Minimum-jerk trajectory planning pertaining to a ...

Transcript of Minimum-jerk trajectory planning pertaining to a ...

Research Article

Advances in Mechanical Engineering2020, Vol. 12(3) 1–18� The Author(s) 2020DOI: 10.1177/1687814020913667journals.sagepub.com/home/ade

Minimum-jerk trajectory planningpertaining to a translational3-degree-of-freedom parallelmanipulator through piecewise quinticpolynomials interpolation

Song Lu1 , Bingxiao Ding2 and Yangmin Li3

AbstractThis article aims to present a minimum-jerk trajectory planning approach to address the smooth trajectory generationproblem of 3-prismatic-universal-universal translational parallel kinematic manipulator. First, comprehensive kinematicsand dynamics characteristics of this 3-prismatic-universal-universal parallel kinematic manipulator are analyzed by virtueof the accepted link Jacobian matrices and proverbial virtual work principle. To satisfy indispensable continuity andsmoothness requirements, the discretized piecewise quintic polynomials are employed to interpolate the sequence ofjoints’ angular position knots which are transformed from these predefined via-points in Cartesian space. Furthermore,the trajectory planning problem is directly converted into a constrained nonlinear multi-variables optimization problemof which objective function is to minimize the maximum of the joints’ angular jerk throughout the whole trajectory.Finally, two typical application simulations using the reliable sequential quadratic programming algorithm demonstratethat this proposed minimum-jerk trajectory planning approach is of explicit feasibility and appreciable effectiveness.

KeywordsTrajectory planning, parallel kinematic manipulator, jerk, the principle of virtual work, piecewise quintic polynomials

Date received: 6 November 2019; accepted: 19 February 2020

Handling Editor: Jose Herreros

Introduction

The last three decades have witnessed a considerabledevelopment of parallel kinematic manipulators(PKMs) which can be treated as positive encouragingcandidates for many advanced automation processesand digitalization applications.1–5 Undoubtedly, theapparent advantages of PKMs are low moving inertia,high stiffness, high dexterity, and high payload-to-weight ratio. These distinct characteristics determinePKMs’ increasing widespread utilization in the fields ofindustrial assembly and practical operations such ashigh-speed picking and placing,6 vibration simulator,7

precise microsurgery,8 cardiopulmonary resuscitation9

and so on. When implementing a specific practical

engineering task (assembly, spot welding, palletization,or three-dimensional printing), for the sake of decreas-ing vibration deformation and improving positioningaccuracy in the movement, the realistic trajectory

1Department of Electromechanical Engineering, Faculty of Science and

Technology, University of Macau, Macao, China2School of Physics and Electromechanical Engineering, Jishou University,

Jishou, China3Department of Industrial and Systems Engineering, The Hong Kong

Polytechnic University, Kowloon, Hong Kong

Corresponding author:

Bingxiao Ding, School of Physics and Electromechanical Engineering,

Jishou University, Jishou 416000, China.

Email: [email protected]

Creative Commons CC BY: This article is distributed under the terms of the Creative Commons Attribution 4.0 License

(https://creativecommons.org/licenses/by/4.0/) which permits any use, reproduction and distribution of the work

without further permission provided the original work is attributed as specified on the SAGE and Open Access pages

(https://us.sagepub.com/en-us/nam/open-access-at-sage).

should possess remarkable continuity, eminent smooth-ness, and high operation efficiency.10

The trajectory planning issue that establishes a para-metric function concerning time under several differentunambiguous constraints is attracting prodigiousresearch interest between academia and industry.11–13

As a particularly critical part of PKMs design and sys-tem scheme, the accurate definition of trajectory candirectly affect the choice of drive motors and reductiongears, vibrations, and efforts impacted on the mechani-cal structure, and tracking accuracy throughout theplanned motion. In other words, the actual trajectorydetermines its real-time kinematics and dynamics per-formance of PKMs.14,15 If the trajectory has a continu-ous curvature or even has a continuous higher orderderivative of curvature, it is believed to be smooth.16

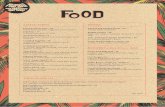

The brief framework of common trajectory planning isillustrated in Figure 1, trajectory planner formulates aspecific excellent trajectory that must satisfy the indis-pensable path constraints, kinematics constraints, anddynamic constraints. In the existing scientific and tech-nological literature of robots and manipulators, thereare many concrete considerations regarding to tradi-tional trajectory planning topic, the most common ofwhich are minimum execution time,17–19 minimumenergy20–22 (or actuator effort), and minimum jerk (i.e.the third-order derivative of position curve withtime).23–26 The presence of discontinuity and roughnesson the trajectory has been found to correlate with adrastically increase of large jerk value reported in thepast several decades.27,28 Limiting the system maximumjerk value, which can diminish vibration influence moti-vated by the dominant vibration factor of the axis,reduce structure wear and resonance frequency emer-gence, improve tracking precision, and enhance trajec-tory smoothness and operational stability, is highlyrecommended to cope with the trajectory planningproblem.29–31 Minimum-jerk trajectory planning theoryand methodology relating to traditional serial kine-matic manipulators have been intensively discussed andinvestigated by numerous researchers. Piazzi andVisioli23 developed a concise approach to globally

minimize the maximum of the absolute value of jerkalong a trajectory which was easily expressed throughcubic splines. The execution time was set a priori, and itwas worth noting that the effect of dynamics propertywas without taking into account. Macfarlane andCroft24 put forward a jerk-limited and near-time-optimal trajectory planning strategy applied on a gen-eral 6-degree-of-freedom (DOF) manipulator, wherethe accompanying point-to-point trajectory was inter-polated using the piecewise fifth-order polynomial func-tion. Gasparetto and colleagues15,26 introduced aminimum time-jerk trajectory planning algorithm ofwhich objective function was to reach a reasonablecompromise between the overall task execution timeand the total integral value of squared jerk. For thesake of formulation of minimum-jerk trajectory plan-ning for surface-mount assembly robots, Gyorfi andWu25 utilized the discretized quintic polynomial curveto obtain an expected trajectory with appealingsmoothness and jerk-limited property. To cope with anotable constrained velocity-level path planning issuefor traditional mobile robots, Guarino Lo Bianco32

introduced a seven-segment parabolic velocity curve tofulfill the complicated minimum-jerk trajectory plan-ning assignment of which objective was to minimize themaximum of longitudinal jerk. To bring out aminimum-time trajectory for a two-DOF translationalPKM in Cartesian space, Huang et al.33 optimized thewhole travel time as well as imposing the path jerk lim-itation as an indispensable constraint condition in orderto achieve satisfactory smooth performance. For anunordinary high-speed 2-DOF two-dimensional PKMdifferent from Huang et al.,33 Hu et al.34 proposed anoptimal time trajectory planning method using piece-wise cubic polynomials in joint space while the inherentdynamic constraints were not taken into full consider-ation. In general, jerk-level trajectory planningapproaches can be frequently employed for addressingthe senior complicated trajectory planning problems oftraditional manipulators with satisfying stringent conti-nuity requirements and sufficient smooth conditions.Unfortunately, to the best of our knowledge, littleresearch has been devoted to jerk-based trajectory plan-ning techniques applied to three-dimensional PKMsscenarios. It is the increasing demand for formulationof smooth trajectory of PKMs that facilitates the pro-found theoretical research, imperative practical applica-tion, and extensive engineering development of thejerk-based trajectory planning concept.

Generally, cubic polynomials are often used insmooth trajectory generation;35 however, they providea constant jerk profile, and they are not applicable tohigh-level trajectory planning. Higher order polyno-mials are needed to generate smoother jerk profile. Thelowest order polynomials to guarantee the smoothnessof jerk profile at the sequence of via-points are quintic

Figure 1. Brief framework of general trajectory planning.

2 Advances in Mechanical Engineering

polynomials of which jerk profile are quadratic polyno-mials and with C2 continuity.23 Also, completedynamics model analysis without neglecting the inertialand gravitational properties of the struts is essential fortrajectory planning. The joints’ actuating torques spe-cific for the given trajectory should not exceed the max-imum output torque of driving motors. Due tosignificant complexity and strong non-linearity inPKMs dynamic equations, the principle of virtual workhas high priority over the dynamics analysis approachesof parallel manipulators. Since the generalized trajec-tory planning problem is typically a complex con-strained programming problem with high dimension,non-linearity and non-convexity properties, as well asconsidering the control system exerts directly on activejoints rather than end effector, a dedicated kinematicsinversion process is required to equivalently transformthe prerequisite path expressed in Cartesian space intoa specific corresponding joints’ profile and thereby tra-jectory planning is usually carried out in joint space. Inaddition, it is important to note that trajectory planningin joint space can prevent the tricky troubles resultingfrom kinematic singularities and manipulatorredundancy.14

The practical implication of jerk-based trajectoryplanning is that since the jerk peak values are limitedrationally during the thorough motion period, the opti-mized smooth trajectory would significantly contributeto reducing structure wear, suppressing dominatingvibration, improving tracking accuracy, and potentiallyextend life cycle. To develop a desirable smooth trajec-tory for PKMs, this article presents a minimum-jerktrajectory planning approach applied to a 3-prismatic-universal-universal (3-PUU, the underline representsactive joint) translational PKM. The remainder of thisarticle is organized as follows. We perform essentialkinematics analysis of the 3-PUU PKM in the secondsection, including position analysis, velocity analysisand acceleration analysis. In the third section, the for-mulation of complete inverse dynamics model relies onthe virtual work principle, where the inertial propertyand gravitational quality of the struts are not ignored.The forth section describes the detailed process of gen-erating the minimum-jerk trajectory that minimizes themaximum value of the absolute jerk value using piece-wise quintic polynomials. Simulation results to demon-strate the effectiveness and feasibility of this proposedminimum-jerk trajectory planning strategy are pro-vided in the fifth section. Finally, concluding remarksare shown in the last section.

Kinematics analysis

As shown in Figure 2, the generalized vertical-distributed 3-PUU PKM is employed a closed-loop

geometric characteristic structure which clearly consistsof a stationary base, a movable platform, and threekinematic chains with uniform configuration. For everydefinite kinematic chain, universal joints are utilized toseamlessly connect the slider and strut, followed byassociation between the strut and moving platform. Togenerate translational motion of prismatic jointdirectly, the slider and guideway of a linear leadscrewassembly subsystem are matched and fitted to eachother. Note that the three straight guideways areequipped into ideal central axisymmetric layout andperpendicular to stationary base, which allows theoverall structure to withstand deformation caused byinertial loads. It is worthy pointing out that the movingplatform’s three specific translational DOFs in X, Y,and Z direction necessitate the satisfaction of the defi-nitive geometric conditions, that is, in each PUU kine-matic chain, the axis of the first revolute joint of upperU joint needs to be parallel to that of the first revolutejoint of lower U joint, and the axis of the second revo-lute joint of upper U joint needs to be parallel to thatof the second revolute joint of lower U joint. Withoutloss of generality, as indicated in Figure 3, the referenceframe O� xyz is located with O at the center of theequilateral triangle DB1B2B3 attached to stationarybase. Similarly, the moving frame O0 � x0y0z0 is locatedwith O0 at the center of the equilateral triangle DA1A2A3

attached to moving platform. The x-axis is regulated to

orientate OB1��!

, and z-axis is normal to DB1B2B3. Sincemoving platform is provided with three independent

translational DOFs, r= ½x, y, z�T is used to define theposition vector relative to the reference coordinate sys-tem O� xyz. Furthermore, observing from the topviewas shown in Figure 4, the moving platform is restrictedin a cylinder geometry with radius R.

Figure 2. 3D model of the vertical-distributed 3-PUU parallelmanipulator.

Lu et al. 3

Inverse position analysis

Give the position of moving platform, a primaryclosed-loop vector equation is intuitively established todetermine the displacement of active joints

r= bi + qie+ di + lwi � ai, (i= 1, 2, 3) ð1Þ

where ai = ½s cos bi, � s sin bi, 0�T , bi = ½S cos bi,�S sin bi, 0�T , di = ½�d cos bi, d sin bi, 0�T , e=½0, 0, 1�T �s, S, qi, bi, and l denote the radius of movingplatform, the radius of fixed base, the linear displace-ment of slider i, the angle of point Bi in the coordinateO� xyz, and the length of the strut, respectively. e, wi,di, ai, and bi represent the unit vector along leadscrew,the unit vector along strut, the vector from leadscrewto center point of universal joint Ci, the position vectorof point Ai in the coordinate O0 � x0y0z0, and the posi-tion vector of point Bi in the coordinate O� xyz,respectively.

As depicted in Figure 5, two independent Eulerangles fi and ui are adopted to accurately explicate theconcrete orientation of each strut with respect to thereference coordinate system, which can be readily visua-lized a rotation of fi about the zi-axis resulting in a(x0i, y0i, z

0i) system followed by another rotation of ui

about the rotated y0i�axis. Consequently, the rotationmatrix of strut i can be obtained

oRi =cficui �sfi cfisui

sficui cfi sfisui

�sui 0 cui

24

35 ð2Þ

where s and c represent sin and cos, respectively.Equating the third column of oRi to wi yields

wi = ½ cfisui sfisui cui �T ð3Þ

Solving equation (3) for fi and ui leads to

cui =wiz, sui =ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiw2

ix +w2iy

q, (0 ł u ł p)

sfi =wiy=sui, cfi =wix=sui

(ð4Þ

Figure 3. Simplified sketch of the 3-PUU PKM.

Figure 4. Topview of the vertical-arranged 3-PUU PKM.

Figure 5. Conversion illustration of the local coordinatesystem.

4 Advances in Mechanical Engineering

Taking the Euclidean norm of equation (1) yields

qi = rTe�ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi(rTe)2 � r+ ai � bi � dik k2 + l2

qð5Þ

and

wi =r+ ai � bi � di � qie

lð6Þ

Forward position analysis

As a necessary and crucial step in trajectory planningprocedure for parallel manipulator, the forward posi-tion analysis involves determining the position vector rof moving platform on the premise of a given set ofinputs qi. For convenience, equation (1) can be furtherrearranged and rewritten as

r� (bi + di � ai)� qie= r� r0i � qie= lwi ð7Þ

where

r0i = (S � d � s) cosbi, (� S + d + s) sinbi, 0½ �T

= x0i, y0i, z0i½ �Tð8Þ

Taking Euclidean norm on both sides of equation(7) gives

q21 � 2q1z+(x� x01)

2 +(y� y01)2 + z2 � l2 = 0 ð9Þ

q22 � 2q2z+(x� x02)

2 +(y� y02)2 + z2 � l2 = 0 ð10Þ

q23 � 2q3z+(x� x03)

2 +(y� y03)2 + z2 � l2 = 0 ð11Þ

Subtracting equation (9) from equation (10), weobtain

(q22 � q2

1)� 2(q2 � q1)z+(x202 � x2

01)� 2(x02 � x01)x

+(y202 � y2

01)� 2(y02 � y01)y= 0

ð12Þ

Subtracting equation (11) from equation (10), weobtain

(q22 � q2

3)� 2(q2 � q3)z+(x202 � x2

03)� 2(x02 � x03)x

+(y202 � y2

03)� 2(y02 � y03)y= 0

ð13Þ

Substituting equation (8) into equation (12) leads to

(q22 � q2

1)� 2(q2 � q1)z+(3x�ffiffiffi3p

y)(S � d � s)= 0

ð14Þ

Substituting equation (8) into equation (13) leads to

(q22 � q2

3)� 2(q2 � q3)z� 2ffiffiffi3p

y(S � d � s)= 0 ð15Þ

Combining equation (14) with equation (15), andsolving the primary three-variable algebraic equations,we can easily obtain

x=q2

1 � 12

q22 � 1

2q2

3

� �� (2q1 � q2 � q3)z

3(S � d � s)ð16Þ

y=(q2

2 � q23)� 2(q2 � q3)z

2ffiffiffi3p

(S � d � s)ð17Þ

By incorporating equations (16) and (17) into equa-tion (10), we acquire a general quadratic equation withrespect to the variable z, namely

G1z2 +G2z+G3 = 0 ð18Þ

where

G1 =(2q1 � q2 � q3)

2 + 3(q2 � q3)2

9(S � d � s)2+ 1

G2 =�(2q2

1 � q22 � q2

3)(2q1 � q2 � q3)� 3(q22 � q2

3)(q2 � q3)

9(S � d � s)2

� 2

3(q1 + q2 + q3)

G3 =(2q2

1 � q22 � q2

3)2+ 3(q2

2 � q23)

2

36(S � d � s)2+(S � d � s)2

+1

3(q2

1 + q22 + q2

3)� l2

8>>>>>>>>>>>>>>>>><>>>>>>>>>>>>>>>>>:

ð19Þ

According to the structural characteristics and prac-tical situation of this 3-PUU physical architecture, theposition of moving platform in z direction can bededuced as

z=�G2 +

ffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiG2

2 � 4G1G3

p2G1

ð20Þ

Substituting equation (20) into equations (16) and(17), the value of x and y are derived directly. Onepotential advantage is that thanks to its pronouncedconfiguration and distinctive geometric layout, therewill always exist a unique solution in the forward posi-tion analysis with respect to this vertical-distributed 3-PUU PKM, which indicates that the dimensional struc-ture of this 3-PUU mechanical PKM can be invariablyconfirmed and determined under the precondition ofthe known input joint value.

Inverse velocity analysis

Taking the derivative of equation (1) with respect totime, the velocity equations of moving platform aredescribed as

v= _qie+ lvi 3wi, (i= 1, 2, 3) ð21Þ

Lu et al. 5

where v, _qi, and vi stand for the velocity of movingplatform, velocity of ith slider, and angular velocity ofith strut, respectively.

Utilizing dot multiplication on both sides of equa-tion (21) with vector wi leads to the critical mappingrelationship between the velocity of slider and the velo-city of moving platform, resulting in

_qi =wT

i

wTi e

v ð22Þ

Then, equation (22) needs to be rearranged brieflyand written in a succinct matrix form

_q= J�1q Jx

_X= J _X ð23Þ

J= J1, J2, J3½ �T =wT

1

wT1 e

,wT

2

wT2 e

,wT

3

wT3 e

� �T

ð24Þ

where _q= ½ _q1, _q2, _q3�T denote the vector that incorpo-rates the velocity of sliders, and _X= ½ _x, _y, _z�T representsthe velocity vector of moving platform. J is therenowned Jacobian matrix with three rows and threecolumns.

Link linear velocity and angular velocity analysis

It is important to point out that strut i cannot spinaround its own longitudinal aixs; thus, wT

i vi = 0.Furthermore, executing cross-multiplication on bothsides of equation (21) with the vector wi, the angularvelocity of the ith strut in the fixed frame O� xyz canbe achieved

vi =1

l~wi(E3 � eJi)v= Jviv ð25Þ

where E3 represents the 3 3 3 identity matrix and ~wi

represents the skew-symmetric matrix of wi; notably

~wi =0 �wiz wiy

wiz 0 �wix

�wiy wix 0

24

35 ð26Þ

The velocity of the center of the ith strut expressed inthe reference frame O� xyz is

vi = _qie+vi 3lwi

2

� ð27Þ

Substituting equation (25) into equation (27), thentaking a rational simplification yields

vi = eJi �1

2~w2

i (E3 � eJi)

� v= Jviv ð28Þ

The linear velocity and angular velocity of strut i canbe further rearranged into a general matrix form, that is

vi

vi

� �=

Jvi

Jvi

� �v= Jvviv ð29Þ

where Jvvi is stated the link Jacobian matrices(LJMs).36 Unlike the preliminary concept defined inTsai,36 however, the LJMs presented in this article referto the straightforward mapping relation between thevelocity of platform and the velocity of the struts,which is particularly expressed in the reference frameinstead of the local coordinates.

Inverse acceleration analysis

Similarly, taking the necessary derivative of equation(21) with respect to time, we can achieve

a= €qie+ l _vi 3wi +vi 3 vi 3wið Þ½ � ð30Þ

where a, €qi, and _vi denote the acceleration of movingplatform, acceleration of the ith slider, and angularacceleration of the ith strut, respectively.

The next step is to perform dot multiplication onboth sides of equation (30) by wi, which results in

€qi =wT

i

wTi e

a+l

wTi e

ð31Þ

Furthermore, equation (31) can be represented as

€q= J€X+U ð32Þ

U=l

wT1 e

,l

wT2 e

,l

wT3 e

� �T

ð33Þ

where €q= ½€q1, €q2, €q3�T denote the vector that incorpo-rates the acceleration of sliders and €X= ½€x,€y,€z�T repre-sents the acceleration vector of moving platform.Clearly, the nonlinear transition relationship from end-effector’s acceleration in operational space to drivingjoints’ acceleration is achieved.

Link linear acceleration and angular accelerationanalysis

Performing cross-multiplication on both sides of equa-tion (30) with the vector wi, the angular acceleration ofstrut the i can be obtained as

_vi =1

l~wi(a� €qie)= Jvia�

~wie

wTi e

ð34Þ

Taking the time derivative of equation (27), itleads to

_vi = €qie+ _vi 3lwi

2

� +vi 3

l

2vi 3wi

�

= €qie�lwi

2� l

2~wi _vi

ð35Þ

6 Advances in Mechanical Engineering

Substituting equations (31) and (34) into equation(35), and taking a justified simplification lead to the lin-ear acceleration of strut i, that is

_vi = Jvia+l

2

~w2i e

wTi e

+2e

wTi e� wi

� ð36Þ

Eventually, complete inverse kinematics modeling iscarried out where the link linear acceleration and linkangular acceleration play an indispensable role inestablishing, analyzing, and estimating the thoroughdynamics model.

Dynamics modeling

Except the exhaustive kinematics equations analyzedabove, the investigation of dynamics features is essen-tial to the smooth trajectory planning of 3-PUUPKM.37 First and foremost, we propose two prevalenthypotheses: (1) even though tiny elastic deformationsof lightweight struts are inevitable in practice process,all components existing in the whole mechanical systemare deemed ideal rigid bodies, which means that theycan withstand the applied forces and do not deform;(2) the effect of frictional force among the joints andactive components is negligible, and there is no energyloss caused by friction, consequently, the exclusive var-iation of virtual work is affected directly by the move-ment of the input and output forces/torques. Based onthe system complexity and calculation efficiency, weapply the acquainted virtual work principle to conductthe subsequent dynamics analysis.

Dynamics analysis of the substructure system

From systemic energy perspective, the entire system canbe reasonably split into four substructure aspects basedon energy coupling principle, including

1. Applied forces of the moving platform. In general,the applied forces and inertia forces imposed atthe mass center of moving platform are definedas

Fp =fpnp

� �=

fe +mpg� mp _vne�oIp _v�v 3 (oIpv)

� �ð37Þ

The external force fe and moment ne imposed on themoving platform are assumed nonexistent, meaningthat fe and ne are both set zero. oIp =

oRo0o0Ip

oRTo0 is the

inertia matrix of the moving platform which isexpressed in the fixed frame O� xyz. g denotes thegravitational acceleration. It is worthy to note thatv= 0, _v= 0, and oRo0 =E3, since the fact that thisdesigned proposed 3-PUU PKM is merely providedwith three translational capacities.

2. Applied forces of the struts. It is clear that thegravitational force is assumed to be the exclusiveexternal force of the rigid struts; hence, the gen-eral applied and inertia forces exerted at themass center of the ith strut in the fixed frameO� xyz is defined as

Fi =fini

� �=

mig� mi _vi

�oIi _vi �vi 3 (oIivi)

� �ð38Þ

where oIi =oRi

iIioRT

i implies the ith strut’s inertia ten-sor, iIi represents the ith strut’s inertia tensor especiallyexpressed in the local coordinate system C � xiyizi, andmi denotes the mass of strut i.

3. Applied forces of the sliders. Apparently, the sli-ders posses single translational movement; thus,the applied and inertia forces imposed on the sli-ders are

fqi =(mqig� mqi€qi)Te ð39Þ

where mqi stands for the mass of slider i.

4. Applied forces of the motor–coupling–leadscrews.The particular applied forces and inertia forcesexerted at motor–coupling–screw are

Ni = ti � (IMi + ICi + ILi)€ui = ti � IMCLi€ui ð40Þ

where IMi, ICi, and ILi are designated as the inertiamoment of the motor, coupling, and leadscrew, respec-tively. ti represents the motor’s driving torque and €ui

denotes the angular acceleration of the motor–cou-pling–leadscrew. The straightforward transition rela-tionship between the motor’s rotation and the slider’stranslation is _ui =(2p=pi) _qi and €ui =(2p=pi)€qi; pi

denotes the pitch of leadscrew.

Dynamics modeling of the whole system

According to the virtual work principle, the energy gen-erated by these substructure systems can be seamlesslyassembled into a thorough interrelated system, that is

dxTpFp +

X3

i= 1

dxTi Fi + dqT fq + duTN= 0 ð41Þ

where dq= ½dq1, dq2, dq3�T , du= ½du1, du2, du3�T ,du= ½du1, du2, du3�T = diag(2p=p1, 2p=p2, 2p=p3)dq=Adq, and fq = ½fq1, fq2, fq3�T , N= ½N1,N2,N3�T . Fi anddxi signify the correlative forces and virtual displace-ments applied to the ith strut, respectively.

Using the LJM defined in equation (29), the crucialmapping relationship between dxi and dxp is formu-lated as follows

Lu et al. 7

dxTi = dxT

p JTvvi ð42Þ

Based on the Jacobian matrix defined in equation(23), the corresponding transition relationship betweendq and dxp is obtained as

dqT = dxTp J

T ð43Þ

Substituting equations (40) and (43) into equation(41) and simplifying, the following is obtained

dxTp Fp +

X3

i= 1

JTvviFi + JT fq + JTATN

!= 0 ð44Þ

Furthermore, in response to discretional virtual dis-placement dxT

p , equation (44) keeps absolutely main-tainable and can be further translated as

Fp +X3

i= 1

JTvviFi + JT fq + JTATN= 0 ð45Þ

Substituting equation (40) into equation (45), theactuating torques can be computed as follows

t =� A�TJ�T Fp +X3

i= 1

JTvviFi + JT fq

!+ IMCL

€u

ð46Þ

where

t = ½t1, t2, t3�T ð47Þ

IMCL = diag(IMCL1, IMCL2, IMCL3) ð48Þ

Simplifying equation (46), the general formulation ofdynamics equations expressed in the joint space can bewritten as

t =D(q)€q+C(q, _q) _q+G(q) ð49Þ

where

D(q)=mpA�TJ�TJ�1 +A�Tmq + IMCLA

+A�TJ�TX3

i= 1

(miJTviJviJ

�1 + JToviIiJviJ

�1)

ð50Þ

C(q, _q) _q=� mpA�TJ�TJ�1U+A�TJ�T

X3

i= 1

Hi ð51Þ

Hi = JTwi(vi 3 (OIivi))+

lmi

2JT

vi

~w2i e

wTi e

+2e

wTi e� wi

�

� (miJTviJvi + JT O

wi IiJwi)J�1U� JT O

wi Ii

~wie

wTi e

ð52Þ

G(q)=� A�TJ�T

mpg+X3

i= 1

JTvvi

mig

0

� �+ JT mq1g

Te,mq2gTe,mq3g

Te �T( )

ð53Þ

mq = diag(mq1,mq2,mq3) ð54Þ

where D(q)€q stands for the inertial term, C(q, _q) _qdenotes the nonlinear term including centrifugal andCoriolis forces, and G(q) represents the gravitationalforce. The accurate dynamics modeling by the virtualwork principle plays a significantly important role inundertaking the quantitative analysis and criticalassessment that pertains to systemic dynamics propertybetween end-effector’s movement and joints’ torque,while simultaneously providing a vital premise for thepractical trajectory planning.

Parameterization of trajectory planningbased on the minimum-jerk strategy

Rational running trajectory is the foundation of pre-eminent kinematics property of PKMs, and the qualityof trajectory planning algorithm directly affects thedynamics performance of PKMs. As a noticeable draw-back, high jerk value during the entire trajectory candecrease the motion precision, excite the dominatingvibration, and even break the structure life. Therefore,the minimum-jerk trajectory planning approach aimingto minimize the jerk value of motion period is recom-mended to regulate the driving joints’ motion functionsto make sure all joints pass through the correspondingjoints’ positions simultaneously and smoothly.38,39

Considering the actual control system effects directlyon the active joints, trajectory planning executed injoint space is more convenient and easier to guaranteethe continuity and smoothness of joints’ angular move-ment curves than that in operation space. Hence, thisminimum-jerk trajectory planning approach is imple-mented by the desired joints’ via-positions which aretransformed from the path points in operation spacethrough inverse kinematics calculation.

Interpolation functions based on piecewise quinticpolynomials

Figure 6 shows a typical geometric description of thesequence of via-points in Cartesian space (i.e. operationspace). The fundamental objective and mission of tra-jectory planning, as stated previously, are to confirm astringent and reasonable trajectory between the desig-nated starting point and the specific destination withinthe reachable workspace.40 In general, the original tra-jectory in Cartesian space is continuous and discretizedinto (n – 1) segments by the requisite n via-points. First,

8 Advances in Mechanical Engineering

the corresponding kth joint angular position knots aredefined as Qk, i that obtained through inverse kine-matics mapping of the given geometric path. Withoutloss of generality, we allow t1\t2\ � � �\tn�1\tn to bean ordered time sequence and define hi = ti+ 1 � ti asthe corresponding time interval; thus, the total execu-tion time is

Pn�1i= 1 hi. The lowest order polynomials to

guarantee the smoothness of jerk profile at the sequenceof via-points are quintic polynomials of which jerk pro-file is quadratic polynomials and with C2 continuity.Thus, to guarantee the demanding continuity andsmoothness property of variation curves of separatejoint’s angular position, velocity, and acceleration, thesequences of via-points denoted in joint space need tobe interpolated by the discretized piecewise quinticpolynomials. The ith interpolation function Qk, i(t) con-necting the point i and the point (i + 1) for the kthjoint can be expressed as

Qk, i(t)=X5

j= 0

uki, jtj ð55Þ

where t 2 ½ti, ti+ 1�. Consequently, in response to theaforementioned position profile, implementing thefirst-, second-, and third-order derivatives regardingtime can immediately yield the corresponding velocity_Qk, i(t), acceleration €Qk, i(t), and jerk €Qk, i(t) in the kthcoordinate direction relative to the ith time interval,that is

_Qk, i(t)=X4

j= 0

(j+ 1)uki, (j+ 1)tj ð56Þ

€Qk, i(t)=X3

j= 0

(j+ 1)(j+ 2)uki, (j+ 2)tj ð57Þ

Q...

k, i(t)=X2

j= 0

(j+ 1)(j+ 2)(j+ 3)uki, (j+ 3)tj ð58Þ

Obviously, the jerk is a quadratic function of time, ithas a continuous second derivative (‘‘C2 continuity’’)and cannot produce severe step change. To meet high-level continuity and smoothness requirements, the posi-tion, velocity, acceleration and jerk at endpoint of ithtime interval must equal to the position, velocity, accel-eration, and jerk at starting point of (i+ 1)th timeinterval, respectively. Thus, equations (55)–(57) can bewritten as a vector-matrix differential equation,specifically

1 0 0 0 0 0

0 1 0 0 0 0

0 0 2 0 0 0

1 ti+ 1 t2i+ 1 t3

i+ 1 t4i+ 1 t5

i+ 1

0 1 2ti+ 1 3t2i+ 1 4t3

i+ 1 5t4i+ 1

0 0 2 6ti+ 1 12t2i+ 1 20t3

i+ 1

2666666664

3777777775

uki, 0

uki, 1

uki, 2

uki, 3

uki, 4

uki, 5

2666666664

3777777775

=

Qk, i

_Qk, i

€Qk, i

Qk, i+ 1

_Qk, i+ 1

€Qk, i+ 1

26666666664

37777777775

ð59Þ

Solving equation (59), the coefficients of equation(55) are obtained, namely

uki, 0 =Qk, i

uki, 1 = _Qk, i

uki, 2 =€Qk, i

2

uki, 3 =20(Qk, i+ 1�Qk, i)�(12 _Qk, i + 8 _Qk, i+ 1)hi�(3€Qk, i�€Qk, i+ 1)h

2i

2h3i

uki, 4 =30(Qk, i�Qk, i+ 1)+ (16 _Qk, i + 14 _Qk, i+ 1)hi�(3€Qk, i + 2€Qk, i+ 1)h

2i

2h4i

uki, 5 =12(Qk, i+ 1�Qk, i)�6( _Qk, i + _Qk, i+ 1)hi�(€Qk, i�€Qk, i+ 1)h

2i

2h5i

8>>>>>>>>>><>>>>>>>>>>:

ð60ÞStrict and necessary constraints

In particular, the total execution time of our minimum-jerk trajectory planning strategy is set as a specificconstraint. Arising from the proposed minimum-jerktrajectory planning algorithm imposed upon the3-PUU PKM, all strict and necessary constraints con-sist of (1) meeting the predefined state conditions at theinitial and ultimate time; (2) fulfilling the definite conti-nuity and smoothness requirements with regard toposition, velocity, acceleration, and jerk for specific rel-evant via-points; (3) satisfying the explicit kinematicsrestraints; (4) abiding by the specific dynamics bounds;

Figure 6. Via-points in Cartesian space.

Lu et al. 9

and (5) subjecting to the limitation of total executiontime.

1. Initial and ultimate time constraints. Consistentwith the initial and ultimate time prerequisites,the joints’ angular velocity, acceleration, andjerk at initial and final time are undoubtedlyguaranteed to be zero simultaneously as follows

Qk, 0 = qk0,Qk, n = qkn

_Qk, 0 = _qk0 = 0, _Qk, n = _qkn = 0€Qk, 0 = €qk0 = 0, €Qk, n = €qkn = 0

Qk, 0 = qk0 = 0,Qk, n = qkn = 0

8>><>>: ð61Þ

2. Continuity constraints. Particularly, the mainchallenge facing trajectory planner is to achievethe essential continuity and smoothness require-ments; therefore, the joints’ angular position,velocity, acceleration, and jerk at every inter-knot must satisfy the following continuity con-straints, namely

Qk, i(ti+ 1)=Qk, i+ 1(ti+ 1)= qki 8k, i_Qk, i(ti+ 1)= _Qk, i+ 1(ti+ 1) 8k, i€Qk, i(ti+ 1)= €Qk, i+ 1(ti+ 1) 8k, iQk, i(ti+ 1)=Qk, i+ 1(ti+ 1) 8k, i

8>><>>: ð62Þ

3. Kinematics constraints.Apparently, kinematics con-straints concern that the joints’ angular velocity,acceleration, and jerk at every inter-knot shouldnot exceed the given specific maximum values

j _Qk, ijł VCk 8k, i

j€Qk, ijł ACk 8k, i

jQk, ijł JCk 8k, i

8<: ð63Þ

where VCk , ACk , and JCk represent the kth joint’s velo-city bound, acceleration bound, and jerk bound,respectively.

4. Dynamics constraints. The torque constraint ofactuating joint based on its motor’s drivingcapacity has to be taken into account when theappointed trajectory is reasonably processed,that is

jtk, ijł tCk 8k, i ð64Þ

where tCk denotes the kth joint’s active torquelimitation.

5. Total execution time constraint. Generally, as anadditional requirement, the total traveling timeallocated to the confirmed operation should beless than the given execution time in order toboost the operation efficiency and productivity,thereby

T =Xn

i= 1

hi ł TC ð65Þ

where TC is the artificial traveling time bound.

Objective function

For sophisticated industrial operations, the smoother tra-jectories are always preferred to the rougher ones;smoother trajectories usually ensure smaller vibrationdeformation and higher positioning accuracy. Since limit-ing the maximum jerk value of the entire trajectory is ofconsiderable benefits—reducing structure wear, suppres-sing motivated vibration, enhancing smoothness degree,and raising tracking accuracy—the maximum absolutevalue of each individual joint’s angular jerk functionwithin every specific segment needs to be minimized.Hence, the objective function we adopt is given as follows

min maxjQ...

k, i(t)j, i= 1, . . . , n; k = 1, . . . ,m ð66Þ

where n is the number of total via-points (including thestarting point and the destination) and m is the numberof driving joints. The indispensable coefficients ukij ofinterpolation functions for joints’ angular position areviewed as the independent design variables. Complyingfully with the multiple fundamental constraints, we canperform the minimum-jerk trajectory planning with apath parameterized by piecewise quintic polynomials.The coefficients ukij of joint’s angular position profileare obtained by _Qk, i, €Qk, i, and hi through equation(60). For a m-joint n-knot trajectory planning problemfeaturing minimum-jerk, the velocity and accelerationat starting point and endpoint ( _Q1, i, €Q1, i, _Qm, i, €Qm, i)are first set zero upon requisite constraints, and itsunknown velocity and acceleration at subsequent intervia-points are primary design factors. Besides, the(n� 1) time internals are needed to be optimized andidentified. Thus, the number of total design variables is½m 3 2 3 (n� 1)+ (n� 1)�.

Optimization method

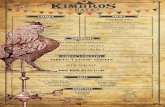

Figure 7 illustrates an overview of the thoroughminimum-jerk trajectory planning procedure aiming atthe 3-PUU PKM. From the perspective of mathe-matics, the complex trajectory planning matter ofPKM is further converted into a traditional con-strained nonlinear multivariable optimization problem.The objective of this particular optimization problem isto minimize the maximum absolute value of joints’angular jerk subject to the aforementioned continuityconstraints, kinematics constraints, dynamics con-straints, and execution time constraints. To solve theoptimal solution of the constrained multivariable objec-tive function, the minimum-jerk trajectory generation

10 Advances in Mechanical Engineering

strategy presented herein has to resort to the profes-sional computing software—MATLAB, which is inte-grated many distinguished and reliable calculationalgorithms including sequential quadratic program-ming (SQP) algorithm, genetic algorithm (GA), andparticle swarm optimization (PSO) algorithm. Amonghighly efficient methods to deal with general con-strained optimization problems, the SQP approach isfilled with significant advantages of solving large-scalecomplex problems and capable of relatively fast con-vergence rate; thus, we employ familiar SQP algorithmembedded in the fmincon function to fully address theminimum-jerk trajectory planning problem.

Numerical simulation

The 3-PUU parallel kinematic manipulator is an auto-matic operation mechanism that can grasp and

transport objects or operation tools accurately andflexibly according to the fixed procedures. To intui-tively observe and evaluate the concrete characteristicsof the presented minimum-jerk trajectory planningapproach, two different but representative examples—an inverted U-shaped trajectory intensively applied forpick-and-place operations and a closed spatial circletrajectory widely used for painting or sprayingoperations—are simulated and discussed in thissection.

Case I: pick-and-place operation application

By investigating the handling process of practical pro-duction line, the most frequently used trajectory ofpick-and-place operation is a bow-shaped trajectory,41

which is approximately considered as an inverted U-shaped trajectory. As depicted in Figure 8, the red solid

Figure 7. Flowchart of the proposed trajectory planning.

Lu et al. 11

line in the dexterous workspace (Wt) of 3-PUU PKMdenotes the presupposed inverted U-shaped trajectoryfor a flexible pick-and-place application. As illustratedin Figure 9, we select 10 predefined points (P1 � P10) inCartesian space as the key via-points for the invertedU-shaped trajectory sample. To ensure the joints’motion trajectories are planned definitely in joint space,these given via-points need to be converted into the cor-responding joints’ angular position knots in joint spacethrough inverse kinematics computation. All indispen-sable prototype parameters of the 3-PUU PKM arereported concisely in Table 1. Its orderly sequence ofvia-points in Cartesian space and joints’ angular posi-tion knots in joint space is listed in Table 2. The neces-sary kinematics and dynamics constraints of the 3-PUUPKM are recorded in Table 3. The allowable joints’angular velocity limitation VCk is 0.5m/s, the joints’angular acceleration limitation ACk is 1.2m/s2, thejoints’ angular jerk limitation JCk is 5m/s3, andthe joints’ torque limitation tCk is 10Nm. In addition,the total traveling time bound TC is artificially set to 5 s

in this case. Finally, in the major parameter options offmincon function, the approved maximum number ofiterations ‘‘MaxIter’’ is set 100, and the authorized max-imum number of function evaluations ‘‘MaxFunEvals’’is set 5000.

Conforming to the specifically designed procedurefor minimum-jerk trajectory planning, the total

Figure 8. The presupposed pick-and-place operationtrajectory.

Figure 9. The via-points of pick-and-place operation trajectory.

Table 1. Physical parameters of the 3-PUU PKM.

Symbol Description Value Unit

s Radius of the moving platform 0.070 mS Radius of the fixed base 0.370 ml Strut’s length 0.450 md Distance from Ci to leadscrew 0.070 mR Radius of the task workspace 0.080 mh Height of the task workspace 0.200 mm Mass of the moving platform 3.500 kgmi Mass of the strut 0.720 kgmqi Mass of the slider 1.377 kgIMi Motor’s inertia moment 1.4e–4 N/m2

ICi Coupling’s inertia moment 1.3e–5 N/m2

ILi Leadscrew’s inertia moment 1.1e–4 N/m2

pi Leadscrew’s pitch 0.010 mg Gravitational acceleration 9.807 m/s2

PUU: prismatic-universal-universal; PKM: parallel kinematic manipulator.

Table 2. The via-points of the pick-and-place operationtrajectory.

Knots Cartesian space (mm) Joint space (mm)

x y z Joint 1 Joint 2 Joint 3

1 290 90 680 376.68 244.16 336.132 290 90 660 356.68 224.16 316.133 290 90 640 336.68 204.16 296.134 260 60 620 281.18 195.62 256.275 220 20 620 246.40 218.29 238.646 20 220 620 222.51 250.90 229.917 60 260 620 207.69 296.43 229.488 90 290 640 221.91 362.79 254.579 90 290 660 241.91 382.79 274.5710 90 290 680 261.91 402.79 294.57

Table 3. Kinematics and dynamics constraints of the 3-PUUPKM.

Constraints values Joint 1 Joint 2 Joint 3

Kinematicsconstraints

VCk (m/s) 0.5 0.5 0.5

ACk (m/s2) 1.2 1.2 1.2JCk (m/s3) 5.0 5.0 5.0

Dynamicsconstraints

jtjmax (N m) 10 10 10

PUU: prismatic-universal-universal; PKM: parallel kinematic manipulator.

12 Advances in Mechanical Engineering

traveling time after massive computation in MATLABenvironment is 4.767 s, as can be seen from Table 4.The four longest time intervals are h1 (from P1 to P2),h3 (from P3 to P4), h7 (from P7 to P8), and h9 (from P9

to P10). As summarized in Table 5, the maximum ofthe absolute value of joints’ velocity, acceleration, jerk,and torque are 0.101m/s, 0.279m/s2, 3.102m/s3, and3.141Nm, respectively, suggesting that none of termsoversteps the fundamental limitations of kinematicsand dynamics bounds. Besides, the mean of the abso-lute value of joints’ velocity, acceleration, jerk, and tor-que are 0.054m/s, 0.095m/s2, 0.516m/s3, and1.078Nm, respectively. Note that the maximum velo-city, acceleration, jerk, and torque occur on Joint 2.Hence, with respect to this inverted U-shaped trajec-tory, Joint 2 needs to be paid more attention and fur-ther strengthened than Joints 1 and 3. Figure 10(a)–(e)shows the associated joints’ position, velocity, accelera-tion, jerk, and torque profiles corresponding to theavailable optimal solution. The red solid line depictedin Figure 10(f) exhibits the generated valid trajectory ofmoving platform by the forward position transforma-tion analyzed above. It is clear that the generatedCartesian trajectory strictly goes through all the prede-fined via-points, approximates the assumed inverted U-shaped path, and satisfies all the specific constraints.Especially, there are no fierce step changes in joints’position, velocity, and acceleration profiles. To sum up,the minimum-jerk trajectory planning strategy enablesthe profiles of joints’ position, velocity, acceleration,jerk, and torque to be characterized by excellent conti-nuity and pronounced smoothness relating to theinverted U-shaped trajectory.

Case II: closed circle application

This section mainly describes the simulation results ofthe presented minimum-jerk trajectory planning strat-egy for a particularly circle trajectory in Cartesianspace. The presupposed closed circle trajectory forpainting operation is a red dash-dotted line displayedin Figure 11. We choose 11 definite points, P1 � P11, asthe important via-points on the circle trajectory wherethe first point P1 coincides exactly with the last pointP11. As listed in Table 6, the sequence of joints’ angularposition knots corresponding for the prescribed pointsin Cartesian space are calculated using inverse kine-matics transformation. The kinematics and dynamicsconstraints with regard to the circle trajectory are asthe same as the constraints for the inverted U-shapedtrajectory. Likewise, the limitation of total travelingtime TC is also set 5 s.

The process implementation of Case II, circle trajec-tory planning, is closely followed with Case I where themajor parameter options of fmincon function remainconstant to resolve the constrained optimization prob-lem. As can be seen from Table 7, the optimized totaltraveling time just equals to the setting time boundunder the satisfied continuity and smoothness require-ments. The four longest time intervals are h1 (from P1

to P2), h5 (from P5 to P6), h6 (from P6 to P7), and h10

(from P10 to P11). As summarized in Table 8, the maxi-mum of the absolute value of joints’ angular velocity,acceleration, jerk, and torque are 0.254m/s, 0.730m/s2,2.808m/s3, and 8.246Nm, respectively, indicating thatno associated term oversteps the principal limitationsof kinematics and dynamics restrictions. Besides, themean of the absolute value of joints’ angular velocity,acceleration, jerk, and torque are 0.111m/s, 0.241m/s2,0.709m/s3, and 2.725Nm, respectively. Figure 12(a)–(e) reveals the simulated joints’ angular position, velo-city, acceleration, jerk, and torque profiles resultedfrom the corresponding ultimate optimal solution.Utilizing the forward position transformation of inputjoints’ angular position functions, the visible trajectoryof moving platform is exhibited in Figure 12(f). It isimportant to note that the generated spatial circle tra-jectory strictly goes through all the predefined via-points, approximates the predefined closed circle path,and satisfies the specific restrictive conditions. The pro-files of joint angular position, velocity, acceleration,jerk, and torque are characterized with excellent conti-nuity; there are no fierce step changes in joint angularposition, velocity, and acceleration profiles. To someextent, the peak and tendency of the angular velocity,acceleration, jerk, and torque variations of these inde-pendent joints are relatively close. Contrasting to simu-lation results of the inverted U-shaped trajectory, noparticular attention needs to be given to Joint 2 for theclosed circle trajectory, suggesting that the choice and

Table 4. Optimized time intervals of the pick-and-placetrajectory.

Intervals (s) h1 h2 h3 h4 h5

0.738 0.238 0.588 0.370 0.388

Intervals (s) h6 h7 h8 h9 T

0.623 0.799 0.267 0.756 4.767

Table 5. Resulting values of the pick-and-place trajectory.

Values Joint 1 Joint 2 Joint 3

Maximum values jVjmax (m/s) 0.101 0.101 0.090jAjmax (m/s2) 0.181 0.279 0.178jJjmax (m/s2) 1.010 3.102 0.952jtjmax (N m) 2.064 3.141 1.996

Mean values jVjmea (m/s) 0.049 0.054 0.037jAjmea (m/s2) 0.077 0.095 0.077jJjmea (m/s2) 0.344 0.516 0.348jtjmea (N m) 0.872 1.078 0.873

Lu et al. 13

determination of driving motor can be influenced bythe quality of practical trajectory. According to the dis-cussions reported in Cases I and II, the results of simu-lation suggest that the established joints’ jerk profilesare undoubtedly continuous, and the joints’ torqueprofiles are clearly smooth. The proposed minimum-jerk trajectory planning strategy for the 3-PUU PKMcan provide a desirable trajectory with great continuityand pleasing smooth performance. By virtue of thisminimum-jerk approach for trajectory planning, wecan expect a steady decline in the number of disconti-nuities and unsmoothness suffered by the inappositemotion trajectory. Moreover, the proposed minimum-jerk trajectory planning approach has advantages ofstrong reliability, high flexibility, and simple

(a) (b)

(c) (d)

(e) (f)

Figure 10. The resulted profiles related to the pick-and-place operation trajectory: (a) joint position, (b) joint velocity, (c) jointacceleration, (d) joint jerk, (e) joint torque, and (f) resulted trajectory.

Figure 11. The presupposed circle trajectory in Cartesianspace.

14 Advances in Mechanical Engineering

implementation. Additionally, as a supplementarystatement, it is important to point out that the opti-mized result computed by fmincon function is sensitiveto the initial solution. The choice of proper initial valuehas slightly influence on the final simulation results; inother words, an inapposite choice may disturb the exe-cution time, the convergence of iterative algorithm, andthe final simulation results. Thus, the determination ofsuitable initial solution is also an important factorneeded to be serious consideration.

Conclusion

Limiting the maximum jerk of manipulator’s trajectorycontributes to suppressing the vibration induced by thedominating vibratory mode, reducing the structure wear,and improving trajectory smoothness and tracking

accuracy. This article focuses on taking jerk minimiza-tion as the most important consideration for trajectoryplanning issue of parallel manipulators. In the presenceof specific kinematics constraints, dynamics constraints,and execution time constraints, this article presents aminimum-jerk trajectory planning approach for smoothtrajectory generation applied to the translational 3-PUUPKM. Despite a little computational cost, the relativelycomprehensive smoothness performance of the proposedminimum-jerk trajectory planning strategy is clearlydescribed and borne out by two hypothesized represen-tative examples. The following conclusions are drawn:

1. The complete kinematics characteristics of thisvertical 3-PUU PKM are thoroughly analyzed.In particular, there exists a reliable unique solu-tion in the forward position analysis aspect ofthe remarkable 3-PUU parallel mechanismstructure. Relying on the LJMs and virtualwork principle, the complicated dynamics modelis formulated without neglecting the inertial andgravitational effects of the struts.

2. The straightforward objective of the proposedminimum-jerk trajectory planning is minimizingthe maximum absolute value of joints’ angularjerk profile relating to satisfy strict and neces-sary constraints of initial time, final time, conti-nuity, kinematics, dynamics, and executiontime. The discretized piecewise fifth-order

Table 6. Trajectory via-points of the circle trajectory.

Knots Operation space (mm) Joint space (mm)

x y z Joint 1 Joint 2 Joint 3

1 286 83.66 597.66 288.39 163.71 248.872 243 97.74 654.74 310.62 222.28 324.363 0 84.85 684.85 307.49 265.09 355.314 43 54.74 697.74 292.11 301.92 361.505 86 22.34 683.66 257.33 335.11 332.456 86 283.66 602.34 184.29 315.81 216.667 43 297.74 545.26 147.80 246.31 136.308 0 284.85 515.15 137.79 185.61 95.399 243 254.74 502.26 148.74 137.79 82.2010 286 2.34 516.34 195.97 112.72 115.0311 286 83.66 597.66 288.39 163.71 248.87

Table 7. Optimized time intervals of the circle trajectory.

Intervals (s) h1 h2 h3 h4 h5 h6

1.027 0.229 0.225 0.347 0.583 0.455

Intervals (s) h7 h8 h9 h10 T

0.255 0.212 0.307 1.359 5.0

Table 8. Resulting values of the circle trajectory.

Values Joint 1 Joint 2 Joint 3

Maximum values jVjmax (m/s) 0.178 0.254 0.224jAjmax (m/s2) 0.496 0.672 0.730jJjmax (m/s3) 2.529 2.808 2.799jtjmax (N m) 5.598 7.588 8.246

Mean values jVjmea (m/s) 0.069 0.090 0.111jAjmea (m/s2) 0.144 0.208 0.241jJjmea (m/s3) 0.631 0.651 0.709jtjmea (N m) 1.630 2.351 2.725

Lu et al. 15

polynomials are utilized to interpolate thesequence of joints’ angular position knots whichare transformed from a series of predefined via-points by inverse kinematics mapping.

3. Using SQP algorithm available in MATLAB,empirical simulation results for the inverted U-shaped trajectory and closed circle trajectorydemonstrate that the planned trajectory stem-ming from the minimum-jerk trajectory plan-ning strategy is of significant continuity andpronounced smoothness. In conclusion, this effi-cient and feasible methodology has substantialcontribution for high-level smoothness require-ments particularly applicable to the general par-allel manipulators.

Acknowledgements

The authors would like to acknowledge the anonymousreviewers for their insightful comments and suggestions.

Declaration of conflicting interests

The author(s) declared no potential conflicts of interest withrespect to the research, authorship, and/or publication of thisarticle.

Funding

The author(s) disclosed receipt of the following financial sup-port for the research, authorship, and/or publication of thisarticle: This work was supported by the National Natural

Science Foundation of China (grant nos 51575544, 51275353),

(a) (b)

(c) (d)

(e) (f)

Figure 12. The resulted profiles related to the circle trajectory: (a) joint position, (b) joint velocity, (c) joint acceleration, (d) jointjerk, (e) joint torque, and (f) resulted trajectory.

16 Advances in Mechanical Engineering

HuXiang High-Level Talent Project of Hunan Province(grant no. 2019RS1066), Education Department of HunanProvince (grant no. 19C1520), and the Macao Science andTechnology Development Fund (grant no. 110/2013/A3).

ORCID iD

Song Lu https://orcid.org/0000-0003-3414-0362

References

1. Zhang D and Gao Z. Hybrid head mechanism of the

groundhog-like mine rescue robot. Robot Cim: Int Manuf

2011; 27: 460–470.2. Liu XJ and Wang JS. A new methodology for optimal

kinematic design of parallel mechanisms. Mech Mach

Theory 2007; 42: 1210–1224.3. Lu S, Li YM and Ding BX. Multi-objective dimensional

optimization of a 3-DOF translational PKM considering

transmission properties. Int J Automat Comput 2019; 16:

748–760.4. Ni YB, Jia SL, Zhang ZW, et al. A manufacturing-

oriented error modelling method for a hybrid machine

tool based on the 3-PRS parallel spindle head. Adv Mech

Eng. Epub ahead of print 6 May 2019. DOI: 10.1177/

16878140198489025. Mei JP, Zhang X, Zhang JW, et al. Optimization design

using a global and comprehensive performance index

and angular constraints in a type of parallel manipulator.

Int J Adv Robot Syst. Epub ahead of print 12 July 2018.

DOI: 10.1177/16878140187870686. Huang T, Li ZX, Li M, et al. Conceptual design and

dimensional synthesis of a novel 2-DOF translational

parallel robot for pick-and-place operations. J Mech

Des: T ASME 2004; 126: 449–455.7. Zhao YJ and Gao F. Dynamic performance comparison

of the 8PSS redundant parallel manipulator and its

non—redundant counterpart—the 6PSS parallel manipu-

lator. Mech Mach Theory 2009; 44: 991–1008.8. Dalvand MM and Shirinzadeh B. Motion control analy-

sis of a parallel robot assisted minimally invasive

surgery/microsurgery system (PRAMiSS). Robot Cim:

Int Manuf 2013; 29: 318–327.9. Li YM and Xu QS. Design and development of a medi-

cal parallel robot for cardiopulmonary resuscitation.

IEEE/ASME T Mech 2007; 12: 265–273.10. Chen QZ, Zhang CR, Ni HP, et al. Trajectory planning

method of robot sorting system based on S-shaped

acceleration/deceleration algorithm. Int J Adv Robot

Syst. Epub ahead of print 22 November 2018. DOI:

10.1177/172988141881380511. Zha XF. Optimal pose trajectory planning for

robot manipulators. Mech Mach Theory 2002; 37:

1063–1086.12. Boryga M and Grabos A. Planning of manipulator

motion trajectory with higher-degree polynomials use.

Mech Mach Theory 2009; 44: 1400–1419.13. Yang P, Tang K, Lozano JA, et al. Path planning for sin-

gle unmanned aerial vehicle by separately evolving way-

points. IEEE T Robot 2015; 31: 1130–1146.

14. Biagiotti L and Melchiorri C. Trajectory planning for

automatic machines and robots. Berlin: Springer-Verlag,

2008.15. Gasparetto A and Zanotto V. A technique for time-jerk

optimal planning of robot trajectories. Robot Cim: Int

Manuf 2008; 24: 415–426.16. Berglund T, Brodnik A, Jonsson H, et al. Planning

smooth and obstacle-avoiding B-spline paths for autono-

mous mining vehicles. IEEE T Autom Sci Eng 2010; 7:

167–172.17. Kieffer J, Cahill AJ and James MR. Robust and accurate

time-optimal path-tracking control for robot manipula-

tors. IEEE T Robotic Autom 1997; 13: 880–890.18. Abdellatif H and Heimann B. Adapted time-optimal tra-

jectory planning for parallel manipulators with full

dynamic modeling. In: Proceedings of the IEEE interna-

tional conference on robotics and automation, Barcelona,

18–22 April 2005, pp.411–416. New York: IEEE.19. Bourbonnais F, Bigras P and Bonev IA. Minimum-time

trajectory planning and control of a pick-and-place five-

bar parallel robot. IEEE/ASME T Mech 2015; 20:

740–749.20. Ur-Rehman R, Caro S, Chablat D, et al. Multi-objective

path placement optimization of parallel kinematics

machines based on energy consumption, shaking forces

and maximum actuator torques: application to the Ortho-

glide.Mech Mach Theory 2010; 45: 1125–1141.

21. Huang MS, Hsu YL and Fung RF. Minimum-energy

point-to-point trajectory planning for a motor-toggle ser-

vomechanism. IEEE/ASME T Mech 2012; 17: 337–344.22. Chen CT and Liao TT. A hybrid strategy for the time- and

energy-efficient trajectory planning of parallel platform

manipulators. Robot Cim: Int Manuf 2011; 27: 72–81.23. Piazzi A and Visioli A. Global minimum-jerk trajectory

planning of robot manipulators. IEEE T Ind Electron

2000; 47: 140–149.24. Macfarlane S and Croft EA. Jerk-bounded manipulator

trajectory planning: design for real-time applications.

IEEE T Robotic Autom 2003; 19: 42–52.25. Gyorfi JS and Wu CH. A minimum-jerk speed-planning

algorithm for coordinated planning and control of auto-

mated assembly manufacturing. IEEE T Autom Sci Eng

2006; 3: 454–462.26. Gasparetto A, Lanzutti A, Vidoni R, et al. Validation of

minimum time-jerk algorithms for trajectory planning of

industrial robots. J Mech Robot 2011; 3: 031003.27. Olabi A, Bearee R, Gibaru O, et al. Feedrate planning

for machining with industrial six-axis robots. Control Eng

Pract 2010; 18: 471–482.28. Li HZ, Le MD, Gong ZM, et al. Motion profile design to

reduce residual vibration of high-speed positioning stages.

IEEE/ASME TMech 2009; 14: 264–269.29. Gasparetto A, Lanzutti A, Vidoni R, et al. Experimental

validation and comparative analysis of optimal time-jerk

algorithms for trajectory planning. Robot Cim: Int Manuf

2012; 28: 164–181.30. Liu HS, Lai XB and Wu WX. Time-optimal and jerk-

continuous trajectory planning for robot manipulators

with kinematic constraints. Robot Cim: Int Manuf 2013;

29: 309–317.

Lu et al. 17

31. Bearee R and Olabi A. Dissociated jerk-limited trajectoryapplied to time-varying vibration reduction. Robot Cim:

Int Manuf 2013; 29: 444–453.32. Guarino Lo and Bianco C. Minimum-jerk velocity plan-

ning for mobile robot applications. IEEE T Robot 2013;29: 1317–1326.

33. Huang T, Wang PF, Mei JP, et al. Time minimum trajec-tory planning of a 2-DOF translational parallel robot forpick-and-place operations. CIRP Ann: Manuf Techn

2007; 56: 365–368.34. Hu JF, Zhang XM and Zhan JQ. Trajectory planning of

a novel 2-DOF high-speed planar parallel manipulator.In: Xiong C, Huang Y, Xiong Y, et al. (eds) Intelligentrobotics and applications, vol. 5314. Berlin: Springer-Ver-lag, 2008, pp.199–207.

35. Lou YJ, Feng F and Wang MY. Trajectory planning andcontrol of parallel manipulators. In: Proceedings of the

IEEE international conference on control and automation,Christchurch, New Zealand, 9–11 December 2009,pp.1013–1018. New York: IEEE.

36. Tsai LW. Solving the inverse dynamics of a Stewart-

Gough manipulator by the principle of virtual work. J

Mech Des: T ASME 2000; 122: 3–9.37. Chen CT and Liao TT. Trajectory planning of parallel

kinematic manipulators for the maximum dynamic load-

carrying capacity. Meccanica 2016; 51: 1653–1674.38. Kucuk S. Maximal dexterous trajectory generation and

cubic spline optimization for fully planar parallel manip-

ulators. Comput Electr Eng 2016; 56: 634–647.39. Kucuk S. Optimal trajectory generation algorithm for

serial and parallel manipulators. Robot Cim: Int Manuf

2017; 48: 219–232.40. Spong MW, Hutchinson S and Vidyasagar M. Robot

modeling and control. New York: Wiley, 2006.41. Zhang HJ, Su TT, Wu SH, et al. Simultaneous path plan-

ning and trajectory optimization for high-speed sorting

system. Int J Adv Robot Syst. Epub ahead of print 27

September 2018. DOI: 10.1177/1729881418797870

18 Advances in Mechanical Engineering