Model 1260 Wheel Balancer Manual - Wheels For Sale ... 1260 Manual.pdf- Avoid placing objects in the...

Transcript of Model 1260 Wheel Balancer Manual - Wheels For Sale ... 1260 Manual.pdf- Avoid placing objects in the...

Model 1260 Wheel Balancer

Manual

I 0642 - 1GB

Instructions for use I

CONTENTS 1 - GENERAL 31.1 - GENERAL SAFETY REGULATIONS 31.1.1 - STANDARD SAFETY DEVICES 31.2 - FIELD OF APPLICATION 31.3 - OVERALL DIMENSIONS 31.4 - TECHNICAL DATA 4

2 - HANDLING AND LIFTING 43 - STARTUP 4

3.1 - ANCHORING 43.2 - ELECTRICAL CONNECTION 43.3 - ADAPTER MOUNTING 53.4 - WHEEL GUARD ASSEMBLY AND ADJUSTMENT (OPTIONAL) 53.5 - WD SPACER (OPTION) 5

4 - CONTROLS AND COMPONENTS 54.1 - MANUAL DISTANCE MEASUREMENT GAUGE 54.2 - KEYBOARD AND DISPLAY 64.2.1 - FUNCTION MENU MANAGEMENT 7

5 - INSTRUCTIONS FOR USE OF THE WHEEL BALANCER 85.1 - SETTING THE WHEEL DIMENSIONS 85.2 - MEASUREMENT RESULT 115.3 - RECALCULATION OF THE UNBALANCE VALUES 115.4 - SPLIT FUNCTION (HIDDEN WEIGHT) 125.5 - OUT OF BALANCE OPTIMIZATION 135.6 - AUTOMATIC MINIMISATION OF STATIC UNBALANCE 13

6 - SET-UP 146.1 - AUTODIAGNOSTICS 146.2 - AUTOCALIBRATION 15

7 - ERRORS 167.1 - INCONSISTENT UNBALANCE READINGS 17

8 - ROUTINE MAINTENANCE 178.1 - REPLACING THE PROTECTION FUSES 17

I 0642 - 2GB

I 0642 - 3

1

GB

1 - General

1.1 - General safety regulations-The wheel balancer may only be used by duly authorized and trained personnel. - The wheel balancer must not be used for purposes other than those described in the instruction manual.- The wheel balancer must not be modifi ed in any way except for those modifi cations made explicitly by the manufacturer.- Do not remove the safety devices. Any work on the machine must be carried out by specialised personnel

only.- Avoid using strong jets of compressed air for cleaning.- Use alcohol to clean plastic panels or shelves (AVOID LIQUIDS CONTAINING SOLVENTS).- Before starting the wheel balancing cycle, make sure that the wheel is securely locked on the fl ange.- The machine operator must not wear clothes with fl apping parts. Do not allow unauthorized personnel to

approach the wheel balancer when the cycle is running.- Avoid placing objects in the base which could impair the correct operation of the wheel balancing machine.- Before disassembling the weight shelf, remove the guard (see specifi c instructions)

1.1.1 - Standard safety devices- Stop push button for stopping the wheel under emergency conditions.- The wheel guard is not compulsory since the balancing speed is less than 100 min-1.

1.2 - Field of applicationThe machine is designed for balancing wheels of cars, light commercial vehicles or motorcycles weighing less than 75 kg. It can be operated in a temperature range of 0° to + 45° C.The following functions are provided: ALUS; SPLIT; Unbalance optimisation; Autodiagnostics; Autocalibration.

1.3 - Overall dimensions

I 0642 - 4

2 2a

GB

1.4 - Technical dataSingle-phase power supply 115 / 230 V - 50/60 HzProtection class IP 54Max. power absorbed 0,8 KwBalancing speed < 100 min-1

Cycle time for average wheel (14 kg) 6-8 secondsMax. resolution of measurement 1 gramPosition resolution ± 1.4 °Average noise < 70dB (A)Rim-machine distance 0 - 252 mmRim width setting range 1.5” - 20” Diameter setting range 10” - 30”

2 - Handling and lifting

Note: DO NOT LIFT THE WHEEL BALANCER USING OTHER GRIPS.

3 - Startup

3.1 - AnchoringThe machine can operate on any fl at non resilient fl oor. Make sure that the machine rests solely on the three support points provided (Fig.2a).It is advisable to secure the system to the ground using the specifi c feet (Fig. 2a). if the machine iscontinually used with wheels weighing over 35 kg.

3.2 - Electrical connectionThe machine is supplied with a single-phase mains cable plus earth (ground).The power supply voltage (and mains frequency) is indicated on the machine identifi cation plate and cannot be changed. Connection to the mains must always be made by expert personnel.The machine must not be set up without proper earthing.Connection to the mains should be through a slow acting safety switch rated at 3 A (230V) or 8 A(115 V). See enclosed diagram.

I 0642 - 5

Spring

DC WD Cone

3

3a

GB

3.3 - Adapter mounting

4 - Controls and components

4.1 - Manual distance measurement gauge This gauge serves to manually measure the distance between the point of application of the counterweight and the machine.

The wheel balancer is supplied complete with cone adapters for fi xing wheels with a central hole. Other optional adapters can be mounted:a) Remove the threaded end-piece A after unscrewing the screw B.b) Mount the new fl ange (see attached sheets).Note: CAREFULLY CLEAN THE COUPLING SURFACES BEFORE PERFORMING ANY

OPERATION.

3.4 - Wheel guard assembly and adjustment (optional)a) Fasten the components to the base as illustrated in specifi c exploded view.b) With the guard closed check that the microswitch prod has slipped into place on the ring.c) Appropriately adjust the angular position of the control ring.N.B.: Do not lean on the guard during the wheel balancing cycle.

3.5 - WD spacer (option)When balancing very wide wheels (9”), there is not enough space to turn the distance gauge. To move the wheel away from the machine side, fi t the WD spacer on the fl ange body and secure it with the standard issue nuts. When centring the wheel with cone from the inside, mount the DC spacer to obtain spring thrust.

I 0642 - 6

4

78

6

4 3

1

5

2

10

9 11

15

16

12

1317

18

19

14

8

GB

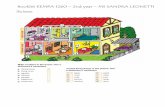

4.2 - Keyboard and display

1-2 Digital readouts, AMOUNT OF UNBALANCE, inside/outside

3-4 Digital readouts, POSITION OF UNBALANCE, inside/outside

5 ALU correction mode selection button6 Indicators, correction mode selected7 STATIC/DYNAMIC correction mode selection button8 Special function indicators9 Manual DISTANCE setting button10 Manual WIDTH setting button

11 Manual DIAMETER setting button12 Push button, FUNCTION MENU13 Balancing cycle/HOME stop button14 Balancing cycle start button15 Gram/ounce unit of measure selection button 16 Push button, SPLIT (unbalance resolution)17 TRUCK ROUND OFF push button18 MENU selection confi rmation pushbutton 19 Push button, unbalance reading < 5 g (.25 oz)

Note: Press buttons only with your fi ngers. Do not use the counterweight grippers or other pointed objects.

I 0642 - 7GB

4.2.1 - Function menu management

start from guard closing

approx. -5 g or 0.1-0.25 oz

See chapter on AUTODIAGNOSTICS

See chapter on AUTOCALIBRATION

RETURN TO MEASUREMENT SCREEN

CONFIRM

CONFIRM

mm/inchdiameter

mm/inch width

CONFIRM

CONFIRM

See chapter on UNBALANCE OPTIMIZATION

I 0642 - 8

5

bb

GB

5 - Instructions for use of the wheel balancer

5.1 - Setting the wheel dimensions

From the measurement frame, press / to select the desired correction mode.

The illuminated LEDs indicate the position where the weights should be applied. If a spin has already been carried out, each time the mode is changed, the processor automatically recalculates the unbalance values on the basis of the new setting.

a)

DYNAMIC balancing of steel or light alloy rims with application of clip-on weights on the edge of the rim.

- Measuring

- Set the distance “a” between the inside of the wheel and the machine

- Set the nominal width, normally indicated on the rim, or measure the width “b” using the caliper gauge supplied.

- Set the nominal diameter “d” indicated on the tyre.

Reading

The STATIC mode is required for motorcycle wheels or when it is not possible to place the counterweights on the two sides of the rim.

Balancing of light alloy rims with application of adhesive weights on the shoulders of the rims. The position of the weights is fi xed from the edges of the rim to the inside of the rim.

Combined balancing: adhesive weight on the outside and clip-on weight on the inside. The position of the outside weight is fi xed from the outside edge of the rim to the inside of the rim.

Combined balancing: adhesive weight on the inside and clip-on weight on the outside. The position of the inside weight is fi xed from the edge of the rim to the inside of the rim

This setting is also valid for the following correction modes:

- Setting

I 0642 - 9

6

+

GB

b)

Setting:

0 gauge

Balancing of alloy rims with hidden application of the outside adhesive weight. The position of the weights can be set.

- Measuring:

(Nominal)

Note: Not setting dE as it is automatic, dE = d - 2”.

for more than 3 seconds to enable the outside diameter

I 0642 - 10

7

+

GB

c)

Combined balancing: clip-on weight on the inside and hidden adhesive weight on the outside (Mercedes).The position of the weights can be set.

0 gauge

Setting:

Note: not setting dE as it is automatic, dE = d - 2”.

- Measuring:

(Nominal)

for more than 3 seconds to enable the outside diameter

I 0642 - 11

8a

8b

cm60 mm

GB

5.2 - Measurement result

Inside correction

Outside correction

After performing a balancing spin, the amounts of unbalance are shown on the digital readouts.The illuminated LEDs 3 and 4 indicate the correct angular position of the wheel to mount the counterweights (12 o’clock).

If the unbalance is less than the threshold value selected, is displayed instead of the unbalance value; with

the values below the threshold can be read, selected gram by gram.

Note : in the case of wheels with a diameter less than or equal to 13” and at temperature conditions near 0°, the wheel balancer automatically inserts a special measuring cycle composed of two successive measurements.

The accuracy of the unbalance values and the reliability of the wheel balancer remain unchanged. This type of operation is reset each time the wheel balancer is started.

5.3 - Recalculation of the unbalance values

Press after new setting of the measurement.

d) Setting with gauge extension

Extension + 60

The extension increases the gauge distance measurement fi eld by 60 mm (Fig. A) and allows distancemeasurement even when the rim has a special profi le (Fig. B).Proceed as indicated below:- Fit the extension on the distance gauge.- Measure the distance as already described.- Having read value “a” on the dial, reset the gauge to 0 and set by hand the value “a + 60”- Manually set the diameter and the width.

I 0642 - 12

15

30

15

15

30

30

15

30

GB

5.4 - SPLIT function (hidden weight)The SPLIT function is used to position the adhesive weights behind the wheel spokes so that they are not visible. This function should be used only in the case of static unbalance or where the hidden adhesive weight is to be applied on the outside. Input the wheel dimensions and do a spin. Start the SPLIT function as follows:

Example of display prior to SPLIT function- Place the wheel in the outside unbalance correction position.- Set one of the top spokes (preferably the one to the left of the unbalance) to 12 o’clock.

- Press the button

- Follow the UP/DOWN indication of the positioning LEDs and set the second top spoke to 12 o’clock.

- Press button

- Set the fi rst split unbalance to correction position 1

- Correction position 1

- Set the second split unbalance to correction position 2

- Correction position 2

N.B.: If error 24 is displayed, repeat the SPLIT function ensuring that the minimum distance between the spokes is greater than 18 degrees. If error 25 is displayed,repeat the split function ensuring that the maximum distance between the spikes is smaller than 120 degrees.

To return to normal unbalance display, press any button.

To carry out a new spin, press the button.

I 0642 - 13GB

5.5 - Out of balance optimization (TYRE MATCHING)- This function serves to reduce the amount of weight to be added in order to balance the wheel- It is suitable for static unbalance greater than 30 g. /1. oz- It improves the residual eccentricity of the tyre.

RIM POSITION

TYRE POSITION

- With a piece of chalk make a reference mark on the fl ange and the rim- With the aid of a tyre remover, turn the tyre on the rim by 180°- Refi t the wheel in such a way that the reference marks on the rim and the fl ange

coincide.

- RH display: percentage reduction value- LH display: actual static unbalance value which can be reduced by rotation

- Mark the two positions of the rim and tyre, and turn the tyre on the rim until the positions correspond in order to obtain the optimization on the display.

CANCEL OPTIMISATION IN ANY PHASE.

Unbalance already measured

No previous unbalancemeasurement

unbalance measurement

5.6 - Automatic minimisation of static unbalance

Initial unbalance

Possible approximations phase shift

With conventional wheel balancer

Choice with minimum static residual

residual static residual static residual static residual static

This program is designed to improve the quality of balancing without any mental effort or loss of time by the operator. In fact by using the normal com-mercially available weights, with pitch of 5 in every 5 g, and by applying the two counterweights which a conventional wheel balancer rounds to the nearest value, there could be a residual static unbalance of up to 4 g. The damage of such approximation is emphasized by the fact that static unbalance is cause of most of disturbances on the vehicle. This new function automatically indicates the optimum entity of the weights to be applied by approximating them in an “intelligent” way according to their position in order to minimize residual static unbalance.

I 0642 - 14GB

6 - Set-up

6.1 - AutodiagnosticsIn Setup, selecting diagnosis gives:

DISPLAY TEST- All the LEDs and the displays should light up simultaneously.

- On the right-hand display the current position of the wheel is indicated with a number from 0 to 127. Turning the wheel in the direction of

rotation, the number displayed should increase. Turning the wheel in the opposite direction of rotation the number displayed should decrease. With one full turn of the wheel the number zero should appear only once.

- Control parameter

- Checking parameter for technical service

- Checking parameter for technical service

END OF AUTODIAGNOSTICS

CANCEL AUTODIAGNOSTICS IN ANY PHASE.

I 0642 - 15GB

6.2 - AutocalibrationFor autocalibration proceed as follows:- Fit a wheel with steel rim of average dimensions on the shaft. Example 6” x 14” (± 1”)- Set the exact dimensions of the wheel mounted.CAUTION !! Setting incorrect dimensions will result in the machine not being properly calibrated and hence all the subsequent measurements will be incorrect until a new autocalibration is performed with the correct dimensions!!

- Perform a spin under normal conditions.

- Add a 100 g. sample weight (3.50 oz) on the outside in any angular position.

- Shift the sample weight from the outside to the inside keeping the same angular position.

- Turn the wheel until the sample weight is in the 12 o’clock position.

END OF AUTOCALIBRATION

CANCEL AUTOCALIBRATION IN ANY PHASE.

I 0642 - 16GB

7 - Errors

During machine operation there may be various causes of malfunctioning which, if detected by the microprocessor, are indicated on the display:

ERRORS CAUSES CONTROLS

Black The wheel balancer does not come on. 1. Check proper connection to the mains.2. Check and if necessary replace the fuses on the power board.3. Replace the computer board.

Err. 1 No rotation signal. 1. Check belt tautness.2. Check functioning of the phase generator and, in particular, the

reset signal.3. Replace the phase generator.4. Replace the computer board.

Err. 2 Too low speed during measurement.During the unbalance measurement revolutions, the wheel speed has fallen to below 42 rpm.

1. Check that a vehicle wheel has been mounted on the wheel balancer.

2. Check belt tautness.3. Check functioning of the phase generator and, in particular, the

reset signal.4. Replace the computer board.

Err. 3 Too high unbalance. 1. Check the wheel dimension setting.2. Check the sensor connections.3. Run the machine calibration function.4. Mount a wheel with a more or less known unbalance (less than 100

grams) and check the machine response.5. Replace the computer board.

Err. 4 Rotation in opposite direction.After pressing [START], the wheel starts turning in the opposite direction (anticlockwise).

1. Verify the connection of the UP/DOWN - RESET signals on the phase generator.

Err. 5 Guard openThe [START] pushbutton was pressed without fi rst closing the guard.

1. Reset the error.2. Close the guard.3. Verify the function of the protection uSwitch.4. Press the [START] button.

Err. 7 / Err. 8 /Err. 9

NOVRAM parameter read error 1. Repeat machine calibration2. Shut down the machine.3. Wait for at least ~ 1 min.4. Restart the machine and check proper functioning.5. Replace the computer board.

Err. 11 Too high speed error.The average spinning speed is greater than 240 rpm.

1. Check if there is any damage or dirt on the timing disc.2. Check functioning of the phase generator and, in particular, the

reset signal.3. Replace the computer board.

Err.14/Err.15/Err.16/Err.17/Err. 18/Err. 19

Unbalance measurement error. 1. Check functioning of the phase generator.2. Check the sensor connections.3. Check the machine earthing connection.4. Mount a wheel with a more or less known unbalance (less than 100

grams) and check the machine response.5. Replace the computer board.

Err.21 Motor on for more than 15 seconds. 1. Check functioning of the phase generator.2. Check the connections on the power board.3. Replace the computer board.

Err.22 Maximum number of spins possible for the unbalance measurement has been exceeded.

1. Check that a vehicle wheel has been mounted on the wheel balancer.

2. Check belt tautness.3. Check functioning of the phase generator and, in particular, the

reset signal.4. Replace the computer board.

Err. 24 Distance between the spokes smallerthan 18 degrees.

1. The minimum distance between the spokes where to split the unbalance must be greater than 18 degrees

2. Repeat the SPLIT function increasing the distance between the spokes.

Err. 25 Distance between the spokes greaterthan 120 degree

1. The minimum distance between the spokes where to split the unbalance must be smaller than 120 degrees

2. Repeat the SPLIT function increasing the distance between the spokes.

I 0642 - 17GB

7.1 - Inconsistent unbalance readingsIt may occur that after balancing a wheel, when removing it from the wheel balancer and then remounting it, the wheel is not balanced.This is not the result of an incorrect indication by the machine, but only of incorrect mounting of the wheel on the fl ange, i.e. in the two mountings the wheel has assumed a different position with respect to shaft axis of the wheel balancer. If the wheel has been mounted on the fl ange with screws, it may be that the screws have not been tight-ened correctly in gradual criss-cross manner one after the other, or (as often occurs) holes have been drilled in the wheel with too wide tolerances.Small errors, up to 10 grams (0.4 oz), are to be considered normal in wheels locked with a cone: the error is normally greater for wheels locked with screws or studs.If, after balancing, the wheel is still unbalanced when refi tted on the vehicle, this could be due to the unbalance of the brake drum or very often is due to the screw holes in the rim and the drum drilled with too wide tolerances. In this case a readjustment would be advisable using the wheel balancer with the wheel mounted.

8 - Routine maintenance

Before carrying out any operation on the machine, cut the power supply to the machine.

8.1 - Replacing the protection fusesA protection fuse is fi tted on the power board, accessible by dismantling the weight shelf (see Exploded Drawings). If fuses require replacement, use ones with an identical current rating.If the fault persists, contact Technical Service.

NONE OF THE OTHER MACHINE PARTS REQUIRE MAINTENANCE.

Err.32/Err.33/Err.34/Err.35/Err.36/Err.37

Errors related to test functions of the wheel balancer.

1. Cancel the error and continue using the wheel balancer as normal.

08.02.06 Fl _Ø40 - 1

Ø 40

GB

UC20UC20-SE2

OPTIONS forUC20

UH20/2

SR

RMC20/mot/2

RMC20/man

RM20/15

Universal cone adaptors

Universal quick adaptor

Adaptor with centering studs

Universal adaptor for motorized balancers

Universal adaptor for manual balancers

Universal adaptors for motorcycle wheels

Options for universal cone adaptors

Equipments for car balancers

Adaptor with centering studs SR-USA SR-USA

2 - Fl _Ø40 08.02.06

Ø 40

GB

Equipments for car balancers

1 2 3 4

5 6 7

8 9

GPM

GP

10

2 11

5 6 7

8 9

41FF52874

41FF52875

41FF52768

09.03.07 Fl UC20/2-UC20/SE2_Ø40 - 1

Ø 40

GB

Universal cone adaptor UC20/2UC20/2with lockring

GP

UC20/2 with lockring

GPM

1 42FM51744 threaded end L = 205

2 325047011 knurled washer Ø 10

3 312120137 screw TCEI M10x160 UNI 5931

4 114008002 allen wrench 8 mm

5 40FF43714 cone A1 Range Ø 43 ÷ 69

6 40FF43715 cone A2 Range Ø 60 ÷ 81

7 40FF43716 cone A3 Range Ø 79 ÷110

8 40FF51315 hollow sleeve Ø 130 outside

9 40FF51334 nylon washer Ø 80 outside

10 40FP52767 SE2 spacer

11 46FP69523 SE2/C threaded end with locking tool

11 46FP69526 SE/B threaded end with locking tool (in-axis motor)

GENERAL FEATURING : - Hardened steel cones and ground shaft.

machine accessoriesstandard adaptor accessories

ITEM CODE DESCRIPTION DATA

UC20-SE2 complete adaptor

for balancers with pneumatic locking

GENERAL FEATURING : - Hardened steel cones and ground shaft.

machine accessoriesstandard adaptor accessories

ABCDCEF

GH

MNOPQ

8 98 9

41FF75815 41FF75868

2 - Fl UC20/2-UC20/SE2_Ø40 09.03.07

Ø 40

GB

Universal cone adaptor UC20/2

UC20/2: • fit the suitable cone (conicity towards the outer side) and, in sequence, the wheel, the lockring complete with hollow sleeve 8;• the hollow sleeve is replaced by the nylon washer 9 for light alloy rims with protruding hub.

FITTINGIt is recommended that the adaptor is used in the "back-cone" method.

UC20-SE2:• press the unlocking pedal• fit the suitable cone (conicity towards the outer side) and, in sequence, the wheel, the lockring complete with hollow sleeve 8;• press the locking pedal• the hollow sleeve is replaced by the nylon washer 9 for light alloy rims with protruding hub.

A 940012977

B 331220059

C 331220055

D 940012975

E 40FF75817

F 183237600

G 40FF75829

H 312120067

M 321232006

N 218295313

O 217295353

P 325035006

Q 312120073

GPMquick lockring with handwheel

GPquick lockring

Compulsory in EC countries for machines without wheel guard (balancing speed < 100 Rpm)

ITEM CODE ITEM CODE

01.03.07 Fl OPZIONI+KIT-VL2_Ø40 - 1

Ø 40

82

65

4

16 17

7

14

15

3

2 940010537

3 40FF52417

4 40FF53534

5 40FF53531

6 940013325

41FF53532 6

5

7 40FF57321

8 41FF51339

GB

OPTIONS - Universal cone adaptor UC20/2

ITEM CODE DESCRIPTION

G/36 Spacer discTo be used with VL/2 cone for wheel with central hole Ø 170

J ConeTo be used for cross-country and 4WD wheels range Ø 101÷119Recommended for WD spacer

VL/2 Cone

To be used with G/36 disc range Ø 97÷170(to extend the range up to Ø 180 use Kit VL/2)

DC Spring pusher spacerRecommended for WD spacer

WD Wheel support spacer

KIT WD + DCRecommended for Wheels with large camber(cross-country and 4WD)

RL Hollow sleeve for alloy rims

Ø 206 external

MT Stepped cone for German wheels

Steps ModelsØ 56,5 OPELØ 57 AUDI (all models) - BMW serie 3 - Porsche 924 VW Polo, Golf, Derby, Scirocco, Vento, Passat, SantanaØ 66,5 MERCEDES BENZ (all models)Ø 72,5 BMW serie 5-6-7-8 - Opel Admiral

2 - Fl OPZIONI+KIT-VL2_Ø40 01.03.07

Ø 40

12

3

11 10 9

41FF73171

13

12 11 10 9

41FF53550

9 940010105

40FF43745

312120119

326035011

10

11

12

41FF60652

40FF606531340FF6104314

Pick Up - FORDF250 super cab XLT F350 crew cab LARIAT F450

F250 crew cab XLT F350 crew cab DUALIE

MercedesSprinter New series

40FF72696

40FF72546

40FF72694

15

16

17

15 16 17

40FF72696

40FF77141

40FF77140

15

18

19

40FF77143

40FF7714220

21

41FF77152

15 18 19 20 21

Ø 60

Ø 66

Ø 71

Ø 88

Ø 129.9

GB

OPTIONS - Universal cone adaptor UC20/2ITEM CODE DESCRIPTION

VL/2 CONE KITNecessary to lock light trucks

wheels with central hole

Ø 170÷180

GG Ring

G40 Spacer disc

Screw TCEI M10x20 UNI 5931

Flat washer Ø 11 30x2,5 UNI 6593

SPECIAL 8.5” CONE IV KIT Required to clamp van wheels - GM series 2500 (GMC, Chevrolet, Oldsmobile etc.)

Special Cone IV 8,5" Ø 202/214/215,9

Special cone Ø 89 / 132

KIT PSA (CITROEN, PEUGEOT)

Centering bush

MT-P 55/58 cone Ø 40 (Ø 54÷ Ø 60)

MT-P 65 cone Ø 40 (Ø 62÷ Ø 68)

Ø 40 (Ø 60)

Centering bush

Centering bush

Centering bush

Centering bush

Centering bush

RENAULT centering KIT

01.03.07 Fl OPZIONI+KIT-VL2_Ø40 - 3

Ø 4012

10

1615 17

10

12

15

16

17

40FF43745

312120119

40FF66115

40FF66117

40FF66116

41FF66118

SR3

- FIAT DAILY- MITSUBISHI CANTER T35- OPEL BEDFORD- FORD TRANSIT FT 130-190 100L

Ø

- TOYOTA Dyna 150

- MITSUBISHI CANTER T75

UC 20/2 UC20/2 - SE2

GB

Centring

KITMAIN FEATURES : - Suitable for van and light-truck wheels with 6 fi xing holes.- Perfect for locking wheels with a worn or deformed central hole.- Insert the stud bolts (16) in the relevant holes in the spider. Lock with the nuts (17).- Tighten the spider with the standard devices provided with the wheel balancer.

G/40 Spacer disc

Screw

Stud

3-arm spider

Nut

Main car models

TCEI M10 X 20 UNI 5931 (2 Pieces)

( 3 pieces)

( 3 pieces)

OPTIONS - Universal cone adaptor UC20/2

6 holes over 170 Ø

6 holes over 184,15 Ø

6 holes over 205 Ø

6 holes over 222,25 Ø

6 holes over 245 Ø

standard KIT equipment

- Light trucks in general

FITTING

ITEM CODE DESCRIPTION DATA

- MERCEDES LLKW series 400, 500, 600, 700, T1/T2- VOLKSWAGEN LLKW LT 35-55 / L80

4 - Fl OPZIONI+KIT-VL2_Ø40 01.03.07

Ø 40

GB

OPTIONS - Universal cone adaptor UC20/2

1 2

6

3 4

5

7

89

12

10

11 6*

Ø ØØ

30.05.02 Fl UH20/2_Ø40 - 1

Ø 40

GB

Universal quick adaptor UH20/2

standard adaptor accessoriesoptions

1 321232008 2 nut M8 UNI 5588

2 325035008 2 flat washer Ø 8,4 x 17

3 40FF33438 1 adaptor body

4 40FF33439 1 guide disc

5 40FF33440 5 complete stud bracket

6 40FF33441 4 gauged screw burnished

6* 40FF33443 1 gauged screw tropicalized

7 940052253 1 gauge

8 115006002 1 t-wrench hexagon 6

9 40FF33442 5 special nut conic 60° / spherical radius 10

10 112019220 1 socket spanner hexagon 19/22

11 40FF42165 1 pre-centering cone Ø 52 ÷ 72,5

12 41FF38501 1 kit of 5 special long nuts conic 60° / spherical radius 8 (for Peugeot 406)

GENERAL FEATURING : • for wheels with or without central hole. • The additional cone 11 (CEMB patent), in most cases, allows to center the wheel on the central hole, thus improving balancing accuracy.

Fit for any motor-vehicle wheels with 3, 4 or 5 holeson Ø 95 up to 210 mm.

ITEM CODE Q.ty DESCRIPTION DATA

complete adaptorfor wheel balancers

with manual orpneumatic locking

UH20/2

41FF42048

9

12

53

11

43

11

345

5 5

5 5

4 4

4

33

33

345 345

4

4

4

345

5 5

5 5

4 53

2 - Fl UH20/2_Ø40 30.05.02

Ø 40

GB

Universal quick adaptor UH20/2FITTING

1) Change the adaptor pattern (3;4;5) according to any requirements.N.B. : do not lock studs (5) leaving screws (6) and (6*) loosen, to enable the operation at point 3).

BASIC SETTING FOR PATTERN MODIFICATION

DON'T DISMOUNT6*

2) Measure the distance between two of wheel holes with the gauge (7).

3) Line the axles of two studs to the gauge prod.

4) Lock the screws(6) and(6*).

5) Fit the wheel.N.B.: The use of cone (11) generally improves the wheel centering accuracy.

6) Lock the nuts by hand (9).

7) Lock the nuts with the socket spanner (10), not too tigh.

04.09.06 Fl SR_SR/SE2_Ø40 - 1

Ø 40

8

1

2

9

6

3 5 4 3

9

8

7

26

3 5 4 3

99

1

2

3

4

5

6

7

8

9

40FF53856

40FF53857

40FF53858

41FF32952

211001081

40FF32949

355122509

40FF32951

40FF55943

40FF55941

40FF55942

40FF32950

213003753

SR541FF53854

SR441FF53853

SR5/241FF53855

SR5-SE241FF55891

SR4-SE241FF55890

SR5/2-SE241FF55892

GB

Adaptor with centering studs SR

standard adaptor accessories

SR4 adaptor body

SR5 adaptor body

SR5/2 adaptor body

complete centering stud

rubber gasket OR 108

stud

belleville washer Ø 12,2 x 25 x 0,9

bush L = 48 mm

SR4-SE2 adaptor body

SR5-SE2 adaptor body

SR5/2-SE2 adaptor body

long bush (Special light alloy rims)

Non-scratch cap

GENERAL FEATURES : - For a quick and accurate

locking of wheels having central hole on cone adaptors, using fixing holes of the vehicle. Centering studs can quickly be inserted in the adaptor disc by simply pressing them by the hand (no need to screw them on) and allow to obtain high accuracy thanks to the elastic system for recovering clearances caused by rim inaccuracies.

NB: eliminates scratching problems with alloy rims caused by the clamping sleeves. The anti-scratch clamps (9) also avoid damage to the rims.

STANDARD LOCKING

ITEM CODE DESCRIPTION DATA

PNEUMATIC LOCKING

STANDARD LOCKING

PNEUMATIC LOCKING

standard adaptor accessories

2 - Fl SR_SR/SE2_Ø40 04.09.06

Ø 40

Ø

Ø

Ø

98 Fiat - Lancia - Alfa Romeo - Autobianchi - Talbot - Lada - Skoda

100 Bmw - Opel - Audi - Volvo - Volkswagen - Toyota - Honda - Nissan

108 Ford - Audi - Alfa Romeo - Citroën BX - Maserati

110 Mazda 323 - Mazda 626

114.3 Mitsubishi - Daihatsu - Mazda - Saab - Toyota - Suzuki - Nissan - Ford USA - Honda - Hyundai

120 Honda - Mazda

130 Volkswagen - Ford Transit - Mecedes

SR4SR4-SE2

100 Toyota - Seat - Audi - Skoda

108 Volvo - Lancia Gamma - Citroën MX

112 Ford - Audi - Mercedes - Bmw

114.3 Mitsubishi - Mazda - Toyota - Nissan - Honda

120 Bmw - Opel

139.7 Volkswagen - Ford Transit - Mercedes

150 Toyota (Land Cruiser)

160 Ford Transit - Mercedes

SR5SR5-SE2

98 Alfa 164 - Citroën CX - Thema 8.32

110 Opel - Saab

118 Ducato - Peugeot - Citroën

120.65 Jaguar - G.M.C. - Maserati - Chevrolet

127 G.M.C. - Rover - USA cars - Jaguar

130 Mercedes - Audi - Porsche

140 Mercedes

SR5/2SR5/2-SE2

GB

Adaptor with centering studs SRFITTING

STANDARD LOCKING PNEUMATIC LOCKING

Ø Main car makes

OPTION recommended for wheel balancers with standard locking

04.09.06 Fl SR_SR USA/SE2_Ø40 - 1

Ø 40

12

6

43

52

6

43

1

2

3

4

6

5

GB

Adaptor with rigid centering studs SR-USA

standard adaptor accessories

40FF56188 1 Adaptor body

940013701 6 Fixed stud L = 50

325035012 6 Flat washer 13 x 24 UNI 6592

321232012 6 Nut

40FF56192 1 adaptor body

42FF46928 6 Long stud L = 80 (Nissan Patrol)

STANDARDLOCKING

ITEM CODE Q.ty DESCRIPTION DATA

PNEUMATICLOCKING

STANDARD LOCKING

PNEUMATICLOCKING

standard adaptor accessories

CARATTERISTICHE GENERALI : - It makes use of stiff metal

studs (no elastic). It must be used without cone on central hole. For light trucks, pick-up, off-road vehicles.

SR-USA41FF56189

SR-USA-SE241FF56193

2 - Fl SR_SR USA/SE2_Ø40 04.09.06

Ø 40

Ø

Ø

Ø

GB

Adaptor with rigid centering studs SR-USAFITTING

STANDARD LOCKING PNEUMATIC LOCKING

N.holes Ø" Ø mm Main car makes

OPTION recommended for wheel balancers with standard locking

5 4.0 101.6 US-Cars, plymouth, chevrolet, Dodge

5 5.5 139.7 Daihatsu, Ford, Lada, Suzuki

5 6.5 165.1 Rover

6 5.5 139.7 Ford, G.B., Isuzu, Mazda, Mitsubishi, Nissan, Opel, Toyota,

Wolkswagen

3 114.3 Nissan Pathfi nder (6 holes)

3 130 Mercedes Sprinter

4 6.5 165.1 Doge, Ford International (8 holes)

4 170 Ford

16171819

1213

11

6 4 5

10

8

9

14

21

21

153

15 14 7

20

20

6

4 5

21

41FF67752

41FF70855

1

07.02.06 Fl RMC20/mot/2_Ø40 - 1

Ø 40

GB

Universal adaptor RMC20/mot/2

RMC20/mot/2

Flanged wheels

standard adaptor accessoriesoptions

GENERAL FEATURES : In standard version, it centers all wheels with central through hole having diam. from 15 to 35 mm and flanged wheels (i.e. rear wheels of Aprilia, Ducati, Bmw, Honda, etc.) with centering up to 68 mm diam. In this case, a special cone(16,17,18,19) pushed onto wheel centering area by adaptor spring is available (CEMB patent).

1 40FF29925 1 shaft Ø 15 L=231

2 40FF48244 1 spring pusher Ø 15

3 41FF67840 1 complete bracket

4 325035008 2 flat washer 8,4x17 UNI 6592

5 311120096 2 screw TE M8x30 EN 24014

6 321232008 2 nut M8 EN 24032

7 40FF29950 1 lockring Ø 15

8 40FF29943 1 counterflange

9 40FF29931 1 spacer Ø 15 L=20

10 40FF29932 1 spacer Ø 15 L=40

11 40FF31377 1 spacer Ø 15 L=95

12 40FF31376 1 disc Ø 15 x 45

13 40FF31649 1 disc Ø 15 x 64

14 325035014 1 washer Ø 15 x 28

ITEM CODE Q.ty DESCRIPTION ITEM CODE Q.tY DESCRIPTION15 40FF29927 2 cone C1 Ø 15-25

16 40FF51119 1 cone C2 Ø 25-30 Yamaha R1-R6

17 40FF29929 1 cone C3 Ø 30-40 BMW

18 40FF31650 1 cone C4 Ø 40-60

19 40FF29944 1 cone C5 Ø 54-68

20 41FF51299 1 COMPLETE KIT OF CENTERING BUSHES

40FF31651 2 B1 L=30 Ø 28

40FF38838 2 B2 L=30 Ø 25

40FF38837 2 B3 L=30 Ø 22

40FF38836 2 B4 L=30 Ø 20

40FF38835 2 B5 L=25 Ø 17

40FF38834 2 B6 L=20 Ø 16

40FF38833 2 B7 L=20 Ø 15

40FF49378 2 B8 L=25 Ø 19,05

21 40FF46706 1 shaft Ø 15 L=270

Aprilia AF1, Honda NTV, Ducati 916

Honda VFR, Yamaha GTS 1000

Yamaha, Honda, Aprilia, Gilera, Kawasaki, Suzuki

Moto Guzzi

Yamaha, Suzuki, KTM

Harley Davidson

Yamaha, Honda, Aprilia, BMW, Triumph, Kawasaki, Suzuki, Laverda, Moto Guzzi, KTM

Yamaha, Honda, Aprilia, Gilera, Kawasaki, Suzuki

Kawasaki

Yamaha

(only for 42"wheel guard) Harley Davidson

for motorized balancers

Wheels with own bearing

18 13 11 9 17 12 11 10

18 13 11

18 12 11 10 15 14 11 10

19 13 11 10

18 13 11 9 19 13 11 10

2 - Fl RMC20/mot/2_Ø40 07.02.06

Ø 40

GB

Universal adaptor RMC20/mot/2FITTING

Some example for flanged wheels.

APRILIA AF1 BMW K-R

DUCATI 916 YAMAHA GTS 1000

HONDA NTV HONDA VFR

EXAGON front wheel EXAGON rear wheel

16171819

1213

11

6 4 5

10

8

9

14

21

21

15

3

15 14 7

20

20

30.05.02 Fl RMC20/man_Ø40 - 1

Ø 40

GB

Universal adaptor RMC20/man

Flanged wheels

standard adaptor accessoriesoptions

GENERAL FEATURES : In standard version, it centers all wheels with central through hole having diam. from 15 to 35 mm and flanged wheels (i.e. rear wheels of Aprilia, Ducati, Bmw, Honda, etc.) with centering up to 68 mm diam. In this case, a special cone(16,17,18,19) pusched onto wheel centering area by adaptor spring is available (CEMB patent).

1 40FF29925 1 shaft Ø 15 L=231

2 40FF48244 1 spring pusher Ø 15

3 21FF31640 1 elastic L=800

4 325035008 2 flat washer 8,4x17 UNI 6592

5 311120096 2 screw TE M8x30 EN 24014

6 321232008 2 nut M8 EN 24032

7 40FF29950 1 lockring Ø 15

8 40FF29943 1 counterflange

9 40FF29931 1 spacer Ø 15 L=20

10 40FF29932 1 spacer Ø 15 L=40

11 40FF31377 1 spacer Ø 15 L=95

12 40FF31376 1 disc Ø 15 x 45

13 40FF31649 1 disc Ø 15 x 64

14 325035014 1 washer Ø 15 x 28

ITEM CODE Q.ty DESCRIPTION ITEM CODE Q.tY DESCRIPTION15 40FF29927 2 cone C1 Ø 15-25

16 40FF51119 1 cone C2 Ø 25-30 Yamaha R1-R6

17 40FF29929 1 cone C3 Ø 30-40 BMW

18 40FF31650 1 cone C4 Ø 40-60

19 40FF29944 1 cone C5 Ø 54-68

20 41FF51299 1 COMPLETE KIT OF CENTERING BUSHES

40FF31651 2 B1 L=30 Ø 28

40FF38838 2 B2 L=30 Ø 25

40FF38837 2 B3 L=30 Ø 22

40FF38836 2 B4 L=30 Ø 20

40FF38835 2 B5 L=25 Ø 17

40FF38834 2 B6 L=20 Ø 16

40FF38833 2 B7 L=20 Ø 15

40FF49378 2 B8 L=25 Ø 19,05

21 40FF46706 1 shaft Ø 15 L=270

Aprilia AF1, Honda NTV,Ducati 916

Honda VFR,Yamaha GTS 1000

Yamaha, Honda, Aprilia, Gilera, Kawasaki, Suzuki

Moto Guzzi

Yamaha, Suzuki, KTM

Harley Davidson

Yamaha, Honda, Aprilia, BMW, Triumph, Kawasaki, Suzuki, Laverda, Moto Guzzi, KTM

Yamaha, Honda, Aprilia, Gilera, Kawasaki, Suzuki

Kawasaki

Yamaha

(only for 42"wheel guard)Harley Davidson

for manualbalancers

Wheels with own bearing

RMC20/man

41FF48071

18 13 11 9 17 12 11 10

18 13 11

18 12 11 10 15 14 11 10

19 13 11 10

18 13 11 9 19 13 11 10

2 - Fl RMC20/man_Ø40 30.05.02

Ø 40

GB

Universal adaptor RMC20/manFITTING

Some example for flanged wheels.

APRILIA AF1 BMW K-R

DUCATI 916 YAMAHA GTS 1000

HONDA NTV HONDA VFR

EXAGON front wheel EXAGON rear wheel

18

16

17

17

2

3

4

1

87 6

5

19

19

3

13

1514

1211

10

9

31.10.03 Fl RM20/15-_Ø40 - 1

Ø 40

GB

Adaptor for motorcycle wheels RM20/15

RM 20/15

41FF49115

standard adaptor accessoriesoptions

GENERAL FEATURES : • It centers all wheels with central through hole.

1 40FF49312 1 adaptor body

2 940013571 1 shaft Ø 15 L=251

3 40FF29927 2 cone C1 Ø 15-25

4 940013796 1 elastic Ø 6 L=580

5 40FF29950 1 lockring Ø 15

6 40FF29932 1 spacer Ø 15 L=40

7 40FF29931 1 spacer Ø 15 L=20

8 325035014 1 washer Ø 15 x 28

9 40FF49313 4 movable pin

10 424115606 2 plate

11 325035013 2 washer Ø 13 x 24 UNI 6592

12 321232012 2 nut M12 UNI 5588

13 315231064 2 screw TS M6x25 UNI 6109

14 325035006 2 washer Ø 6,4x12,5 UNI 6592

15 321232006 2 nut M6 UNI 5588

ITEM CODE Q.ty DESCRIPTION ITEM CODE Q.ty DESCRIPTION16 40FF46721 1 shaft Ø 15 L=270

17 424116877 2 cone Ø 15-35

18 42FF46162 1 elastic (17") Ø 6 L=680

19 41FF51299 1 COMPLETE KIT OF CENTERING BUSHES

40FF31651 2 B1 L=30 Ø 28

40FF38838 2 B2 L=30 Ø 25

40FF38837 2 B3 L=30 Ø 22

40FF38836 2 B4 L=30 Ø 20

40FF38835 2 B5 L=25 Ø 17

40FF38834 2 B6 L=20 Ø 16

40FF38833 2 B7 L=20 Ø 15

40FF49378 2 B8 L=25 Ø 19,05

Yamaha, Honda, Aprilia, Gilera, Kawasaki, Suzuki

Moto Guzzi

Yamaha, Suzuki, KTM

Harley Davidson

Yamaha, Honda, Aprilia, BMW, Triumph, Kawasaki, Suzuki, Laverda, Moto Guzzi, KTM

Yamaha, Honda, Aprilia, Gilera, Kawasaki, Suzuki

Kawasaki

Yamaha

(only for 42" wheel guard)Harley Davidson

Ø 15

Fitting with elastic

2 - Fl RM20/15_Ø40 31.10.03

Ø 40

GB

Adaptor for motorcycle RM20/12

D0348-1 0374-1 1 MANDRINO SHAFT ASSEMBLY

D0287-2 642-2 2 MOTORE+DATORE DI FASE+ MOTOR+POSITION PICK-UP+TRASDUTTORI PIEZO PIEZO TRANSDUCER

D564-4 564-4 4 BASAMENTO (1) CASING (1)

D642-5 642-5 5 BASAMENTO (2) CASING (2)

D563-6-CM 543-6 6-CM CALIBRO DISTANZA (MANUALE) DISTANCE GAUGE (MANUAL)

D457-7 457-7 7 POTENZA POWER UNIT

* Particolari reperibili in commercio * Parts on the market

E-642-1250-GB.PDF

1260 (A)

�

�

�

�

�

���

D0348-1 0374-1 1 DORN BROCHE MANDRIL

D0287-2 642-2 2 MOTOR+PHASENGEBER+ MOTEUR+DONNEUR DE PHASE+ MOTOR+CAPTADOR DE FASE+PIEZOGEBER TRANSDUCTEURS PIEZO TRANSDUCTORES PIEZOELECTRICOS

D564-4 564-4 4 SOCKEL (1) BASE (1) BASE (1)

D642-5 642-5 5 SOCKEL (2) BASE (2) BASE (2)

D563-6-CM 543-6 6-CM ABSTAND MESSLEHRE (MANUELL) CALIBRE DISTANCE (MANUEL) CALIBRE DISTANCIA (MANUAL)

D457-7 457-7 7 NETZEINHEIT PUISSANCE POTENCIA

* Handelsübliche Teile * Pièces se trouvant dans le commerce * Piezas que se encuentran en el mercado

E-642-1250-D.PDF

1260 (A)

�

�

�

�

�

���

1D0348-1

� � � � � � � �

��

��

��

� � �� �� ��

� � �� �� �� �� ��

0374-10374-1

N. CODE DESCRIPTION N. CODE DESCRIPTION N. CODE DESCRIPTION

1 311225120 * SCREW

2 325046010 * SPRING WASHER

3 326035011 * FLAT WASHER

4 42FM49794 DRIVEN PULLEY

5 04FM38621 PHASE DISC

6 341000025 * SEEGER RING

7 020600503 * BEARING

8 42FM60997 LEAF SPRING SET

9 040010101 STICK-ON ARROW

10 342000047 * SEEGER RING

11 04FM40630 PLASTIC RING SPINDLE

12 42FM41391 COMPLETE SHAFT Ø 40

13 114008002 * ALLEN WRENCH

14 312120137 * SCREW

15 325047011 * KNURLED WASHER

16 42FM51744 THREADED END Ø 40

17 344200118 * SEEGER RING

18 42FP41056 COVER

19 181198630 SPRING

20 326035009 * FLAT WASHER

21 325046008 * SPRING WASHER

22 312120093 * SCREW

�

����

��

�� ��

�����

������

��

��

������

������

��

��

��

��

��

��

��

�

�

�

��

�

����������������������� �����

��

�

642-2

2D0287-2

N. CODE DESCRIPTION N. CODE DESCRIPTION N. CODE DESCRIPTION

1 86SD73910 COMPL. POSITION PICK UP

2 420610639 CABLE RETAINER

3 42SD36228 SUPPORT

4 314231018 * SCREW

5 67M38954J POSITION PICK-UP BOARD

6 42SD69942 * SPACER NO BP

7 321232003 * NUT

8 311220072 * SCREW

9 325046006 * SPRING WASHER

10 325035006 * FLAT WASHER

11 325046005 * SPRING WASHER

12 50FG55641 MOTOR 230V

12 50FG55643 MOTOR 115V

13 348016018 * MOTOR KEY

14 07FG56429 DRIVING PULLEY

15 326035004 * FLAT WASHER

16 312120035 * SCREW

17 325046004 * SPRING WASHER

19 080077007 RIGID BELT

20 325035010 * FLAT WASHER

21 321212010 * EXAGONAL NUT

22 940701232 PIEZO ASSEMBLY

23 345122515 CUP SPRING

24 326035011 * FLAT WASHER

25 105110165 THREADED BAR

26 105114744 EYE ROD

27 940701233 PIEZO ASSEMBLY

4D564-4

564-4

�� �

�

��

� �

��

��

�

N. CODE DESCRIPTION N. CODE DESCRIPTION N. CODE DESCRIPTION

1 14FB72050 COVER WITH WEIGHT TRAY

2 42FB72183 REAR CASING

3 213008753 * PLUG

4 311920400 * SELF-THREADING SCREW

5 42FB67389 CASING

6 42FB72182 FRONT CASING

7 42FB70336 SUPPORT

8 200000016 * SQUARE NUT

9 317220072 * SELF-THREADING SCREW

10 311920200 * SELF-THREADING SCREW

5D642-5

642-5

�

�

�

�

�

�

��

� �

N. CODE DESCRIPTION N. CODE DESCRIPTION N. CODE DESCRIPTION

1 86PR79614 COMPLETE MONITOR

2 321232003 * NUT

3 86SC79613 COMPUTER BOARD

4 527034980 * SPACER

5 42PR79499 PANEL SUPPORT

6 315231015 * SCREW

7 05PR79518 CONTROL PANEL

8 329007663 * RAPID PIN

9 329004434 * RAPID CONNECTION

10 681002000 * FUSE

6-CMD563-6-CM

543-6

��

�

��

�

�

N. CODE DESCRIPTION N. CODE DESCRIPTION N. CODE DESCRIPTION

1 181206560 DISTANCE GAUGE SPRING

2 42FC40572 DISTANCE GAUGE ROD

3 335310040 * ELASTIC DOWEL

4 42FC73156 GAUGE BRACKET

5 040142902 GRADUATED BAND

8 21FC47315 INDEX FOR DIST. GAUGE

9 312120071 * SCREW

11 311920380 * SCREW

7D457-7

457-7

�

�

�

��

��

�

��

��

N. CODE DESCRIPTION N. CODE DESCRIPTION N. CODE DESCRIPTION

1 511242101 PLATFORM SWITCH

3 86SZ76201 COMPL. POWER PLATE 230V

3 86SZ73369 COMPL. POWER PLATE 115V

5 527006175 * SPACER

6 67M70968M POWER SUPPLY BOARD 230V

6 67M70968N POWER SUPPLY BOARD 115V

7 568001058 CAPACITOR 230V

7 568003558 CAPACITOR 115V

11 526003246 * CABLE CIRCLIP

12 311920300 * SCREW

13 681002001 FUSE