhighly extended polymer downstream of the spherecaused the velocity in the wake to decay much moreslowly than for a Newtonian fluid and produced anincrease in the drag coefficient. The form of thedownstream wake was comparable to that measuredby Bisgaard (1983).

In the present paper we report flow effects and theirinteraction with molecular orientation around a singlesphere. We also report how the wake of a single spherecan affect a second sphere, downstream of the first, andaxially aligned in the direction of flow. Such a studyshould shed light on the still largely unexplained time-dependent ‘‘velocity effect’’, which has been observedwhen two or more spheres follow the same paththrough a polymer solution (Bisgaard 1983; Cho et al.1984; Jones et al. 1994), reviewed above. These previ-ous studies have been performed with a wide range ofconcentrations (generally semi-dilute or concentrated)in highly viscous solvents of variable quality. All ofthese factors can cause the effective orientational

relaxation time to vary by orders of magnitude. In thispaper we shall concentrate upon the well-definedproblem of dilute theta solutions of well-definedmonodisperse polymers in a relatively inviscous sol-vent.

The understanding of how two aligned particles mayinteract in polymeric liquids has clear relevance tounderstanding porous media flows, since porous mediaare usually modelled in the laboratory by beds packedwith spheres. The relevance to particle settling and sus-pensions is also clear.

Experimental

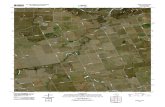

Apparatus The ‘‘single sphere’’ and ‘‘double sphere’’ flow cells usedin the experiments are shown schematically in Fig. 1. The walls ofthe cells were cut from a 4 mm thick sheet of soda glass, which hadbeen annealed to improve its optical isotropy, and were bondedtogether into square tubes of 100mm2 cross-section (inside) usingan inert silicon based adhesive. One of the walls of each cell had a10 mm diameter hole cut through it to allow the insertion of thesphere/cantilever assembly.

The glass spheres were of diameter 2±0.02 mm and were sup-plied by Sigmund-Lindner of Germany. The spheres were eachglued to one end of a cantilever cut from a length of flexible opticfibre of diameter 125±2 lm. The opposite end of the cantileverwas fixed rigidly into one end of a 10 mm diameter glass cylinder.The lengths of the cantilever and the cylinder were such that, whenthe spheres were inserted into the cell and the cylinder was securedto the cell wall, the rest position of the spheres was on the centralaxis of the flow cell. In the double sphere flow cell the spheres wereseparated by a centre-centre distance of �5 mm.

The cantilevers were cut to a length of �19 mm, to provide aspring constant, k, of �0.4 Nm-1 to provide a measurable dis-placement of the spheres in the flowing solvent. The spring constantof the cantilever was measured approximately, before the spherewas attached, by holding the cantilever in a horizontal position andmeasuring the vertical displacement of the free end of the cantileveras increasing weights were added to it. By ensuring the range ofcantilever deflection was greater than would occur under experi-mental conditions, this measurement of k also ensured that k wouldbe constant over the experimental range of movement. A moreaccurate value for the spring constant was determined with thesphere and cantilever ‘‘in situ’’ by attaching the flow cell rigidly to a

Fig. 1 a Schematic diagram of the single sphere flow cell. bSchematic diagram of the double sphere flow cell (the centre-centrespacing between spheres was �5 mm)

352

magnetic coil driven by a signal generator and exciting the firstnatural resonant frequency, x, of the cantilever. The correspondingspring constant was calculated using x ¼

ffiffiffiffiffiffiffiffiffi

k=mp

, where m is themass of the sphere.

All of the dimensions of the flow cell were carefully calculatedto provide a good range of strain rate and an easily measurablecantilever deflection in the given solvents and at the available flowrates while, at the same time, minimising the volume of solutionrequired per experiment and also minimising wall effects.

The flow cells were incorporated into the apparatus shownschematically in Fig. 2. The polymer solution (or solvent) wasdrawn through the test cell from reservoir 1 to reservoir 2 by thevacuum pump. The volume flow rate was controlled by adjustingvalves 1 and 2 to control the vacuum pressure inside reservoir 2 andwas calculated from a measurement of the pressure drop, DP,across a calibrated capillary connected to reservoir 1. When anexperiment had been completed valve 3 was closed to stop the flowand the vacuum was switched off. The liquid in reservoir 2 couldthen be either returned to reservoir 1 by opening valve 4, or couldbe discarded to waste.

The spheres inside the flow cells were viewed using a cooledC.C.D. camera interfaced to a PC, allowing the displacement of thespheres to be measured directly, and allowing individual photoframes and sequences to be captured. The test cells were mountedon a translation stage to allow adjustments to be made for thedisplacement of the spheres when the cantilevers bent in the flowingliquid. The cantilever bend inevitably introduced a small degree oferror into the experiment because the spheres were pulled slightlyaway from the flow axis causing asymmetry in the flow field. Themaximum deviation of the sphere from the flow axis occurred at thehighest flow rates in viscous solutions and was �0.5 sphere radii. Inthe double sphere flow-cell the different displacement of eachsphere caused them to become slightly non-colinear. The typicaldifference in axial position corresponded to 1/60 of a radius,reaching a maximum of 1/10 radius for high flow-rates of viscoussolutions.

Force measurement and estimation of specific viscosity The force, F,upon each sphere was measured for polymer solutions, Fsolution, andfor the pure solvent, Fsolvent as a function of the superficial flowvelocity. Since Stokes’ law relates the force felt by a sphere to theviscosity of the fluid in which the sphere is moving an estimate of

the specific viscosity, gsp, of the polymer solutions was made at agiven flow rate simply by

gsp ¼Fsolution � Fsolvent

Fsolventð1Þ

This method has some important advantages over other ap-proaches. Since the flow is unlikely to be strictly creeping flow, i.e.since the Reynolds’ number will be greater than zero, correctionsought to be made to both Fsolution and Fsolvent due to inertial forces.However, since the inertial force contributions to Fsolution andFsolvent should be essentially equal, the process of subtraction inEq. (1) should largely obviate errors due to these effects. Also, sincethe solvent specific viscosity is identically equal to zero, polymereffects (i.e. shear thinning or the increase in extensional viscosity)should be clear when gsp is plotted as a function of strain rate orDeborah number. In the double sphere flow cell, the application ofEq. (1) to each sphere separately should also obviate the effects ofslipstreaming.

The superficial flow velocity, v, was calculated from the mea-surement of volume flow rate divided by the cross-sectional area ofthe flow cell. This value of v was used in the calculation of Reynoldsnumber, Re, according to

Re ¼ qvrg

ð2Þ

where r is the radius of the sphere and q and g are the density andviscosity of the solvent, respectively. For polymer solutions thestrain rate was determined by

_e � vr

ð3Þ

The Deborah number was determined using

De � svr¼ s_e ð4Þ

where s is taken as the longest molecular, Zimm, relaxation time.The relaxation times of the polymer samples used in the experi-ments are discussed below.

Observation and estimation of birefringence Birefringence in theflow cells was detected using the optical system illustrated sche-matically in Fig. 3. A 4-mW helium-neon laser was positioned suchthat the beam passed orthogonally through the walls of the flowcell and the observation area (the trailing stagnation point of asphere). The laser beam was detected by the cooled C.C.D. camera,

Fig. 2 Vacuum driven flow systemFig. 3 Optical system used to measure birefringence in the singlesphere flow cell

353

which was focussed on the stagnation point area. The polarizer andanalyser were placed on either side of the flow cell with their axes at45� to the flow axis and at 90� to each other to minimize the signalreceived by the C.C.D. camera. A k/4 plate was inserted betweenthe polarizer and analyser to compensate for residual birefringencein the glass walls of the cell. The k/4 plate was rotated to achievethe minimum signal and the polarizer and analyser were readjustediteratively to achieve extinction of the beam.

During experiments with polymer solutions, 25-ms images werecaptured for a range of flow rates. When the flow was stopped a 25-ms background image was captured. The background image wassubtracted from the images captured under flow to reveal thebirefringent signal. This was done within 1 s to provide the bestpossible background image for subtraction.

The intensity of the detected signal was calibrated by placing ak/30 compensator in the optical line shown in Fig. 3. The change inthe signal intensity was measured as the compensator was rotatedto produce a range of retardation values.

The retardation, R, is related to the birefringence, Dn, by

R ¼ Dnl ð5Þ

where l is the path-length through the birefringent material. Notethat some previous authors have used an algorithm to de-convolvethe cylindrical symmetry of birefringent lines observed in opposedjet flow (Cathey and Fuller 1990; Carrington et al. 1997a, 1997b).This was inappropriate for the present study, since the birefrin-gence observed here was not necessarily symmetric about the flowaxis and frequently became unstable (i.e. fluctuated with time) athigh flow rates.

Flow visualization Flow visualization experiments were performedin the single sphere flow cell using a modification to the opticalsystem illustrated in Fig. 3. Two orthogonal cylindrical lenses werepositioned so as to focus the laser beam into a very narrow plane(�100 lm) that passed through the observation area, bisecting thesphere. The C.C.D. camera was positioned at 90� to the plane ofthe light and was focussed on the observation area to receive lightscattered from latex tracer particles suspended in the fluid.

Images were captured and the local fluid velocity around thesphere was resolved in the direction of the flow axis using theknown exposure time of the image and the lengths of the streakscreated by the tracer particles.

Polymer solutions Dilute solutions of mono-disperse atacticpoly(styrene) in di-octyl phthalate (a-PS in DOP) were employed inthe experiments. DOP is a viscous, low molecular weight, solvent ofviscosity gDOP=0.04 Pa s (Durrans 1971). The h-temperature forthe a-PS/DOP system is 22 �C (Berry 1967).

Three a-PS samples of molecular weights Mw=6.9·106,Mw=8.5·106 and Mw=10.2·106 were used. The samples, all sup-plied by Polymer Laboratories, were closely monodisperse, havingpolydispersity indices, Mw/Mn, of 1.15, 1.2 and 1.17, respectively.Solutions were prepared in concentrations between 0.005 wt% and0.03 wt%. The solution temperatures were measured prior toexperiment to be 22±1 �C.

An estimate of s for the polymer solutions was determined fromexperiments on 0.01% solutions of a-PS in DOP using a newtechnique called ‘‘oscillatory extensional rheometry’’, in which asmall volume of fluid is repeatedly oscillated through the stagna-tion point of a cross-slot device (Carrington et al. 1997a, 1997b;Carrington and Odell 2003). The molecular weights tested wereMw=6.9·106 and Mw=10.2·106 and the solutions were, in fact,identical to those studied here. The intensity of birefringence wasmeasured as a function of strain rate in the oscillatory cross-slotsand the critical strain rate, _ec ¼ 1=s, of each solution was deter-mined from the points of inflection on the birefringence vs strainrate curves. Such experiments are thought to give reliableestimates of the Zimm relaxation time s, including hydrodynamic

interactions. The estimates of s for the a-PS solutions, including alinear extrapolation for the Mw=8.5·106 sample, are shown inTable 1, together with calculated values for the Zimm relaxationtime, intrinsic viscosities calculated from the Mark-Houwink equa-tion and values of c*. There is reasonable agreement between thecalculated and measured values, the measured values being consis-tently around twice the calculated value. This probably reflects theuncertainty in solvent quality and viscosity and in the polymerphysics of the coil-stretch process intrinsic to the technique.

Our estimate of c* concentration was made on the assumptionof each molecule occupying the volume of a cube of dimension 2Rg,i.e.

c� ¼ Mw

NA 2Rg� �3

ð6Þ

where Rg represents the equilibrium radius of gyration and NA isAvogadro’s number. This assumption yields a considerably lowerestimate of c* than the common assumption of each moleculeoccupying a sphere of radius Rg (e.g. Graessley 1980).

From our conservative estimates of c* given in Table 1 it can beseen that our experimental concentrations lie in the range c*/42<c<c*/7. For all but our highest experimental concentrations,c<c*/10. For this reason we consider our test solutions to be highlydilute.

From the values of [g] given in Table 1, calculated from theMark-Houwink coefficients for a-PS in DOP, it can be shown thatthe relative viscosities of our test solutions lie in the range 1.01<grel<1.08. This indicates that our solutions should not be greatly af-fected by shear flow and should be expected to behave as non-shearthinning Boger fluids.

Results

Single sphere flow cell

Force measurements and estimates of specific viscosity

Figure 4a shows how the force on the single sphere in-creases with the Reynolds number in solutions of vari-ous concentration of Mw=10.2·106 a-PS in DOP. Theforce on the sphere in the pure solvent is represented bythe solid line in Fig. 4a and is well fitted by a quadraticin Re, indicating the presence of low Re inertial effects.Increasing departures from the solvent behaviourare observed with increasing polymer concentrationand Re.

In Fig. 4b the data from Fig. 4a has been convertedinto a plot of the specific viscosity, gsp, as a function ofthe Deborah number, De, as described above. In this

Table 1 Estimated Zimm relaxation times, theoretical values forthe intrinsic viscosities and c* for a-PS/DOP solutions

a-PS molecular weight 6.9·106 8.5·106 10.2·106

Experimental relaxation time,s (ms) ±20%

2.00 2.75 3.60

Calculated Zimm Relaxationtime (ms)

1.08 1.49 1.95

[g] (Mark-Houwink), cm3 g)1 210.1 233.2 255.5C* (wt%) 0.26 0.23 0.21

354

plot the solvent curve lies identically along the x-axis, sothe departures from Newtonian behaviour due to thepolymer additives are much clearer than in Fig. 4a.

The polymer solutions in Fig. 4b display a rapid in-crease in the specific viscosity above an onset Deborahnumber, Deo. Below Deo the specific viscosity has anapproximately constant value. The increase in specificviscosity tends (except for the highest concentration)towards a plateau value with increasing Deborah num-ber. As expected, the plateau values increase withpolymer concentration. It is notable that the value ofDeo becomes progressively lower as the polymer con-centration is increased. The range of De over which theviscosity increase occurs could be considered critical, aseven these ‘‘monodisperse’’ polymers contain a signifi-cant range of molecular weights, corresponding to arange of s of about 10:1.

Figure 5 shows a comparison between the behaviourof the different molecular weight a-PS samples for aconstant concentration of 0.02%. Qualitatively thesolutions behave as expected, showing an increase in themaximum specific viscosity with increasing Mw.

The a-PS solutions display qualitatively similarbehaviour at all three molecular weights and concen-trations tested. The specific viscosities of the polymersolutions are seen to have an approximately constant, or‘‘pseudo-Newtonian’’, value below an onset Deborahnumber, Deo. Above the onset Deborah number thespecific viscosity rises steadily and tend towards plateauvalues.

The general behaviour of the a-PS solutions in thesingle sphere cell is consistent with an increase in thespecific viscosity as a result of polymer extension. In factthe curves are comparable in nature to the results ofCarrington et al. (1997a, 1997b), who made pressuredrop measurements across the opposed jets, which cor-related with the increase in molecular strain in a 0.02%solution of Mw=8·106 a-PS in dekalin. These authorssuggested that the behaviour was due to the coilMstretch transition in dilute solutions.

However, the onset Deborah number marking theonset of the viscosity increase in the a-PS/DOP solutionsin the single sphere cell is lower than the expected valueof Deo�0.5–1. Flow field measurements in the singlesphere flow cell show that the flow velocity along thesymmetry axis may be up to double the superficial flowvelocity used to calculate the Deborah number; see be-low. Also the polydispersity of the a-PS samples, thoughsmall, may be significant in showing extension effects atlow De due to the high molecular weight tail (this mayalso account for the reduction in Deo with increasingpolymer concentration and Mw). Furthermore the flow-field around the sphere is not well enough understood,especially in polymer solutions, to allow an accuratedefinition of the strain rate and therefore Deborahnumber. For this reason calculations of strain rate andDeborah number are based purely on the geometryof the flow cell and complications to the flow field areignored.

Fig. 5 Specific viscosity as a function of Deborah number in thesingle sphere cell for 0.02% solutions of a-PS in DOP at themolecular weights indicated

Fig. 4 a Force as a function of Reynolds’ number in the singlesphere cell for solutions of Mw=10.2·106 a-PS in DOP. The solidline represents the data obtained from the pure solvent. b Specificviscosity as a function of Deborah number in the single sphere cell.Derived from Fig. 4a

355

Observations and estimates of birefringence

Figure 6 shows the development of birefringence in thetrailing wake of the sphere as the Deborah numberincreases in a 0.02% solution of Mw=10.2·106 a-PS inDOP. At the lowest Deborah numbers (De=0.04, 0.07)no birefringence is visible. At De=0.14 a weak localisedbirefringent line is visible originating from the stagna-tion point. The line increases in width and intensity withincreasing De until, at De=0.29, two separate lines canclearly be distinguished. With further increases in theDeborah number the structure of the birefringence isseen to become more complicated, consisting of manystriations. At high De flow instabilities in the wakebecame evident as the complex birefringent structurebegan to fluctuate. The individual strands that form thestructure were observed to oscillate in position andintensity as shown in Fig. 7, where successive framescorrespond to 200-ms time intervals. The typical time-scale for these fluctuations was around 0.25 s, around200 times the characteristic relaxation time. Such fluc-tuations were predicted by Harris and Rallison (1994)for moderate De in stagnation point flow of a dilutepolymer solution modelled by dumbbells with non-linearhydrodynamic friction. They are thought to arise from acoupling between the stretching of the polymer andconsequent modification of the flow-field.

Estimates of the birefringence (Dn) of the strand inthe 0.02% solution of Mw=10.2·106 a-PS produced a

maximum value at De=0.5 of Dnmax�6·10-6. This canbe compared with a theoretical maximum value ofDn0=1.6·10-5, from an expression derived by Peterlin(1961). Using the model of Treloar (1975), based on thesegmental isotropy of a strained network, the ratio ofDnmax to Dn0 suggests that the polymer molecules haveextended to some 60% of their contour length, i.e. theextension ratio of �0.6 (see also Carrington et al. 1997a,1997b). Similar estimates for more dilute solutions(Mw=10.2·106 sample at c=0.005% and Mw=6.9·106and Mw=8.5·106 samples at c £ 0.01%) yielded maxi-mum extension ratios of �1 (i.e. full extension) at highDe.

Birefringent lines were followed for approximately5 mm downstream of the trailing stagnation point byslowly moving the flow cell in front of the C.C.D.camera using the translational stage. At the highestexperimental flow velocity of �150 mm s)1 this distancerepresents a time interval of �0.03 s, almost an order ofmagnitude longer than the expected relaxation time ofthe Mw=10.2·106 a-PS sample; see Table 1.

Flow-field visualisation

Figure 8 shows a sequence of flow field plots for a 0.02%solution of Mw=10.2·106 a-PS in DOP. Vectors are

Fig. 6a–h Development of birefringence with strain rate andDeborah number downstream of the stagnation point of the singlesphere flow cell. 0.02% Mw=10.2·106 a-PS in DOP: a De=0.04;b De=0.07; c De=0.14; d De=0.22; e De=0.29; f De=0.36;g De=0.43; h De=0.50. For clarity the position of the sphereis indicated by a superimposed circular section. Flow is from rightto left

Fig. 7 A selection of images captured within a 1 s time interval thatdemonstrate the instabilities in the birefringent strands observed inthe wake of the sphere. 0.02% solution of Mw=10.2·106 a-PS inDOP at _�=140 s)1 (De=0.5). Flow is from right to left

356

shown corresponding to the flow velocity and direction.At the lowest flow rate of v=20 mm s)1 (De=0.07,Fig. 8a) the flow field is seen to be only slightly asym-metric about the x=0 axis, which is similar to the flowfield expected from viscous flow of a Newtonian fluid.As the flow rate is increased to v=80 mm s)1 (De=0.29,Fig. 8b); however, a high degree of asymmetry can beobserved in front of and behind the sphere. An extendedwake has formed downstream of the sphere with verylow fluid velocities along the stagnation streamline. Atthe highest flow rate, v=160 mm s)1 (De=0.58,Fig. 8c), the low velocity trailing wake has become verypronounced and extends for nearly eight radii behind thesphere. This is a large perturbation to the flow fieldobserved in Newtonian liquids. In pure DOP, forexample, we observed a symmetric flow field around thesphere even at a superficial flow velocity of v=200 mms)1. Although more qualitative, our results are consistentwith those of Fabris et al. (1999).

In the a-PS solutions it is seen that fluid in the trailingwake of the sphere requires a considerable distance, incomparison to the solvent, in which to accelerate awayfrom the stagnation point up to the superficial flowvelocity. There are two important consequences of thisextended period of fluid acceleration in the wake. The

first is a reduction in the value of v/r for the strain rate atthe trailing stagnation point. The second is that anextensional component will remain in the flow field onthe stagnation point axis for up to several radii down-stream of the sphere.

Double sphere flow cell

Force measurements and estimates of specific viscosity

Figure 9a shows the forces measured on each sphere ofthe double sphere flow cell with a 0.02% solution ofMw=10.2·106 a-PS in DOP, compared to the forcesmeasured in pure DOP. For the solvent the force curvecorresponding to the first sphere to encounter the flow,‘‘sphere 1’’, is well fitted by a quadratic equation in Re.The second sphere along the flow axis, ‘‘sphere 2’’, isseen to experience a force that increases linearly withReynolds’ number, indicating an absence of significantfluid inertial contributions to the force. Sphere 2 is seento experience a reduction in force, compared to sphere 1,for Re>�0.5. This is probably due to the onset ofinertial effects in the downstream wake of sphere 1 (as

Fig. 8a–c Vector plots of the velocity field around the sphere in thesingle sphere flow cell for a 0.02% solution of Mw=10.2·106 a-PSin DOP flowing at: a v=20 mm s)1; De=0.07; b v=80 mm s)1;De=0.29; c v=160 mm s)1; De=0.58. Flow is from left to rightand the sphere is centred at (0,0). In each case the superficial flowvelocity, v, is represented by fi

Fig. 9 a Force as a function of Reynolds number, Re, for eachsphere of the double sphere flow cell in pure DOP and in a 0.02%solution of Mw=10.2·106 a-PS in DOP. The solid lines represent aquadratic fit to the data for sphere 1 and a linear fit to the data forsphere 2 in pure DOP. The equations for the lines of best fit are:F=5.2Re2+170.4Re, and F=167.4Re, respectively. b Specificviscosity, gsp, as a function of the Deborah number, De, derivedfrom Fig. 8a

357

indicated by the quadratic fit to the force curve) causinga slight reduction in the flow velocity, i.e. a slipstreamingeffect.

The polymer solution force curves for each sphere inFig. 9a appear to follow closely the respective solventcurves until an onset Reynolds’ number is reached. Be-yond the onset Reynolds’ number, which appears to beapproximately the same for both spheres, the polymercurves begin to diverge from the solvent curves. Thedeparture from Newtonian behaviour increases with Re.Although it is clear that sphere 1 experiences a greatertotal force than sphere 2 in the polymer solution, it is notentirely clear how much of this extra force arises fromthe polymer additive to the solvent.

By comparing the polymer curves in Fig. 9a with thesolvent curve for the respective sphere, the apparentspecific viscosity, gsp, has been estimated for each sphereseparately using Eq. (1). Thus both solvent curves be-come identically equal to zero, for all Re, removing theslipstreaming effect from the data and making compar-isons between the polymer curves much simpler. InFig. 9b the data from Fig. 9a has been treated in thisway and plotted as a function of De. The curves for bothspheres in Fig. 9b show an increase in the specificviscosity from pseudo-Newtonian behaviour above anonset Deborah number, Deo. The curve obtained fromsphere 1 of the double sphere cell is similar to the curveobtained with the same solution in the single sphere flowcell; see above. However it is immediately obvious inFig. 9b that sphere 2 experiences a significantly lowerincrease in specific viscosity due to the polymer thansphere 1. Also the apparent onset Deborah number forthe viscosity increase is greater for sphere 2 thansphere 1.

With increasing De the curves appear to be tendingtowards plateau values of gsp. The difference in maxi-mum values of gsp in Fig. 9b represents a difference inapparent viscosity of �40%, i.e. sphere 2 experiences�40% less force than sphere 1 due to the polymeradditive in the solution. This relative reduction in forceis entirely analogous to the ‘‘velocity effect’’ observed infalling ball experiments. Since Stokes’ law relates theviscous force on a spherical particle to the velocity of thefluid, sphere 2 could be expected to fall �40% fasterthan sphere 1, if a falling ball experiment was conductedunder identical conditions. In fact the increase invelocity may well be greater than this, since the 40%does not include the Newtonian slipstreaming effect (thetotal maximum difference in force between the 2 spheresin the 0.02% solution of Mw=10.2·106 a-PS can beestimated from Fig. 9a to be �55%).

The time for fluid to flow between the spheres is�0.03 s, which is almost an order of magnitude greaterthan the longest expected molecular relaxation time ofthe Mw=10.2·106 a-PS sample (s=0.0036 s); Carring-ton and Odell (2003). However, in relation to falling ball

experiments, 0.03 s is an extremely short time intervalbetween spheres, and difficult to achieve experimentally.Though the effect is short-lived in comparison to pre-vious studies (Bisgaard 1983; Cho et al. 1984; Jones et al.1994), the present system is highly dilute and the solventrelatively inviscous, so that the effect is long-lived interms of the polymer relaxation time, s.

Due to the analogy with falling ball experiments thequantity defined by the difference in plateau values ofspecific viscosity for spheres 1 and 2 will, from now on,be termed the ‘‘effective velocity effect’’ and denoted byDveff. Therefore, in Fig. 9b, Dveff�0.4, which means thata difference of �40% was measured in the force exertedby the polymer on each ball.

To show the effect of molecular weight, Fig. 10 showssimilar curves to Fig. 9b for a 0.02% solution ofMw=6.9·106 a-PS in DOP. Similar features are ob-served as for the Mw=10.2·106 solution. There is asmall increase in the onset Deborah number betweensphere 1 and sphere 2. Both curves rise to plateau valuesindicating an effective velocity effect of Dveff�0.15. Itshould be noted that the second sphere shows a drop inspecific viscosity around a De of 0.4. This has been seena number of times with other solutions. Beyond thisvalue the curves tend towards a plateau value.

Concentration dependence is shown in Fig. 11, whichshows the specific viscosity as a function of De for a0.01% solution of Mw=10.2·106 a-PS in DOP. InFig. 11, Dveff reaches a maximum value of �0.25 atDe=0.5.

Observations of birefringence

Due to experimental difficulties with calibrating theretardation in the double sphere experiments, quantita-tive measurements of birefringence were not possible. Itwas also not possible to obtain background images frompositions situated behind sphere 1 of the cell due to the

Fig. 10 Specific viscosity, gsp, as a function of the Deborahnumber, De, for the spheres of the double sphere flow cell in a0.02% solution of Mw=6.9·106 a-PS in DOP

358

change in position of the spheres with and without flow.Background corrections were possible for images cap-tured from behind sphere 2, however, and comparison ofthese images with those captured in the single sphereflow cell allow useful insights to be made on theassumption that observations made in the single sphereflow cell would be similar to observations made onsphere 1 of the double sphere flow cell.

Accordingly, Fig. 12 shows a comparison betweenthe birefringence observed at the stagnation point ofsphere 2 with that observed at the stagnation pointof the single sphere flow cell for a 0.02% solution ofMw=10.2·106 a-PS in DOP. It is apparent that, for agiven Deborah number, the birefringent signal detectedin the wake of sphere 2 is significantly weaker than thesignal observed behind the single sphere. As shown byFig. 12, the onset Deborah number for the appearanceof the birefringent line is greater for sphere 2 than for thesingle sphere. The onset Deborah number for theobserved increase in birefringence broadly correspondswith the Deborah number for the increase in specificviscosity.

The birefringent strands that originated from behindsphere 1 of the double sphere cell were tracked as theyflowed into the flow field of sphere 2. Due to theaforementioned difficulties with making backgroundcorrections a 0.03% solution of Mw=10.2·106 a-PS inDOP was used and the experiment was conducted at ahigh strain rate ( _�=250 s)1) so that the birefringentsignal would be intense and could be seen above thelaser background. Even so, individual photo-frames didnot show the birefringence clearly; however, when se-quences of frames were viewed as videos, the fluctuationof intensity and position of the birefringent lines allowedthem to be seen.

Many sequences of frames were captured as thedouble sphere flow cell was translated past the CCDvideo camera. Birefringent lines were followed from

their origin immediately behind sphere 1, from wherethey flowed towards sphere 2 in more or less straightlines. Near the leading edge of sphere 2 the lines divergedas if following the streamlines around the surface of thesphere. Approaching sphere 2, the birefringent strandscould be seen flowing very closely around the sides of thesphere. Sometimes birefringent lines that had originatedfrom behind sphere 1 could be seen through the glass ofsphere 2 as they flowed around the opposite side of thesphere from the CCD camera. The birefringent linesmoved erratically around the circumference of sphere 2,probably due to viscoelastic instabilities, see discussion.Immediately behind sphere 2 the existing birefringentstrands were observed to detach from the surface of thesphere and flow downstream, gradually converging.Also additional birefringent strands were generatedaround the trailing stagnation point of sphere 2, thoughthese were of reduced intensity to those formed behindsphere 1 and appeared to occupy a smaller volume. Aschematic of the observed interaction between thespheres is provided by Fig. 13.

Discussion

It should be remembered when considering the resultspresented here that the present experiment is subtly

Fig. 11 Specific viscosity, gsp, as a function of the Deborahnumber, De, for the spheres of the double sphere flow cell in a0.01% solution of Mw=10.2·106 a-PS in DOP

Fig. 12a–d Development of birefringence with De in the stagnationpoint of sphere 2 of the double sphere flow cell in a 0.02% solutionof Mw=10.2·106 a-PS in DOP. Shown for comparison is thebirefringence observed in the stagnation point of the single spherein the same solution and for the same values of De. De=: a 0.07;b 0.22; c 0.36; d 0.5. For clarity the position of the sphere isindicated by a superimposed circular section. Flow is from right toleft

359

different from the falling ball experiment in variousrespects.

Since the flow rate in the present experiment is forcedto be steady state (for both spheres) the difference inforce felt by the spheres results in a fixed separationbetween them. Also, in the present experiment there isno independent control of flow velocity or initial tem-poral separation between the spheres: increasing the flowrate has the unavoidable simultaneous effect of reducingthe time interval for flow between the spheres. Also,of course, the difference in stress in the two cantileversresults in a slight reduction of the 5-mm gap betweenthe spheres, which further compounds this effect.

There are various reasons why falling ball experi-ments could not be expected to produce results such asobserved here, particularly as regards the magnitude ofDveff. It is hard to achieve high De flows in falling ballexperiments because the increase in extensional viscosityhas the effect of limiting the strain rate of the experiment(the strain rate is also limited by the force of gravity andthe density and buoyancy of available spheres). Even ifequivalent strain rates could be achieved, to drop ballswith controlled 5-mm (or 1/30 s) gaps between themwould be extremely difficult.

In a falling ball experiment the different viscous for-ces felt by two spheres falling along the same path wouldresult in different sphere velocities. If the difference invelocity could be as great as Dveff suggests, this wouldresult in a rapid change in the distance between thespheres. If sphere 2 fell faster than sphere 1, the 5-mmgap between the spheres would quickly reduce and thespheres would eventually converge. This was observed inthe experiments of Riddle et al. (1977).

Whilst 5 mm or 1/30 s is very small compared toprevious studies (Bisgaard 1983; Cho et al. 1984; Joneset al. 1994), it should be remembered that here we areusing highly dilute solutions of very low s.

Although there are subtle complications in the anal-ogy between the falling ball experiment and the presentstudy, since the flow geometries of the two experimentsare virtually identical and the non-Newtonian effectsthat are observed in both experiments are clearlyequivalent, conclusions drawn from the present studycan certainly be applied to the falling balls.

It has been shown that the specific viscosity of dilutea-PS/DOP solutions can increase significantly whenflowing around a sphere beyond an onset Deborahnumber. Considering the lower concentrations of thesolutions in the present study, the increases in specificviscosity are consistent with the increases in drag coef-ficient reported by Solomon and Muller (1996).

As mentioned above, the force and specific viscositycurves obtained from the a-PS/DOP solutions are simi-lar in form to the results of Carrington et al. (1997a,1997b), for a 0.02% solution of Mw=8·106 a-PS indekalin in the opposed jets. The increase in viscositybetween the jets observed by Carrington et al. wasconfirmed as being due to the coilMstretch transitionpostulated by de Gennes (1974) and Hinch (1977) as itcoincided with the increase in birefringence between thejets.

The images of birefringence presented here (seeFig. 6) also confirm that a-PS molecules in solution canaccumulate significant strain near the stagnation pointof a sphere at Deborah numbers where there is anincrease in the specific viscosity of the solution. Semi-quantitative estimates of the birefringence show that atsufficient dilution and strain rate, close to full molecularstrain can occur. There is a reasonable correlationbetween the onset De for the viscosity increase and theonset De for the appearance of a birefringent signal.Therefore it is reasonable to make the assumption thatthe increase in specific viscosity felt by the spheres ina-PS solutions is due to the accumulation of molecularstrain, i.e. an increase in the extensional viscosity of thesolution.

Logically, the stagnation point appears to be themost crucial region where polymer molecules accumu-late strain, since in the locality of the stagnation pointmolecules will experience the longest residence time inthe extensional flow field and are subjected to a highstrain rate. Evidently polymer molecules remain highlystretched as they flow away from the sphere along thestagnation point streamline.

Hysteresis in the coilMstretch transition may play acrucial role in maintaining the molecules in the stretchedconformation. As predicted by de Gennes (1974), therelaxation time of a highly coiled polymer molecule mayincrease when the molecule is stretched due to increased

Fig. 13a,b Schematic showing how the birefringent strands developin the double-sphere cell: a at ‘‘moderate’’ flow rates thebirefringent strands from the first sphere screen the flow-field inthe wake such that _�< _�c behind sphere 1 and _�< _�c behind sphere 2;b at higher flow rates the strain rate can exceed the critical valuebehind both spheres but is still reduced behind sphere 2 due toincreased flow screening

360

viscous contacts between the polymer chain and thesolvent molecules. Therefore a molecule that becomesstretched in the stagnation point behind a sphere mayhave to flow for some distance away from the stagnationpoint before the strain rate becomes sufficiently low forthe molecule to relax again.

The results of the flow visualization study show thatthe flow along the symmetry axis in the wake of thesphere can be considerably perturbed by the presence ofthe polymer additives in the solution. It must be as-sumed that the strands of highly stretched birefringentpolymers in the wake of the sphere are the cause of theselarge alterations to the flow dynamics. A single localizedbirefringent line emanating from the trailing stagnationpoint causes a reduction in the strain rate at the stag-nation point due to the increase in extensional viscosity.The presence of this strand will affect the flow dynamicssuch that the point of greatest strain rate is movedradially away from the symmetry axis of the flow (i.e. thestagnation ‘‘point’’ may effectively become a ring cen-tred on the stagnation point), so that the birefringentstrand gets broader with increasing flow rate. As Deincreases and the birefringence spreads in a radialdirection from the stagnation point streamline, the flowalong the stagnation point streamline becomes increas-ingly screened from the bulk flow field. Eventually theflow velocity in the centre of the birefringent strand maybecome reduced such that the macromolecules therecannot stretch, resulting in the complex birefringentstructures that are observed. This is essentially the sameas was predicted by Harlen et al. (1992), who used aFENE dumbbell model with non-linear hydrodynamicfriction to show how birefringent pipe structures couldform in the flow of dilute polymer solutions near stag-nation points.

Our measurements of the flow field around the singlesphere are qualitative; however they show a similar formto the detailed measurements of Fabris et al. (1999) forspheres falling in a 0.16% solution of Mw=20·106 a-PSin a viscous solvent. The important message of our flowvisualisation study is that the flow field in an a-PSsolution can be significantly perturbed from a Newto-nian type flow field by the stretching of polymer mole-cules behind the sphere, even at very high dilution.

It seems reasonable to conclude that the excess stressfelt by the sphere in an a-PS solution (compared with thesolvent) is supported by the strain in the polymer mol-ecules in the wake of the sphere. There are two reasonswhy stretched polymers in the wake may contribute tothe force experienced by the sphere. First, the stretchedpolymeric material in the wake can be thought of as anelastic strand connected to the stagnation point andtrailing behind the sphere. Viscous forces between thebirefringent strand and the flowing solution will there-fore contribute to the drag force on the sphere. Second,entropic elastic forces are also likely to be significant

since the polymers in the birefringent strand are con-stantly striving to return to a randomly coiled confor-mation, which will pull the sphere towards the directionof flow.

The accumulation of strain by the polymer moleculesnear the stagnation point in the single sphere flow cell(visible as birefringence) is therefore responsible for theincrease in the apparent viscosity of the solution, whichhas the additional effect of causing modifications to theNewtonian flow field in the wake of the sphere. Theresulting interaction between the flow modification andthe polymer stretch may help to create the long wakebehind the sphere by maintaining a velocity gradientalong the stagnation streamline for several sphere radiidownstream.

This interaction is also likely to be the cause of flowinstabilities in the wake of the sphere at high De. Thestretching polymers modify the flow, which affects thepolymer stretch. This in turn modifies the flow further,resulting in the rapid fluctuation in the birefringentstructure, i.e. essentially visco-elastic instabilities. Itshould be noted that Harris and Rallison (1994) havesuggested a similar explanation for the occurrence offlow instabilities near an isolated stagnation point indilute dumbbell solutions incorporating non-linearhydrodynamic friction. Flow instabilities of this typehave also been observed in flow of a 0.25% solution ofMw=1.92·106 PS in a viscous solvent past a rear stag-nation point in a study by Li et al. (2000).

In the double sphere flow cell, the specific viscosity vsDe curves for the a-PS solutions indicate that polymermolecules undergo a coilMstretch transition in thewakes of both spheres. However the viscosity increasefor sphere 2 generally occurs at a higher strain rate thanfor sphere 1 and does not reach such a great plateauvalue.

Observations of birefringence in the wake of sphere 2indicate that the onset of molecular stretching is delayedto higher strain rate than in the single sphere flow cell.Also, for a given strain rate, the intensity of the bire-fringence is lower in the wake of sphere 2 than it is in thewake of sphere 1, which indicates that the polymersthere do not accumulate such a high degree of strain.

The specific viscosity curves and observations ofbirefringence in the double sphere cell are thereforeconsistent with each other and support the hypothesisthat the excess force experienced by the spheres inpolymer solutions, compared to the solvent, is due to theaccumulation of strain in the polymer molecules thatpass near the trailing stagnation points.

The birefringent lines coming from sphere 1 are evi-dently quite stable, as they are long lived on the timescaleof the molecular relaxation time and are not destroyed bythe flow field that surrounds sphere 2. The birefringentlines are probably best imagined as highly viscous andelastic oriented fibres or strands ‘‘attached’’ by one end

361

to the stagnation point of the sphere. The extensionalviscosity of the strands can be hugely increased by thepresence of highly extended molecules (Carrington andOdell 1996). However, the strands can also be thought ofas highly elastic, as there is a strong entropic restoringforce arising in the stretched macromolecules. Thisdescription of the birefringent strands provides expla-nations for both the increased drag force experienced bythe spheres above Deo and the flow modification in thewake seen in the single sphere flow cell.

Since the local fluid velocity in the wake of sphere 1 isknown to be reduced from the Newtonian value by thepresence of the polymer and the viscous birefringentstrands have been observed to follow the streamlinesaround sphere 2, the velocity effect can thus be ex-plained. It appears that sphere 2 effectively becomesconfined inside a slow moving, close-fitting, birefringenttube, formed from the strands originating from sphere 1.Inside the tube sphere 2 encounters fluid in which thepolymer molecules are un-stretched. Also the flowvelocity of fluid inside the birefringent tube is reducedfrom the bulk flow rate due to screening of the flow fieldby the extension-resisting strands.

The reduction in flow velocity in the wake of sphere 1may partially account for the velocity effect; however,the screening of the flow field around sphere 2 alsomeans that sphere 2 effectively experiences a lowerDeborah number than sphere 1. Hence sphere 2 expe-riences the increase in extensional viscosity at a highervolume flow rate than sphere 1. For a given volume flowrate less of the polymer molecular weight distributionwill stretch behind sphere 2 than sphere 1, so the bire-fringence will be lower resulting in a smaller increase inthe apparent extensional viscosity.

Conclusions

We have shown that monodisperse polymer molecules indilute solution stretch in flow around a sphere beyondan onset strain rate or Deborah number. The mostimportant region in the flow field for the accumulationof molecular strain is the trailing stagnation point of thesphere, where the strain rate is high and the residencetime is long, so that accumulated strains can be close tofull extension of the macromolecules. The effect is to

produce a birefringent strand in which the highly stret-ched molecules give rise to an appreciable increase in theextensional viscosity of the polymer solution, coupledwith a high entropic elastic restoring force. The strandsextend over long times and length scales, which weattribute to hysteresis in the coilMstretch, stretching andrelaxation processes.

At concentrations well below the conventional criticaloverlap concentration, c*, the increase in extensionalviscosity and elasticity in the wake of the sphere, due tothe presence of stretched polymer molecules, dramati-cally affects the local flow field in the wake. The inter-actions between the modified flow-field and the polymerstretch help to maintain the extended wake far down-stream of the sphere and, at high De, give rise to com-plex birefringent structures and flow instabilities.

The apparent onset Deborah number for polymerstretching at the stagnation point of a downstreamsphere (sphere 2) is increased compared to the firstsphere to encounter the flow (sphere1). Beyond the onsetDeborah number the extensional viscosity of the poly-mer solutions increases to a higher apparent value forflow around sphere 1 than for sphere 2. The differencesin the estimates of extensional viscosity between thespheres are consistent with the observations of bire-fringence of greater intensity and radial dimension be-hind sphere 1 than behind sphere 2. The differences inextensional viscosity and birefringence can be explainedby screening of the flow field around sphere 2 by thehighly viscous and elastic birefringent strands originat-ing from the stagnation point of sphere 1. We suggestthis as a mechanism for the ‘‘velocity effect’’ anomaliesin some falling ball systems.

These mechanisms are likely to be of major relevanceto the viscosification mechanism in porous media flow.The double sphere results show a marked reduction inthe effectiveness of the down-stream stagnation points inaligned systems due to screening effects. This might haveprofound implications for modelling of porous media byclose-packed arrangements of spheres, because localcrystallographic arrangements are likely to result inalignment and therefore reduce the effectiveness ofstagnation points (Haward and Odell 2003).

Acknowledgements We gratefully acknowledge the support ofEPSRC and the EU Alfa programme. We are indebted to DrS.P. Carrington for helpful discussions.

References

Arigo MT, Rajagopalan D, Shapley N,McKinley GH (1995) The sedimenta-tion of a sphere through an elastic fluid.Part 1. Steady motion. J Non-Newto-nian Fluid Mech 60:225–257

Berry GC (1967) Thermodynamic andconformational properties of polysty-rene. II. Intrinsic viscosity studies ondilute solutions of linear polystyrene.J Chem Phys 46:1338–1352

Bisgaard C (1983) Velocity fields aroundspheres and bubbles investigated by la-ser-Doppler velocimetry. J Non-New-tonian Fluid Mech 12:283–302

362

Carrington SP, Odell JA (1996) How dopolymers stretch in stagnation pointextensional flow-fields?. J Non-Newto-nian Fluid Mech 67:269–283

Carrington SP, Odell JA (2003) Extensionalflow oscillatory rheometry. J Rheol(submitted)

Carrington SP, Tatham JP, Odell JA, SaezAE (1997a) Macromolecular dynamicsin extensional flows. 1. Birefringenceand viscometry. Polymer 38:4151–4164

Carrington SP, Tatham JP, Odell JA, SaezAE (1997b) Macromolecular dynamicsin extensional flows. 2. The evolution ofmolecular strain. Polymer 38:4595–4607

Cathey CA, Fuller GG (1990) The opticaland mechanical response of flexiblepolymer solutions to extensional flow.J Non-Newtonian Fluid Mech 34:63–88

Chhabra RP, Uhlherr PHT (1979) Estima-tion of zero-shear viscosity of polymersolutions from falling sphere data.Rheol Acta 18:593–599

Chilcott MD, Rallison JM (1988) Creepingflow of dilute polymer solutions pastcylinders and spheres. J Non-Newto-nian Fluid Mech 29:381

Cho YI, Hartnett JP, Lee WY (1984) Non-Newtonian viscosity measurements inthe intermediate shear rate range withthe falling-ball viscometer. J Non-Newtonian Fluid Mech 15:61–74

de Gennes PG (1974) Coil-stretch transitionof dilute flexible polymers under ultra-high velocity gradients. J Chem Phys60:5030–5042

Degand E, Walters K (1995) On the motionof a sphere falling through an elasticliquid contained in a tightly-fittingcylindrical container. J Non-NewtonianFluid Mech 57:103–115

Durrans TH (1971) Solvents, 8th edn.Chapman and Hall, London

Fabris D, Muller SJ, Liepmann D (1999)Wake measurements for flow around asphere in a viscoelastic fluid. PhysFluids 11:3599–3612

Gottlieb M (1979) Zero-shear-rate viscositymeasurements for polymer solutions byfalling ball viscometry. J Non-Newto-nian Fluid Mech 6:97–109

Graessley WW (1980) Polymer chaindimensions and the dependence of vis-coelastic properties on concentration,molecular weight and solvent power.Polymer 21:258–262

Harlen OG (1990) High-Deborah-numberflow of a dilute polymer solution past asphere falling along the axis of a cylin-drical tube. J Non-Newtonian FluidMech 37:157

Harlen OG, Rallison JM, Chilcott MD(1990) High-Deborah-number flows ofdilute polymer solutions. J Non-New-tonian Fluid Mech 34:319–349

Harlen OG, Hinch EJ, Rallison JM (1992)Birefringent pipes: the steady flow of adilute polymer solution near a stagna-tion point. J Non-Newtonian FluidMech 44:229–265

Harris OJ, Rallison JM (1994) Instabilitiesof a stagnation point flow of a dilutepolymer solution. J Non-NewtonianFluid Mech 55:59–90

Haward SJ, Odell JA (2003) Viscosityenhancement in non-Newtonian flow ofdilute polymer solutions through crys-tallographic porous media. Rheol Acta42:516–526

Hinch EJ (1977) Mechanical models ofdilute polymer solutions in strong flows.Phys Fluids 20:S22–S30

Jones WM, Price AH, Walters K (1994)The motion of a sphere falling undergravity in a constant-viscosity elasticliquid. J Non-Newtonian Fluid Mech53:175–196

Leal LG, Denn MM, Keunings R (1988)Lake Arrowhead workshop special issuepapers. Introduction. J Non-NewtonianFluid Mech 29:1–8

Li J-M, Burghardt WR, Yang B, KhomamiB (2000) Birefringence and computa-tional studies of a polystyrene Bogerfluid in axisymmetric stagnation flow.J Non-Newtonian Fluid Mech 91:189–220

Peterlin A (1961) Streaming birefringenceof soft linear macromolecules with finitechain length. Polymer 2:257–264

Riddle MJ, Narvaez C, Bird RB (1977)Interactions between two spheres fallingalong their line of centres in a visco-elastic fluid. J Non-Newtonian FluidMech 2:23–35

Solomon MJ, Muller SJ (1996) Flow past asphere in polystyrene-based Boger flu-ids: the effect on the drag coefficient offinite extensibility, solvent quality andpolymer molecular weight. J Non-Newtonian Fluid Mech 62:81–94

Treloar LKG (1975) The physics of rubberelasticity, 3rd edn. Clarendon Press,Oxford

363