Millenium Park Annual Environmental Report Rpt002-0 · ANNUAL ENVIRONMENTAL REPORT 2015 ... 1 Issue...

Transcript of Millenium Park Annual Environmental Report Rpt002-0 · ANNUAL ENVIRONMENTAL REPORT 2015 ... 1 Issue...

STARRUS ECO HOLDINGS LTD (T/A GREENSTAR) – MILLENNIUM BUSINESS PARK MATERIALS RECOVERY FACILITY, GRANGE, BALLYCOOLIN, CO. DUBLIN ANNUAL ENVIRONMENTAL REPORT 2015 INDUSTRIAL EMISSIONS LICENCE REF. NO. W0183-01

MARCH 2016

LW15/172/01/Rpt002-1

STARRUS ECO HOLDINGS LTD (T/A GREENSTAR) – MILLENNIUM BUSINESS PARK MATERIALS RECOVERY FACILITY, GRANGE, BALLYCOOLIN, CO. DUBLIN ANNUAL ENVIRONMENTAL REPORT 2015 INDUSTRIAL EMISSIONS LICENCE REF. NO. W0183-01

REVISION CONTROL TABLE, CLIENT, KEYWORDS AND ABSTRACT

User is Responsible for Checking the Revision Status of This Document Rev. Nr.

Description of Changes

Prepared by: Checked by: Approved by: Date:

1 Issue to Client BD/MG BG BG 31.03.2016 Client: Starrus Eco Holdings Ltd (t/a Greenstar) Keywords: Annual Environmental Report (AER), Materials Recovery Facility (MRF),

environmental monitoring Abstract: This report represents the monitoring results for Millennium Business Park Material

Recovery Facility, Grange, Ballycoolin, Co. Dublin. This report covers the annual reporting period of 2015 in accordance with Industrial Emissions Licence Reg. No. W0183-01.

LW15/172/01/Rpt002-1 i/ii

TABLE OF CONTENTS

PAGE 1. INTRODUCTION ...................................................................................................... 1

1.1. REPORTING PERIOD................................................................................................. 1 1.2 IED LICENCE ........................................................................................................ 1

2. SITE DESRIPTION ................................................................................................... 2 2.1. FACILITY LOCATION AND ACTIVITIES ............................................................................. 2 2.2 WASTE ACTIVITIES AT THE FACILITY ............................................................................... 2

2.1.1. Waste Types ................................................................................................... 2 2.1.2 Waste Processing .............................................................................................. 2

2.3 PLANT & MACHINERY LIST ........................................................................................... 3 3. EMISSIONS MONITORING ...................................................................................... 4

3.1. SURFACE WATER MONITORING ................................................................................... 4 3.1.1 Monitoring locations ........................................................................................... 4 3.1.2 Monitoring parameters ....................................................................................... 4 3.1.3 Monitoring Results ............................................................................................. 4 3.1.3 Interpretation of Results ................................................................................... 5

3.2. WASTEWATER MONITORING ......................................................................................... 5 3.2.1 Monitoring locations ........................................................................................... 5 3.2.2 Monitoring Parameters ....................................................................................... 5 3.2.3 Monitoring Results ........................................................................................... 5 3.2.4 Interpretation of Results ..................................................................................... 6

3.3. NOISE MONITORING .................................................................................................. 6 3.3.1 Noise monitoring Locations and Parameters ........................................................... 6 3.3.2 Monitoring Results ............................................................................................. 6 3.3.3 Interpretation of Results ..................................................................................... 7

3.4. DUST MONITORING .................................................................................................. 10 3.4.1 Monitoring locations & parameters ...................................................................... 10 3.4.2 Monitoring Results ............................................................................................ 10 3.4.3 Interpretation of Results .................................................................................... 11

4. SITE DEVELOPMENT WORKS ................................................................................. 12 4.1. SPECIFIED ENGINEERING WORKS ............................................................................... 12 4.2. SUMMARY OF RESOURCE & ENERGY CONSUMPTION ............................................................. 12 4.3. BUND INTEGRITY TESTING .......................................................................................... 12

5. WASTE RECEIVED AND CONSIGNED FROM THE FACILITY ..................................... 13 6. ENVIRONMENTAL INCIDENTS AND COMPLAINTS ................................................. 16

6.1. INCIDENTS ............................................................................................................ 16 6.2. REGISTER OF COMPLAINTS .......................................................................................... 16

7. ENVIRONMENTAL DEVELOPMENT & CONTROL ...................................................... 17 7.1. ENVIRONMENTAL MANAGEMENT PROGRAMME REPORT ........................................................... 17

7.1.1. Site Management Structure 2015 ...................................................................... 17 7.1.2. Staff Training ................................................................................................. 18

7.2. ENVIRONMENTAL MANAGEMENT PROGRAMME PROPOSAL ........................................................ 18 7.2.1. Schedule of Objectives 2015 ............................................................................. 18 7.2.2. Schedule of Objectives 2016 ............................................................................. 18

7.3. COMMUNICATIONS PROGRAMME .................................................................................... 18 7.4. ELRA & REPORT ON FINANCIAL PROVISION ...................................................................... 21 7.5. NUISANCE CONTROLS ............................................................................................... 21

LW15/172/01/Rpt002-1 ii/ii

TABLE OF CONTENTS - Cont'd… PAGE

7.6. RAINWATER AND WASTEWATER VOLUMES ........................................................................ 21

8. OTHER REPORTS ................................................................................................... 22 8.1. EUROPEAN POLLUTANT RELEASE AND TRANSFER REGISTER REGULATION ..................................... 22

LIST OF FIGURES FIGURE 3.1: MONITORING LOCATIONS, MILLENNIUM BUSINESS PARK ............................................... 8 FIGURE 3.2: NOISE SENSITIVE LOCATION (OFFSITE) .................................................................. 9 LIST OF TABLES TABLE 2.1: WASTE ACCEPTANCE CATEGORIES & QUANTITIES AT MILLENNIUM PARK ............................. 2 TABLE 2.2: PLANT & MACHINERY AT MILLENNIUM PARK .............................................................. 3 TABLE 3.1: SURFACE WATER MONITORING RESULTS SW-1 ......................................................... 4 TABLE 4.1: ESTIMATES OF RESOURCES USED ON-SITE 2014 – 2015 ........................................... 12 TABLE 5.1: WASTE RECEIVED & CONSIGNED 2015 ................................................................. 13 TABLE 5.2: WASTE RECEIVED AND CONSIGNED 2014 .............................................................. 14 TABLE 5.3: WASTE RECEIVED AND CONSIGNED (TONNES) ......................................................... 15

Section 1 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 1 of 22

1. INTRODUCTION 1.1. Reporting period This is the 2015 Annual Environmental Report (AER) for the Starrus Eco Holdings Ltd (T/A Greenstar), Materials Recovery & Transfer facility (MRF) at Millennium Business Park, Ballycoolin, Dublin 11. It covers the period from the 1st January 2015 to the 31st December 2015. 1.2 IED Licence The Environmental Protection Agency (EPA) transferred the licence No. W0183-01 to Starrus Eco Holdings Ltd (T/A Greenstar) for its facility at Millennium Business Park, Grange, Ballycoolin, Co. Dublin on 4th March 2014. On the 16th December 2015, the Licence was amended by the EPA and deemed to be an industrial emissions licence (IED) granted under Part IV of the Environmental Protection Act 1992 as amended. This report is prepared in accordance of condition 10.9 of the IED Licence, which requires and Annual Environmental Report (AER) for the facility to be submitted to the EPA.

Chapter 2 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 2 of 22

2. SITE DESRIPTION 2.1. Facility Location and Activities The Materials Recovery & Transfer facility (MRF) is located at Millennium Business Park, Ballycoolin, Dublin 11. The facility occupies 4.45 hectares (ha) in the east side of the Millennium Business Park. The facility is situated in south Dublin, approximately 5km north-west of Finglas. The facility is situated in west Dublin, approximately 5km north-west of Finglas. The surrounding area is characterised mainly by industrial and commercial land use. It was intended to develop the facility in a number of Phases. Phases 1 and 2 opened in July 2006 and involved the construction of the Materials Recovery Facility (MRF) building and supporting ancillaries. The licence allows for the construction of a biowaste treatment building but this has not yet been constructed. 2.2 Waste Activities at the Facility The facility is in operation since July 2006. It is currently licensed to accept and process 220,000 tonnes of waste per annum, comprising commercial/industrial non-hazardous waste, municipal waste and construction and demolition wastes. All waste processing takes place inside the waste transfer building, as specified in Condition 4.1 of the Licence. The Agency has granted approval for the outdoor storage of wrapped bales of Solid Recovered Fuel (SRF). 2.1.1. Waste Types The licensed waste types and quantities under the IED Licence Schedule A are: Table 2.1: Waste Acceptance Categories & Quantities at Millennium Park

Waste Type Phase 1 Phase 2

Municipal 65,000 100,000

Commercial & Industrial 70,000 45,000

Construction & Demolition Waste 24,000 30,000

Total 159,000 220,000

No hazardous wastes or liquid waste are accepted at the facility. 2.1.2 Waste Processing The main processes carried out at the facility are:

The Baling and Compaction of Municipal and Commercial & Industrial (C&I) waste, Separation of C&I waste into different waste streams (paper, cardboard, glass, metal, organic), Screening of C&D waste into different waste streams (metals, concrete, bricks, tiles, plaster board,

timber etc.), Producing SRF which is baled and stored outdoors for shipment.

Chapter 2 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 3 of 22

Commercial & Industrial (C&I) Waste Commercial and Industrial waste is delivered to the facility by refuse collection vehicles or ejection trailers in two forms, mixed waste and pre segregated dry recyclables. This waste is off loaded in dedicated bays inside the MRF building. The dry mixed recyclables are placed in separate bays from mixed waste. The waste upon tipping is inspected for contamination and unsuitable materials. These are removed immediately into a quarantine area. The dry recyclables are moved into separate storage bays for wood, metal, paper and plastics. Papers and plastics are baled, then loaded into trailers and transported off site. Confidential papers are shredded before baling and then transported off site. The mixed C&I waste is initially sorted using a mechanical grab to remove large items such as timber and metal, which are removed to other storage areas in the building. The remaining mixed C&I is transported off site for further processing. C&I light fractions are put through a processing line, and resulting SRF material sold on for Energy recovery. Construction & Demolition Waste (C&D) C&D waste is tipped inside the MRF building. The waste upon tipping is inspected for contamination and unsuitable materials. These are removed immediately into a quarantine area. Remaining C&D is loaded into trailers and transported off site. MSW (Municipal Solid Waste), compost and green waste continues to be bulked at the site and transported to other sites for processing or disposal. 2.3 Plant & Machinery List A list of the plant in use at the facility is given in Table 2.1. Table 2.2: Plant & Machinery at Millennium Park

No. Plant Model Operational Capacity (tons per day)

Standby Capacity (tons per day)

1 Bollegraaf 110 baler 35 15

1 Bollegraaf 80 baler 25 10

1 Loading Grab Fuchs MHL 340 2160 1710

1 Bollegraaf BAS 75 Shredder 20 0

1 Loading Shovel Volvo L120E 8640 7440

1 Ulster Shredder 10 0

2 Mitsubishi Forktruck Forktruck - -

1 Mustang Skid Steer Loader - -

2 Linde Clamp Forktruck - -

Chapter 3 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 4 of 22

3. EMISSIONS MONITORING The monitoring required for the facility includes monitoring of: surface water, wastewater, dust (quarterly) and noise (annual). The monitoring locations are shown on Figure 3.1. As per the Licence, monitoring results are included in reports submitted to the Agency at quarterly intervals in quarterly reports. An overview of the results of the monitoring is presented in this Section. 3.1. Surface Water Monitoring 3.1.1 Monitoring locations Quarterly surface water monitoring and analysis was carried out for the parameters listed in Schedule D of the licence at the surface water monitoring points SW-1, SW-2 as shown on Figure 3.1. The surface water drainage system serves most of the paved area of the site and roofed areas. 3.1.2 Monitoring parameters Quarterly surface water monitoring and analysis was carried out for the parameters listed in Schedule D of the licence. Surface water quality is being impacted by malfunctions in the site drainage network of the Business Park and the management company with responsibility for the park have liaised with Fingal County Council to provide a solution. This issue has been notified to the EPA by Greenstar. Essentially, with the approval of the Council, the management company is developing a revision to the current drainage layout to improve the hydraulic performance of the system serving the business park. Failure in the current system resulted in ingress of water to the facility surface water drainage system throughout 2015. The full surface water laboratory analysis was carried out by jones Environmental Forensics Ltd (Q1 2015), Alcontrol Laboratories Ltd (Q2, Q3 2015) and Eurofins Food Testing Ireland Limited (Q4 2015) 3.1.3 Monitoring Results The Q2, Q3 & Q4 2015 results were not submitted to the Agency as per companies letter to the Agency 20/01/16 due to ongoing issues with the site drainage network, affecting the credibility of these results. The results for Q1 2015 are presented in Tables 3.1 which include the trigger levels set in the licence. Table 3.1: Surface Water Monitoring Results SW-1

Parameter ELV/Trigger Level Q1 2015

SW-1 SW-2

pH (pH units) (Field) N/A 7.03 NS

Conductivity (mS/cm) (Field) N/A 0.542 -

Temperature (°C) (Field) N/A 7.6 -

Ammoniacal Nitrogen as N (mg/l) N/A 0.37 -

BOD (mg/l) 25 4 -

COD (mg/l) N/A 28 -

Total Suspended Solids (mg/l) 35 <10 -

Mineral Oils (mg/l) 5 4.41 -

Fats, oil & Greases (mg/l) N/A 4.41 -

NS – Not sampled as sampling SW-2 point was dry

Chapter 3 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 5 of 22

3.1.3 Interpretation of Results Results for Q1 2015 were compared to trigger levels for surface water in Condition 5.4.1 of the licence. At SW-1 all parameters were below the trigger levels for Q1 2015. SW-2 was not sampled as it was dry at time of sampling. 3.2. Wastewater Monitoring 3.2.1 Monitoring locations The waste water discharge comes from vehicle washing, drainage from the materials recovery shed, and yard area where waste processing and handling take place. It flows then to a silt trap and oil interceptor, before entering the municipal sewer system. Bi-monthly sewer monitoring was carried out at one location (SE-1) as defined in schedule D of the licence and shown in the Drawing LW15-172-01_Monitoring Locations (Millennium Park) in Figure 3.1. 3.2.2 Monitoring Parameters The sampling frequency is bimonthly and sampling was undertaken by FT staff with laboratory analysis undertaken by Alcontrol Laboratories for the parameters as listed in Schedule D of the licence. Six samples were collected in 2015 (February, March (EPA Sample), April, August, September, December). Laboratory analysis was carried out for the parameters as listed in Schedule D of the licence by Alcontrol Laboratories Ltd. 3.2.3 Monitoring Results The results are compared to the Emission Limit Values (ELV) as per Schedule C.4 of the licence. Table 3.2: Wastewater Monitoring Results SE-1

Parameter ELV SE-1

Feb-15 Mar-15*** Apr-15 Jun-15 Sep-15 Oct-15 Dec-15

pH (pH units) (Field)

6.0-10.0 8.85 7.1 7.08 NS 7.914 7.493 7.66

Temperature (°C) (Field) 42 6.7 5.8 9.7 - 13.9 13.3 10.6

Conductivity (mS/cm) (Field)

- 0.896 0.81 1.089 0.568 0.556 0.548

Ammoniacal Nitrogen as N (mg/l)

100 98.43 0.02** 3.06 1.2 4.71 2.42

BOD (mg/l) 6000 8 - <1 2.27 26.1 <1

COD (mg/l) 12000 69 151 11.6 25.2 894 21.7

Total Suspended Solids (mg/l)

2500 448 <20 10 8.5 1210 3.5

Fats, oil & 100 <0.01 - <1 4.99 19.7 <1

Chapter 3 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 6 of 22

Parameter ELV SE-1

Feb-15 Mar-15*** Apr-15 Jun-15 Sep-15 Oct-15 Dec-15

Greases (mg/l)

Phosphates as P (mg/l) 100 0.5* 0.06 <.02 0.0636 <0.02 0.0346

Surfactants, (mg/l) 100 1.5 - 0.061 <0.05 0.0753 <0.05

Sulphate (mg/l) 1000 95.34 146 0.311 59.9 59.4 117

* Measured Orthophosphate as PO4 ** Ammonia Total as N *** EPA Sample. FOG’s and surfactant results for this sample were not available. NS: Not sampled as sampling point was dry 3.2.4 Interpretation of Results Results were within ELV’s for the 2015 monitoring period. 3.3. Noise Monitoring 3.3.1 Noise monitoring Locations and Parameters Annual noise monitoring was undertaken by FT staff on 04 June 2015 at three on-site boundary locations and one off-site location. The monitoring locations included those specified in the Licence (N-1, N-2 and N-3) and one off-site noise sensitive location NSL-1 as set out in Schedule F of the Licence and in LW15-172-01_Monitoring Locations (Millennium Park) in Figure 3.1. This survey was undertaken to measure the licence parameters detailed in Schedule D.2 of the facilities licence. The measurements are used to determine compliance with the noise emissions limits specified in Table C.1 of the facilities waste licence. It is understood from a client instruction that the noise emissions limits, as set out in the licence, only apply to the noise sensitive locations. Condition 5.5 of the waste licence also required that “There shall be no clearly audible tonal component or impulsive component in the noise emissions from the activity at the noise sensitive locations.” There are no night-time operations or night-time noise sources therefore noise monitoring was only carried out in daytime hours. 3.3.2 Monitoring Results Results of the noise monitoring conducted are summarised in Table 3.4 over.

Chapter 3 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 7 of 22

Table 3.4: Noise Monitoring Results 2015

Location Sample Time Daytime

LAeq, 30 min (dB) LA10, 30 min (dB) LA90, 30 min (dB)

N1 04/06/2015 11.28 44.6 46.9 39.4

N2 04/06/2015 12:55 56.7 59.3 51.2

N3 04/06/2015 12:17 67.3 69.7 64.5

NSL1 04/06/2015 13:42 71.7 76.0 53.6 3.3.3 Interpretation of Results Boundary Locations The daytime limit value of 55dB(A) is only applicable at noise sensitive locations therefore the following descriptions of boundary noise levels are not assessed for compliance with the daytime limit. The LAeq value recorded at N1 was below with the limit value of 55 dB(A) with the noise level contributed to by both on-site and off-site noise sources. At N2, an LAeq level of 56.73 dB(A) measured. On site truck movements was the dominant noise source, together with machinery working in the plant. The LAeq value is thus representative of site noise. For N3, 67.3 dB LAeq was measured. The noise level was generated by the onsite plant air fan system and truck movements on site. Offsite noise sources included trucks, loaders and plant activity at the Kilsaran plant. The LAeq value is representative of contributions from both sites, which were both active throughout monitoring period. Noise Sensitive Locations At NSL1, an LAeq level of 71.7dB was recorded. The dominant noise source at this location was off-site road traffic along the Cappagh Road. Contemporaneous notes at this location show that site noise was barely audible at this location. The background noise level (LA90) is 53.6dB and is more representative of the contributing off site noise than the LAeq measurement. For all locations on analysis, no tonal characteristics were found and the LAeq values are not required to be penalised. Therefore rated levels are not required to be presented for these locations. In conclusion, it is understood from the client’s instruction that the noise emission limits as per licence do not apply to boundary locations and are only applicable to off-site noise sensitive locations. Therefore the site is considered compliant with its daytime off-site noise emission limit of 55dB. Figure 3.1 over shows the Monitoring Locations.

Chapter 3 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 9 of 22

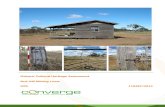

Figure 3.2: Noise Sensitive Location (offsite)

Chapter 3 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 10 of 22

3.4. Dust Monitoring 3.4.1 Monitoring locations & parameters Dust monitoring was carried out on three occasions at four on-site locations (DS-01, DS-02, DS-03 and DS-04) in June, August and October 2015. The Licence requires two of these monitoring events be carried out between May and September. The locations of these monitoring points are shown on Drawing LW15-172-01_Monitoring Locations (Millennium Park) in Appendix I. Bergerhoff style gauges were used to determine total dust deposition levels at the site. Four gauges were set up so that the dust jars were at a height of at least 1.5 m above the ground and the jars were set in place during the monthly monitoring event. The samples were submitted to Alcontrol Laboratories Ltd. for analysis of dust contents. 3.4.2 Monitoring Results The results for total dust deposition for the monitoring period reported in Quarter 4 are presented in Table 3.5 Table 3.5: Dust Monitoring Results 2015

Sampling Point

Total Dust

09/06/2015-08/07/2015

mg/m2/d

DS-01 329

DS-02 819

DS-03 316

DS-04 324

Limit 350 Table 3.6: Dust Monitoring Results 2015

Sampling Point

Total Dust

06/08/2015-04/09/2015

mg/m2/d

DS-01 62

DS-02 546

DS-03 145

DS-04 159

Limit 350

Chapter 3 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 11 of 22

Table 3.7: Dust Monitoring Results 2015

Sampling Point

Organic Dust Inorganic Dust

Total Dust

28/10/15-25/11/15

mg/m2/day

DS-01 115 45.4 160

DS-02 173 40.4 213

DS-03 69.4 32.6 102

DS-04 11 7.76 18.8

Limit 350 3.4.3 Interpretation of Results In the two rounds (June-July, August-September), contamination of samples at DS-02 due to bird faecal matter has occurred during both sampling events in Q3, resulting in elevated results. Notes and photographs of monitoring at this sampling point recorded high levels of faecal bird matter on the dust pot holder and in the dust pot. There has been no change in activity in 2015 on site to contribute to these readings. For the Q4 round (November 2015), all monitoring points were below the daily deposition limit. Visual observation and notes on the day show leaves, algae, insects and faecal bird matter in the dust pots. The organic/organic breakdown demonstrates the composition of the dust sampled.

Chapter 4 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 12 of 22

4. SITE DEVELOPMENT WORKS 4.1. Specified Engineering Works No specified engineering works in accordance with those listed in Schedule B of the IED licence were carried out during the 2015 reporting period. The site continues to bulk MSW, C&I and C&D waste for processing or disposal at other licensed sites. 4.2. Summary of Resource & Energy Consumption Resources consumed at Millennium Business Park MRF include diesel fuel, electricity, oil (hydraulic, transmission, engine), truck wash detergent, water (mains supply), natural gas, anti-freeze. Table 4.1 presents an estimate of the resources used on-site during 2014 as well as 2015. Table 4.1: Estimates of Resources Used On-Site 2014 – 2015

Resource Quantities used 2014 Quantities used 2015

Diesel (litres) 73,780 60,000

Electricity (kWh) 1,492,273 927,715

Oils (hydraulic, transmission, engine) (litres) 1,640 2,000

Detergent (truck wash) (litres) 30 30

Water (mains)(litres) 4,842,000 3,890,000

Natural Gas (kWh) 52,040 52,040

Anti-Freeze (litres) 75 75

*: Water usage is an estimate as meter is not in use There was a large decrease in the consumption of electricity observed in 2015 when compared to levels observed in 2014. 4.3. Bund Integrity Testing Condition 3.13.3 of the Licence requires that tank, drum, pipeline and bund testing is to be carried out every three years on site. The on-site mobile bunds were tested in December 2013 and past fit for purpose. A report was submitted to the Agency. A CCTV survey was also carried out on the site drains by Horizon Environmental in May 2013. The drains were passed fit for purpose. Integrity testing is due again in 2016.

Chapter 5 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 13 of 22

5. WASTE RECEIVED AND CONSIGNED FROM THE FACILITY The waste processing and volumes are described in section 2.2 of this document. A detailed description of the wastes received and consigned in 2015 is presented in the PRTR submission in Appendix 1. Table 5.1 shows the quantities of wastes accepted and consigned for the reporting period. For 2015 a total of 105,517.447 tonnes of waste was received, with 100,462.678 tonnes sent offsite. The amounts of waste received and consigned from 2006 to 2014 are presented in Table 5.2 and 5.3. As per Condition 5.8 of the Licence, all the wastes consigned from the site went to authorised recovery and disposal facilities. A copy of the relevant Facility Permit or Waste Licences is retained on site for Agency inspection. The records show that more waste was received at the site than transferred off. The difference was 5,054.769 tonnes. The remaining difference is due to waste which remained on site at the end of 2015 which will be consigned in 2016. All the wastes consigned from the site went to recovery and disposal facilities were agreed with the Agency. Table 5.1: Waste Received & Consigned 2015

EWC Code Description Waste In Waste Out

10409 Sand 9.54

70599 Peat Based Air Filter Media 109.3

101008 Gyspum 6.22

130208 Waste Oil 1.9

130309 Plastic Film 0.049

150101 Cardboard Packaging 14442.103 13882.6

150102 Plastic Packaging 1270.532 1135.87

150103 Wooden Packaging 1060.379 500.435

150104 Metal Packaging 34.366

150105 Tetra Pak Cartons 11.9

150106 Mixed Packaging 6308.585 8054.93

150107 Glass 21.31

160601 Batteries 0.81

160103 Tyres 14.04

170203 Plastic 198.2 8.24

170302 Bitmac 98.02 98.2

170405 Stainless Steels 0.62

170504 Soil & Stones 2668.82 2789.96

170802 Plasterboard 151.033

170904 C&D Inert Mixed 1047.661

180104 Solid Recovered Fuel (SRF) 66.58

190902 Interceptor Sludge 34.24

190905 Resin 7.94

191201 Paper & Cardboard Residue 10.259

191204 Rubber 1.19

191207 Wood 69.634 344.62

Chapter 5 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 14 of 22

EWC Code Description Waste In Waste Out

191209 C&D Inert Mixed 689.91

191210 Solid Recovered Fuel (SRF) 1012.192 5862

191212 C&I Dry Mixed 9419.703 1921.14

200101 Cardboard & Paper 24138.367 22997.1

200102 Glass 23.53

200108 Compost 3580.268 3308.9

200111 Textile 8.72

200138 Wood 2491.794 1343.86

200139 Plastic 32.82 15.58

200140 Metal 720.581 901.473

200201 Green Biogradable Waste 1504.569 1372.34

200301 MSW Municipal Mixed Waste 15958.956 17314.3

200303 LDF Street Cleaning 626.949 56.92

200307 C&I Dry Mixed 17700.807 18517.28

Total Received 105,517.447

Total Consigned 100,462.678

Total Disposed 22,910.12

Total Recovered 77552.558

Recovery Rate (%) 77.20 Table 5.2: Waste Received and Consigned 2014

EWC Code Description Waste In Waste Out

101008 Gypsum 1.88

130208 Engine Oil 1.90 150101 Cardboard 1,263.18 1,098.10

150102 Plastic Packaging 157.93 79.92 150103 Wooden 397.43 112.22

150104 Metal Packaging 26.81

150105 Tetra Pak Cartons 3.46

150106 Mixed Packaging 6,834.19 7,445.98

150107 Glass Packaging 7.29

150203 Protective 0.04

160103 Tyres 9.40 10.48 160304 C&I Dry Mixed 4.07

160601 Batteries 0.85 170101 Concrete 931.26 170203 Plastic 3.20 14.24

170504 Soil & Stones 100.17

170802 Plasterboard 28.62

170904 C&D Inert Mixed 2,518.80

Chapter 5 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 15 of 22

EWC Code Description Waste In Waste Out

190902 Sludge 9.10 191207 Wood 375.19 1,482.38

191209 C&D Inert Mixed 399.98 14,002.82 191210 Solid Recovered 434.98 11,084.00

191212 C&I Dry Mixed 20,509.35 12,416.50 200101 Cardboard 2,462.28 1,632.12

200102 Fibre Glass 4.12

200108 Compost 4,123.41 4,636.70 200110 Clothing 0.36

200111 Textile 2.50

200135 REC Electronics 1.94

200138 Wood 2,029.47 2,299.50 200139 Plastic 8.64

200140 Metal 402.40 1,611.32

200199 Grease Trap 0.40

200201 Green 525.04 350.36

200301 MSW 10,161.31 8,188.62 200303 LDF Street Cleaning 3,970.89 2,956.13

200307 C&I Dry Mixed 24,219.07 9,485.91 Total Received 80,987.80 Total Consigned 79,850.41 Total Disposed 22,608.62 Total Recovered 57,241.79

Recovery Rate (%) 71.69

Table 5.3: Waste Received and Consigned (Tonnes)

Year Total Received Total Consigned

2015 105,517.447 100,462.678 2014 80,987.80 79,850.41 2013 83,500.66 81,230.14 2012 92,484.12 87,448.73 2011 87,191 83,181 2010 74,694.50 68,868.59 2009 79,469.57 77,224.94 2008 133,813.88 129,366.26 2007 167,056.84 161,828.21 2006 79,570.21 80,725.68

Chapter 6 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 16 of 22

6. ENVIRONMENTAL INCIDENTS AND COMPLAINTS 6.1. Incidents There were no reportable incidents in 2015. 6.2. Register of Complaints Starrus Eco Holdings Ltd (t/a Greenstar) maintains a register of complaints received in accordance with Condition 9.4 of the waste licence. There were no complaints received in 2015.

Chapter 7 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 17 of 22

7. ENVIRONMENTAL DEVELOPMENT & CONTROL 7.1. Environmental Management Programme Report Starrus Eco Holdings Ltd (t/a Greenstar) has implemented an Integrated Management System (IMS) in accordance with the requirements of Occupational Health and Safety Assessment Series (OHSAS) 18001:2007 and International Standard Organisation (ISO) 14001:2004. This is in to manage the Health, Safety and Environmental performance of the business. It is also to control health and safety risk and to minimise their environmental aspects and impacts. The Integrated Management System (IMS) has been developed to allow continual improvement taking into the requirements of the Waste Licence Conditions. Starrus Eco Holdings Ltd (t/a Greenstar) has prepared and effectively implement documented procedures and instructions in accordance with the requirements of both the OHSAS 18001:2007 and ISO 14001:2004. The company has developed a list of environmental, management, operating and maintenance procedures, details of which are outlined in Appendix 2. A successful external surveillance was completed during June 2015. There were no non-conformances were no recorded against the facility. The schedule of Objectives and Targets, including their status for 2015 (Table 7.1), as well as the proposed Objectives and Targets for 2016 (Table 7.2) are presented below. 7.1.1. Site Management Structure 2015 The site management structure was changed 2014. This was to incorporate changes to the processing operations as discussed in Section 4.1. The 2015 structure is detailed below: Name: Donal Monahan Role: Director of Operations Experience: 15 years’ experience waste management experience; January – October 2015 Name: John Richardson Role: Facilities Manager, Dublin Processing Experience: 20 years’ experience; has completed the FÃS waste management course. October – December 2015 Name: Gwen Cooper Role: Acting Facility Manager Experience: 10 years’ experience; has completed the FÃS waste management course. Name: Robert Hughes Responsibility: Site Operations Manager Experience: 13 years’ experience in Waste Management.

Chapter 7 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 18 of 22

7.1.2. Staff Training Environmental awareness, manual handling and lock out/tag out training was undertaken by the operations staff. Managers received environmental management system (Scannell) training and are trained to “FAS Waste Management course” standard. 7.2. Environmental Management programme Proposal 7.2.1. Schedule of Objectives 2015 The objectives that were achieved during this reporting period are outlined in Table 7.1 7.2.2. Schedule of Objectives 2016 The schedule of targets and objectives for 2015 are presented in Table 7.2. 7.3. Communications Programme Starrus Eco Holdings Ltd (t/a Greenstar) is committed to setting the standard in waste management and ensuring environmental compliance in all operations. The companies’ Environmental, Health & Safety Policy makes a specific commitment to make the environmental policy and records available to the public and interested parties. Starrus Eco Holdings Ltd (t/a Greenstar) has drawn up a Communications Programme, which details how members of the public are facilitated in accessing environmental information at the facility. Records available for public inspection on site include:

Environmental, Health & Safety Policy, Waste Licence, Licence Application and Review documentation, Monitoring Records, Complaints File, EPA Correspondence File.

These Records are available for inspection from 10 am - 4 pm each business day. Visits to the site should be arranged in advance by ringing the Facility Manager or Supervisor at 1890 600 90.

Chapter 7 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 19 of 22

Table 7.1: Objectives and Targets for 2015

No. Objective Target Timescale Responsibility

1

Document a Preventative Maintenance (PM) plan for the inspection and cleaning of plant & equipment wrt

fire

Incorporate into existing Site Inspection Database (EF-10A) and site specific PM plans

Ongoing, site specific PM plans currently under review

Site Management/EHS

2 Document PM plan for all hardstand and drainage

infrastructure on site Incorporate into existing Site Inspection Database (EF-10A) Completed Site Management/EHS

3

Review EWC codes in active use group wide and

implement recommendations at each

site

Review EWC codes with Finance/WIMS & advise changes to site management

Completed EHS/Finance/WIMS

4 Increase awareness of

Odour Management on site group wide

Specify Odour detection in Site Inspection Database (EF-10A) on a daily basis and generate actions as appropriate

Completed Site Management/EHS

5 Track Energy Usage on site Record electricity, gas, water and fuel consumption on site group wide

Ongoing Site Management/EHS

6 Pipeline integrity testing Complete pipeline integrity testing and carry out any remedial works required

Postponed till after the external

Management Company issues

have been rectified

Site Management/EHS

7 Setting of Surface Water

trigger levels Complete surface water investigation and submit required data

and proposed trigger level to EPA for approval

On-going, also linked to external

drainage issue in Business

Park

Site Management/EHS

Chapter 7 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 20 of 22

Table 7.2: Schedule of Objective and Targets 2016

No. Objective Target Timescale Responsibility

1

Increase awareness of Odour Management on site group wide

Specify Odour detection in Site Inspection Database(EF-10A) on a daily basis and generate actions as appropriate Q1-Q2 Site Management/EHS

2 Waste storage practices

Review waste storage practices on each site to ensure that they are in line with licence conditions, fire prevention and

insurance recommendations Q2 Site Management/EHS

3

Emergency response procedures - ER pack update

Review the Emergency Response Pack on each site and ensure that all information & equipment required in case of

an emergency is available. Confirm that relevant staff training adequately addresses. Q2 Site Management/EHS

4 CRAMP, ELRA & Financial Provision CRAMP, ELRA & Financial Provision to be reviewed Q2/Q3 EHS team

5 Waste acceptance, classification & records

EWC training for all weighbridge ops. Centralisation of all licences & permits including NWCPs for hauliers. Q2/Q3 EHS team

6 Pipeline integrity & bund testing

Arrange for integrity testing of pipelines and bunds as per licence requirements. Testing of three concrete bunds to be

included Q2/Q3 Site Management/EHS

7 Energy Audit Completed energy audit as per amended licence conditions Q4 Site Management/EHS

8 Occupational Noise Survey Complete Occupational Noise Survey of the Facility Q1 EHS Team

9 Surface Water Drainage Review onsite surface water drainage and add protective grill

mesh to vulnerable gullies Q1/2 Site management/EHS

Chapter 7 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 21 of 22

7.4. ELRA & Report on Financial Provision A Decommissioning Management Plan (DMP) and Environmental Liabilities Risk Assessment (ELRA) including Financial Provision (FP) have been developed for the site and were submitted to the Agency in 2013. These have both been approved by the Agency and provision and provision is in place with their agreement. A review of both reports will be completed in 2016. 7.5. Nuisance Controls Starrus Eco Holdings Ltd (t/a Greenstar) has contracted a vermin control company Pestguard to carry out nuisance control at the facility. Pestguard undertake a 6 weekly review of the vermin activity on-site along with an inspection of the bait traps that are located throughout the facility. 7.6. Rainwater and Wastewater Volumes No rainwater was reused at the facility in 2015. The grey water reuse system has been de-commissioned. As it is not possible to give an exact figure for the amount of wastewater produced during 2015 an estimate of 6,200 m3 of water was used by the truck wash during the year. Wastewater discharges to the municipal sewer serving the industrial estate. The sewer water then flows to a waste water treatment plant operated by Fingal County Council.

Chapter 8 Starrus Eco Holdings Ltd (t/a Greenstar) Millennium Business Park Materials Recovery Facility

Annual Environmental Report 2015

LW15/172/01/Rpt002-1 Page 22 of 22

8. OTHER REPORTS 8.1. European Pollutant Release and Transfer Register Regulation The Pollution Emission Register (PER) has been replaced by the European Pollutant Release and Transfer Register Regulation (EC) No. 166/2006. A copy of the information submitted to the Agency via the web-based data reporting system is included in Appendix 1.

| PRTR# : W0183 | Facility Name : Starrus Eco Holdings Limited (Millenium Business Park) | Filename : W0183_2015.xls | Return Year : 2015 |

Guidance to completing the PRTR workbook

Version 1.1.19

REFERENCE YEAR 2015

1. FACILITY IDENTIFICATIONParent Company Name Starrus Eco Holdings Limited

Facility Name Starrus Eco Holdings Limited (Millenium Business Park)PRTR Identification Number W0183

Licence Number W0183-01

Classes of ActivityNo. class_name

- Refer to PRTR class activities below

Address 1 Millennium Business ParkAddress 2 GrangeAddress 3 BallycoolinAddress 4 Dublin 11

DublinCountry Ireland

Coordinates of Location -6.34044 53.4084River Basin District IEEA

NACE Code 3832Main Economic Activity Recovery of sorted materials

AER Returns Contact Name Malcolm DowlingAER Returns Contact Email Address [email protected]

AER Returns Contact Position 012947976AER Returns Contact Telephone Number 012947976

AER Returns Contact Mobile Phone NumberAER Returns Contact Fax Number

Production Volume 0.0Production Volume Units

Number of Installations 0Number of Operating Hours in Year 0

Number of Employees 14User Feedback/Comments The level of Ammonia, and Suspended Solids had increased in 2015, whereas the levels of BOD, COD,Detergents, FOG's

had decreased since 2014. The backing up of the onsite drainage system from the wider business park in 2014/2015 has continued to cause water drainage issues for The Millennium Park Materials Recovery Facility in 2015.

Web Address

2. PRTR CLASS ACTIVITIESActivity Number Activity Name50.1 General5(c) Installations for the disposal of non-hazardous waste50.1 General3. SOLVENTS REGULATIONS (S.I. No. 543 of 2002)

Is it applicable?Have you been granted an exemption ?

If applicable which activity class applies (as per Schedule 2 of the regulations) ?

Is the reduction scheme compliance route being used ?

4. WASTE IMPORTED/ACCEPTED ONTO SITE Guidance on waste imported/accepted onto siteDo you import/accept waste onto your site for on-

site treatment (either recovery or disposal activities) ?

This question is only applicable if you are an IPPC or Quarry site

PRTR Returns Workbook

4.1 RELEASES TO AIR Link to previous years emissions data | PRTR# : W0183 | Facility Name : Starrus Eco Holdings Limited (Millenium Business Park) | Filename : W0183_2015.xls | Return Year : 2015 | 31/03/2016 16:55

8 8 16 16 24 24 6 6 6 6SECTION A : SECTOR SPECIFIC PRTR POLLUTANTS

Please enter all quantities in this section in KGsQUANTITY

No. Annex II Name M/C/E Method Code Designation or Description Emission Point 1 T (Total) KG/Year A (Accidental) KG/Year F (Fugitive) KG/Year0.0 0.0 0.0 0.0

* Select a row by double-clicking on the Pollutant Name (Column B) then click the delete button

SECTION B : REMAINING PRTR POLLUTANTSPlease enter all quantities in this section in KGs

QUANTITY

No. Annex II Name M/C/E Method Code Designation or Description Emission Point 1 T (Total) KG/Year A (Accidental) KG/Year F (Fugitive) KG/Year0.0 0.0 0.0 0.0

* Select a row by double-clicking on the Pollutant Name (Column B) then click the delete button

SECTION C : REMAINING POLLUTANT EMISSIONS (As required in your Licence)Please enter all quantities in this section in KGs

QUANTITY

Pollutant No. Name M/C/E Method Code Designation or Description Emission Point 1 T (Total) KG/Year A (Accidental) KG/Year F (Fugitive) KG/Year0.0 0.0 0.0 0.0

* Select a row by double-clicking on the Pollutant Name (Column B) then click the delete button

Additional Data Requested from Landfill operators

Landfill:Starrus Eco Holdings Limited (Millenium Business Park)

Please enter summary data on the quantities of methane flared and / or utilised

additional_pollutant_no T (Total) kg/Year M/C/E Method CodeDesignation or

DescriptionFacility Total Capacity m3

per hourTotal estimated methane generation (as per

site model) 0.0 N/AMethane flared 0.0 0.0 (Total Flaring Capacity)

Methane utilised in engine/s 0.0 0.0 (Total Utilising Capacity)Net methane emission (as reported in Section

A above) 0.0 N/A

RELEASES TO AIRMETHOD

POLLUTANT METHODMethod Used

For the purposes of the National Inventory on Greenhouse Gases, landfill operators are requested to provide summary data on landfill gas (Methane) flared or utilised on their facilities to accompany the figures for total methane generated. Operators should only report their Net methane (CH4) emission to the environment under T(total) KG/yr for Section A: Sector specific PRTR pollutants above. Please complete the table below:

Method Used

Method Used

RELEASES TO AIRPOLLUTANT METHOD

Method Used

POLLUTANT

RELEASES TO AIR

4.2 RELEASES TO WATERS Link to previous years emissions data | PRTR# : W0183 | Facility Name : Starrus Eco Holdings Limited (Millenium Business Park) | Filename : W0183_2015.xls | Return Year : 2015 | 31/03/2016 17:05

8 8 16 16 24 24 6 6 6 6 6 6SECTION A : SECTOR SPECIFIC PRTR POLLUTANTS Data on ambient monitoring of storm/surface water or groundwater, conducted as part of your licence requirements, should NOT be submitted under AER / PRTR Reporting as this only concerns Releases from your facili

Please enter all quantities in this section in KGsQUANTITY

No. Annex II Name M/C/E Method Code Designation or Description Emission Point 1 T (Total) KG/Year A (Accidental) KG/Year F (Fugitive) KG/Year0.0 0.0 0.0 0.0

* Select a row by double-clicking on the Pollutant Name (Column B) then click the delete button

SECTION B : REMAINING PRTR POLLUTANTSPlease enter all quantities in this section in KGs

QUANTITY

No. Annex II Name M/C/E Method Code Designation or Description Emission Point 1 T (Total) KG/Year A (Accidental) KG/Year F (Fugitive) KG/Year0.0 0.0 0.0 0.0

* Select a row by double-clicking on the Pollutant Name (Column B) then click the delete button

SECTION C : REMAINING POLLUTANT EMISSIONS (as required in your Licence)Please enter all quantities in this section in KGs

QUANTITY

Pollutant No. Name M/C/E Method Code Designation or Description Emission Point 1 T (Total) KG/Year A (Accidental) KG/Year F (Fugitive) KG/Year0.0 0.0 0.0 0.0

* Select a row by double-clicking on the Pollutant Name (Column B) then click the delete button

RELEASES TO WATERS

RELEASES TO WATERS

Method Used

POLLUTANTMethod Used

POLLUTANT

POLLUTANTRELEASES TO WATERS

Method Used

4.3 RELEASES TO WASTEWATER OR SEWER Link to previous years emissions data | PRTR# : W0183 | Facility Name : Starrus Eco Holdings Limited (Millenium Business Park) | Filename 31/03/2016 17:11

8 8 16 22 6 6 6 6SECTION A : PRTR POLLUTANTS

Please enter all quantities in this section in KGsQUANTITY

No. Annex II Name M/C/E Method Code Designation or Description Emission Point 1 T (Total) KG/Year A (Accidental) KG/Year F (Fugitive) KG/Year0.0 0.0 0.0 0.0

* Select a row by double-clicking on the Pollutant Name (Column B) then click the delete button

SECTION B : REMAINING POLLUTANT EMISSIONS (as required in your Licence)Please enter all quantities in this section in KGs

QUANTITY

Pollutant No. Name M/C/E Method Code Designation or Description Emission Point 1 T (Total) KG/Year A (Accidental) KG/Year F (Fugitive) KG/Year

238 Ammonia (as N) M PER

Based on an estimate of water used in the wheel wash. Analysis is ISO accredited 136.718 136.718 0.0 0.0

303 BOD M PER

Based on an estimate of water used in the wheel wash. Analysis is ISO accredited 75.165 75.165 0.0 0.0

306 COD M PER

Based on an estimate of water used in the wheel wash. Analysis is ISO accredited 1211.58 1211.58 0.0 0.0

240 Suspended Solids M PER

Based on an estimate of water used in the wheel wash. Analysis is ISO accredited 2083.2 2083.2 0.0 0.0

314 Fats, Oils and Greases M PER

Based on an estimate of water used in the wheel wash. Analysis is ISO accredited 76.539 76.539 0.0 0.0

308 Detergents (as MBAS) M PER

Based on an estimate of water used in the wheel wash. Analysis is ISO accredited 3.38 3.38 0.0 0.0

343 Sulphate M PER

Based on an estimate of water used in the wheel wash. Analysis is ISO accredited 493.88 493.88 0.0 0.0

* Select a row by double-clicking on the Pollutant Name (Column B) then click the delete button

OFFSITE TRANSFER OF POLLUTANTS DESTINED FOR WASTE-WATER TREATMENT OR SEWER

OFFSITE TRANSFER OF POLLUTANTS DESTINED FOR WASTE-WATER TREATMENT OR SEWER

Method Used

Method Used

POLLUTANT METHOD

POLLUTANT METHOD

4.4 RELEASES TO LAND Link to previous years emissions data | PRTR# : W0183 | Facility Name : Starrus Eco Holdings Limited (Millenium Business Park) | Filename : W0183_2015.xls | Return Year : 2015 | 31/03/2016 17:12

8 8 16 16 6 6 6 6SECTION A : PRTR POLLUTANTS

Please enter all quantities in this section in KGsQUANTITY

No. Annex II Name M/C/E Method Code Designation or Description Emission Point 1 T (Total) KG/Year A (Accidental) KG/Year0.0 0.0 0.0

* Select a row by double-clicking on the Pollutant Name (Column B) then click the delete button

SECTION B : REMAINING POLLUTANT EMISSIONS (as required in your Licence)Please enter all quantities in this section in KGs

QUANTITY

Pollutant No. Name M/C/E Method Code Designation or Description Emission Point 1 T (Total) KG/Year A (Accidental) KG/Year0.0 0.0 0.0

* Select a row by double-clicking on the Pollutant Name (Column B) then click the delete button

POLLUTANT METHODMethod Used

RELEASES TO LAND

RELEASES TO LAND

POLLUTANT METHODMethod Used

5. ONSITE TREATMENT & OFFSITE TRANSFERS OF WASTE | PRTR# : W0183 | Facility Name : Starrus Eco Holdings Limited (Millenium Business Park) | Filename : W0183_2015.xls | Return Year : 2015 | 31/03/2016 17:20

5 77 Please enter all quantities on this sheet in Tonnes 0

Quantity (Tonnes per

Year)

Haz Waste : Name and Licence/Permit No of Next

Destination Facility Non Haz Waste: Name and Licence/Permit No of

Recover/Disposer

Haz Waste : Address of Next Destination Facility

Non Haz Waste: Address of Recover/Disposer

Name and License / Permit No. and Address of Final Recoverer /

Disposer (HAZARDOUS WASTE ONLY)

Actual Address of Final Destination i.e. Final Recovery / Disposal Site

(HAZARDOUS WASTE ONLY)

Transfer DestinationEuropean Waste

CodeHazardous Quantity T/Year Description of Waste

Waste Treatment Operation

M/C/E Method UsedLocation of Treatment

Name and Licence / Permit No. of Recoverer / Disposer / Broker Address of Recoverer / Disposer / Broker Name and Address of Final Destination i.e. Final Recovery / Disposal Site (HAZARDOUS WASTE ONLY) Licence / Permit No. of Final Destination i.e. Final Recovery / Disposal Site (HAZARDOUS WASTE ONLY)

Within the Country 13 02 08 Yes 1.9 other engine, gear and lubricating oils R3 M Weighed Offsite in Ireland ENVA Ireland,W0184-01Clonminam IE , Portlaoise ,Co. Laois,-,ireland

Enva Ireland Ltd, W0184-01,Clonminam IE,., Portlaoise,Co Laois,Ireland

Clonminam IE,., Portlaoise,Co Laois,Ireland

To Other Countries 15 01 01 No 65.98 paper and cardboard packaging R3 M Weighed AbroadNorthwood Recycling Ltd,IRE/G282/15

Waterside,Disley,Stockport,CheshireSK12 2HW,united kingdom

To Other Countries 15 01 01 No 162.84 paper and cardboard packaging R3 M Weighed Abroad

Huhtamaki (Bailey Waste Recycling NI Ltd) ,TFS Broker IRE/AG032/11

Inn Road Dollingstown,Lurgan ,County Armagh ,BT66 7JN,united kingdom

To Other Countries 15 01 01 No 2004.48 paper and cardboard packaging R3 M Weighed AbroadMark Lyndon Paper Enterprises,IRE/G021/12

12 The Triangle,Nottingham,Nottinghamshire NG2 1AE,.,United Kingdom

To Other Countries 15 01 01 No 81.54 paper and cardboard packaging R3 M Weighed Abroad

Paperman Products Ltd ,TFS Broker Greenstar Ltd IRE/AG032/11

Rathdown Close

,Lissue Industrial Estate

,Lisburn,County AntrimBT28 2RB,United Kingdom

Within the Country 15 01 01 No 810.46 paper and cardboard packaging R3 M Weighed Offsite in IrelandAgnail,TFS Broker IRE/AG117/11

Ballymacken Ind. Estate ,Ballymacken ,Portlaoise ,Laois,ireland

BOC Gas Dublin,.,Bluebell,.,Dublin 12,.,Ireland Bluebell,.,Dublin 12,.,Ireland

To Other Countries 15 01 01 No 608.8 paper and cardboard packaging R3 M Weighed AbroadCellmark,TFS Broker IRE/G180/11

CellMark AB,Lilla Bommen 3C,P O Box 11927,SE-404 39 Gothenburg ,Sweden

To Other Countries 15 01 01 No 7587.44 paper and cardboard packaging R3 M Weighed AbroadMLM (ACN Europe) Ltd ,TFS Broker IRE/G022/11

Egerton House ,Towers Business Park ,Wilmslow Rd Didsbury ,M/CR M20 2DX. ,united kingdom

Within the Country 15 01 01 No 40.38 paper and cardboard packaging R3 M Weighed Offsite in Ireland Greenstar Limited,W0053-03Fassaroe,Bray,Co. Wicklow,.,Ireland

To Other Countries 15 01 01 No 495.0 paper and cardboard packaging R3 M Weighed AbroadMateria Environment Ltd,IRE/AG161/17

The Kipper House,Scilly,Kinsale,Cork,Ireland

To Other Countries 15 01 01 No 1674.86 paper and cardboard packaging R3 M Weighed AbroadPeute paper Recycling,IRE/G006/16

Veeplat 40,3313,LJ ,Drodrecht,Netherlands

To Other Countries 15 01 01 No 128.38 paper and cardboard packaging R3 M Weighed AbroadPaper packaging Company,WMEX35/04

.,.,.,Northern Ireland,United Kingdom

To Other Countries 15 01 01 No 150.96 paper and cardboard packaging R3 M Weighed AbroadSaica Natur UK Limited,IRE/G277/15 .,.,.,.,United Kingdom

To Other Countries 15 01 01 No 71.48 paper and cardboard packaging R3 M Weighed AbroadTRC Recycling Ltd,IRE/G385/15

.,Kilquade,Co. Wicklow,.,Ireland

KMK Metals Recycling Limited,W0113-03

Cappincur Industrial Estate ,Daingean Road ,Tullamore , Co. Offaly.,ireland

Within the Country 15 01 02 No 329.265 plastic packaging R3 M Weighed Offsite in IrelandAgnail,TFS Broker IRE/AG117/11

Ballymacken Ind. Estate ,Ballymacken ,Portlaoise ,Laois,ireland

Within the Country 15 01 02 No 751.425 plastic packaging R3 M Weighed Offsite in Ireland

Leinster Environmental/Eco WM Ltd ,WFP-LH-09-0004-01 dundalk,-,-,-,ireland

To Other Countries 15 01 02 No 11.44 plastic packaging R3 M Weighed AbroadEnvirogreen Polymers,IRE/G418/16 .,.,.,.,United Kingdom

Method Used

Quantity (Tonnes per

Year)

Haz Waste : Name and Licence/Permit No of Next

Destination Facility Non Haz Waste: Name and Licence/Permit No of

Recover/Disposer

Haz Waste : Address of Next Destination Facility

Non Haz Waste: Address of Recover/Disposer

Name and License / Permit No. and Address of Final Recoverer /

Disposer (HAZARDOUS WASTE ONLY)

Actual Address of Final Destination i.e. Final Recovery / Disposal Site

(HAZARDOUS WASTE ONLY)

Transfer DestinationEuropean Waste

CodeHazardous Quantity T/Year Description of Waste

Waste Treatment Operation

M/C/E Method UsedLocation of Treatment

Name and Licence / Permit No. of Recoverer / Disposer / Broker Address of Recoverer / Disposer / Broker Name and Address of Final Destination i.e. Final Recovery / Disposal Site (HAZARDOUS WASTE ONLY) Licence / Permit No. of Final Destination i.e. Final Recovery / Disposal Site (HAZARDOUS WASTE ONLY)

Method Used

To Other Countries 15 01 02 No 11.6 plastic packaging R3 M Weighed AbroadMarwin Environmental Trading Ltd,IRE/G027/17

Cuil Greine House,Ballincollig Commercial Park,Link Road Ballincollig,Co. Cork,Ireland

To Other Countries 15 01 02 No 2.4 plastic packaging R3 M Weighed AbroadTRC Recycling Ltd,IRE/G385/15

.,Kilquade,Co. Wicklow,.,Ireland

To Other Countries 15 01 02 No 29.74 plastic packaging R3 M Weighed AbroadWRC Recycling Ltd,IRE/AG121/17 .,.,.,.,United Kingdom

Within the Country 15 01 03 No 195.26 wooden packaging R13 M Weighed Offsite in IrelandClonmel Waste Disposal Ltd ,WP-008-02

Lawlesstown , Clonmel ,Co. Tipperary ,-,ireland

Within the Country 15 01 03 No 5.44 wooden packaging R13 M Weighed Offsite in IrelandAgnail,TFS Broker IRE/AG117/11

Ballymacken Ind. Estate ,Ballymacken ,Portlaoise ,Laois,ireland

Within the Country 15 01 03 No 284.575 wooden packaging R13 M Weighed Offsite in IrelandGrey Stag T/A Euro Pallets Solutions,Meath

Sean Fox's Yard,Coolquay,The Ward,Co.Dublin,Ireland

Within the Country 15 01 03 No 15.16 wooden packaging R13 M Weighed Offsite in IrelandMax Pallet Services Ltd,Max Pallet Services Ltd

Colmanstown,.,.,RathCoole,Ireland

Within the Country 15 01 06 No 7862.65 mixed packaging R13 M Weighed Offsite in Ireland Greenstar Limited,W0053-03Fassaroe,Bray,Co. Wicklow,.,Ireland

Within the Country 15 01 06 No 192.28 mixed packaging R13 M Weighed Offsite in Ireland Panda,W039-02

Ballymount Cross,Tallaght,Dublin 24,-,ireland

Within the Country 16 06 01 Yes 0.81 lead batteries R4 M Weighed Offsite in IrelandKMK Metals Recycling Limited,W0113-03

Cappincur Industrial Estate ,Daingean Road ,Tullamore , Co. Offaly.,ireland

KMK Metals Recycling Ltd,W0113-03,Cappincur Industrial Estate,Daingean Road,Tullamore,Offaly,Ireland

Cappincur Industrial Estate,Daingean Road,Tullamore,Offaly,Ireland

Within the Country 17 02 03 No 8.24 plastic R3 M Weighed Offsite in Ireland

Leinster Environmental/Eco WM Ltd ,WFP-LH-09-0004-01 dundalk,-,-,-,ireland

Within the Country 17 03 02 No 98.2bituminous mixtures containing other than those mentioned in 17 03 01 R5 M Weighed Offsite in Ireland

Breffni Group Plant Hire,WFP/MH/11/0003/01

Roadstone Mullaghcrone,.,.,Meath,Ireland

Within the Country 17 05 04 No 2789.96soil and stones other than those mentioned in 17 05 03 R5 M Weighed Offsite in Ireland

Breffni Group Plant Hire,WFP/MH/11/0003/01

Roadstone Mullaghcrone,.,.,Meath,Ireland

Within the Country 19 09 02 No 8.14 sludges from water clarification R3 M Weighed Offsite in Ireland

Rilta Environmental Ltd ,W0192-03 Block 402 Greenogue Business Park Rathcoole Co. Dublin Greenogue Business Park Rathcoole Co. Dublin ireland

Block 402 Greenogue Business Park Rathcoole Co. Dublin ,Greenogue Business Park ,Rathcoole ,Co. Dublin ,ireland

Within the Country 19 09 02 No 26.1 sludges from water clarification R3 M Weighed Offsite in Ireland

Rilta Environmental Ltd ,W0192-03 Block 402 Greenogue Business Park Rathcoole Co. Dublin Greenogue Business Park Rathcoole Co. Dublin ireland

Block 402 Greenogue Business Park Rathcoole Co. Dublin ,Greenogue Business Park ,Rathcoole ,Co. Dublin ,ireland

Within the Country 19 12 07 No 321.08 wood other than that mentioned in 19 12 06 R5 M Weighed Offsite in IrelandKnockharley Landfill Ltd,W0165-02

Ballynagran,Coolbeg & Kilcandra,Co. Wicklow,.,Ireland

To Other Countries 19 12 07 No 23.54 wood other than that mentioned in 19 12 06 R5 M Weighed AbroadBallynagran Landfill Ltd,W0165-02

Ballynagran,Coolbeg & Kilcandra,Co. Wicklow,.,Ireland

Within the Country 19 12 10 No 5462.2 combustible waste (refuse derived fuel) R1 M Weighed Offsite in Ireland Irish Cement,IE-GHG043-05

Irish Cement,platin works,platin ,drogheda,Ireland

Quantity (Tonnes per

Year)

Haz Waste : Name and Licence/Permit No of Next

Destination Facility Non Haz Waste: Name and Licence/Permit No of

Recover/Disposer

Haz Waste : Address of Next Destination Facility

Non Haz Waste: Address of Recover/Disposer

Name and License / Permit No. and Address of Final Recoverer /

Disposer (HAZARDOUS WASTE ONLY)

Actual Address of Final Destination i.e. Final Recovery / Disposal Site

(HAZARDOUS WASTE ONLY)

Transfer DestinationEuropean Waste

CodeHazardous Quantity T/Year Description of Waste

Waste Treatment Operation

M/C/E Method UsedLocation of Treatment

Name and Licence / Permit No. of Recoverer / Disposer / Broker Address of Recoverer / Disposer / Broker Name and Address of Final Destination i.e. Final Recovery / Disposal Site (HAZARDOUS WASTE ONLY) Licence / Permit No. of Final Destination i.e. Final Recovery / Disposal Site (HAZARDOUS WASTE ONLY)

Method Used

Within the Country 19 12 10 No 304.02 combustible waste (refuse derived fuel) R1 M Weighed Offsite in Ireland Greyhound,W0205-01

Crag Avenue,Clondalkin Industrial Estate,Clondalkin,Dublin 12,Ireland

Within the Country 19 12 10 No 95.78 combustible waste (refuse derived fuel) R1 M Weighed Offsite in Ireland Lagan Cement,P0487-05Killaskillen,Kinnegad,.,Meath,Ireland

Within the Country 19 12 12 No 596.16

other wastes (including mixtures of materials) from mechanical treatment of wastes other than those mentioned in 19 12 11 D5 M Weighed Offsite in Ireland

Ballynagran Landfill Ltd,W0165-02

Ballynagran,Coolbeg & Kilcandra,Co. Wicklow,.,Ireland

Within the Country 19 12 12 No 1174.6

other wastes (including mixtures of materials) from mechanical treatment of wastes other than those mentioned in 19 12 11 D5 M Weighed Offsite in Ireland

Knockharley Landfill Ltd,W0165-02

Ballynagran,Coolbeg & Kilcandra,Co. Wicklow,.,Ireland

Within the Country 19 12 12 No 142.32

other wastes (including mixtures of materials) from mechanical treatment of wastes other than those mentioned in 19 12 11 R13 M Weighed Offsite in Ireland Greenstar Limited,W0053-03

Fassaroe,Bray,Co. Wicklow,.,Ireland

Within the Country 19 12 12 No 8.06

other wastes (including mixtures of materials) from mechanical treatment of wastes other than those mentioned in 19 12 11 R13 M Weighed Offsite in Ireland

Eco Matress Recycling Ltd,WFP-DC-12-0032

133A,Glasnevin,Dublin,Dublin11,Ireland

Within the Country 20 01 01 No 7995.08 paper and cardboard R3 M Weighed Offsite in IrelandAgnail,TFS Broker IRE/AG117/11

Ballymacken Ind. Estate ,Ballymacken ,Portlaoise ,Laois,ireland

To Other Countries 20 01 01 No 5058.48 paper and cardboard R3 M Weighed AbroadNorthwood Recycling Ltd,IRE/G282/15

Waterside,Disley,Stockport,CheshireSK12 2HW,united kingdom

Within the Country 20 01 01 No 1421.72 paper and cardboard R3 M Weighed Offsite in IrelandCellmark,TFS Broker IRE/G180/11

CellMark AB,Lilla Bommen 3C,P O Box 11927,SE-404 39 Gothenburg ,Sweden

Within the Country 20 01 01 No 539.8 paper and cardboard R3 M Weighed Offsite in Ireland

FAILAND PAPER SERVICES LTD,IRE/G010/15

Embassy House ,Queen's Avenue ,Bristol BS8 1SB ,-,united kingdom

Within the Country 20 01 01 No 72.52 paper and cardboard R3 M Weighed Offsite in Ireland

HIGHLANDER NTERNATIONAL(IRELAND)LTD,IRE/G034/15

Linwood Avenue ,East Kilbride ,Glasgow City G74 5NE ,-,united kingdom

Within the Country 20 01 01 No 2466.16 paper and cardboard R3 M Weighed Offsite in IrelandMLM (ACN Europe) Ltd ,TFS Broker IRE/G022/11

Egerton House ,Towers Business Park ,Wilmslow Rd Didsbury ,M/CR M20 2DX. ,united kingdom

Within the Country 20 01 01 No 71.4 paper and cardboard R3 M Weighed Offsite in IrelandMark Lyndon Paper Enterprises,IRE/G021/12

12 The Triangle,Nottingham,Nottinghamshire NG2 1AE,.,United Kingdom

Within the Country 20 01 01 No 263.66 paper and cardboard R3 M Weighed Offsite in IrelandMateria Environment Ltd,IRE/AG161/17

The Kipper House,Scilly,Kinsale,Cork,Ireland

To Other Countries 20 01 01 No 3423.6 paper and cardboard R3 M Weighed AbroadPeute paper Recycling,IRE/G006/16

Veeplat 40,3313,LJ ,Drodrecht,Netherlands

To Other Countries 20 01 01 No 1338.54 paper and cardboard R3 M Weighed AbroadSaica Natur UK Limited,IRE/G277/15 .,.,.,.,United Kingdom

Within the Country 20 01 08 No 3308.9 biodegradable kitchen and canteen waste R3 M Weighed Offsite in IrelandClonmel Waste Disposal Ltd ,WP-008-02

Lawlesstown , Clonmel ,Co. Tipperary ,-,ireland

Within the Country 20 01 38 No 387.88 wood other than that mentioned in 20 01 37 R3 M Weighed Offsite in IrelandClonmel Waste Disposal Ltd ,WP-008-02

Lawlesstown , Clonmel ,Co. Tipperary ,-,ireland

Within the Country 20 01 38 No 955.98 wood other than that mentioned in 20 01 37 R3 M Weighed Offsite in Ireland Eirbloc,WFP-CK-11-0087-02 Lisarda,Cork,-,-,ireland

Quantity (Tonnes per

Year)

Haz Waste : Name and Licence/Permit No of Next

Destination Facility Non Haz Waste: Name and Licence/Permit No of

Recover/Disposer

Haz Waste : Address of Next Destination Facility

Non Haz Waste: Address of Recover/Disposer

Name and License / Permit No. and Address of Final Recoverer /

Disposer (HAZARDOUS WASTE ONLY)

Actual Address of Final Destination i.e. Final Recovery / Disposal Site

(HAZARDOUS WASTE ONLY)

Transfer DestinationEuropean Waste

CodeHazardous Quantity T/Year Description of Waste

Waste Treatment Operation

M/C/E Method UsedLocation of Treatment

Name and Licence / Permit No. of Recoverer / Disposer / Broker Address of Recoverer / Disposer / Broker Name and Address of Final Destination i.e. Final Recovery / Disposal Site (HAZARDOUS WASTE ONLY) Licence / Permit No. of Final Destination i.e. Final Recovery / Disposal Site (HAZARDOUS WASTE ONLY)

Method Used

Within the Country 20 01 39 No 1.855 plastics R3 M Weighed Offsite in IrelandAgnail,TFS Broker IRE/AG117/11

Ballymacken Ind. Estate ,Ballymacken ,Portlaoise ,Laois,ireland

Within the Country 20 01 39 No 13.725 plastics R3 M Weighed Offsite in IrelandAgnail,TFS Broker IRE/AG117/11

Ballymacken Ind. Estate ,Ballymacken ,Portlaoise ,Laois,ireland

Within the Country 20 01 40 No 147.153 metals R4 M Weighed Offsite in Ireland

Davis Recycling at Hammond Lane Metal Co Ltd,WFP-CK-10-0077-02

.,.,Ringaskiddy,Co Cork,Ireland

Within the Country 20 01 40 No 205.78 metals R4 M Weighed Offsite in IrelandClearcirlce,WCP-LK-08-589-01

ClearCircle Metals (Limerick) Ltd

,Ballysimon Road,Limerick,.,ireland

Within the Country 20 01 40 No 548.54 metals R4 M Weighed Offsite in IrelandMulti Metals,WFP-WW-09-0014-01

.,.,Blessington,Co Wicklow ,Ireland

Within the Country 20 02 01 No 1372.34 biodegradable waste R3 M Weighed Offsite in IrelandEnrich Environmental,WMP 2004/57

Kilcock Co. Kildare,.,.,.,Ireland

Within the Country 20 03 01 No 97.54 mixed municipal waste D5 M Weighed Offsite in Ireland Bord na Mona.,W0201-03Drehid Landfill,.,Carbury,Co Kildare,Ireland

Within the Country 20 03 01 No 75.18 mixed municipal waste D5 M Weighed Offsite in IrelandBallynagran Landfill Ltd,W0165-02

Ballynagran,Coolbeg & Kilcandra,Co. Wicklow,.,Ireland

Within the Country 20 03 01 No 14734.7 mixed municipal waste R1 M Weighed Offsite in Ireland Indaver IWMF,W0167-02Carlanstown,.,Duleek,Co Meath,Ireland

Within the Country 20 03 01 No 2392.46 mixed municipal waste D5 M Weighed Offsite in IrelandKnockharley Landfill Ltd,W0165-02

Ballynagran,Coolbeg & Kilcandra,Co. Wicklow,.,Ireland

Within the Country 20 03 01 No 14.42 mixed municipal waste R3 M Weighed Offsite in Ireland Greenstar Limited,W0053-03Fassaroe,Bray,Co. Wicklow,.,Ireland

Within the Country 20 03 03 No 56.92 street-cleaning residues D5 M Weighed Offsite in IrelandKnockharley Landfill Ltd,W0165-02

Ballynagran,Coolbeg & Kilcandra,Co. Wicklow,.,Ireland

Within the Country 20 03 07 No 36.94 bulky waste D5 M Weighed Offsite in Ireland Bord na Mona.,W0201-03Drehid Landfill,.,Carbury,Co Kildare,Ireland

Within the Country 20 03 07 No 734.22 bulky waste D5 M Weighed Offsite in IrelandBallynagran Landfill Ltd,W0165-02

Ballynagran,Coolbeg & Kilcandra,Co. Wicklow,.,Ireland

Within the Country 20 03 07 No 17744.8 bulky waste D5 M Weighed Offsite in Ireland Greenstar Limited,W0053-03Fassaroe,Bray,Co. Wicklow,.,Ireland

Within the Country 20 03 07 No 1.3 bulky waste D5 M Weighed Offsite in IrelandEco Matress Recycling Ltd,WFP-DC-12-0032

133A,Glasnevin,Dublin,Dublin11,Ireland

Within the Country 20 01 01 No 346.14 paper and cardboard R3 M Weighed Offsite in Ireland Solutions,IRE/G443/17 .,.,.,.,Ireland

* Select a row by double-clicking the Description of Waste then click the delete button

Link to previous years waste dataLink to previous years waste summary data & percentage changeLink to Waste Guidance

Procedure Listing

Doc. No.: Control Revision No.: As Shown Issue Date: As Shown

Approved By: Malcolm Dowling – Group Compliance Manager Page 1 of 5

Integrated Procedures - IP

IP-01 Document & Record Control Procedure Rev 01, 28/04/14

IP-02 Health & Safety Risk Assessment Procedure Rev 01, 28/04/14

IP-03 Environmental Aspects & Impacts Procedure Rev 01, 28/04/14

IP-04 Legal & Regulatory Requirements Procedure Rev 01, 28/04/14

IP-05 Objectives, Targets & Management Programmes Procedure Rev 01, 28/04/14

IP-06 Competence, Training & Awareness Procedure Rev 01, 28/04/14

IP-07 Communication & Consultation Procedure Rev 01, 28/04/14

IP-08 Monitoring, Measurement & Improvement Procedure Rev 01, 28/04/14

IP-09 Evaluation of Compliance Procedure Rev 01, 28/04/14

IP-10 Non Conformances, Corrective/Preventive Actions Procedure Rev 01, 28/04/14

IP-11 Internal Audit Procedure Rev 01, 28/04/14

IP-12 Management Review Procedure Rev 01, 28/04/14

IP-13 Control of Contractors/Visitors Procedure Rev 01, 28/04/14

IP-14 Health & Safety & Environmental Monitoring Rev 01, 28/04/14

IP-15 Emergency Preparedness & Response Procedure Rev 01, 28/04/14

IP-16 Fire Prevention Procedure Rev 01, 28/04/14

IP-17 Bin Washing Procedure Rev 01, 28/04/14

Safety Procedures - SP

SP-01 Permit to Work Procedure Rev 01, 28/04/14

SP-02 Maintenance & Calibration Procedure Rev 01, 28/04/14

SP-03 Mobile Plant Procedure Rev 01, 28/04/14

SP-04 Fork Truck Procedure Rev 01, 28/04/14

SP-05 Operation of Fixed Plant Procedure Rev 01, 28/04/14

SP-06 Lock Out / Tag Out Procedure Rev 01, 28/04/14

SP-07 Health & Safety Notification Procedure Rev 01, 28/04/14

SP-08 MSW Shredder routine Maintenance & Clearing of Blockages Procedure (SCGT)

Rev 01, 28/04/14

SP-09 Weighbridge & Tipping Procedure (SCGT) Rev 01, 28/04/14

SP-10 Cleaning of Washing Bay (Greenogue) Rev 01, 28/04/14

Procedure Listing

Doc. No.: Control Revision No.: As Shown Issue Date: As Shown

Approved By: Malcolm Dowling – Group Compliance Manager Page 2 of 5

Environmental Procedures - EP

EP-01 Office Waste & Energy Management Procedure Rev 01, 28/04/14

EP-02 Decommissioning and Aftercare Procedure Rev 01, 28/04/14

EP-03 Environment Communications Procedure Rev 01, 28/04/14

EP-04 Waste Permits & Licences Procedure Rev 01, 28/04/14

EP-05 Waste Acceptance Procedure Rev 01, 28/04/14

EP-06 Unacceptable Waste Procedure Rev 01, 28/04/14

EP-07 Waste & Material Storage Procedure Rev 01, 28/04/14

EP-08 Waste Processing Procedure Rev 01, 28/04/14

EP-09 Site Infrastructure Procedure Rev 02, 06/05/15

EP-10 Nuisance Management Procedure (Site Specific) (Site Specific)

Rev 01, 28/04/14

EP-11 Civic Amenity Site Procedure Rev 01, 28/04/14

Circulation List

Doc. No.: Control Revision No.: As Shown Issue Date: As Shown

Approved By: Malcolm Dowling – Group Compliance Manager Page 3 of 5

Amendment History

Date Amendment No.

Procedure No: Revision No:

Comment Authorised By

05.07.10 01 All 01 Initial Issue M.D & O.C

13.09.10 02 EP-03 02 Issue of Incident Reports

M.D

20.09.10 03 IP-10 02 Env issues not logged on WIMS Database

M.D

29.10.10 04 IP-13 02 Use of M&M equipment by contractors

M.D & O.C

29.10.10 05 IP-14 02 Use of M&M equipment

by contractors

M.D & O.C

29.10.10 06 SP-02 02 Inclusion of Maintenance Schedule

M.D & O.C

05.11.10 07 IP-04 02 Inclusion of other requirements

S.B & O.C

01.02.11 08 SP-08 01 Inclusion of new procedure

O.C

01.02.11 09 IP-10 03 Inclusion of SP-08 O.C

01.02.11 10 IP-15 02 Removal of SF-022 O.C

01.02.11 11 Contents As shown

EP-10 Site Specific M.D & O.C

01.02.11 12 IP-06 02 Addressing Agency Staff needs

M.D & O.C

01.02.11 13 Circ List 02 Amendment to document control

M.D & O.C

04.04.11 14 SP-02 03 Inclusion of Site

Specific Maintenance schedules

O.C

07.06.11 15 IP-11 02 Inclusion of H&S & Env Internal Audit Schedules

M.D & O.C

14/09/11 16 EP-02 02 Inclusion of decommissioning of

plant/equipment

S.B

15/09/11 17 IP-09 02 Inclusion of Statutory Inspections

O.C

01/12/11 18 SP-09 01 Inclusion of new

procedure for SCGT

O.C

01/12/11 19 SP-10 01 Inclusion of new procedure for SCGT

O.C

03/05/12 20 SP-01 02 Amendment to remove SF 028

O.C

05/05/12 21 SP-11 01 Inclusion of a new procedure for Greenogue

O.C

28/05/12 22 IP-11 03 General Amendments to internal audit procedure

M.D & O.C

08/06/12 23 IP-13 03 Grammatical amendment

M.D & O.C

15/04/13 24 IP-06 03 Agency staff – sign-off record sufficient proof of training. TMS

optional

M.D & O.C

Circulation List

Doc. No.: Control Revision No.: As Shown Issue Date: As Shown

Approved By: Malcolm Dowling – Group Compliance Manager Page 4 of 5

Date Amendment No.

Procedure No: Revision No:

Comment Authorised By

30/06/13 25 IP-16 01 Inclusion of new procedure

M.D.

09/09/13 26 IP-03 02 Use of Scannell Software Solutions

(EnviroManager) instead of IF-03A

M.D & O.C

09/09/13 27 IP-04 30 Use of Scannell Software Solutions (EnviroManager)

instead of IF-03A

M.D & O.C

09/09/13 28 IP-05 02 Use of Scannell

Software Solutions (EnviroManager) instead of IF-03A

M.D & O.C

16/10/13 29 EP-03 03 Introduction of EPA ALDER Portal

K.B

28/04/14 30 All EP’s & IP’s 01 Change of Company name and review of all

Integrated and Env procedures

M.D & O.C

28/04/14 31 SP’s 01 Change of Company name and review of all safety procedures

including re-numbering & deletion of Motor Claim Notification Procedure

– SP 08

O.C

06/05/15 32 EP-09 02 Ref to new form EF-11 added

SS

Circulation List

Doc. No.: Control Revision No.: 01 Issue Date: 28th April 2014

Approved By: Malcolm Dowling – Group Compliance Manager Page 5 of 5

Circulation List The Integrated Procedures Manual is a controlled document. Copies of the Procedures Manual are

available as follows;

Copy Number

Holder

1 (Master Copy)

Group H&S Manager

2 Greenstar EnviroManager

3 Greenstar Intranet – Electronic Copy