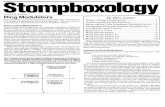

MODS USA brochure email

Transcript of MODS USA brochure email

www.modsmanagement.com

a division ofa division of

A Step Change, driven by MODS technology for asset economic viability

Reduce CostsReduce SchedulesAchieve TargetsWork Safely

With global Oil and Gas CAPEX cuts continuing, it has never been more critical, to make sure the principle objective to minimize life cycle

costs and maximize productivity; are actually being met.

As Operational costs rise, placing further pressure on Owner Operators, it is a struggle remaining commercially viable and maintain existing assets in order to prevent problems occurring. With some Operators canceling or delaying projects, the industry needs to adapt its long term goals using available technology developed by niche companies like MODS, to increase the economic viability of existing and future assets.

The ROI delivered to Operators by completing projects depends not just on the minimization of project CAPEX, but the long-term goal of minimizing the operating costs of the assets life-cycle.

MODS provides an affordable and easily adoptable solution utilizing experience personnel, 3D technology and Advanced Work-flow Processes, to reduce costs throughout CAPEX and OPEX phases and help institutionalize Operation Excellence in organizations.

Risk Mitigation

Knowledge Sharing

Integrity

Productivity

Integration

MODS achieve this by addressing five key factors that have an effect on operations:

IntegrityReal-time verification, matrix based authorizations and real-time reporting. Global cloud-based access to data to get the right information, at the right time, for practical leadership. A fully auditable and verified trail, assuring operating procedures and legislative compliance are being implemented.

Knowledge SharingRecord everything in secure, reliable archives, assisted by using RFID’s, Barcodes and Intrinsically Safe hand-held devices. Analyze data to improve efficiency levels. Use lessons learned to eliminate the mundane tasks and speed up critical decisions. A single source of truth for engineering data verified against the true basis of design enabling reporting of correct up to date data.

IntegrationOptimize operating practices, procedures, and behaviors to get maximum productivity. Create a culture where the team can work together economically and efficiently and in line with Operational Excellence and on schedule.

ProductivityAdvanced Work-flow System that captures essential data in a digital capacity. Verified and automated dissemination and system population of information. Eliminate the repetition and margin for error enabling Owner Operators to keep assets in a safe and reliable functioning condition, according to pre-defined operational excellence requirements.

Risk MitigationTechnology to give you immediate, accurate access to critical information in 3D visibility, systems data and customized reports. The ability to have effective and predictable control measures through transparent cross-discipline data sharing for informed decision-making. Reliable information to implement proactive measures rather than reactive.

How can MODS help you?MODS Innovative solutions cover six key areas:

OperationsTurnaroundsDecommissioning

ConstructionHook-upsCommissioning

MODS Solutions:Reduce cost and schedules

Optimize critical paths

Enhance visibility

Streamline knowledge transfer

Optimize resource management

Prioritize integrity management

Increase efficiency levels

Achieve full traceability

Administer accountability

Minimize downtime

Improve productivity

Stabilize operations

There has been little change since the early sixties in use of technology and processes to document asset management, especially in the completions and performance testing of Oil and Gas facilities. Existing software solutions still follow the same logic and culture by disregarding the visibility and structure of 3D design model data. They rely heavily on color coded markups of the P&IDs and endless technical documents that are deliverables of the 3D model to setup and administer the processes.

As far back as 1992 the industry recognized that using the 3D model to manage the life of plant would improve efficiency and maximize the ROI. But until recently there has been no incentive for change and a reluctance for operators to invest. The recent downturn in the oil price has started a rush for innovation to improve the ROI.

Over ten years ago MODS recognized the niche in the market and have been actively engaged in developing products and services implemented around a cloud-based model-centric solution that delivers efficiency and integrity to Operators assets from cradle to grave.

Our core valuesHealth and Safety, Integrity, Performance and Innovation; these are long-term commitments, which guide MODS Management in making our decisions and conducting business.

We work with our customers in long-term partnerships that help improve their productivity and profitability, and safety.

Time for change

MODS provides specialized services that deliver five critical pillars to support Oil and Gas Projects and Operations.

D2CADJOINTMANAGEMENT

Utilizing MODS 3D software, Virtual Manager (VM), supported by our experienced personnel, we provide a single source interface for projects and operations, reducing complexity and breaking down silos. Streamlined and automated processes in VM means costs can be signi�cantly reduced and resources can be used with greater e�ciency.

An e�ective and e�cient service to ensure the reduction of hydrocarbon leaks Utilizing our 3D Integrity, tracking and verifying technology, alongside highly skilled asset personnel, we o�er a unique and complete life-cycle package for the Oil and Gas industry.

Our innovative solutions, combined with extensive experience in the oil and gas sector, enables us to be a trusted Joint Integrity Management Provider for all types of piping systems.

Our priority is to provide a service that gives you con�dence that every step will be taken to give you systems integrity assurance. Accountable Integrity directly reduces risks to production and is valuable to Process Safety and Major Hazard avoidance.

Our services include:

Bolt torquing and tensioning

Pipe hydrostatic testing

Systems leak & weld isolation testing

Mechanical cutting and bevelling pipework

We transform industry best practice using the latest high definition scanning technology and our bespoke software D2CAD to interpret survey data efficiently and verify design to improve assurance of dimensional control and space management solutions.

Proactive dimensional control provides verification of design and fabrication to give confidence that solutions are installed efficiently, safely and incident-free.

Heavy Lift AssuranceInstallation Guides

Use of fine guides

Exclusion zones

3rd Party assurance for Heavy Lift Contractor

Construction VerificationMain Structural Layout

Verification of bumper and guide tolerances

Main interface checks between buckets and pins

Major Equipment layout

Tie-Point position for Hook-Up items

JOBSETTINGCOMPLETIONS

Delivering the right materials to the right place at the right time

Improves work control and increases productivity

Minimizes hotwork o�shore, reduces man hours and improves safety

* Full Joint Management service currently only available in the USA. Joint Integrity Software available globally.