Mold cleaning machine for optical components CLIPIKA ACE OPT

Transcript of Mold cleaning machine for optical components CLIPIKA ACE OPT

Example of cleaning a mold for prism sheets

▲ Before cleaning ▲ After cleaning with the CLIPIKA ACE OPT

(Laser microscope, magnification×1000 [height, cross-sectional form (horizontal/vertical axes)])

Adhesion of dirt and grime observed

SOMAX facility: Laser microscope

The mold is revived by removing dirt and grime without any damage

FeaturesCLIPIKA ACE OPT

▼

Anode electrodes made of a rare metalWith the CLIPIKA ACE OPT series, particular attention is given to the affinity with nickel. It adopts special material properties that take into consideration differences in potential, ionization trends, infiltration of foreign matter and chemical reactions.

2

No toxic gas generated by electrolysis.

Superior swelling effect against dirt and grime.

Protected against foreign matter infiltration throughout the full manufacturing process from the selection of raw material to production.

Allows the electric current to run efficiently at a low voltage

Made with a special inhibitor for nickel to prevent adsorption and precipitation of foreign matter.

Specified cleaning solution developed exclusively for delicate optical components

3

Saves space with a flip-up systemThere is no need to secure extra space for the anode electrodes.

4

※The cleaning solution level drops automatically after cleaning.

Foams generated during cleaning that contain impurities are collected to prevent the impurities from attaching to the mold again.

It is easy to load and unload molds since the cleaning solution is transferred from the cleaning tank to the cleaning solution heating tank after the cleaning automatically.

Cleaning solution overflow system5

This ultrasonic wave irradiation system demonstrates its cleaning performance without damaging delicate molds for optical components, such as nickel-electroformed stampers and nickel-plated molds

Ultrasonic wave irradiation system that does not cause any damage, even on the level of nanometers, to molds for optical components

1

Validated after a 3 hours of continuous cleaning with 28/40 kHz ultrasonic waves produced by CLIPIKA ACE OPT

(Electron microscope, magnification×3000)(Electron microscope, magnification×3000)

28 kHz ultrasonic waves 40 kHz ultrasonic waves

After cleaning with the CLIPIKA ACE OPTBefore cleaning

Comparison of damages to a nickel-electroformed stamper due to ultrasonic wave cleaning

CLIPIKA ACE OPTComparison with conventionalmaintenance methodComparison with conventionalmaintenance method

Optical waveguide mold (optical microscope, magnification×100)Optical waveguide mold (optical microscope, magnification×100)

Lens mold (optical microscope, magnification×100)Lens mold (optical microscope, magnification×100)

Optical waveguide mold (optical microscope, magnification×100)Optical waveguide mold (optical microscope, magnification×100)

Lens mold (optical microscope, magnification×100) Lens mold (optical microscope, magnification×100)

▲Problem: Scratches caused by manual maintenance

▲Problem: Dirt and grime cannot be removed completely by wiping with solvent

Current maintenance method: Swiping with a cotton swab impregnated with alcohol

Current maintenance method: Wiping with a sponge swab impregnated with a solvent

▲Solution to the problem: The CLIPIKA ACE OPT does not cause any damage to the mold.

▲Solution to the problem: The CLIPIKA ACE OPT removes even the most stubborn dirt and grime completely.

After cleaning with the CLIPIKA ACE OPT

After cleaning with the CLIPIKA ACE OPT

Company O, Osaka

Company A, Mie

Eliminate manual operations, in which a difference in the skill level can cause scratches.

Save the time and manpower spent on maintaining molds.

Remove dirt and grime on the surface of molds for optical components without inflicting damage.

Solve problems with the CLIPIKA ACE OPT.

ComparisonsCLIPIKA ACE and CLIPIKA ACE OPT

OPT- H3023

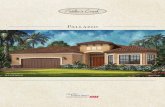

Mold cleaning machinefor optical components

CLIPIKA ACE OPT

CPⅢ- 66-H15

Steel mold cleaning machineCLIPIKA ACE

Cleaning solution 102C Super HG

Cleaning solution 102C Super HG

This system cleans delicate molds used for making optical componentswithout causing any damageby ultrasonic wave irradiation.

Indirect irradiation of ultrasonic wave

Foams generated duringcleaning that contain impuritiesare collected to prevent the impurities from reattaching to the mold.

Cleaning solution overflow system

It is easy to load and unload the mold since the cleaning solution is automatically transferred from the cleaning tank to the cleaning solution heating tank after cleaning.

Independent cleaning tank and

cleaning solution tankAnode electrode for OPT focusing on the affinity with nickel

DiscLath

Rare metal

Cleaning solution 102C Super

Cleaning solution 107

Special cleaning solutions for strong steel molds unsusceptible to damage

Cleaning solution 102C Super,

cleaning solution 107

Specified cleaning solution

Ultrasonic wave irradiation system

This system makes ultrasonic irradiation efficient by putting the ultrasonic wave transducer close to the mold.

Direct irradiation of ultrasonic wave

Anode electrode material

Anode electrode developed for steel molds

Oval Disc

Iron

Circulation method

This circulation method drains the cleaning solution from the bottom of the cleaning tank and discharges it at the surface level.

Cleaning solution circulation within

the tank

Loading and unloading the mold

Only one cleaning tankWith this system, a cleaning basket containing a mold is submerged in a cleaning tank filled with the cleaning solution and then the anode electrodes are set.

Flip-up anode electrode

The anode electrodes are attached to the flip-up cover of the cleaning tank to save on space.

Anode electrode mounting method

Manual setting onto the cleaning tankThe suspended anode electrodes need to be removed and placed in a location that does not hinder operation every time the mold is taken in and out of the cleaning tank.

OPT specificationA plastic cover of superior insulation performance is attached to the stainless steel cleaning tank to improve the efficiency of electrolysis.

Efficiency of electrolysis

Simple constructionThe cleaning tank features a simple construction with the stainless steel exposed without any insulated lining.

This special cleaning solution is for delicate molds for optical components. It contains a special inhibitor for nickel to prevent the infiltration of impurities and adsorption/precipitation of foreign matter.

Setting the mold

2

5

Primary washing by immersion

4

Submerging in purified water (May be omitted.)

3

CLIPIKA ACE OPT cleaning

6

Secondary washing by immersion (May be omitted.)

7 Ethanol substitution (May be omitted.)

Tertiary washing by flushing

Drying by clean air blow

Drying with fluorinated solvent vapor

1

If the mold will not be flushed with water immediately after cleaningwith CLIPIKA ACE OPT, submerging it in purified water will help prevent impurities from reattaching to the mold.Wash the mold for 5 seconds or longer by swaying it back and forth in purified water.This helps to dilute the cleaning solution attached to the mold and jigs.

Spray ethanol over the mold to remove any remaining moisture from the mold.

In order to remove the cleaning solution clinging to the mold and jigs completely, repeat washing in purified water in the same manner as primary washing.

Before the ethanol evaporates, quickly apply a clean air blow to dry the mold.

Finally, spray purified water over the mold for 10 seconds or longer to remove the cleaning solution clinging to the mold completely.

Apart from the clean air blow, it is also possible to dry the mold after the ethanol substitution process by placing it in the vapor generated by heating a fluorinated solvent.Although the time depends on the shape and size of the mold, drying will be complete in about 10 minutes.(Longer time may be required for drying depending on the shape and size of the mold.)

・・・・・

・・・・・・・・・・

・・・・・

・・・・・

・・・・・・・

・・・・

・・・・・・・・

Run the CLIPIKA ACE OPT.・・・

Place a mold used for making optical components in the cleaning basket and then set the basket in the CLIPIKA ACE OPT.

・・・・・・・・・

8-a

8-b

Cleaning processCleaning processCLIPIKA ACE OPT

2017.11

OPT- H2015

Global standard model that clears the stringent safety regulations for use in the EU countries.

CLIPIKA ACE OPT series

CPⅡ-2430-CE-OPT(Model with the CE marking)

OPT- H3023

▲

1-7-17 Tamatsu, Higashinari-ku, Osaka 537-0023Tel:+81-6-6976-1108 E-mail: [email protected]:+81-6-6977-5702 http://www.somax.co.jp