MODEL PWFY-P100VM-E-BU PWFY-P100VM-E1-AU PWFY...

Transcript of MODEL PWFY-P100VM-E-BU PWFY-P100VM-E1-AU PWFY...

DATA BOOK

5th edition

PWFY-P100VM-E-BUPWFY-P100VM-E1-AUPWFY-P200VM-E1-AU

MODEL

- � -

• Donotuserefrigerantotherthanthetypeindicatedinthemanualsprovidedwiththeunitandonthenameplate.

- Do�ng so may cause the un�t or p�pes to burst, or result in explosion or fire during use, during repair, or at the time of disposal of the unit.

- It may also be in violation of applicable laws.- MITSUBISHI ELECTRIC CORPORATION cannot

be held responsible for malfunctions or accidents result�ng from the use of the wrong type of refrigerant.

• Donotusesteelpipesaswaterpipes.- Copper pipes are recommended. • Thewatercircuitshouldbeaclosedcircuit.• Askthedealeroranauthorizedtechnicianto

installtheairconditioner.- Improper �nstallat�on by the user may result �n water

leakage, electric shock, or fire.• Installtheunitinaplacethatcanwithstandits

weight.- Inadequate strength may cause the unit to fall down,

resulting in injuries.• Donottouchtheunit.Theunitsurfacecanbehot.• Donotinstalltheunitwherecorrosivegasis

generated.• Usethespecifiedcablesforwiring.Makethe

connectionssecurelysothattheoutsideforceofthecableisnotappliedtotheterminals.

- Inadequate connection and fastening may generate heat and cause a fire.

• Prepareforrainandothermoistureandearthquakesandinstalltheunitatthespecifiedplace.

- Improper �nstallat�on may cause the un�t to topple and result in injury.

• AlwaysuseanstrainerandotheraccessoriesspecifiedbyMitsubishiElectric.

- Ask an authorized technician to install the accesso-ries. Improper installation by the user may result in water leakage, electric shock, or fire.

• Neverrepairtheunit.Iftheairconditionermustberepaired,consultthedealer.

- If the unit is repaired improperly, water leakage, electric shock, or fire may result.

• DonottouchtherefrigerantpipesandWaterpipes.

- Improper handling may result in injury.• Whenhandlingthisproduct,alwayswearprotec-

tiveequipment. EG:Gloves,fullarmprotectionnamelyboilersuit,

andsafetyglasses.- Improper handling may result in injury.• Ifrefrigerantgasleaksduringinstallationwork,

ventilatetheroom.- If the refrigerant gas comes into contact with a flame,

poisonous gases will be released.• Installtheunitaccordingtothismanual.- If the unit is installed improperly, water leakage,

electric shock, or fire may result.• Haveallelectricworkdonebyalicensedelectri-

cianaccordingto“ElectricFacilityEngineeringStandard”and“InteriorWireRegulations”andtheinstructionsgiveninthismanualandalwaysuseaspecialcircuit.

- If the power source capacity is inadequate or electric work is performed improperly, electric shock and fire may result.

• Keeptheelectricpartsawayfromwater(washingwateretc.).

- It might result in electric shock, catching fire or smoke.

• Securelyinstalltheheatsourceunitterminalcover(panel).

- If the terminal cover (panel) is not installed properly, dust or water may enter the heat source unit and fire or electric shock may result.

• Wheninstallingandmovingtheairconditionertoanothersite,donotchargeitwitharefrigerantdifferentfromtherefrigerant(R410A)specifiedontheunit.

- If a different refrigerant or air is mixed with the origi-nal refr�gerant, the refr�gerant cycle may malfunct�on and the unit may be damaged.

SafetyPrecautions

- �� -

• Donotusetheexistingrefrigerantpiping.- The old refrigerant and refrigerant oil in the existing

p�p�ng conta�ns a large amount of chlor�ne wh�ch may cause the refrigerant oil of the new unit to dete-riorate.

- R410A is a high-pressure refrigerant and can cause the existing piping to burst.

• UserefrigerantpipingmadeofC1220(CU-DHP)phosphorusdeoxidizedcopperasspecifiedintheJISH3300“Copperandcopperalloyseamlesspipesandtubes”.Inaddition,besurethatthein-nerandoutersurfacesofthepipesarecleanandfreeofhazardoussulphur,oxides,dust/dirt,shav-ingparticles,oils,moisture,oranyothercontami-nant.

- Contaminants on the inside of the refrigerant piping may cause the refrigerant residual oil to deteriorate.

• Storethepipingtobeusedduringinstallationindoorsandkeepbothendsofthepipingsealeduntiljustbeforebrazing.(Storeelbowsandotherjointsinaplasticbag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and compressor trouble may result.

• Applyasmallamountofesteroil,etheroil,oralkylbenzenetoflares.(forindoorunit)

- Infiltration of a large amount of mineral oil may cause the refrigerant oil to deteriorate.

• Useliquidrefrigeranttofillthesystem.- If gas refrigerant is used to seal the system, the

composition of the refrigerant in the cylinder will change and performance may drop.

• DonotusearefrigerantotherthanR410A.- If another refrigerant (R22, etc.) is mixed with

R410A, the chlor�ne �n the refr�gerant may cause the refrigerant oil to deteriorate.

• Useavacuumpumpwithareverseflowcheckvalve.

- The vacuum pump oil may flow back into the refrig-erant cycle and cause the refrigerant oil to deterio-rate.

• Donotusethefollowingtoolsthatareusedwithconventionalrefrigerants.

(Gaugemanifold,chargehose,gasleakdetector,reverseflowcheckvalve,refrigerantchargebase,refrigerantrecoveryequipment)

- If the conventional refrigerant and refrigerant oil are mixed in the R410A, the refrigerant may deterio-rated.

- If water is mixed in the R410A, the refrigerant oil may deteriorate.

- Since R410A does not contain any chlorine, gas leak detectors for conventional refrigerants will not react to it.

• Donotuseachargingcylinder.- Using a charging cylinder may cause the refrigerant

to deteriorate.• Donotuseantioxidantorleak-detectionadditive.• Beespeciallycarefulwhenmanagingthetools.- If dust, dirt, or water gets in the refrigerant cycle, the

refrigerant may deteriorate.

• Iftheairconditionerisinstalledinasmallroom,measuresmustbetakentopreventtherefriger-antconcentrationfromexceedingthesafetylimiteveniftherefrigerantshouldleak.

- Consult the dealer regarding the appropriate meas-ures to prevent the safety limit from being exceeded. Should the refrigerant leak and cause the safety limit to be exceeded, hazards due to lack of oxygen in the room could result.

• Whenmovingandreinstallingtheairconditioner,consultthedealeroranauthorizedtechnician.

- If the air conditioner is installed improperly, water leakage, electric shock, or fire may result.

• Aftercompletinginstallationwork,makesurethatrefrigerantgasisnotleaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove, oven, or other heat source, �t may gen-erate noxious gases.

• Donotreconstructorchangethesettingsoftheprotectiondevices.

- If the pressure sw�tch, thermal sw�tch, or other protection device is shorted and operated forcibly, or parts other than those specified by Mitsubishi Electric are used, fire or explosion may result.

• Todisposeofthisproduct,consultyourdealer.• Theinstallerandsystemspecialistshallsecure

safetyagainstleakageaccordingtolocalregula-tionorstandards.

- Following standards may be applicable if local regu-lation are not available.

• Payaspecialattentiontotheplace,suchasabasement,etc.whererefrigerationgascanstay,sincerefrigerationisheavierthantheair.

- ��� -

• Donotinstalltheunitwherecombustiblegasmayleak.

- If the gas leaks and accumulates around the unit, an explosion may result.

• Donotusetheairconditionerwherefood,pets,plants,precisioninstruments,orartworkarekept.

- The quality of the food, etc. may deteriorate.• Donotusetheairconditionerinspecialenviron-

ments.- Oil, steam, sulfuric smoke, etc. can significantly reduce

the performance of the air conditioner or damage its parts.

• Wheninstallingtheunitinahospital,communica-tionstation,orsimilarplace,providesufficientprotectionagainstnoise.

- The inverter equipment, private power generator, high-frequency medical equipment, or radio commu-nication equipment may cause the air conditioner to operate erroneously, or fail to operate. On the other hand, the air conditioner may affect such equipment by creating noise that disturbs medical treatment or image broadcasting.

• Donotinstalltheunitonastructurethatmaycauseleakage.

- When the room humidity exceeds 80 % or when the drain pipe is clogged, condensation may drip from the indoor unit. Perform collective drainage work together with the unit, as required.

- �v -

• Groundtheunit.- Do not connect the ground wire to gas or water

pipes, lightning rods, or telephone ground lines. Improper grounding may result in electric shock.

• Installthepowercablesothattensionisnotappliedtothecable.

- Tension may cause the cable to break and generate heat and cause a fire.

• Installaleakcircuitbreaker,asrequired.- If a leak circuit breaker is not installed, electric shock

may result.• Usepowerlinecablesofsufficientcurrent

carryingcapacityandrating.- Cables that are too small may leak, generate heat,

and cause a fire.• Useonlyacircuitbreakerandfuseofthe

specifiedcapacity.- A fuse or c�rcu�t breaker of a larger capac�ty or a

steel or copper w�re may result �n a general un�t failure or fire.

• Donotwashtheairconditionerunits.- Washing them may cause an electric shock.• Becarefulthattheinstallationbaseisnot

damagedbylonguse.- If the damage is left uncorrected, the unit may fall

and cause personal injury or damage property.• Installthedrainpipingaccordingtothismanualto

ensureproperdrainage.Wrapthermalinsulationaroundthepipestopreventcondensation.

- Improper drain piping may cause water leakage and damage to furniture and other possessions.

• Beverycarefulaboutproducttransportation.- If the un�t we�ghs more than 20kg, carry the un�t w�th

more than one person.- Some products use PP bands for packaging. Do not

use any PP bands for a means of transportation. It is dangerous.

- When transporting the unit, support it at the specified positions on the unit base. Also support the unit at four points so that it cannot slip side ways.

• Safelydisposeofthepackingmaterials.- Packing materials, such as nails and other metal or

wooden parts, may cause stabs or other injuries.- Tear apart and throw away plastic packaging bags

so that it is out of reach of children. If children play w�th a plast�c bag wh�ch was not torn apart, they face the risk of suffocation.

- v -

• Turnonthepoweratleast12hoursbeforestartingoperation.

- Starting operation immediately after turning on the main power switch can result in severe damage to internal parts. Keep the power switch turned on during the operational season.

• Donottouchtheswitcheswithwetfingers.- Touching a switch with wet fingers can cause elec-

tric shock.• Donottouchtherefrigerantpipesduringandim-

mediatelyafteroperation.- During and immediately after operation, the

refrigerant pipes are may be hot and may be cold, depending on the condition of the refrigerant flowing through the refrigerant piping, compressor, and other refrigerant cycle parts. Your hands may suffer burns or frostbite if you touch the refrigerant pipes.

• Donotoperatetheairconditionerwiththepanelsandguardsremoved.

- Rotat�ng, hot, or h�gh-voltage parts can cause injuries.

• Donotturnoffthepowerimmediatelyafterstoppingoperation.

- Always wait at least five minutes before turning off the power. Otherwise, water leakage and trouble may occur.

• Donottouchthesurfaceofthecompressorduringservicing.

- If unit is connected to the supply and not running, crank case heater at compressor is operating.

• Donottouchthepanelsnearthefanoutletwithbarehands:theycangethotwhiletheunitisinoperation(evenifitisstopped)orimmediatelyafteroperationtopreventburns.Wearglovestoprotectyourhandswhenitisnecessarytotouchthepanels.

• Whiletheunitisinoperationorimmediatelyafteroperation,high-temperatureexhaustairmayblowoutofthefanexhaustoutlet.Donotholdyourhandsovertheoutletortouchthepanelsneartheoutlet.

• Besuretoprovideapathwayfortheexhaustairfromthefan.

• Waterpipescangetveryhot,dependingonthepresettemperature.Wrapthewaterpipeswithinsulatingmaterialstopreventburns.

ContentsSafetyPrecautions

I GeneralEquipmentDescriptions

1. Unit configuration table ················································· 12. Operable temperature range ······································· 13. Connectable outdoor unit/heat source unit

capac�ty range ······························································· 2

II ProductSpecifications1. Specifications ································································· 3

(1) PWFY-P100VM-E-BU(2) PWFY-P100VM-E1-AU(3) PWFY-P200VM-E1-AU(4) CMB-P104V-G1(5) CMB-PW202V-J

2. External Dimensions ····················································· 7(1) PWFY-P100VM-E-BU(2) PWFY-P100, 200VM-E1-AU(3) CMB-P104,105,106,108,1010,1013,1016V-G1(4) CMB-PW202V-J

3. Electrical Wiring Diagrams ········································· 11(1) PWFY-P100VM-E-BU(2) PWFY-P100, 200VM-E1-AU(3) CMB-P104V-G1(4) CMB-PW202V-J

4. Accessories ···································································15(1) PWFY(2) CMB-P104V-G1(3) CMB-PW202V-J

5. Optional parts ·······························································16(1) Solenoid valve kit

III ProductData1. Capacity tables·····························································17

(1) Correction by temperature (Estimated performance without defrost)

(2) Correct�on by water flow rate(3) Correction by total indoor(4) Correct�on by refr�gerant p�p�ng length(5) Correction at frosting and defrosting(6) Water pressure drop(7) Operat�on temperature range

2. Sound pressure levels ················································ 44(1) PWFY-P100VM-E-BU(2) PWFY-P100, 200VM-E1-AU

3. Vibration levels ·····························································45(1) PWFY-P100VM-E-BU

4. Refrigerant circuit diagrams and thermal sensors ····· 46(1) PWFY-P100VM-E-BU(2) PWFY-P100VM-E1-AU(3) PWFY-P200VM-E1-AU(4) PAC-SV01PW-E

IV Installation1. How to calculate the necessary heating capacity ·· 48

(1) Heat�ng capac�ty calculat�on(2) Calculat�on example

2. Installation ·····································································49(1) Select�ng an �nstallat�on s�te(2) Install�ng the un�t(3) Refrigerant pipe and drain pipe specifications(4) Connecting refrigerant pipes and drain pipes

3. Water pipe installation················································· 55(1) Water c�rcu�t sample(2) Select�ng a water pump(3) Install�ng the stra�ner(4) Precautions during installation(5) Example of un�t �nstallat�on(6) Insulat�on �nstallat�on(7) Flow sw�tch �nstallat�on(8) Water processing and water quality control(9) Br�ne(10) Pump �nterlock(11) Anti freeze mode (Dip SW4-4 ON)

V SystemDesign1. Electrical work ······························································63

(1) General cautions(2) Power supply for PWFY unit(3) Connecting remote controller, indoor and outdoor

transm�ss�on cables(4) Transm�ss�on cable spec�f�cat�ons(5) Connect�ng electr�cal connect�ons(6) Indoor unit address setting(7) External input/output function

2. Piping Design ·······························································75(1) BC controller piping design(2) WCB piping design(3) Solenoid valve kit piping design(4) Refr�gerant charg�ng calculat�on (R2 system)(5) Refr�gerant charg�ng calculat�on

(PWFY-AU with R2 system)

VI Controller1. PAR-W21MAA specifications·····································822. Dip switch functions ····················································83

VIIMaintenanceCycle1. Routine maintenance checks ····································842. Parts Replacement Cycle···········································84

VIIIProductData(additionalinformationforchapterIII.)

1. Outdoor unit capacity tables ······································85(1) Correction by total indoor(2) Correct�on by refr�gerant p�p�ng length(3) Correction at frosting and defrosting

- 1 -

1.UnitconfigurationtableModel PWFY-P100VM-E-BU PWFY-P100VM-E1-AU PWFY-P200VM-E1-AU

Outdoor unitR2, Replace R2 ser�es,

WR2 ser�es only

S series, Y, Replace Y series, HP (ZUBADAN) series, WY series,R2, Replace R2 ser�es, WR2 ser�es

Y, Replace Y series, HP (ZUBADAN) series, WY series,R2, Replace R2 ser�es, WR2 ser�es

Connect�onBC controller

BC controller: CMB-P104,105,106,108,1010,1013,1016V-G1Main BC controller: CMB-P108,1010,1013,1016V-GA1 / CMB-P1016V-HA1

Sub BC controller: CMB-P104,108V-GB1 / CMB-P1016V-HB1 WCB CMB-PW202V-J

2.Operabletemperaturerange<PWFY-P100VM-E-BU>

Only PWFY PWFY with standard indoor unit

Only standard indoor units

Heat�ngInlet water temperature R2/WR2 series 10 to 70ºC 10 to 70ºC –Outdoor temperature R2 ser�es -20 to 32ºCWB -20 to 32ºCWB -20 to 15.5ºCWBC�rculat�ng water temperature WR2 ser�es 10 to 45ºC 10 to 45ºC 10 to 45ºC

<PWFY-P100,200VM-E1-AU>Only PWFY PWFY with standard indoor units

Cool�ng Heat�ng Cool�ng Heat�ng

Inlet water temperatureR2/WR2 series 10 to 35ºC 10 to 40ºC 10 to 35ºC 10 to 40ºCS ser�es *1 – 10 to 45ºC – –Y/HP/WY series 10 to 35ºC 10 to 40ºC 10 to 35ºC 10 to 40ºC

Outdoor temperature

R2 ser�es -5 to 46ºCDB -20 to 32ºCWB -5 to 46ºCDB -20 to 32ºCWBS ser�es *1 – -15 to 15ºCWB – –Y series -5 to 46ºCDB -20 to 15.5ºCWB -5 to 46ºCDB -20 to 15.5ºCWBHP ser�es -5 to 43ºCDB -25 to 15.5ºCWB -5 to 43ºCDB -25 to 15.5ºCWB

C�rculat�ng water temperature

WR2 ser�es 10 to 45ºC 10 to 45ºC 10 to 45ºC 10 to 45ºCWYseries 10 to 45ºC 10 to 45ºC 10 to 45ºC 10 to 45ºC

*1 For the S-series, only one PWFY-P100VM-E1-AU unit can be used and only heating operation is available.

Only standard indoor unitsCool�ng Heat�ng

Outdoor temperature

R2 ser�es -5 to 46ºCDB -20 to 15.5ºCWBS ser�es -5 to 46ºCDB -15 to 15ºCWBY series -5 to 46ºCDB -20 to 15.5ºCWBHP ser�es -5 to 43ºCDB -25 to 15.5ºCWB

C�rculat�ng water temperature

WR2 ser�es 10 to 45ºC 10 to 45ºCWYseries 10 to 45ºC 10 to 45ºC

GeneralEquipmentDescriptions I

- 2 -

3.Connectableoutdoorunit/heatsourceunitcapacityrange<PWFY-P100VM-E-BU>

Only PWFY PWFY with standard indoor units

Only standard indoor units

R2/WR2 series 50 to 100% 50 to 150%*1 50 to 150%*1*1 In case of WCB connection, the capacity range will be "50 to 130%".

<PWFY-P100,200VM-E1-AU>

Only PWFY PWFY with standard indoor units

Only standard indoor units

R2/WR2 series 50 to 100% 50 to 150%*1 50 to 150%*1

S ser�es – standard indoor units 50 to 100% + PWFY 50 to 130%

Y/HP/WY series 50 to 100% 50 to 130% 50 to 130%*1 In case of WCB connection, the capacity range will be "50 to 130%".

<BC controller>Connectable un�t

CMB-P104/P105/106/107/1010/ 1013/1016V-G1

PURY-(E)P200-350YJM-A(-BS) PQRY-P200-300YHM-A

CMB-P108/1010/1013/1016V-GA1PURY-(E)P200-650Y(S)JM-A(1)(-BS)

PQRY-P200-600Y(S)HM-ACMB-P1016V-HA1 PURY-(E)P700-900YSJM-A(1)(-BS)

CMB-P104/108V-GB1, CMB-P1016V-HB1 CMB-P108/1010/1013/1016V-GA1, CMB-P1016V-HA1<WCB>

Connectable un�t

CMB-PW202V-JPURY-(E)P200-350YJM-A(-BS) *1

PQRY-P200-300YHM-A*1 Except PURY-EP350YJM-A(-BS)

- 3 -

1.Specifications(1) PWFY-P100VM-E-BUModel

Power sourcekWHeating capacity *1

*1*1

kcal / h(Nominal )BTU / hkWAW.B

dB<A>mm(in.) mm(in.)mm(in.)mm(in.)mm(in.)

mmin.kg(lbs)

kW

-

Power input

LiquidGas

Current inputOutdoor temp.

Inlet Water temp.-Circulating Water temp.

Total capacity

Temp. range ofheating

Connectableoutdoor unit/heat source unit

Model / Quantity

Sound pressure level (measured in anechoic room)Diameter of refrigerant pipeDiameter of water pipeField drain pipe size

External finishExternal dimension H × W × D

Net weightCompressor

MakerType

Starting methodMotor output

Circulating waterRange

Protection on Internal circuit(R134a)

High pressure protectionInverter circuit (COMP)CompressorType × original chargeRefrigerantControlR410aDesign pressureR134aWaterExternalDrawing

Standard attachment

Optional parts

Remark

Note: *1 Nominal heating conditions (PWFY conditions are indicated in the parentheses.)<R2-series>

Outdoor Temp. : 7°CDB/6°CWB (45°FDB / 43°FWB) kcal = kW × 860

Pipe length : 7.5 m (24-9/16 ft) BTU/h = kW × 3,412

Level difference : 0 m (0 ft) cfm = m3/min x 35.31

(Inlet water Temp 65°C Water flow rate 2.15 m3/h)

<WR2-series> Circulating water Temp. : 20°C (68°F) Pipe length : 7.5 m (24-9/16 ft) Level difference : 0 m (0 ft) (Inlet water Temp 65°C Water flow rate 2.15 m3/h)

lbs = kg / 0.4536

* Due to continuing improvement, the above specifications may be subject to change without notice. * Install the unit in an environment where the wet bulb Temp. will not exceed 32°C.

* The unit is not designed for outside installations. * Please don't use the steel material for the water piping material. * The water circuit must use the closed circuit.

* Please do not use it as a drinking water. * Please always make water circulate or add the brine to the circulation water when the ambient temperature becomes 0°C or less. * Please always make water circulate or pull out the circulation water completely when not using it. * Please do not use groundwater and well water.

* The specification data is subject to rounding variation.

Unit converter

LubricantOperation volume

InletOutlet

Accessory

WiringDocument

m3/h

MPaMPaMPa 1.00

Installation Manual, Instruction Book

800 (785 without legs) × 450 × 300

WKE94C229

Inverter1.0

Over-heat protection, Over-current protection

R134a × 1.1kg (0.50lbs)

10,80012.5

WKB94L762

NONE

44

NO

Strainer, Heat insulation material, 2 × Connector sets, wire

PWFY-P100VM-E-BU1-phase 220-230-240V 50/60Hz

PT3/4 Screw

MITSUBISHI ELECTRIC CORPORATION

NEO22

Φ32 (1-1/4'')

Inverter rotary hermetic compressor

31-1/2" (30-15/16" without legs) × 17-3/4” × 11-13/16”60 (133)

PT3/4 Screw

11.63 - 11.12 - 10.66

50~100% of outdoor unit/heat source unit capacityPURY-(E)P • Y(S)JM-A(1)(-BS)

PQRY-P • Y(S)HM-A

Φ15.88 (Φ5/8") Brazed

-20~32°C (-4~90°F) R2-series10~45°C (50~113°F) WR2-series

Φ9.52 (Φ3/8") Brazed

42,700

10~70°C (50~158°F)

2.48

0.6~2.15

LEV 4.15

High pressure sensor, High pressure switch at 3.60 MPa (601 psi)

Discharge thermo protection, Over-current protection

3.60

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, andother items shall be referred to the Installation Manual.

ProductSpecifications II

- 4 -

Model

Power sourcekW*1Heating capacitykcal / hBTU / hkWA

W.BW.B

*1(Nominal)*1

Power inputCurrent inputOutdoor temp.Temp. range of heating

W.BW.B

-

--

-Inlet Water temp.

Circulating Water temp.

kW*2Cooling capacitykcal / hBTU / hkWAD.B

*2(Nominal)*2

Power inputCurrent inputOutdoor temp.Temp. range of cooling

D.BD.B

-Inlet Water temp.Total capacityModel / Quantity

Connectableoutdoor unit/heat source unit

Sound pressure level (measured in anechoic room) dB<A>mm(in.)mm(in.)

Diameter of refrigerant pipe

mm(in.)mm(in.)

Diameter of water pipe

mm(in.)

mm

Field drain pipe size

External finishExternal dimension H × W × D

in. kg(lbs)Net weight

Circulating waterRange

Design pressureWaterR410a

Drawing

Standard attachment

Optional parts

Remark

Note:

*2 Nominal cooling conditions (PWFY conditions are indicated in the parentheses.)

*1 Nominal heating conditions (PWFY conditions are indicated in the parentheses.)

Outdoor Temp. : 7°CDB/6°CWB (45°FDB / 43°FWB)

Outdoor Temp. : 35°CB (95°FDB)

kcal = kW × 860BTU/h= kW × 3,412

Pipe length : 7.5 m (24-9/16 ft)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0 m (0 ft)

Level difference : 0 m (0 ft)

<S/Y/HP (ZUBADAN)/R2-series>

<Y/HP (ZUBADAN)/R2-series>

Circulating water Temp. : 20°C (68°F) Pipe length : 7.5 m (24-9/16 ft)Level difference : 0 m (0 ft)

<WY/WR2-series>

<WY/WR2-series>

cfm = m3/min × 35.31

(Inlet water Temp 30°C Water flow rate 2.15 m3/h) (Inlet water Temp 30°C Water flow rate 2.15 m3/h)

(Inlet water Temp 23°C Water flow rate 1.93 m3/h)

Circulating water Temp. : 30°C (86°F)Pipe length : 7.5 m (24-9/16 ft)Level difference : 0 m (0 ft)(Inlet water Temp 23°C Water flow rate 1.93 m3/h)

* Install the unit in an environment where the

lbs = kg / 0.4536

* Due to continuing improvement, the above specifications may be subject to change without notice. wet bulb Temp. will not exceed 32°C. * The unit is not designed for outside installations.

* Please don't use the steel material for the water piping material. * The water circuit must use the closed circuit. * Please always make water circulate or add the brine to the circulation water when the ambient temperature becomes 0°C or less. * Please always make water circulate or pull out the circulation water completely when not using it.

InletOutlet

Operation Volume

LiquidGas

m3/h

MPaMPa

Accessory

ExternalWiringDocument

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, andother items shall be referred to the Installation Manual.

Unit converter

* The specification data is subject to rounding variation.

38,200

10~35°C (50~95°F)

0.015

Φ15.88 (Φ5/8") BrazedΦ9.52 (Φ3/8") Brazed

PT3/4 Screw

Installation Manual, Instruction Book

PT3/4 Screw

NO

WKB94L763

0.068 - 0.065 - 0.063

50~100% of outdoor unit/heat source unit capacityPUMY-P• V/YHMB

PUHY-(E)P • Y(S)JM-A(1)(-BS)PUHY-HP • Y(S)HM-A(-BS)

PQHY-P • Y(S)HM-APURY-(E)P • Y(S)JM-A(1)(-BS)

PQRY-P • Y(S)HM-A

-5~46°C (23~115°F) R2-series-5~46°C (23~115°F) Y-series

-5~43°C (23~110°F) HP (ZUBADAN)-series

1.1~2.15

1.00

Strainer, Heat insulation material, 2 × Connector sets, wire, Flow switch × 1set

Φ32 (1-1/4'')

PWFY-P100VM-E1-AU1-phase 220-230-240V 50/60Hz

9,60011.2

29

12.5

800 (785 without legs) × 450 × 300

WKE94C230

4.15

Solenoid valve kit: PAC-SV01PW-E

10,80042,700

-20~15.5°C (-4~60°F) Y-series-15~15°C (5~60°F) S-series

-25~15.5°C (-13~60°F) HP (ZUBADAN)-series10~45°C (50~113°F) WR2-series10~45°C (50~113°F) WY-series10~45°C (50~113°F) S-series

--

Circulating Water temp. 10~45°C (50~113°F) WR2-series10~45°C (50~113°F) WY-series

10~40°C (50~104°F) R2/Y/HP(ZUBADAN)/WR2/WY-series

0.0150.068 - 0.065 - 0.063

-20~32°C (-4~90°F) R2-series

31-1/2" (30-15/16" without legs) × 17-3/4” × 11-13/16”35 (78)

* Please do not use it as a drinking water. * Please do not use groundwater and well water.

(2) PWFY-P100VM-E1-AU

- 5 -

Model

Power sourcekW*1Heating capacitykcal / hBTU / hkWAW.B

*1(Nominal)*1

Power inputCurrent inputOutdoor temp.Temp. range of

W.B

-

heating

Inlet Water temp.kW*2Cooling capacitykcal / hBTU / hkWAD.B

*2(Nominal)*2

Power inputCurrent inputOutdoor temp.Temp. range of cooling

D.B

-Inlet Water temp.Total capacityModel / Quantity

Connectableoutdoor unit/heat source unit

Sound pressure level (measured in anechoic room) dB<A>mm(in.)mm(in.)

Diameter of refrigerant pipe

mm(in.)mm(in.)

Diameter of water pipe

mm(in.)

mm

Field drain pipe size

External finishExternal dimension H × W × D

in. kg(lbs)Net weight

Circulating waterRange

Design pressureWaterR410a

Drawing

Standard attachment

Optional parts

Remark

Note:

InletOutlet

Operation Volume

LiquidGas

m3/h

MPaMPa

Accessory

ExternalWiringDocument

Unit converter

*2 Nominal cooling conditions (PWFY conditions are indicated in the parentheses.)

*1 Nominal heating conditions (PWFY conditions are indicated in the parentheses.)

Outdoor Temp. : 7°CDB/6°CWB (45°FDB / 43°FWB)

Outdoor Temp. : 35°CDB (95°FDB)Pipe length : 7.5 m (24-9/16 ft)

Pipe length : 7.5 m (24-9/16 ft)

Level difference : 0 m (0 ft)

Level difference : 0 m (0 ft)(Inlet water Temp 30°C Water flow rate 4.30 m3/h) (Inlet water Temp 30°C Water flow rate 4.30 m3/h)

(Inlet water Temp 23°C Water flow rate 3.86 m3/h) (Inlet water Temp 23°C Water flow rate 3.86 m3/h)

* Due to continuing improvement, the above specifications may be subject to change without notice. * Install the unit in an environment where the wet bulb Temp. will not exceed 32°C. * The unit is not designed for outside installations.

* Please don't use the steel material for the water piping material. * The water circuit must use the closed circuit. * Please always make water circulate or add the brine to the circulation water when the ambient temperature becomes 0°C or less. * Please always make water circulate or pull out the circulation water completely when not using it.

Details on foundation work, duct work, insulation work, electrical wiring, power source switch, andother items shall be referred to the Installation Manual.

10~40°C (50~104°F)

0.0150.068 - 0.065 - 0.063

21,50085,300

W.B

WKE94C230

Solenoid valve kit: PAC-SV01PW-E

Φ32 (1-1/4'')

PWFY-P200VM-E1-AU1-phase 220-230-240V 50/60Hz

19,30022.4

29

25.0

1.8~4.30

1.00

Strainer, Connecter, Heat insulation material, 2 × Connector sets, Expansion joint, wire, Flow switch × 1set

PT 1 Screw

Installation Manual, Instruction Book

NO

WKB94L763

31-1/2" (30-15/16" without legs) × 17-3/4” × 11-13/16”38 (84)

800 (785 without legs) × 450 × 300

4.15

0.015

Φ19.05 (Φ3/4") BrazedΦ9.52 (Φ3/8") Brazed

PT 1 Screw

0.068 - 0.065 - 0.063

76,400

10~35°C (50~95°F)50~100% of outdoor unit/heat source unit capacity

PUHY-(E)P • Y(S)JM-A(1)(-BS)PUHY-HP • Y(S)HM-A(-BS)

PQHY-P • Y(S)HM-APURY-(E)P • Y(S)JM-A(1)(-BS)

PQRY-P • Y(S)HM-A

D.B

kcal = kW × 860BTU/h = kW × 3,412cfm = m3/min × 35.31lbs = kg / 0.4536* The specification data is subject to rounding variation.

--

Circulating Water temp.

--

Circulating Water temp.

<Y/HP (ZUBADAN)/R2-series>

<Y/HP (ZUBADAN)/R2-series>

Circulating water Temp. : 20°C (68°F) Pipe length : 7.5 m (24-9/16 ft)Level difference : 0 m (0 ft)

<WY/WR2-series>

<WY/WR2-series>Circulating water Temp. : 30°C (86°F)Pipe length : 7.5 m (24-9/16 ft)Level difference : 0 m (0 ft)

-5~46°C (23~115°F) R2-series-5~46°C (23~115°F) Y-series

-5~43°C (23~110°F) HP(ZUBADAN)-series

-20~15.5°C (-4~60°F) Y-series-25~15.5°C (-13~60°F) HP(ZUBADAN)-series

10~45°C (50~113°F) WR2-series10~45°C (50~113°F) WY-series

10~45°C (50~113°F) WR2-series10~45°C (50~113°F) WY-series

-20~32°C (-4~90°F) R2-series

* Please do not use it as a drinking water. * Please do not use groundwater and well water.

(3) PWFY-P200VM-E1-AU

- 6 -

*Other models of BC controller are available. For unit information, refer to the Data Book.(4) CMB-P104V-G1Model CMB-P104V-G1Number of branch 4Power source 1-phase 220/230/240V

50Hz 60HzPower �nput(220/230/240)

Cool�ng kW 0.067/0.076/0.085 0.054/0.061/0.067Heat�ng 0.030/0.034/0.038 0.024/0.027/0.030

Current(220/230/240)

Cool�ng A 0.31/0.34/0.36 0.25/0.27/0.28Heat�ng 0.14/0.15/0.16 0.11/0.12/0.13

External finish Galvanized steel plate(Lower part drain pan painting N1.5)

Connectable outdoor unit/heat source unit PURY-(E)P200/250/300/350YJM-A(-BS)PQRY-P200/250/300YHM-A

Indoor unit capacityconnectable to 1 branch

Model P80 or smaller( Use optional joint pipe combing 2 branches when the total unit capacity exceeds 81. )

External dimension H x W x D mm (in.) 284 x 648 x 432 (11-3/16 x 25-17/32 x 17-1/32)Refr�gerantp�p�ngdiameter

Connectable outdoor unit/heat source unitcapac�ty

To outdoor unit/heat source unitHigh press. pipe Low press. pipe

to P200mm (in.) O.D.

15.88 (5/8)Brazed

19.05 (3/4)Brazed

P250/P300mm (in.) O.D.

19.05 (3/4)Brazed

22.2 (7/8)Brazed

to P350mm (in.) O.D.

19.05 (3/4)Brazed

28.58 (1-1/8)Brazed

To indoor unitLiquid pipe Gas pipe

mm (in.) O.D.Indoor unit Model 50 or smaller 6.35 (1/4) Brazed

bigger than 50 9.52 (3/8) Brazed(12.7 (1/2) with optional joint pipe used.)

Indoor unit Model 50 or smaller 12.7 (1/2) Brazedbigger than 50 15.88 (5/8) Brazed

(19.05 (3/4) with optional joint pipe used.)

Field drain pipe size mm (in.) O.D. 32 (1-1/4)Net we�ght kg (lbs) 24 (53)Accessor�es Drain Connection pipe (with flexible hose and insulation)

ReducerRemark

Note: *1. Installation/foundation work, electrical connection work, insulation work, power source switch, and other items shall be referred to the Installation Manual.*2. The equipment is for R410A refrigerant.*3. Install this product in a location where noise (refrigerant noise) emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position the BC CONTROLLER at least 5m away from any indoor units.)*4. Indoor units P100, P125, P140 can be connected to 1 branch. (In this case, cooling capacity decrease a little.)*5. Refrigerant piping diameter for connection of plural indoor units with 1 branch shall be referred to the Installation Manual.

(5) CMB-PW202V-JModel

Power sourceNumber of branch

Power input

Current

External finish

Connectable outdoor unit/heat source unit

Connectable unit capacity

External dimension H x W x D

Field drain pipe sizeNet weightAccessories

kW

A

TotalIndoor / PWFYbranchPWFY branchmm(in.)

mm(in.)mm(in.)

mm(in.)

mm(in.)

kg(lbs)

Refrigerantpipingdiameter

Tooutdoor unit/heat sourceunit

Toindoor/PWFY unit

High press. pipeLow press. pipe

Liquid pipe

Gas pipe

Note: *1. For installation/foundation work, electrical connection work, insulation work, and power source switch etc., refer to the Installation Manual. *2. The equipment is for R410A refrigerant. *3. Install this product in a location where noise (refrigerant noise) emitted by the unit will not disturb the neighbors. (For use in quiet environments with low background noise, position the Water system Connection Box at least 5m away from any indoor units.) *4. Install the unit horizontally. *5. The indoor / PWFY unit branch is for cooling / heating. The indoor / PWFY unit cannot be simultaneously operated in different operation modes. *6. The PWFY unit branch is for the heating only. *7. Seal the unused branch using the optional cover cap (CMY-S202-J).

PURY-(E)P200/250/300/350YJM-A(-BS)PQRY-P200/250/300YHM-A

Cooling : 0.019/0.020/0.021Heating : 0.020/0.022/0.024

Cooling : 0.018/0.019/0.019Heating : 0.019/0.020/0.021

Cooling : 0.09/0.09/0.09Heating : 0.10/0.10/0.10

Cooling : 0.09/0.09/0.09Heating : 0.09/0.09/0.09

Galvanized steel plate(Lower part drain pan painting N1.5)

CMB-PW202V-J

1N ~ 220/230/240V50Hz 60Hz

20 (45)

2

O.D. 32mm (1-1/4" )

284 x 648 x 432 (11-3/16" x 25-9/16" x 17-1/16" )

50% ~ 130% of outdoor unit/heat source unit

up to 130% of outdoor unit/heat source unit

up to 100% of outdoor unit/heat source unit

Total down-stream Indoor unit capacity

Connectable outdoor unit capacity

ø19.05 (ø3/4" ) Brazed

·Drain Connection pipe (with flexible hose and insulation)·Refrigerant connection pipe

P200ø15.88 (ø5/8" ) Brazed

ø15.88 (ø5/8" )Brazed

~P140ø9.52 (ø3/8" )

Brazedø19.05 (ø3/4" )

Brazed

P141~P200ø9.52 (ø3/8" )

Brazedø22.2 (ø7/8" )

Brazed

P201~P300ø9.52 (ø3/8" )

Brazedø28.58 (ø1-1/8" )

Brazed

P301~P400ø12.70 (ø1/2" )

Brazedø28.58 (ø1-1/8" )

Brazed

P401~ø15.88 (ø5/8" )

Brazed

ø22.2 (ø7/8" ) Brazed

P250/P300ø19.05 (ø3/4" ) Brazed

ø28.58 (ø1-1/8" ) Brazed

P350ø19.05 (ø3/4" ) Brazed

- 7 -

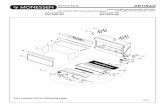

2.ExternalDimensions(1) PWFY-P100VM-E-BU

P�p

�ng

spac

e(r

ight

sid

e)

Fig.

A

Ser

v�ce

spa

ce(fr

ont s

ide)

Top

v�ew

300

400

600

ø27

Kno

ckou

t hol

e<H

ole

for e

xter

nal w

iring

out

put>

Dra

�n (R

1 sc

rew

)

Con

trol b

ox

Wat

er o

utle

t(R

C3/

4 sc

rew

)

ø27

Kno

ckou

t hol

e<H

ole

for e

xter

nal w

iring

inpu

t>

ø27

Kno

ckou

t hol

e<H

ole

for p

ower

sup

ply>

ø27

Kno

ckou

t hol

e<H

ole

for c

ontro

l wiri

ng>

Ser

v�ce

pan

el

Top

v�ew

Rig

ht s

ide

view

Fron

t v�e

w

2X2-

ø14

Hol

e

Con

nect

ion

pipe

of o

utdo

or u

nit

(Liq

uid)

ø15.

88 <

Bra

zed>

ø9.5

2 <B

raze

d>

Con

nect

ion

pipe

of o

utdo

or u

nit

(Gas

)

Wat

er �n

let

(R3/

4 sc

rew

)

525

(Mou

nt�n

g p�

tch)

(Mount�ng p�tch)205

800300

450

500

5535 35

919113

4480

46

60 140100 19180 165

102

54

184

114

Not

e 1.

Ens

ure

no ra

in w

ater

or d

ebris

can

ent

er th

e un

it th

roug

h an

y ga

ps a

roun

d

w

iring

or p

ipin

g.

2.E

nsur

e ad

equa

te s

ervi

ce s

pace

is ri

ght a

roun

d th

e un

it, a

ccor

ding

to F

ig A

.

3.P

leas

e al

way

s m

ake

wat

er c

ircul

ate

or a

dd th

e br

ine

to th

e ci

rcul

atio

n w

ater

w

hen

the

amb�

ent t

empe

ratu

re b

ecom

es 0

°C o

r les

s.

4.T

he u

nit i

s no

t des

igne

d fo

r out

side

inst

alla

tions

.

5.In

stal

l the

uni

t in

an e

nviro

nmen

t whe

re th

e w

et b

ulb

Tem

p.

will

not

exc

eed

32de

gC.

6

.Ple

ase

alw

ays

mak

e w

ater

circ

ulat

e or

pul

l out

the

circ

ulat

ion

wat

er c

ompl

etel

y w

hen

not u

sing

it.

7

.The

wat

er c

ircui

t mus

t use

the

clos

ed c

ircui

t.

8.P

leas

e do

n't u

se th

e st

eel m

ater

ial f

or th

e w

ater

pip

ing

mat

eria

l.

9.C

onne

ct th

e st

rain

er w

hich

is p

ut a

s ac

cess

ory

to w

ater

inle

t pip

e.

<Acc

esso

ries>

●Y-ty

pe s

train

er (R

C3/

4) ··

······

······

······

······

1pc

.●H

eat I

nsul

atio

n m

ater

ial ·

······

······

······

······

1pc

.●C

onne

ctor

set

····

······

······

······

······

······

······

2se

t●W

ire ·

······

······

······

······

······

······

······

······

······

1pc

.

<Uni

t:mm

>

- 8 -

(2) PWFY-P100, 200VM-E1-AU

300 600

Fig.

A

Ser

v�ce

spa

ce(fr

ont s

ide)

Top

v�ew

400

P�p

�ng

spac

e(r

ight

sid

e)P

200:

Use

the

Exp

ans�

on jo

�nt

o

f acc

esso

r�es

Dra

�n (R

1 sc

rew

)

ø9.5

2 <B

raze

d>

ø27

Kno

ckou

t hol

e<H

ole

for c

ontro

l w�r�

ng>

ø27

Kno

ckou

t hol

e<H

ole

for p

ower

sup

ply>

Wat

er o

utle

t(R

C3/

4 sc

rew

)

Wat

er �n

let

(R3/

4 sc

rew

)

P10

0:ø1

5.88

<B

raze

d>P

200:

ø19.

05 <

Bra

zed>

ø27

Kno

ckou

t hol

e<H

ole

for e

xter

nal w

iring

inpu

t>ø2

7 K

nock

out h

ole

<Hol

e fo

r ext

erna

l w�r�

ng o

utpu

t>

Con

nect

ion

pipe

of o

utdo

or u

nit

(Gas

)

Con

nect

ion

pipe

of o

utdo

or u

nit

(Liq

uid)

Fron

t v�e

wR

ight

sid

e vi

ew

Con

trol b

ox

Ser

v�ce

pan

el

Top

v�ew

2X2-

ø14

Hol

e

525

(Mou

nt�n

g p�

tch)

450

(Mount�ng p�tch)300 800

205

500

<Acc

esso

ries>

●Y-ty

pe s

train

er (R

C3/

4) ··

······

······

······

······

··· 1

pc.

●Wire

·····

······

······

······

······

······

······

······

······

·····

1pc.

●Flo

w s

witc

h ···

······

······

······

······

······

······

······

·· 1s

et

●Hea

t Ins

ulat

ion

mat

eria

l ····

······

······

······

······

1pc

.●C

onne

ctor

set

·····

······

······

······

······

······

······

··· 2

set

●Exp

ansi

on jo

int (

P20

0) ··

······

······

······

······

···· 2

pcs.

[F

rom

RC

3/4

to R

C1]

Not

e 1.

Ens

ure

no ra

in w

ater

or d

ebris

can

ent

er th

e un

it th

roug

h an

y ga

ps a

roun

d

w

iring

or p

ipin

g.

2.E

nsur

e ad

equa

te s

ervi

ce s

pace

is ri

ght a

roun

d th

e un

it, a

ccor

ding

to F

ig A

.

3.P

leas

e al

way

s m

ake

wat

er c

ircul

ate

or a

dd th

e br

ine

to th

e ci

rcul

atio

n w

ater

w

hen

the

amb�

ent t

empe

ratu

re b

ecom

es 0

°C o

r les

s.

4.T

he u

nit i

s no

t des

igne

d fo

r out

side

inst

alla

tions

.

5.In

stal

l the

uni

t in

an e

nviro

nmen

t whe

re th

e w

et b

ulb

Tem

p.

will

not

exc

eed

32de

gC.

6

.Ple

ase

alw

ays

mak

e w

ater

circ

ulat

e or

pul

l out

the

circ

ulat

ion

wat

er c

ompl

etel

y w

hen

not u

sing

it.

7

.The

wat

er c

ircui

t mus

t use

the

clos

ed c

ircui

t.

8.P

leas

e do

n't u

se th

e st

eel m

ater

ial f

or th

e w

ater

pip

ing

mat

eria

l.

9.C

onne

ct th

e st

rain

er w

hich

is p

ut a

s ac

cess

ory

to w

ater

inle

t pip

e.

9191

35 5535

480 102

206

134

114

100 1914660 140 80 165

54

<Uni

t:mm

>

- 9 -

(3) CMB-P104,105,106,108,1010,1013,1016V-G1 *Other models of BC controller are available. For unit information, refer to the Data Book.

60XC

=D60

76

60XC

=D

60

46

Con

nect

ion

pipe

of

indo

or u

nit(G

as)

200

255

250

(700)

200

284

128

58

Con

nect

ion

pipe

of

indo

or u

nit(L

iqui

d)

27

Band

(Acc

esso

ry)

Dra

in h

ose

I.D.3

2 (1

-1/4

”)

X

(200

)

Acce

ssdo

or45

0

362

Y

181

298

CM

B-P1

013V

-G1

CM

B-P1

016V

-G1

CM

B-P1

010V

-G1

CM

B-P1

06V-

G1

CM

B-P1

08V-

G1

CM

B-P1

05V-

G1

CM

B-P1

04V-

G1

1098

648

1152702

900

720

540

420

300

240

180

151297543

(Lifting bolt pitch)

(Lift

ing

bolt

pitc

h)

DC

BA

103

90

130

130

2313

0

70

Ø31

(Not

e 2.

)

12

34

56

78

910

1112

1314

1516

Det

ail o

f Y s

ectio

nnoitces Z fo liate

Dnoitces X fo liate

D

Con

trol b

ox

Indo

or u

nit m

odel

(Not

e 4.

)P5

0 or

less

:Ø12

.7<B

raze

d>P5

0 ov

er

: Ø15

.88<

Braz

ed>

Indo

or u

nit m

odel

(Not

e 4.

)P5

0 or

less

: Ø6.

35<B

raze

d>P5

0 ov

er

:Ø9.

52<B

raze

d>

248

Con

nect

ion

pipe

of o

utdo

or u

nit(H

igh

pres

sure

)

C

onne

ctio

n pi

pe o

f out

door

uni

t(Low

pre

ssur

e)

A B

Dra

in p

ipe

O.D

.32

(1-1

/4”)

30

14

12

Serv

ice

spac

e

P200

: Ø15

.88<

Braz

ed>(

use

atta

chm

ent p

ipe)

P250

,P30

0,P3

50: Ø

19.0

5<Br

azed

>

P200

:Ø19

.05<

Braz

ed>(

use

atta

chm

ent p

ipe)

P250

,P30

0:Ø

22.2

<Bra

zed>

P350

: Ø28

.6<B

raze

d>(u

se a

ttach

men

t pip

e)

Not

e1.S

uspe

nsio

n bo

lt(Ø

10),w

ashe

r(M10

),and

nut

(M10

)

pr

epar

e in

the

field

.

2.T

ake

notic

e of

ser

vice

spa

ce a

s fo

llow

s.

(P

leas

e gi

ve a

ttent

ion

not t

o oc

cupy

ser

vice

sp

ace

by le

tting

duc

ts a

nd p

ipes

thro

ugh.

)

3.In

stal

l thi

s pr

oduc

t in

a lo

catio

n w

here

noi

se (r

efrig

eran

t noi

se)

emitt

ed b

y th

e un

it w

ill no

t dis

turb

the

neig

hbor

s.

(For

use

in q

uiet

env

irom

ents

with

low

bac

kgro

und

nois

e,po

sitio

n

the

BC

CO

NTR

OLL

ER a

t lea

st 5

m a

way

from

any

indo

or u

nits

.)

4.R

efer

to th

e In

stal

latio

n M

anua

l for

refri

gera

nt p

ipin

g di

amet

er s

ize

whe

n co

nnec

ting

plur

al in

door

uni

ts w

ith 1

bra

nch.

<Acc

esso

ries>

Ref

riger

ant<

Low

pre

ssur

e> c

onn.

pipe

······

······

·····2

pcs.

Ref

riger

ant<

Hig

h pr

essu

re>

conn

.pip

e····

······

······

1pc.

Dra

in h

ose

I.D.3

2 (1

-1/4

”)····

······

······

······

······

······

···1p

c. H

ose

band

······

······

······

······

······

······

······

······

······

······

1pc.

Tie

ban

d····

······

······

······

······

······

······

······

······

······

······

1pc.

Z

Cut

ting

poin

t

Cut

ting

poin

t(In

door

uni

t Mod

el:P

50 o

r les

s)

(Indo

or u

nit M

odel

:P50

ove

r)

<Uni

t:mm

>

- 10 -

(4) CMB-PW202V-J

Con

nect

ion

pipe

of

PW

FY

(G

as)

Con

nect

ion

pipe

of

PW

FY

(Li

quid

)

Con

nect

ion

pipe

of

indo

or u

nit/P

WF

Y (

Liqu

id)

Con

nect

ion

pipe

of

indo

or u

nit/P

WF

Y (

Gas

)

Liqu

id li

neIn

door

uni

t/PW

FY

(Coo

ling/

Hea

ting)

PW

FY(H

eatin

g on

ly)

Gas

line

Liqu

id li

ne

Gas

line

(Lifting bolt pitch)

(Lift

ing

bolt

pitc

h)

250

700

200

200

Acce

ssdo

or45

0

~P30

0: ø

9.52

<Bra

zed>

(use

atta

chm

ent p

ipe)

P30

1~P

400:

ø12

.7<B

raze

d>(u

se a

ttach

men

t pip

e)P

401~

: ø15

.88<

Bra

zed>

~P14

0: ø

15.8

8<B

raze

d>(u

se a

ttach

men

t pip

e)P

141~

P20

0: ø

19.0

5<B

raze

d>(u

se a

ttach

men

t pip

e)P

201~

P30

0: ø

22.2

<Bra

zed>

(use

atta

chm

ent p

ipe)

P30

1~: ø

28.5

8<B

raze

d>(u

se a

ttach

men

t pip

e)

~P14

0: ø

15.8

8<B

raze

d>(u

se a

ttach

men

t pip

e)P

141~

P20

0: ø

19.0

5<B

raze

d>P

201~

P30

0: ø

22.2

<Bra

zed>

(use

atta

chm

ent p

ipe)

~P30

0: ø

9.52

<Bra

zed>

Dra

in h

ose(

Acc

esso

ry)

Ban

d(A

cces

sory

)

C

onne

ctio

n pi

pe o

f out

door

uni

t (Lo

w p

ress

ure)

Con

nect

ion

pipe

of o

utdo

or u

nit (

Hig

h pr

essu

re)

12

14

30

ø31

27

Y

X

Dta

il of

Y s

ectio

n

284

648

90

Dra

in p

ipin

gV

P-2

5 co

nnec

tion

Con

trol

box

200

255

Det

ail o

f X s

ectio

n

298

702

190

423

300

252

10358

90

127

21

90181

255

70 362

103

PU

RY-

P20

0: ø

19.0

5<B

raze

d>(u

se a

ttach

men

t pip

e)P

UR

Y-P

250,

P30

0: ø

22.2

<Bra

zed>

PU

RY-

P35

0: ø

28.5

8<B

raze

d>(u

se a

ttach

men

t pip

e)

PU

RY-

P20

0: ø

15.8

8<B

raze

d>(u

se a

ttach

men

t pip

e)P

UR

Y-P

250,

P30

0,P

350:

ø19

.05<

Bra

zed>

<A

cces

sorie

s>R

efrig

eran

t<Lo

w p

ress

ure>

con

n. p

ipe

Ref

riger

ant<

Hig

h pr

essu

re>

con

n. p

ipe

Ref

riger

ant<

Gas

> c

onn.

pip

eR

efrig

eran

t<Li

quid

> c

onn.

pip

eD

rain

hos

e(V

P-2

5 co

nnec

tion)

Hos

e ba

ndT

ie b

and

2pcs

.1p

c.6p

cs.

2pcs

.1p

c.1p

c.1p

c.

Not

e1. S

uspe

nsio

n bo

lt (ø

10),

was

her

(M10

), a

nd n

ut (

M10

) pr

epar

e in

the

field

.

2. T

ake

notic

e of

ser

vice

spa

ce a

s fo

llow

s.(P

leas

e gi

ve a

ttent

ion

not t

o oc

cupy

ser

vice

sp

ace

by le

tting

duc

ts a

nd p

ipes

thro

ugh.

)

3

. Ins

tall

this

pro

duct

in a

loca

tion

whe

re n

oise

(re

frig

eran

t noi

se)

emitt

ed b

y th

e un

it w

ill n

ot d

istu

rb th

e ne

ighb

ors.

(For

use

in q

uiet

env

irom

ents

with

low

bac

kgro

und

nois

e, p

ositi

onth

e B

C C

ON

TR

OLL

ER

at l

east

5m

aw

ay fr

om a

ny in

door

uni

ts.)

4. I

nsta

ll th

e un

it ho

rizon

tally

.

5. T

he in

door

uni

t/PW

FY

bra

nch

is fo

r co

olin

g/he

atin

g.T

he in

door

uni

t/PW

FY

cann

ot b

e si

mul

tane

ousl

y op

erat

ed in

diff

eren

t ope

ratio

n m

odes

.

6. T

he P

WF

Y u

nit b

ranc

h is

for

the

heat

ing

only

.

Ser

vice

spa

ce

<Uni

t:mm

>

- 11 -

3.ElectricalWiringDiagrams(1) PWFY-P100VM-E-BU

M

4-20

mA

4-20

mA

gray

21

gray

blac

k

To o

utdo

or u

nit/

B

C c

ontro

ller/W

CB

To M

A re

mot

eco

ntro

ller

Pow

er S

uppl

y~2

20/2

30/2

40V

50H

z/60

Hz

32

1

blue

red

yello

w/g

reen

blue

red

CN

4

63LS

CN

63H

S

1

13

2

2 3

THH

S

12

CN

63LS

12

3

t°TH

8

21C

N40

3re

dt°

TH6

1 2C

N40

4bl

ack

t°

31

CT1

Mot

er

3~

CY

N

RS

4

MS

RS

3

(Com

pres

sor)

CN

3Abl

ue

U

t°

red

yello

wTH

22C

N40

5

IPM

WVU

blac

k

1

63H

S

7

21 3

12

CN

3

21

t°

CN

401

CN

22

56

t°

red

CN

52 1

TH11

1 2

TH13

21 wh�

te

CN

402

gree

n

red

56

RS1

blac

k

2

CN

52C

R1

LOU

CN

AC

2

red 2

CN

5 1

12

red

blue

red

LEV2

WM

LI24V

blue

+C

B3

Z2

1

UCT1

LEV1

W

1

CN

2

63H

1

6 5

CNAC

2

red

1

CX

2

L

CN

506A

L3

N

6 5

N

CN

-E1

CN

631

DS

A

p�nk

E2

31

E1

4 3 2 1

CY

4

P

CY

3

31

L4

Z1

NI

CB

1 +

1

TB2

CN

661

2

L2

3

X50

6

W

4

CN

4

blue

U

CN

52C

12

+

CX

3

INV

cont

rol

c�rcu

�t

PFC

E3

1

L1

2

M

ZNR

01

AC

L

CY

1C

Y2

CT2

No�

seF�

lter

red

Fan

mot

or

1 3

(DC

)

CX

5

CY

P

CIS

CX

6

12

7

V

yello

w

LED

3:Li

t whe

n po

wer

ed

INV

Boa

rd

Con

trol B

oard

CB

2

(DC

)

CY

6

S

CX

4

R

CN

AC

1

M

CN

LVA

NO

Fan

mot

or

3

12

RS2

CY

5

P

CN

LVB

blue

CX

1

CX

7

CN

506B

CP

S +

RS

F01

AC25

0V6.

3A

F631

DC

700V

4A

Powe

rSu

pply

c�rcu

�t

blue

red

TB5

M1

M2

S(SH

IELD

)S(

SHIE

LD)

TB15

yello

wpu

rple

blac

kor

ange

gray

red

blac

kw

h�te

gray

gray

52C

1 2C

N2M

blue

31

*4TB

141B

TB14

2B

IN6

COM+

OUT5

TB14

2C

OUT7

OUT6

X515

X517

X516

IN8

IN5

IN7

TB14

2A

X514

OUT2

X512

X511

X513

OUT1

OUT3

OUT4

TB14

1A

*5*6

*7

IN3

IN4

COM+

LED

4:R

emot

e co

ntro

ller

w

hen

pow

ered

SWU1

10

SW1

5

ON OFF

1

Unit a

ddre

ss se

tting(

SWU1

,SW

U2)

Conn

ectio

n No

.(SW

U3)

LED1

D�sp

lay se

tt�ng(

SW2)

Func

t�on

sett�n

g(SW

1,SW

3,SW

4)SW

P3

SW5

SWP1

SWU3

SWP2

SWU2

OFF

ON

110

SW4

OFF

ON

110

LED

1OF

FON

1

SW3

OFF

ON

110

SW2

gray

CN

421

blac

k

31

CN

422

blue

IN1

IN2

31

CN

421

blac

k

31

CN

422

blue

22

22

BC

con

trolle

r/WC

B/o

utdo

or u

nit

Boo

ster

un�

tL�

near

expa

ns�o

n va

lve

LEV

1WLE

V2WIN

7A

nt�-f

reez

eIN

6H

eat�n

g E

CO

Sym

bol

Func

t�on

CO

M+

Com

mon

IN5

Hot

wat

er

IN4

Ope

ratio

n O

N/O

FFCo

nnec

tion

dem

and

Sym

bol

IN3

Func

t�on

Sym

bol

Pum

p �n

terlo

ckFu

nct�o

nIN

1

*4 T

B14

1A(o

utpu

t)

*5 T

B14

2A(�n

put)

*6 T

B14

2B(�n

put)

*7 T

B14

2C(�n

put)

Func

t�on

Sym

bol

OU

T1O

pera

tion

ON

/OFF

OU

T2D

efro

stO

UT3

Com

pres

sor

OU

T4E

rror

s�g

nal

<HIG

H V

OLT

AG

E W

AR

NIN

G>

·Con

trol b

ox h

ouse

s hi

gh-v

olta

ge p

arts

. B

efor

e in

spec

ting

the

insi

de o

f the

con

trol b

ox, t

urn

off t

he p

ower

, k

eep

the

un�t

off f

or a

t lea

st 1

0 m

inut

es,a

nd c

onfir

m th

at th

e vo

ltage

CN

631

on C

ontro

l Boa

rd h

as d

ropp

ed to

DC

20V

or l

ess.

<CA

UTI

ON

FO

R IN

STA

LLAT

ION

> ·P

rior t

o in

stal

latio

n,re

ad th

e In

stal

latio

n M

anua

l car

eful

ly.*1

.Sin

gle-

dotte

d lin

es in

dica

te w

iring

not

sup

plie

d w

ith th

e un

it.*2

.Dot

-das

h lin

es in

dica

te th

e co

ntro

l box

bou

ndar

ies.

*3.F

asto

n te

rmin

als

have

a lo

ckin

g fu

nctio

n.

Mak

e su

re th

e te

rmin

als

are

secu

rely

lock

ed in

pla

ce a

fter i

nser

tion.

P

ress

the

tab

on th

e te

rmin

als

to re

mov

ed th

em.

TH8

wat

er o

utle

t tem

pTH

6w

ater

�nle

t tem

pTH

22liq

uid

pipe

tem

pTH

13E

vapo

rato

r out

let t

emp

Com

pres

sor d

isch

arge

tem

pTH

11Th

erm

�sto

rTB

15M

A re

mot

e co

ntro

ller

TB5

Out

door

uni

t/BC

con

trolle

r/WC

B

AC

reac

tor

Pre

ssur

esw

�tch

H�g

h pr

essu

re s

w�tc

h(H

�gh

pres

sure

pro

tect

�on

for t

he b

oost

er u

n�t)

D�s

char

ge p

ress

ure

Low

pre

ssur

e

TB2

CT1,

CT2

AC

L

THH

S

Mag

net�c

rela

y(m

a�n

c�rc

u�t)

Cur

rent

sen

sor(

AC

)

Exp

lana

t�on

Term

�nal

bloc

kP

ower

sup

ply

IGB

T te

mp

Pre

ssur

ese

nsor

Sym

bol

63H

1

63H

S63

LS52

C

<Sym

bol e

xpla

nat�o

n>

- 12 -

gray

red

M

For o

peni

ng/c

losi

ng th

e by

pass

circ

uit

Sol

enoi

d va

lve

SV

1

TB5

M1M2

S(SH

IELD)

To o

utdo

or u

nit/

B

C c

ontro

ller/

W

CB

4-20

mA

4-20

mA

13

2C

N42

1bl

ack

13

2C

N42

2bl

ue1

32

CN

422

blue

2bl

ack

CN

421

13

IN1

2345

yello

w/g

reen

LEV1

Wa

LEV1

Wb

L�ne

arex

pans

�on

valv

eB

C c

ontro

ller/W

CB

/out

door

uni

tB

C c

ontro

ller/W

CB

/out

door

uni

t

Func

t�on

Func

t�on

Func

t�on

blac

kye

llow

purp

lebl

uere

d

NL

IN7IN

8IN

6IN

5CO

M+IN

4IN

3

oran

ge

*3.D

iffer

ence

of a

ppl�a

nce

*4 T

B14

1A(o

utpu

t)

*5 T

B14

2A(�n

put)

*6 T

B14

2B(�n

put)

*7 T

B14

2C(�n

put)

Mod

el n

ame

App

l�anc

eP

100

*3 d

o no

t exi

stP

200

*3 e

x�st

*7*6

*5

*4

Coo

l�ng

TH23

gas

p�pe

tem

p

CN50

2bla

ck

COM+

TH8

TH6

TH23

t°t°t°

blue

CN

2M2121

CN

402

gree

n

21C

N40

3re

d

1 2C

N40

4bl

ack

yello

wC

N40

5t°

TH22

1 2

21 To

MA

rem

ote

cont

rolle

rP

ower

Sup

ply

~220

/230

/240

V50

Hz/

60H

z

Unit a

ddre

ss se

tting(

SWU1

,SW

U2)

Conn

ectio

n No

.(SW

U3)

LED

1

TB15

ZNR

1

UD

SA

1

CN

11 3

SWU2

SWU1

SWP3

SWP2

SWP1

OFF

ON

110

SW

4OF

FON

110

SW

3

OFF

ON

110

SW

1

OFF

ON

110

SW

2LE

D4:

Rem

ote

cont

rolle

r

whe

n po

wer

ed5

CN

LVC

6 1

LEV1

Wb

1234

X50

2

CN50

7

31

M56

ON OFF 1S

W5

SWU3

LED

3:Li

t whe

n po

wer

ed

Con

trol B

oard

CN

LVB

LEV1

Wa

TB2

SV1

*3

DS

A B

oard

CN

3Tre

d13

T01

ZNR

01

31

12

CNAC

red

U

F01

AC25

0V6.

3A

LED1

D�sp

lay se

tt�ng(

SW2)

Func

t�on

sett�n

g(SW

1,SW

3,SW

4)

OUT4

OUT3

OUT2

X514

X513

X512

TB14

1A

OUT1

X511

31

CN

3Abl

ue

TB14

2CTB

142B

X516

X517

X515

OUT6

OUT7

OUT5

TB14

1B

TB14

2A

IN2

IN8

IN7

Ant

�-fre

eze

IN6

Hea

t�ng

EC

O

Sym

bol

CO

M+

Com

mon

IN5

Hea

t�ng

IN4

Ope

ratio

n O

N/O

FFC

onne

ctio

n de

man

dS

ymbo

lIN

3

Sym

bol

Flow

sw

�tch

IN1

Func

t�on

Sym

bol

OU

T1O

pera

tion

ON

/OFF

OU

T2D

efro

stO

UT4

Err

or s

�gna

l

<CA

UTI

ON

FO

R IN

STA

LLAT

ION

> ·P

rior t

o in

stal

latio

n,re

ad th

e In

stal

latio

n M

anua

l car

eful

ly.*1

.Sin

gle-

dotte

d lin

es in

dica

te w

iring

not

sup

plie

d wi

th th

e un

it.*2

.Dot

-das

h lin

es in

dica

te th

e co

ntro

l box

bou

ndar

ies.

TH8

wat

er o

utle

t tem

pTH

6w

ater

�nle

t tem

p

TH22

liqui

d pi

pe te

mp

Ther

m�s

tor

TB15

MA

rem

ote

cont

rolle

rTB

5O

utdo

or u

nit/W

CB

/BC

con

trolle

rTB

2

Exp

lana

t�on

Term

�nal

bloc

kP

ower

sup

ply

Sym

bol

<Sym

bol e

xpla

natio

n>

(2) PWFY-P100, 200VM-E1-AU

- 13 -

(3) CMB-P104V-G1

LEV

3

TRTB

02

CN2631

CN

121

53

CN

05(R

ed)

65

43

21C

ON

T.B

1 2

CN

023

CN

P1 1 2 3

CN

P3

21 1 2 3 4 5 6 7 8 4321

12

32

1

CN

03(Y

ello

w)

CN

13(R

ed)

CN

10

CN

11

CN

07(Y

ello

w)

TH11

TH12

TH15

TH16

PS

1

PS

3

65

43

21

LEV

1

TB01

S(S

HIE

LD)

M2

M1

220V

~240

V20

V~2

2V

L

Not

e: 1

.TB

02 is

tran

smis

sion

term

inal

blo

ck.

Nev

er c

onne

ct p

ower

line

to it

.

2.Th

e in

itial

set

val

ues

of s

witc

h on

CO

NT.

B

ar

e as

follo

ws.

S

W1:

0

SW

2:0

1 2 3 41098

42 3 10

21 432 43

75 6432

1 2 3 41 2 3 42 3 4

98765

753175317531

CN27

(Red

)

CN28

(Blue

)

11

11

2 3 4131211

161514131211

15 1614

1 2 3 4

1

7531CN

29(G

reen

)

1 2 3

1 2 3

1 3

CN36

(Gre

en)

N

ZNR

01ZN

R02

CN

TR(R

ed)

X02

X01 X30 X31

X03

X04

X06

X05 X32

X33

X07

X08 X21

SV

M1

SV

1B

SV

1A

SV

1C

SV

2C

SV

2A

SV

2B

SV

3C

SV

3A

SV

3B

SV

4C

SV

4A

SV

4B

T1 T2 T3 T4

Indo

or/o

utdo

orTr

ansm

issi

on L

ine

PO

WE

R S

UP

PLY

~220

V–2

40V

50H

z/60

HzBR

EA

KE

R(1

6A)

FUS

E(1

6A)

PU

LL B

OX

TO N

EX

T IN

DO

OR

UN

IT

1313 22

t° t° t°t°

MM

UU

LD

1:C

PU

in

oper

atio

n

8

1O

N

SW

4

8

OFF

SW

5

1

OFFON

ON

OFF

1

SW

6

8

DS

A

(Bla

ck)

F01

250V

AC6.

3A F

101

SW

1S

W2

Sym

bol

TR TH11

,12,

15,1

6

LEV

1,3

PS

1,3

CO

NT.

B

TB01

TB02

SV

1~4A

,B,C

SV

M1

T1~4

F01

N

ame

Tran

sfor

mer

Ther

mis

ter s

enso

rE

xpan

sion

val

veP

ress

ure

sens

orC

ircui

tB

C c

ontro

ller

boar

dTe

rmin

al b

lock

(for p

ower

sou

rce)

Term

inal

blo

ck(fo

r Tra

nsm

issi

on)

Sol

enoi

d va

lve

Sol

enoi

d va

lve

Term

inal

Fuse

AC

250V

6.3

A F

(Sym

bol e

xpla

natio

n)*Other models of BC controller are available. For unit information, refer to the Data Book.

- 14 -

(4) CMB-PW202V-J

TB

01M1

M2

WC

B B

oard

Not

e:1.

TB

02 is

tran

smis

sion

term

inal

blo

ck.

Nev

er c

onne

ct p

ower

line

to it

.

2. T

he in

itial

set

val

ues

of s

witc

h on

WC

B B

oard

are

as

follo

ws.

S

W1:

0

SW

2:0

Exp

ansi

on v

alve

The

rmis

tor

sens

orTr

ansf

orm

er

(Sym

bol e

xpla

natio

n)N

ame

Sym

bol

TB

01Te

rmin

al b

lock

(for

pow

er s

ourc

e)Te

rmin

al b

lock

(for

Tra

nsm