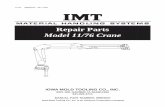

Repair Parts Model 11/76 Crane - Iowa Mold Tooling Co., Inc.

Mold Making Arte Tooling

-

Upload

arte-tooling -

Category

Business

-

view

423 -

download

1

Transcript of Mold Making Arte Tooling

Introduction

Molding is the process of manufacturing by shaping liquid orpliable raw material using a rigid frame called a mold or matrix,manufacturing by shaping pliable raw material using a rigid frameor model called a pattern. This itself may have been made using apattern or model of the final object.

The manufacturer who makes the molds is called the mold maker.A release operators is ordinarily used to make evacuation of thesolidified/set substance from the mold less demanding.

Types of molding include

• Blow molding• Compression molding• Extrusion molding• Injection molding• Laminating• Reaction injection molding• Matrix molding• Rot molding• Transfer molding

Injection Molding

• Injection Molding It is a fast process and is used to produce large numbers of identical items from high precision engineering components to disposable consumer goods. It is a fast process and is used to produce large numbers of identical items from high precision engineering components to disposable consumer goods.

• The process is very fast and complicated shapes can be made from both thermoplastic and thermosetting polymers.

Types of Injection Molding

• Reaction injection molding• Liquid injection molding• Gas assist injection molding• Co-injection molding• Shot Injection Molding• Fusible core injection molding• Rapid injection molding

Arte Tooling’s other major services

• Rapid prototyping• Plastic injection tooling and molding• CNC Machining• Pressure die casting