Mike Lyons & Associates Pty Ltd - EPA Victoria · Project Description ... recycling of steel, ......

Transcript of Mike Lyons & Associates Pty Ltd - EPA Victoria · Project Description ... recycling of steel, ......

1

For 201

EXECUTIVE SUMMMARY:APPLICATION FOR WORKS APPROVAL

COMPANY Valen Pty Ltd

PURPOSE Works Approval Application

DATE 16th May 2012

OUR REFERENCE ma3532

Mike Lyons & Associates Pty Ltd53 Willis Street, Hampton Victoria 3188Ph: (03) 9598 3803 fax: (03) 9598 2174 email: [email protected]

2

APPLICANT

Company details

Valen Pty Ltd ACN 007 267 441

Contact details

Terry Paproth

7/55 Glenbarry Rd, Campbellfield Vic 3062Phone: (03) 9357 6983

Email: [email protected]

Premises details

7/55 Glenbarry Rd, Campbellfield Vic 3062 Municipality: Hume

Site Location - Melways

3

Town Planning Zone Map IN1Z - Industrial Use Zone 1 – City of Hume

The nearest resident is approximately 400 metres from the site.

4

Valen - Site Map

5

PROPOSAL

Project Description

Recovery of discarded Acetylene cylinders, recycling of steel, disposal to landfill ofcalcium silicate filler containing 8% asbestos and disposal to licensed contractor of washwater containing 1% acetone.

Cost of Works and Application fee

Cost of works: Less than $250,000

Application fee will be 257.5 fee units, 1 fee unit=$12.22. Total: $3,146.65

Financial Assurance

Financial assurance is being assessed under the guidelines for “Schedule 4 Premises” –EPA Publication 456.1 (February 2006). Soil testing is being undertaken to establish abaseline prior to full operation of this site.Proposed dates

This site is currently operating under RD&D Approval – RD69953 Issued 12/12/2011,expires 12/6/2012

APPROVALS

Need for Works Approval

Environment Protection (Scheduled Premises and Exemptions) Regulations 2007.

This site is classified under Schedule 1 of the above regulation as A01 (PrescribedIndustrial Waste management) for storage, treatment, reprocessing containment ordisposal facilities handling any PIW not generated at the premises.

No exemptions apply under sections 19A or 20(1) of the Act.

Financial assurance is required for this operation.

Planning and other approvals

Planning Zone Type of approval Approving authority Approval received or pending

IN1Z RD&D EPA Approval Received RD69953 – Approved12/12/2011

IN1Z Town Planning Hume City Council Hume city council confirmed the siteoperation does not require additionalplanning approval.

Existing EPA approvals

Research, Development and Demonstration (RD&D) – RD69953 Issued 12/12/2011,expires 12/6/2012

History

Until the change in Scheduled Premises and Exemptions Regulations in 2007, BritishOxygen Company (BOC) were disposing of acetylene cylinders to landfill. In May 2009,Valen was approached by BOC to investigate and establish a process for disposal.

In mid 2010 discussions with WorkSafe verified the Risk Management and SafetyProcedures. Agreement between BOC and Valen was reached and signed in August2010. In February 2011 discussions were initiated with EPA, and a Research,Development and Demonstration Approval was issued in December 2011. The processcommenced late December 2011.

6

PROCESS AND BEST PRACTICE

Environmental best practice

This is an innovative process which has no known equivalent elsewhere in the world.There are anecdotal reports that parts of Europe are developing processes of a similarnature to the one discussed here.

The main features of this method are:

No exposure of dry asbestos to the atmosphere

Removal of acetone from the cylinder and into the separate aqueous stream

Recovery of all metallic components for recycling

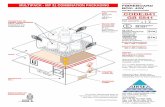

Total enclosure of the process from receipt of cylinders to the removal of wastesfrom site

Negative air pressure extraction system, using a pre-filter and HEPA filter.

Fail-safe extraction system controlled by differential pressure

Low energy usage

Low carbon footprint

Small physical footprint

All of the process is set on a concrete slab, eliminating any possibility of soilcontamination

No risk of explosion from acetone

Secure wrapping of all asbestos containing substances

Cylinder structure:The Calcium Silicate completely fills the internal void of the cylinder and acts as a solidsponge for Acetone solvent which is pumped in to the cylinder before the cylinder isfilled with Acetylene. The cut cylinder pictured has the fibreglass additive (not asbestos).

7

Process Flow Chart

8

Start of Process - Loading cylinders into container#1:

Cutting head off cylinder in container #2:This is cut under a continuous water spray, to prevent dry asbestos particles frombecoming airborne.

9

Water blasting the mass:After cutting the cylinders, water is blasted into the mass. This is performed remotely,with the water lance operated from outside.

Air handling:The entire system is maintained under negative air pressure, and passed through aHEPA filter.If the filter becomes clogged, the Magnehelic pressure gauge will indicate a highpressure drop and close the system down until a new filter is installed.

10

Integrated environmental assessment

These premises are designed for the purpose of recovering steel from waste acetylenecylinders as supplied. The environmental benefit of this process will be an improvementon the previous practice of burying the entire cylinder in landfill.

This process will:

Recycle 13kgs of steel per cylinder

Isolate acetone from landfill

Comply with EPA regulations to divert VOC (acetone) from landfill

Handling hazards associated with asbestos are minimised by having the calciumsilicate / asbestos mixture damp and double wrapped for licensed disposal

Choice of process and technology

This method has been developed and finalized under RD&D Approval. It representscurrent world's best practice for this type of process.

Choice of location and layout

Location has been chosen on the basis of appropriate council zoning. The layout hasbeen designed to minimise the operating footprint of the process, which is fullyenclosed, bunded and under negative air pressure to prevent any egress of materials tothe environment.

Resources and Greenhouse Equivalents

Item Usage CO2 equivalent

Power use 8.0 MWHr/yr 9.76 t/yr

Diesel for forklift 300 litres/yr. 0.83 t/yr

Water use 1.0 ML/yr nil

Total CO2 - 10.59 t/yr

The ecological footprint of this process is extremely small resulting in a total CO2

emission of approximately 11 tonnes per annum, less than the average household.

Product for recycling

It is estimated that more than 300 tonnes of recycled steel will be produced by thisprocess.

Prescribed industrial waste

All water based and solid wastes are removed from site by licensed contractor. Thefigures below represent usage at the current rate of cylinder recovery.

Type of aqueous waste Amount t/yr Destination

Water included in solids* 900 Brooklyn Landfill

Aqueous waste with ~3% acetone 120 Trans Pacific

Type of solid waste Amount t/yr Destination

Calcium Silicate with ~8% chrysotile asbestos 1200 Brooklyn Landfill

*The calcium silicate asbestos mix contains about 4x its weight of water.

11

POTENTIAL EMISSIONS

Air emissions

At no time will there be emissions to the outside air from this process. Monthly airbornemonitoring on site has confirmed that there have been no asbestos particles detected inexcess of the WorkSafe standard. This process is carried out within fully enclosedcontainers with extractive “Negative Air” ventilation system – built in pre-filter and HEPAfilter.

Cylinders are cut and cleaned in fully enclosed environment using water sprays anddeluge systems to eliminate airborne particles. Managing of materials is done remotely,entry is only provided through decontamination airlock.

Water Handling and Treatment

There are no discharges to storm drains or ground water, and the process has nodischarge connection to the sewer. All water based operations are carried out in a fullyenclosed system. The entire operation (including outside parking) is on a concrete slab,and the factory area bunded to prevent egress of waste water. High pressure waterhose is used to flush out the contained mass from within the cylinders.

Water consumption is minimised for efficiency during the flushing process which uses amaximum of 3KL per day, approximately 1% by volume of acetone is present in thewash water.

All loading and unloading is performed inside the factory which utilises a rollover bund atthe front door to prevent spillages to the outside storm drains. Liquid waste collectiontaken to EPA licensed facility by licensed contractors (TransPacific).

Discharge to land

Asbestos mixture will be kept wet at all times, and undergoes a 2 stage filtration process

Sealing and encapsulation process carried out in purpose-built chamber – covered byrisk assessment in the RD&D process.

Solid residues are sealed in a 200 micron polythene bag after filter/drain period andadditionally sealed into a 10m³ bin lined with 200 micron polythene

Double wrapped material is sent to deep burial disposal at Brooklyn landfill – licensed totake asbestos prescribed industrial waste.

Noise emissions

The site will operate one daily shift of eight hours per day, between the hours of 8amand 6pm. This period of operation includes staff break periods, and allows for flexibilityaround the start and finish times of the eight hour shift. Process operations comply withSEPP requirements (Control of Noise from Commerce, Industry and Trade) No: N1. AnN1 noise profile was performed in late March 2012 demonstrating compliance with N1.

It should be noted that: The nearest resident is approximately 400m from site The site is under the main flight path to Tullamarine The site is close to the Hume highway The site is Zone 1 - Industrial

12

HAZARD AND RISK MANAGEMENT

Hazard and Risk Assessment

The risk assessment procedure was developed in accord with AS4360: 2004 (RiskManagement) and as part of the requirement for compliance for AS4801: 2001 (0H&SManagement Systems). This procedure is progressively being applied to all activitiesassociated with the process that might reasonably be seen as any form of OccupationalHealth and Safety or environmental risk.

The company has implemented a full risk management program that will be compliantwith the requirements of AS4801: 2001.

Monitoring

A monthly monitoring program has been established to gather data over the mediumterm to validate process compliance.

![Air Layering with Polythene Film - Arnold Arboretum - …arnoldia.arboretum.harvard.edu/...air-layering-with-polythene-film.pdf · 49 ] ARNOLDIA A continuation of the BULLETIN OF](https://static.fdocuments.in/doc/165x107/5b481b997f8b9a501f8d473b/air-layering-with-polythene-film-arnold-arboretum-49-arnoldia-a-continuation.jpg)