Mid-term Review Meeting - WP4

-

Upload

slope-project -

Category

Education

-

view

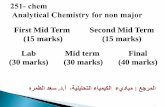

252 -

download

0

Transcript of Mid-term Review Meeting - WP4

Project SLOPE1

WP 4 – Multi-sensor model-based quality control of mountain forest production

Work Package 4: Multi-sensor model-based quality

control of mountain forest production

The goals of this WP are:• to develop an automated and real-time grading (optimization) system for the forest production, in order to improve log/biomass segregation and to help develop a more efficient supply chain of mountain forest products• to design software solutions for continuous update the pre-harvest inventory procedures in the mountain areas • to provide data to refine stand growth and yield models for long-term silvicultural management

Work Package 4: work to be done T4.1

Quality rules & specificationsCNR, TRE:

Develop tool Harvest Simulator TRE:

Develop models of treesGRA, TRE:

Compare models with real dataTRE, GRA, TRE:

Link automatic system with visualTRE,CNR:

Develop 3D quality indexTRE, CNR:

Measurement of standing treesCNR, TRE:

Measurement of felled treesCNR:

T4.1 3D quality

D03.01

D01.04

D04.07

TRE

D04.02

TRE

D01.04

Determine optimal protocolCNR:

Calibration transferBOK, CNR:

Develop models for labCNR, BOK:

Measure NIR on standing treesTRE, CNR, FLY:

Measure NIR on felled treesCNR, GRE:

Measure NIR on processor headCNR, COM:

Measure NIR on pale of logsCNR, BOK:

Develop models for in fieldCNR, BOK:

Compare models with lab dataCNR, BOK:

Develop NIR quality indexCNR, BOK:

Develop provenance NIR modelsCNR, BOK:

Design data base of NIR spectraBOK, CNR:

T4.2 NIR quality

D04.03

CNR

D04.08

CNR

Determine usabilityCNR:

Calibration transferBOK, CNR:

Develop models for labCNR, BOK:

Imaging standing trees BOK, FLY, TRE:

Imaging fallen trees BOK, GRE:

Imaging on processor headBOK, COM:

Imaging on pale of logsBOK, CNR:

Develop models for in fieldCNR, BOK:

Compare models with lab dataCNR, BOK:

Develop hyperspectral indexCNR, BOK:

Design data base of hyperspectraBOK, CNR:

T4.3 hyperspectral quality

D04.04

D04.09

BOK

BOK

Determine optimal set-up for the hyperspectral camera, illumination, and sample holdingBOK, CNR:

D01.04

Determine optimal set-up for the NIR sensor, illumination, and sample holdingCNR, BOK:

Develop report on using SWCNR:

Develop models for SW qualityCNR:

Test on standing trees CNR, GRE:

Tests on fallen trees CNR, GRE:

Tests on processor headCNR, COM:

Imaging on pale of logsCNR:

Develop SW quality indexCNR:

Define quality thresholdsCNR:

Analyze material dependant factorsCNR:

T4.4 stress wave quality

D04.05

D04.10

CNR

CNR

Determine optimal set-up for the stress wave measurement, including time of flight and free vibrations sensorCNR:

D01.04

Determine quality requirements for high-end assortments

CNR:

Laboratory scale tests for delimbing energy needs

CNR:

Develop CP quality indexCNR:

T4.5 cutting power quality

D04.11

D04.06

CNR

CNR

Determine optimal set-up for the measurement of cutting forces on the processor headCNR:

D01.04Laboratory scale tests for chain saw energy needs

CNR:

Develop models linking CP in delimbing and quality

CNR:

Develop models linking CP in chain sawing and quality

CNR:

Develop report on using CPCNR:

Link in-field data with cloud database

CNR:

Compare automatic and visual grading resultsBOK, CNR:

Determine threshold valuesCNR:

Develop grading expert systemCNR:

Develop algorithm for data fusionCNR, COM, TRE:

In field visual quality assessment CNR, BOK:

Develop data base for prices of woody commodities

CNR, BOK:

Reliability studiesBOK:

Economic advantage studiesBOK, CNR:

T4.6 quality implementation

D04.01

CNR

D04.12

CNR

Identify grading rules for standard and niche productsCNR:

Prepare state-of-the-art report on grading rulesCNR:

T4.1: Data mining and model integration of stand quality indicators from on-field survey

Quality rules & specificationsCNR, TRE:

Develop tool Harvest Simulator TRE:

Develop models of treesGRA, TRE:

Compare models with real dataTRE, GRA, TRE:

Link automatic system with visualTRE,CNR:

Develop 3D quality indexTRE, CNR:

Measurement of standing treesCNR, TRE:

Measurement of felled treesCNR:

T4.1 3D quality

D03.01

D01.04

D04.07

TRE

D04.02

TRE

draft: October 2014

accepted: July 2015

31.05.2015

the resources planned: 9 M/Mthe resources utilized:PROBLEMS: Not reported

Work Package 4: work to be done T4.2

Quality rules & specificationsCNR, TRE:

Develop tool Harvest Simulator TRE:

Develop models of treesGRA, TRE:

Compare models with real dataTRE, GRA, TRE:

Link automatic system with visualTRE,CNR:

Develop 3D quality indexTRE, CNR:

Measurement of standing treesCNR, TRE:

Measurement of felled treesCNR:

T4.1 3D quality

D03.01

D01.04

D04.07

TRE

D04.02

TRE

D01.04

Determine optimal protocolCNR:

Calibration transferBOK, CNR:

Develop models for labCNR, BOK:

Measure NIR on standing treesTRE, CNR, FLY:

Measure NIR on felled treesCNR, GRE:

Measure NIR on processor headCNR, COM:

Measure NIR on pale of logsCNR, BOK:

Develop models for in fieldCNR, BOK:

Compare models with lab dataCNR, BOK:

Develop NIR quality indexCNR, BOK:

Develop provenance NIR modelsCNR, BOK:

Design data base of NIR spectraBOK, CNR:

T4.2 NIR quality

D04.03

CNR

D04.08

CNR

Determine usabilityCNR:

Calibration transferBOK, CNR:

Develop models for labCNR, BOK:

Imaging standing trees BOK, FLY, TRE:

Imaging fallen trees BOK, GRE:

Imaging on processor headBOK, COM:

Imaging on pale of logsBOK, CNR:

Develop models for in fieldCNR, BOK:

Compare models with lab dataCNR, BOK:

Develop hyperspectral indexCNR, BOK:

Design data base of hyperspectraBOK, CNR:

T4.3 hyperspectral quality

D04.04

D04.09

BOK

BOK

Determine optimal set-up for the hyperspectral camera, illumination, and sample holdingBOK, CNR:

D01.04

Determine optimal set-up for the NIR sensor, illumination, and sample holdingCNR, BOK:

Develop report on using SWCNR:

Develop models for SW qualityCNR:

Test on standing trees CNR, GRE:

Tests on fallen trees CNR, GRE:

Tests on processor headCNR, COM:

Imaging on pale of logsCNR:

Develop SW quality indexCNR:

Define quality thresholdsCNR:

Analyze material dependant factorsCNR:

T4.4 stress wave quality

D04.05

D04.10

CNR

CNR

Determine optimal set-up for the stress wave measurement, including time of flight and free vibrations sensorCNR:

D01.04

Determine quality requirements for high-end assortments

CNR:

Laboratory scale tests for delimbing energy needs

CNR:

Develop CP quality indexCNR:

T4.5 cutting power quality

D04.11

D04.06

CNR

CNR

Determine optimal set-up for the measurement of cutting forces on the processor headCNR:

D01.04Laboratory scale tests for chain saw energy needs

CNR:

Develop models linking CP in delimbing and quality

CNR:

Develop models linking CP in chain sawing and quality

CNR:

Develop report on using CPCNR:

Link in-field data with cloud database

CNR:

Compare automatic and visual grading resultsBOK, CNR:

Determine threshold valuesCNR:

Develop grading expert systemCNR:

Develop algorithm for data fusionCNR, COM, TRE:

In field visual quality assessment CNR, BOK:

Develop data base for prices of woody commodities

CNR, BOK:

Reliability studiesBOK:

Economic advantage studiesBOK, CNR:

T4.6 quality implementation

D04.01

CNR

D04.12

CNR

Identify grading rules for standard and niche productsCNR:

Prepare state-of-the-art report on grading rulesCNR:

T4.2: Evaluation of NIRS as a tool for determination of log/biomass quality index

D01.04

Determine optimal protocolCNR:

Calibration transferBOK, CNR:

Develop models for labCNR, BOK:

Measure NIR on standing treesTRE, CNR, FLY:

Measure NIR on felled treesCNR, GRE:

Measure NIR on processor headCNR, COM:

Measure NIR on pale of logsCNR, BOK:

Develop models for in fieldCNR, BOK:

Compare models with lab dataCNR, BOK:

Develop NIR quality indexCNR, BOK:

Develop provenance NIR modelsCNR, BOK:

Design data base of NIR spectraBOK, CNR:

T4.2 NIR quality

D04.03

CNR

D04.08

CNR

Determine optimal set-up for the NIR sensor, illumination, and sample holdingCNR, BOK:

the resources planned: 13 M/Mthe resources utilized:PROBLEMS: Delay in purchasing sensorSOLUTIONS: The sensor already ordered

30.09.2015

!

!

!

!

draft: October 2014

accepted: July 2015

!

Work Package 4: work to be done T4.3

Quality rules & specificationsCNR, TRE:

Develop tool Harvest Simulator TRE:

Develop models of treesGRA, TRE:

Compare models with real dataTRE, GRA, TRE:

Link automatic system with visualTRE,CNR:

Develop 3D quality indexTRE, CNR:

Measurement of standing treesCNR, TRE:

Measurement of felled treesCNR:

T4.1 3D quality

D03.01

D01.04

D04.07

TRE

D04.02

TRE

D01.04

Determine optimal protocolCNR:

Calibration transferBOK, CNR:

Develop models for labCNR, BOK:

Measure NIR on standing treesTRE, CNR, FLY:

Measure NIR on felled treesCNR, GRE:

Measure NIR on processor headCNR, COM:

Measure NIR on pale of logsCNR, BOK:

Develop models for in fieldCNR, BOK:

Compare models with lab dataCNR, BOK:

Develop NIR quality indexCNR, BOK:

Develop provenance NIR modelsCNR, BOK:

Design data base of NIR spectraBOK, CNR:

T4.2 NIR quality

D04.03

CNR

D04.08

CNR

Determine usabilityCNR:

Calibration transferBOK, CNR:

Develop models for labCNR, BOK:

Imaging standing trees BOK, FLY, TRE:

Imaging fallen trees BOK, GRE:

Imaging on processor headBOK, COM:

Imaging on pale of logsBOK, CNR:

Develop models for in fieldCNR, BOK:

Compare models with lab dataCNR, BOK:

Develop hyperspectral indexCNR, BOK:

Design data base of hyperspectraBOK, CNR:

T4.3 hyperspectral quality

D04.04

D04.09

BOK

BOK

Determine optimal set-up for the hyperspectral camera, illumination, and sample holdingBOK, CNR:

D01.04

Determine optimal set-up for the NIR sensor, illumination, and sample holdingCNR, BOK:

Develop report on using SWCNR:

Develop models for SW qualityCNR:

Test on standing trees CNR, GRE:

Tests on fallen trees CNR, GRE:

Tests on processor headCNR, COM:

Imaging on pale of logsCNR:

Develop SW quality indexCNR:

Define quality thresholdsCNR:

Analyze material dependant factorsCNR:

T4.4 stress wave quality

D04.05

D04.10

CNR

CNR

Determine optimal set-up for the stress wave measurement, including time of flight and free vibrations sensorCNR:

D01.04

Determine quality requirements for high-end assortments

CNR:

Laboratory scale tests for delimbing energy needs

CNR:

Develop CP quality indexCNR:

T4.5 cutting power quality

D04.11

D04.06

CNR

CNR

Determine optimal set-up for the measurement of cutting forces on the processor headCNR:

D01.04Laboratory scale tests for chain saw energy needs

CNR:

Develop models linking CP in delimbing and quality

CNR:

Develop models linking CP in chain sawing and quality

CNR:

Develop report on using CPCNR:

Link in-field data with cloud database

CNR:

Compare automatic and visual grading resultsBOK, CNR:

Determine threshold valuesCNR:

Develop grading expert systemCNR:

Develop algorithm for data fusionCNR, COM, TRE:

In field visual quality assessment CNR, BOK:

Develop data base for prices of woody commodities

CNR, BOK:

Reliability studiesBOK:

Economic advantage studiesBOK, CNR:

T4.6 quality implementation

D04.01

CNR

D04.12

CNR

Identify grading rules for standard and niche productsCNR:

Prepare state-of-the-art report on grading rulesCNR:

T4.3: Evaluation of hyperspectral imaging for the determination of log/biomass quality index

Determine usabilityCNR:

Calibration transferBOK, CNR:

Develop models for labCNR, BOK:

Imaging standing trees BOK, FLY, TRE:

Imaging fallen trees BOK, GRE:

Imaging on processor headBOK, COM:

Imaging on pale of logsBOK, CNR:

Develop models for in fieldCNR, BOK:

Compare models with lab dataCNR, BOK:

Develop hyperspectral indexCNR, BOK:

Design data base of hyperspectraBOK, CNR:

T4.3 hyperspectral quality

D04.04

D04.09

BOK

BOK

Determine optimal set-up for the hyperspectral camera, illumination, and sample holdingBOK, CNR:

D01.04

the resources planned: 17 M/Mthe resources utilized:PROBLEMS: Delay with Deliverable + setting of the lab scanner + in-field sensor selectionSOLUTIONS: collaboration with experts + new solutions for HI sensor(s)

31.10.2015

draft: May 2014

accepted: July 2015

!

!

!

!

!

Work Package 4: work to be done T4.4

Quality rules & specificationsCNR, TRE:

Develop tool Harvest Simulator TRE:

Develop models of treesGRA, TRE:

Compare models with real dataTRE, GRA, TRE:

Link automatic system with visualTRE,CNR:

Develop 3D quality indexTRE, CNR:

Measurement of standing treesCNR, TRE:

Measurement of felled treesCNR:

T4.1 3D quality

D03.01

D01.04

D04.07

TRE

D04.02

TRE

D01.04

Determine optimal protocolCNR:

Calibration transferBOK, CNR:

Develop models for labCNR, BOK:

Measure NIR on standing treesTRE, CNR, FLY:

Measure NIR on felled treesCNR, GRE:

Measure NIR on processor headCNR, COM:

Measure NIR on pale of logsCNR, BOK:

Develop models for in fieldCNR, BOK:

Compare models with lab dataCNR, BOK:

Develop NIR quality indexCNR, BOK:

Develop provenance NIR modelsCNR, BOK:

Design data base of NIR spectraBOK, CNR:

T4.2 NIR quality

D04.03

CNR

D04.08

CNR

Determine usabilityCNR:

Calibration transferBOK, CNR:

Develop models for labCNR, BOK:

Imaging standing trees BOK, FLY, TRE:

Imaging fallen trees BOK, GRE:

Imaging on processor headBOK, COM:

Imaging on pale of logsBOK, CNR:

Develop models for in fieldCNR, BOK:

Compare models with lab dataCNR, BOK:

Develop hyperspectral indexCNR, BOK:

Design data base of hyperspectraBOK, CNR:

T4.3 hyperspectral quality

D04.04

D04.09

BOK

BOK

Determine optimal set-up for the hyperspectral camera, illumination, and sample holdingBOK, CNR:

D01.04

Determine optimal set-up for the NIR sensor, illumination, and sample holdingCNR, BOK:

Develop report on using SWCNR:

Develop models for SW qualityCNR:

Test on standing trees CNR, GRE:

Tests on fallen trees CNR, GRE:

Tests on processor headCNR, COM:

Imaging on pale of logsCNR:

Develop SW quality indexCNR:

Define quality thresholdsCNR:

Analyze material dependant factorsCNR:

T4.4 stress wave quality

D04.05

D04.10

CNR

CNR

Determine optimal set-up for the stress wave measurement, including time of flight and free vibrations sensorCNR:

D01.04

Determine quality requirements for high-end assortments

CNR:

Laboratory scale tests for delimbing energy needs

CNR:

Develop CP quality indexCNR:

T4.5 cutting power quality

D04.11

D04.06

CNR

CNR

Determine optimal set-up for the measurement of cutting forces on the processor headCNR:

D01.04Laboratory scale tests for chain saw energy needs

CNR:

Develop models linking CP in delimbing and quality

CNR:

Develop models linking CP in chain sawing and quality

CNR:

Develop report on using CPCNR:

Link in-field data with cloud database

CNR:

Compare automatic and visual grading resultsBOK, CNR:

Determine threshold valuesCNR:

Develop grading expert systemCNR:

Develop algorithm for data fusionCNR, COM, TRE:

In field visual quality assessment CNR, BOK:

Develop data base for prices of woody commodities

CNR, BOK:

Reliability studiesBOK:

Economic advantage studiesBOK, CNR:

T4.6 quality implementation

D04.01

CNR

D04.12

CNR

Identify grading rules for standard and niche productsCNR:

Prepare state-of-the-art report on grading rulesCNR:

T4.4: Data mining and model integration of log/biomass quality indicators from stress-wave

Develop report on using SWCNR:

Develop models for SW qualityCNR:

Test on standing trees CNR, GRE:

Tests on fallen trees CNR, GRE:

Tests on processor headCNR, COM:

Imaging on pale of logsCNR:

Develop SW quality indexCNR:

Define quality thresholdsCNR:

Analyze material dependant factorsCNR:

T4.4 stress wave quality

D04.05

D04.10

CNR

CNR

Determine optimal set-up for the stress wave measurement, including time of flight and free vibrations sensorCNR:

D01.04

Determine quality requirements for high-end assortments

CNR:

the resources planned: 5.5 M/Mthe resources utilized:PROBLEMS: Delay related to the processor headSOLUTIONS: LAB scanner + collaboration with engineers

31.11.2015

draft: December 2014

accepted: July 2015

!

!

Work Package 4: work to be done T4.5

Quality rules & specificationsCNR, TRE:

Develop tool Harvest Simulator TRE:

Develop models of treesGRA, TRE:

Compare models with real dataTRE, GRA, TRE:

Link automatic system with visualTRE,CNR:

Develop 3D quality indexTRE, CNR:

Measurement of standing treesCNR, TRE:

Measurement of felled treesCNR:

T4.1 3D quality

D03.01

D01.04

D04.07

TRE

D04.02

TRE

D01.04

Determine optimal protocolCNR:

Calibration transferBOK, CNR:

Develop models for labCNR, BOK:

Measure NIR on standing treesTRE, CNR, FLY:

Measure NIR on felled treesCNR, GRE:

Measure NIR on processor headCNR, COM:

Measure NIR on pale of logsCNR, BOK:

Develop models for in fieldCNR, BOK:

Compare models with lab dataCNR, BOK:

Develop NIR quality indexCNR, BOK:

Develop provenance NIR modelsCNR, BOK:

Design data base of NIR spectraBOK, CNR:

T4.2 NIR quality

D04.03

CNR

D04.08

CNR

Determine usabilityCNR:

Calibration transferBOK, CNR:

Develop models for labCNR, BOK:

Imaging standing trees BOK, FLY, TRE:

Imaging fallen trees BOK, GRE:

Imaging on processor headBOK, COM:

Imaging on pale of logsBOK, CNR:

Develop models for in fieldCNR, BOK:

Compare models with lab dataCNR, BOK:

Develop hyperspectral indexCNR, BOK:

Design data base of hyperspectraBOK, CNR:

T4.3 hyperspectral quality

D04.04

D04.09

BOK

BOK

Determine optimal set-up for the hyperspectral camera, illumination, and sample holdingBOK, CNR:

D01.04

Determine optimal set-up for the NIR sensor, illumination, and sample holdingCNR, BOK:

Develop report on using SWCNR:

Develop models for SW qualityCNR:

Test on standing trees CNR, GRE:

Tests on fallen trees CNR, GRE:

Tests on processor headCNR, COM:

Imaging on pale of logsCNR:

Develop SW quality indexCNR:

Define quality thresholdsCNR:

Analyze material dependant factorsCNR:

T4.4 stress wave quality

D04.05

D04.10

CNR

CNR

Determine optimal set-up for the stress wave measurement, including time of flight and free vibrations sensorCNR:

D01.04

Determine quality requirements for high-end assortments

CNR:

Laboratory scale tests for delimbing energy needs

CNR:

Develop CP quality indexCNR:

T4.5 cutting power quality

D04.11

D04.06

CNR

CNR

Determine optimal set-up for the measurement of cutting forces on the processor headCNR:

D01.04Laboratory scale tests for chain saw energy needs

CNR:

Develop models linking CP in delimbing and quality

CNR:

Develop models linking CP in chain sawing and quality

CNR:

Develop report on using CPCNR:

Link in-field data with cloud database

CNR:

Compare automatic and visual grading resultsBOK, CNR:

Determine threshold valuesCNR:

Develop grading expert systemCNR:

Develop algorithm for data fusionCNR, COM, TRE:

In field visual quality assessment CNR, BOK:

Develop data base for prices of woody commodities

CNR, BOK:

Reliability studiesBOK:

Economic advantage studiesBOK, CNR:

T4.6 quality implementation

D04.01

CNR

D04.12

CNR

Identify grading rules for standard and niche productsCNR:

Prepare state-of-the-art report on grading rulesCNR:

T4.5: Evaluation of cutting process (CP) for the determination of log/biomass CP quality index

Laboratory scale tests for delimbing energy needs

CNR:

Develop CP quality indexCNR:

T4.5 cutting power quality

D04.11

D04.06

CNR

CNR

Determine optimal set-up for the measurement of cutting forces on the processor headCNR:

D01.04Laboratory scale tests for chain saw energy needs

CNR:

Develop models linking CP in delimbing and quality

CNR:

Develop models linking CP in chain sawing and quality

CNR:

Develop report on using CPCNR:

the resources planned: 6.0 M/Mthe resources utilized:PROBLEMS: Delay related to the processor head and final sensor selection/designSOLUTIONS: LAB scanner + collaboration with engineers + list of sensor(s) for purchase ready

31.12.2015

!

!

draft: January 2014

accepted: July 2015

Work Package 4: work to be done T4.6

Quality rules & specificationsCNR, TRE:

Develop tool Harvest Simulator TRE:

Develop models of treesGRA, TRE:

Compare models with real dataTRE, GRA, TRE:

Link automatic system with visualTRE,CNR:

Develop 3D quality indexTRE, CNR:

Measurement of standing treesCNR, TRE:

Measurement of felled treesCNR:

T4.1 3D quality

D03.01

D01.04

D04.07

TRE

D04.02

TRE

D01.04

Determine optimal protocolCNR:

Calibration transferBOK, CNR:

Develop models for labCNR, BOK:

Measure NIR on standing treesTRE, CNR, FLY:

Measure NIR on felled treesCNR, GRE:

Measure NIR on processor headCNR, COM:

Measure NIR on pale of logsCNR, BOK:

Develop models for in fieldCNR, BOK:

Compare models with lab dataCNR, BOK:

Develop NIR quality indexCNR, BOK:

Develop provenance NIR modelsCNR, BOK:

Design data base of NIR spectraBOK, CNR:

T4.2 NIR quality

D04.03

CNR

D04.08

CNR

Determine usabilityCNR:

Calibration transferBOK, CNR:

Develop models for labCNR, BOK:

Imaging standing trees BOK, FLY, TRE:

Imaging fallen trees BOK, GRE:

Imaging on processor headBOK, COM:

Imaging on pale of logsBOK, CNR:

Develop models for in fieldCNR, BOK:

Compare models with lab dataCNR, BOK:

Develop hyperspectral indexCNR, BOK:

Design data base of hyperspectraBOK, CNR:

T4.3 hyperspectral quality

D04.04

D04.09

BOK

BOK

Determine optimal set-up for the hyperspectral camera, illumination, and sample holdingBOK, CNR:

D01.04

Determine optimal set-up for the NIR sensor, illumination, and sample holdingCNR, BOK:

Develop report on using SWCNR:

Develop models for SW qualityCNR:

Test on standing trees CNR, GRE:

Tests on fallen trees CNR, GRE:

Tests on processor headCNR, COM:

Imaging on pale of logsCNR:

Develop SW quality indexCNR:

Define quality thresholdsCNR:

Analyze material dependant factorsCNR:

T4.4 stress wave quality

D04.05

D04.10

CNR

CNR

Determine optimal set-up for the stress wave measurement, including time of flight and free vibrations sensorCNR:

D01.04

Determine quality requirements for high-end assortments

CNR:

Laboratory scale tests for delimbing energy needs

CNR:

Develop CP quality indexCNR:

T4.5 cutting power quality

D04.11

D04.06

CNR

CNR

Determine optimal set-up for the measurement of cutting forces on the processor headCNR:

D01.04Laboratory scale tests for chain saw energy needs

CNR:

Develop models linking CP in delimbing and quality

CNR:

Develop models linking CP in chain sawing and quality

CNR:

Develop report on using CPCNR:

Link in-field data with cloud database

CNR:

Compare automatic and visual grading resultsBOK, CNR:

Determine threshold valuesCNR:

Develop grading expert systemCNR:

Develop algorithm for data fusionCNR, COM, TRE:

In field visual quality assessment CNR, BOK:

Develop data base for prices of woody commodities

CNR, BOK:

Reliability studiesBOK:

Economic advantage studiesBOK, CNR:

T4.6 quality implementation

D04.01

CNR

D04.12

CNR

Identify grading rules for standard and niche productsCNR:

Prepare state-of-the-art report on grading rulesCNR:

T4.6: Implementation of the log/biomass grading system

Link in-field data with cloud database

CNR:

Compare automatic and visual grading resultsBOK, CNR:

Determine threshold valuesCNR:

Develop grading expert systemCNR:

Develop algorithm for data fusionCNR, COM, TRE:

In field visual quality assessment CNR, BOK:

Develop data base for prices of woody commodities

CNR, BOK:

Reliability studiesBOK:

Economic advantage studiesBOK, CNR:

T4.6 quality implementation

D04.01

CNR

D04.12

CNR

Identify grading rules for standard and niche productsCNR:

Prepare state-of-the-art report on grading rulesCNR:

the resources planned: 8.0 M/Mthe resources utilized:PROBLEMS: Delay related to other tasks – difficulties with implementationSOLUTIONS: LAB scanner + prototype software developed in lab + algorithms ready

31.06.2016

draft: October 2014

accepted: July 2015

!

!

fulfillment of the project work plan:related deliverables (M17)

WP4 M17

task deliverable title type of

deliverable

lead participant

due date foreseen or actual delivery date comment

T4.1D4.2 on field survay data for tree characterization report TRE 31.10.2014 31.10.2014 accepted

D4.7 estimation of log/biomass quality by external tree shape analysis software tool TRE 31.05.2015 same as planed working ver.

T4.2D4.3 establisghing NIR measurement protocol report CNR 31.10.2014 31.10.2014 accepted

D4.8 estimation of log/biomass quality by NIR software tool CNR 30.09.2015 postponed (new DoW) NO

T4.3D4.4 establisghing hyperspectral imaging measurement protocol report BOK 30.11.2014 05.05.2015 accepted

D4.9 estimation of log/biomass quality by hyperspectral imaging software tool BOK 31.10.2015 postponed (new DoW) NO

T4.4D4.5 establishing acoustic-based measurement protocol report CNR 31.12.2014 05.05.2015 accepted

D4.10 estimation of log/biomass quality by acoustic methods software tool CNR 31.11.2015 postponed (new DoW) NO

T4.5D4.6 establisghing cutting power measurement protocol report CNR 31.01.2015 31.01.2015 accepted

D4.11 estimation of log/biomass quality by cutting power analysis software tool CNR 30.12.2015 postponed (new DoW) NO

T4.6D4.1 existing grading rules for log/biomass report CNR 31.10.2014 31.10.2014 accepted

D4.12 implementatio and callibration of prediction models for log/biomass quality classes software tool CNR 31.06.2016 postponed

(new DoW) NO

Work Package 4: Multi-sensor model-based quality

control of mountain forest production

Planning actions for all activities and deliverables to be executed in M18-24:

Finalize + close: D04.7, D04.8, D04.9, D04.10, D04.11Deliver + finalize + close: -Initiate + deliver: D04.12

Finalize purchase of sensors + install sensors

Perform field tests with portable instruments

Collaborate with WP3 (and others) in hardware development

Work Package 4: Multi-sensor model-based quality

control of mountain forest production

the expected potential impact in scientific, technological, economic, competition and social terms, and the beneficiaries' plan for the use and dissemination of foreground.

Work Package 4: Multi-sensor model-based quality

control of mountain forest production

Risks and mitigating actions:

Significant delay related to DoW amandment:•the purchase and set-up of the new processor head was delayed; development of the laboratory scanner capable to simulate log scanning

Technologies provided will not be appreciated by “conservative” forest users; demonstrate financial (and other) SLOPE advantages

Limited reliability of some sensors when implemented on the forest machinery; careful planning, collaboration with SLOPE (+outside) engineers

Work Package 4: Multi-sensor model-based quality

control of mountain forest production

criticalities, recommendations for partners/consortium

How about demonstrations?• No sensors available yet (but ordered already)• expected state of WP4 development during the first demo?

The communication between partners has been substantially improved, but can be always better!

MS Kinect

MicroNIR

Hamamatsu C11708

Hamamatsu C12666

Accelerometers time of flight

Mechanical excitator

Accelerometers free vib ration LDS correction

Laser Displacement Sensor

AE sensor + amplifier

Tensionmeters 1/4 bridge

Dynamic load cell

Hydraulic pressure sensor

Hydraulic flow sensor

Absolute encoders

Hamamatsu C11351

NI 9234

NI 9223

NI 9235

NI 9220

Port #8

CRio (CompactDaq Win7) SENSORS

Port #7 Port #6 Port #5 Port #4 Port #3 Port #2 Port #1

LAN port #2

Industrial PC

LAN port #1 Port #6 Port #5

Video output + USB port #4 USB port #3 USB port #2 USB port #1

NI 9403 (Dig ital I/O)

Custom line scan camera

Port #8

CRio (real t ime?) MACHINE CONTROL

Port #7 Port #6 Port #5 Port #4 Port #3 Port #2 Port #1

SEA 9744 (GSM + GPS)

Joystic(s)

RFID reader

Hydraulic actuators

???

???

???

???

CMOS camera

3D camera #1

3D camera #2 LAN port #5 LAN port #4 LAN port #3

Touch screen

T4.2

+T4

.3

T4.4

T4

.5

T4.5

T4

.4

WP3

T4.2

+T4

.3

WP3

W

P3

NI 9220

Temperatures of oil and air

Sensors and electronics (WP3 & WP4)

Work Package 4: Multi-sensor model-based quality

control of mountain forest production

Thank you! – Grazie!

Task 4.01: Data mining and model integration of stand quality indicators from on-field survey for the determination of the tree “3D Quality Index”

Task Leader: Treemetrics

Partners involved: GRAPHITEC, CNR, FLYBY

Deliverable: D4.02 On-field survey data for tree characterization

Status: Completed

Mid-term Review 2/July/15

T2.03 Timber Products Quality Index

Task 4.0 Timber Products Quality Index This task includes:•Overview of process for tree 3D model creation•TLS Quality Indicators•Harvest Simulation

D4.2 TLS data analysisaims at evaluating the effectiveness/reliability, as quality indicators, of single andcombined parameters related to the external characteristics of the standing tree,such as tree height, diameter, stem taper, straightness, sweep and lean,branchiness, branch length, thickness and dimension of the live crown.

T2.03 Timber Products Quality Index Introduction

Mid-term Review 2/July/15

T2.03 Timber Products Quality Index Introduction

Mid-term Review 2/July/15

4 ( 4 ) y Index TLS data capture

•Automated tree detection•Branches removal•3D tree shape (each 10cm)

Mid-term Review 2/July/15

Automted generation of 3D model of one sampled trees.

Profile disks are fitted around cylinders in the point cloud data at every 10cm.

-Diameter distribution- Leaning of the tree

Upper section of tree is calculated using local taper equations.

3D Models

4 ( 4 ) y Index TLS data capture

Mid-term Review 2/July/15

4 ( 4 ) y Index Tree defects

The main stem is the most useful part of a tree for conventional wood products such as roundwood, pulpwood, posts, poles, and lumber. Defects reduce the total volume of usable wood in the tree.

The stem defects are potential indicators of the timber quality

Mid-term Review 2/July/15

4 ( 4 ) y Index Field Defects measurment

Mid-term Review 2/July/15

Stemfiles are generated that fully support the Standard for "Forestry Data andCommunication" (StanForD) standard in a widely accepted file with ".stm" extension. Theallows for storing of x,y,z and diameter for each decimetre disk on the stem.

The extra information should either be stored in a linked file to the .stm file or a newapproach that does not support the StanForD standard can be used.

STEM FILE GENERATION

4 ( 4 ) y Index Stemfile

Mid-term Review 2/July/15

4 ( 4 ) y Index Tree defects

The stem defects can have different impact in the in the final timber product, depending on how there are cut.

Defect affecting a low value log

Defect affecting a high value log

Treemetrics has developed a system to define and characterize the stems defects and to optimize the cutting of timber logs to minimise losses due to defects.

Mid-term Review 2/July/15

Timber Log Specifications

Length: Targeted length of the log.

Small End Diameter (Min + Max SED)

Large End Diameter (Min + Max LED)

Straightness: Maximum deviation

4 ( 4 ) y Index Log definition

Mid-term Review 2/July/15

Timber Log Quality Specifications

Maximum defects specification

-Defect grade 1: Stem sections with severe timber defects -Defect grade 2: Stem sections with scar defects, cracks, decay, or similar that prevents to create quality timber logs. - Dead tree: Sanding dead tree that will not be commercialized.

4 ( 4 ) y Index Log definition

Maximum log bow (Straightnes)

Defects can affect one section of the tree or the entire tree.

Mid-term Review 2/July/15

1-straight log;; 3 - maximum deviation (d) exceeds 1 cm over 1 m;

2- maximum deviation (d) does not exceed 1 cm over 1 m

4 - bow in more than one direction.

Straightness

4 ( 4 ) y Index Log definition

Mid-term Review 2/July/15

Log ID/name LOG1 LOG2 LOG3 LOG4 LOG5 LOG6Length 4m 4m 5m 2.5m 4.8m 2.5Min SED 20cm 40cm 40cm 20cm 20cm 40cmStraightness - - - - - -Quality restrictions

No Defect No Defect

No Defect Defect grade 1

Defectgrade 1

Defectgrade 2

Slope Log Definitions

4 ( 4 ) y Index Log definition

Mid-term Review 2/July/15

4 ( 4 ) y Index Cutting instrutions

A Cutting Instruction is a collection of Log Products, weighted by priority (e.g.value).

Treemetrics system needs a defined set of Cutting Instruction in order to run thecutting simulation.

The cutting instruction needs to be defined by the user according the industrystandards in his/her region.

Cutting instruction

LOG1 LOG2 LOG3 LOG4 LOG5 LOG6

Example 1 50 100 200 - - -Example 2 50 100 100 20 50 10Example 3 50 100 300 20 30 10

Mid-term Review 2/July/15

LOGWeight

LOG1100

LOG210

LOG350

LOG40

Total

Assortment 1Value (m3) 1*0.3 2*0.15 - 0.1

33

Assortment 2Value (m3) 1*0.3 - 1*0.2 0.2

40

4 ( 4 ) y Index Cutting simulation

Mid-term Review 2/July/15

4 ( 4 ) y Index Cutting simulation

Mid-term Review 2/July/15

Optimising Waste Logs: waste log has a value of zero

4 ( 4 ) y Index Stemfile

Mid-term Review 2/July/15

Product ratio

4 ( 4 ) y Index Quality indexes

∑ =

=+

= ni

i i wvwWR

1

∑ =

=

= ni

i i

n

vvPR

1

Waste ratio valuepotential Maximum valueTotal

=TPI

Total profitability index

KWRPRTPI ⋅−⋅= )1(nn

ni

i ii

vpvp

K⋅

⋅= ∑

=

=1

Modified Total profitability index

Assumes that the that the price of the highest volume is the double that the average price of the others products.

)5.0()1( PRWRMTPI +⋅−=

Mid-term Review 2/July/15

4 ( 4 ) y Index Quality indexes

Quality index (MTPI)

Quality class Description

1+ 1 Very high quality

0.5-1 2 High quality

0.3-0.5 3 Regular quality

0-0.3 4 Low quality

0 5 Very low quality

Mid-term Review 2/July/15

Conclusions

The main conclusions about the stand quality indicators and harvest simulation are thefollowing:

• The MAIN parameters to define the log can be easily measured using the stem 3D modelcreated using TLS data (including straightness).

• Additional quality indicators can be measured and applied to the log constraints.

• Intelligent cutting instructions can reduce the loss caused by stem defects

• It has successfully defined a quality index to apply in slope based on the timber productinformation.

Mid-term Review 2/July/15

Future work

Crosscutting results for Picine complete (to be implemented with FSI within thenext weeks)

Next analysis:

•Montsover (Province of Trento, Italy) –August

• Austria

Mid-term Review 2/July/15

TASK 4.2Evaluation of NIR spectroscopy as a tool for determination of

log/biomass quality index in mountain forest

Work Package 4: Multi-sensor model-based quality control of mountain

forest production

Task leader: Anna Sandak (CNR)

Task 4.2: Partners involvement

Task Leader: CNRTask Partecipants: BOKU, FLY, GRE

CNR: Project leader, •will coordinate all the partecipants of this task•will evaluate the usability of NIR spectroscopy for characterization of bio-resources along the harvesting chain•will provide guidelines for proper collection and analysis of NIR spectra •will develop the “NIR quality index”; to be involved in the overall log and biomass quality grading

Boku: will support CNR with laboratory measurement and calibration transfer

Greifenberg and Flyby: will support CNR in order to collect NIR spectra at various stages of the harvesting chain

• evaluating the usability of NIR spectroscopy for characterization of bio-resources along the harvesting chain

• providing guidelines for proper collection and analysis of NIR spectra

• The raw information provided here are near infrared spectra, to be later used for the determination of several properties (quality indicators) of the sample

4.2 Objectives

4.2 Deliverables

Deliverable D.4.03 Establishing NIR measurement protocolevaluating the usability of NIR spectroscopy for characterization of bio-resources along the harvesting chain, providing guidelines for proper collection and analysis of NIR spectra.

Delivery Date M10, October 2014 Estimated person Month = 5

Deliverable D.4.08 Estimation of log/biomass quality by NIRSet of chemometric models for characterization of different “quality indicators” by means of NIR and definition of “NIR quality index”

Delivery Date M21, Septembe 2015Estimated Man/Month = 8

T4.2: Evaluation of NIRS as a tool for determination of log/biomass quality index

D01.04

Determine optimal protocolCNR:

Calibration transferBOK, CNR:

Develop models for labCNR, BOK:

Measure NIR on standing treesTRE, CNR, FLY:

Measure NIR on felled treesCNR, GRE:

Measure NIR on processor headCNR, COM:

Measure NIR on pale of logsCNR, BOK:

Develop models for in fieldCNR, BOK:

Compare models with lab dataCNR, BOK:

Develop NIR quality indexCNR, BOK:

Develop provenance NIR modelsCNR, BOK:

Design data base of NIR spectraBOK, CNR:

T4.2 NIR quality

D04.03

CNR

D04.08

CNR

Determine optimal set-up for the NIR sensor, illumination, and sample holdingCNR, BOK:

the resources planned: 13 M/Mthe resources utilized:PROBLEMS: Delay in purchasing sensorSOLUTIONS: The sensor already ordered

30.09.2015

!

!

!

!

draft: October 2014

accepted: July 2015

!

Deliverable 4.03

This report contains a recommended protocol for proper collection of NIR spectra within SLOPE project.

Brief presentation of currently available hardware, listing their advantages and disadvantages.

Basic information regarding mathematical algorithms for spectra pre-processing and data evaluation are provided.

Detailed procedure, potential obstacles and important considerations related to measurement of NIR along the whole harvesting scenario according to SLOPE approach are discussed here.

Brief description of various forest operation steps and information regarding quality indexes obtained at varying harvesting chain stages are provided.

Brief description of wood properties and log defects that can be measured and detected by means of NIR spectroscopy.

Spectrophotometers

laboratory

in-field

NIR spectrophotometers

cameras FT-NIR DA LVF DM AOTF MEMS

Spectral range limited full limited limited full limited limited

Scanning time (s) cont. 30 1 0.5 10 1 1

resolution high very high high limited high limited limited

cost N/A high middle low middle middle middle

Signal/noise high high limited limited high limited limited

Calibrations transfer

limited very good

good good very good

good limited

Shock resistance yes no yes yes no yes yes

Suitable for SLOPE

Mathematical methods and algorithms suitable for NIR spectroscopic evaluation of log/wood quality in SLOPE scenario

Algorithms for pre-processing of spectra•Averaging•Derivative•Smoothing normalization•Baseline correction•Multiplicative Scatter Correction

Algorithms for NIR data post-processing and data mining•Cluster Analysis (CA)•Principal Component Analysis (PCA)•Identity Test (IT)•Quick Compare (QC)•Partial Least Squares (PLS)

– NIR spectra will be collected at various stages of the harvesting chain

– measurement procedures will be provided for each field test

– In-field tests will be compared to laboratory results

Activities: Feasibility study and specification of the

measurement protocols for proper NIR data acquisition

Collection of NIR spectra and flow of samples/data at different stages of the harvesting process chain

(optional) prepare samples #1

measurement of infrared spectra (wet state)

prepare samples #2

condition samples

chemometric models for wet wood and/or in field

chemometric models for dry/conditioned wood (lab)

measurement of infrared spectra

collect sample #1: chip of axe

collect sample #2: core ~30mm deep

collect sample #3: chips after drilling core

collect sample #4: triangular slices

measurement NIR profile or hyperspectral image

measurement profile of infrared spectra

consider approach: max slope, pith position, WSEN

compute NIR quality index#2

compute NIR quality index#3

compute NIR quality index#4

measurement profile of infrared spectra

consider approach: pith position, defects

compute NIR quality index#5

tree marking

cutting tree

processor head

pile of logs

expert system & data base

refresh sample surface

measurement of infrared spectra (dry state)

compute dry wood NIR quality index#6 compute the log quality

class (optimize cross-cut)

estimated tree quality

forest models

update the forest database

compare results of wet and dry woods

combine all available char-acteristics of the log

lab

Calibration transfer f(MC, surface_quality)

3D tree quality index

hyperspectral HI quality index

stress wave SW quality index

cutting force CF quality index

compute NIR quality index#1

Detailed procedure related to measurement of NIR along the whole harvesting scenario

Forest modelingNIR quality index #1 will be related directly to the health status, stress status and to the productivity capabilities of the tree(s) foreseen for harvest

Tree markingDirect measurement of the NIR spectra by means of portable instruments (DA and LVF) will be performed in parallel to the tree marking operation. The spectra will be collected and stored for further analysis (NIR quality index #2)

Cutting of treetesting the possibility of collecting sample of wood in a form of the triangular slice being a part of the chock cut-out from the bottom of the log (NIR quality index #3)

Processor headNIR sensors will be integrated with the processor head (NIR quality index #4). All the sensors will be positioned on a lifting/lowering bar on the head processor near the cutting bar. The cutting bar will be activated in two modes: automatic and manual

the scanning bar #1 with NIR sensor

Sensor position in the intelligent processor head

CRio

NIR spectra (USB)

Control system

Detailed procedure related to measurement of NIR along the whole harvesting scenario

Pile of logsThe cross section of logs stored in piles is easily accessible for direct measurement. Such measurements will be repeated periodically in order to monitor the quality depreciation and to determine the most optimal scanning frequency. The result of measuring NIR spectra of logs stored in piles will be NIR quality index #5

LaboratorySamples collected in the forest will be measured instantaneously after arrival in the laboratory (at the wet state and with rough surface) by using the bench equipment (NIR quality index #6). However, samples will be conditioned afterward and their surfaces prepared (smoothed) in order to eliminate/minimize effects of the moisture variations and light scatter due to excessive roughness on the evaluation results of fresh samples.

Protocol for NIR measurement of logs/wood

Procedure for logs:• turn on instruments• warm up detector• measure white reference• measure black reference• measure series of spectra• save results• post processing of spectra• in field data mining

(assuming availability of previously developed chemometric models)

Procedure for wood:• turn on instrument• warm up detector• perform instrument validation • PQ (Performance Qualification)• OQ (Operational Qualification)• measure background• measure series of spectra• save results• post-process the spectra• develop calibration models• perform calibration transfer (if required)

Important considerations

Logs:• Resolution (both spatial and spectral)• Measurement time• Number of measurements• Effect of ruggedness (effect of moisture, temperature and vibrations)

Wood:• Number of scanes per averaging• Number of measurements• Selection of scanning zones (wood section, early/late wood)• Effect of roughness and surface preparation• Effect of moisture• Effect of time (surface deactivation)

Potential for detection of defects and determination of material properties as measured by means of various NIR sensors

Instrument type FT-NIR dispersive linear variable filter MicroNIR Moisture content of sample wet dry wet dry wet dry Surface of sample smooth rough smooth rough smooth rough smooth rough smooth rough smooth rough

knots resin pocket twist eccentric pith compression wood ? ? sweep taper shakes insects ? ? ? ? ? ? ? ? dote ? ? ? ? ? ? ? ? rot W

ood

defe

cts a

ccor

ding

to E

N

1927

-1:2

008

stain ? ? ? ? ? ? ? lignin ? ? ? ? ? ? ? cellulose ? ? ? ? ? ? ? hemicellulose ? ? ? ? ? ? ? extractives ? ? ? ? ? ? ? microfibryl angle ? ? ? ? ? ? calorific value ? ? ? ? ? ? ? ? heartwood/sapwood ? ? ? ? density ? ? ? ? mechanical properties ? ? ? ? moisture content provenance ? resonance wood ? ? ? ? ? ? ? ? ? ? ?

Oth

er w

ood

prop

ertie

s/ch

arac

teris

tics

• spectra pre-processing, wavelength selection, classification,calibration, validation, external validation (sampling –prediction – verification)

• prediction of the log/biomass intrinsic “quality indicators”(such as moisture content, density, chemical composition,calorific value) (CNR).

• classification models based on the quality indicators will bedeveloped and compared to the classification based on theexpert’s knowledge.

• calibrations transfer between laboratory instruments(already available) and portable ones used in the fieldmeasurements in order to enrich the reliability of theprediction (BOKU).

Development and validation of chemometric models.

Thank you very much

Project SLOPE

Mid-term Review2/Jul/2015

T4.3– Evaluation of hyperspectral imaging (HI) for the determination of log/biomass

“HI quality index”

Brussels, July 2th, 2015

Overview

Mid-term Review2/Jul/2015

• Status: Completed (70 %)• Length: 14 Months (From M8 to M21)• Involved Partners

• Leader: BOKU• Participants: CNR, GRAPHITECH, COMPOLAB, FLY, GRE

• Aim: Evaluating the usability of hyperspectral imaging for characterization o bio-resources along the harvesting chain and providing guidelines for prope collection and analysis of data

• Output: • D4.04 Establishing hyperspectral measurement protocol (M13/M15)• D4.09 Estimation of log quality by hyperspectral imaging (due to M21)

Mid-term Review 2/Jul/15

Task 4.3 – OutputD4.04 Establishing hyperspectral measurement protocol (M13/M15)

• Methodology, laboratory setup and field transferD4.09 Estimation of log quality by hyperspectral imaging (M21)

• Labscale investigations (visible range and near infrared hyperspectral cameras)

• Validation by NIR measurements• Application of chemometric approaches for data evaluation and multivariate

image analysis• Identification of most relevant spectral information

• Transfer to (harsh) field conditions• Development of the “HI quality index” for quality grading• Technological implementation on prototype

Mid-term Review 2/Jul/15

D4.03 Hyperspectral measurement protocol – potential HSI application

hyperspectral measurement (wet & rough state at differ-

ent temperatures)

compute wet wood HSI quality index#3

cut pieces for drying, wood moisture determination

chemometric models for wet & rough wood and/or in f ield

chemometric models for wet & rough wood (lab)

collect samples: wood logs

measurement hyperspectral image

measurement of hyperspectral imaging

handheld device

compute HSI quality index#2

compute HSI quality index#5

(optional) measurement hyperspectral

image handheld device

compute HSI quality index#6

tree marking

cutting tree

processor head

pile of logs

expert system & data base

condition rough samples to norm climate (20 °C, 60 %)

hyperspectral measurement (cond. grinded state)

compute the log quality class (optimize cross-cut)

estimated tree quality

forest models

update the forest database

compare results of different temperatures, roughness,

wet and dry states

combine all available char-acteristics of the log

lab

calibration transfer f (MC, surface_quality)

3D tree quality index

NIR quality index

stress wave SW quality index

cutting force CF quality index

compute HSI quality index#1

grind samples

Storage of samples in lab (f rozen -20°C)

measure surface roughness & temp

hyperspectral measurement (cond. rough state)

compute dry wood HSI quality index#4

Mid R i

D4.03 Establishing HS measurement protocol – laboratory setups

VIS-NIR HSI system a CNR (spectral range 400 – 1000 nm)

NIR HSI system a BOKU (spectral range 900-1700 nm)

Pushbroom Hyperspectral Imaging Systems at CNR and BOKU

Mid-term Review 2/Jul/15

NIR used to validate HSI data D4.03 Establishing NIR measurement protocol

Mid-term Review2/Jul/15

D4.03 Establishing HS measurement protocol – analytical approachAnalytical approach• rough surface with original moisture

content at 5 different temperatures (-5, 0, 5, 15, 25° C) from both sides

• rough surface at conditioned moisture & temperature (norm climate 20 °C and 60 % air moisture, represents about 12 % wood moisture) from both sides

• grinded surface at conditioned moisture/temperature to assess the effect of surface roughness on the results in relation to the targeted deficits from both sides

• different angles/sources of lightning• different contaminations (soil and/or oil)• NIR measurements for validation

Analytical steps & model developm

D4.03 – Initial results - fungus• Fungus clearly identifiable on the dry and wet wood • Influence of wood surface roughness was negligible (diffuse lightning)• Comparable results of HSI and NIR – causal/explanatory model possible

@ IASIM Conference 3.-5.December 2014

Mid-term Review2/Jul/15

Task 4.3 – Sampling campaign

BOKU education forest at Forchtenstein (Rosalia), Burgenland

25 samples of spruce (Picea abies) with different defects (ø 15 - 45 cm), March 2015

Mid-term Review2/Jul/15

Mid-term Review2/Jul/15

Task 4.3 – 25 samples (spruce, Picea abies) with defects

resin pockets

eccentric pith + compression wood + rot

eccentric pith + rot + knot

shakes, checks, splits

knots

D4.01 Existing grading rules for log/biomass

Task 4.3 – First results resin pocketsNIR vs. HSI (NIR)

NIR

HSI

Mid-term Review2/Jul/15

Task 4.3 – First results resin pocketsNIR vs. HSI (NIR)

Subtraction spectrumNIR

Mid-term Review2/Jul/15

Subtraction spectrumHSI

Task 4.3 – First results resin pocketsNIR vs. HSI (NIR)

Brussels3/jul/2015

NIR

HSI

1190 nm

RGB

NIR of resin

1000 nm

HSI of resin

Subtraction spectra HSI & NIR

Task 4.3 – Results for resin pockets Intensity slabs

Brussels3/jul/2015

1190 nm 1377 nm

Task 4.3 – First results training & classification

Training sample - PLS-DA supervisedclassification

Mid-term Review2/Jul/15

Task 4.3 – First results training & classification

Test sample – PLS-DA supervisedclassification

Class Pred. Membership Class Pred. Probability

Mid-term Review2/Jul/15

Task 4.3 – Analytical challenges

• Temperature

• Roughness

• Lightning & referencing

• Water & Ice

• Other contam.

Roughness can becalculated by z-valuesof 3D scan

Measurements at different temperaturesyield temperature effect

0°C 5°C 15°C

1190 nm

Diffuse lightning reduces morphological effects, needs to becarefully considered

Ice and water have specificbands, wavelength selectionimportant

1190 nm

1377 nm

-5°C 5°C 15°C

Mid-term Review2/Jul/15

Task 4.3 – Field transfer optionsImplementation of the hyperspectral imaging in the field:• Hyperspectral imaging using new technologies

Optimal accuracy and spatial resolution Rigidity of sensors (not suitable for harsh conditions) Relatively high cost

• Mono/multi spectral imaging the log cross-section Optimal spatial resolution Reasonable cost Poor spectral accuracy Challenges with implementation

• Several simple spectrometers installed on the scanning bar & measuring the log cross-section Optimal spectral accuracy and sufficient spatial resolution Reasonable cost Difficulties with implementation

Mid-term Review2/Jul/15

T3.4 Intelligent processor head

Mid-term Review 2/Jul/15

Task 4.3 – Dissemination outcomes (WP8)

• Scientific publications1. Inspection of log quality by hyperspectral imaging (Scientific Poster,

Fifth IASIM conference in spectral Imaging, IASIM-14, Rome, DEC 3-5, 2014)2. Assessing resin pockets on freshly cut wood logs of spruce by NIR and hyperspectral

imaging, European Journal of Wood and Wood Products (Scientific paper, Oct 2015)3. Determination of wood quality using HSI in the near infrared, European Journal of

Wood and Wood Products (Scientific paper, Nov 2015)• HSI Workshop and links to other EU projects

58 participants /11 countries, 13 Universities/Research Institutions, 4 companies, from 8 out of 15 BOKU departments1. FP7 project project n°284181 Trees4future - Designing Trees for the future2. FP7 project n°211326 CONFFIDENCE - CONtaminants in Food and Feed:

Inexpensive DEtectioN for Control of Exposure3. FP7 project n°618080 HELICoiD - HypErspectraL Imaging Cancer Detection

TASK 4.4Data mining and model integration of log/biomass quality indicators from

stress-wave (SW) measurements, for the determination of the

“SW quality index”

Work Package 4: Multi-sensor model-based quality of mountain forest

production

Task leader: Mariapaola Riggio (CNR)

The objectives of this task is to optimize testing procedures and prediction models for characterization of wood along the harvesting chain, using acoustic measurements (i.e. stress-wave tests).

A part of the activity will be dedicated to the definition of optimal procedures for the characterization of peculiar high-value assortments, typically produced in mountainous sites, such as resonance wood.

Task Leader: CNRTask Participants: Greifenberg, Compolab

WP4: T 4.4 Data mining and model integration of log/biomass quality indicators from stress-wave (SW) measurements, for the determination of the “SW quality index”

Objectives

WP4: T 4.4 Deliverables

D4.05) Establishing acoustic-based measurement protocol: This deliverable contains a report and protocol for the acoustic-based measurement procedureStarting Date: August 2014 - Delivery Date: December 2014

D4.10) Estimation of log quality by acoustic methods: Numerical procedure for determination of “SW quality index” on the base of optimized acoustic velocity conversion models.Starting Date: January 2015 - Delivery Date: August 2015

Estimated person Month= 6.00

T4.4: Data mining and model integration of log/biomass quality indicators from stress-wave

Develop report on using SWCNR:

Develop models for SW qualityCNR:

Test on standing trees CNR, GRE:

Tests on fallen trees CNR, GRE:

Tests on processor headCNR, COM:

Imaging on pale of logsCNR:

Develop SW quality indexCNR:

Define quality thresholdsCNR:

Analyze material dependant factorsCNR:

T4.4 stress wave quality

D04.05

D04.10

CNR

CNR

Determine optimal set-up for the stress wave measurement, including time of flight and free vibrations sensorCNR:

D01.04

Determine quality requirements for high-end assortments

CNR:

the resources planned: 5.5 M/Mthe resources utilized:PROBLEMS: Delay related to the processor headSOLUTIONS: LAB scanner + collaboration with engineers

31.11.2015

draft: December 2014

accepted: July 2015

!

!

D: 4.5 Establishing acoustic-based measurement protocol

Stress-wave data acquisition and analysis

D: 4.5 Establishing acoustic-based measurement protocol

Accelerometer #1

Accelerometer #2

Laser displacementsensor

SW generator

TOF

Resonance method

Localcharacterization

Globalcharacterization

Stress-wave data acquisition and analysis

D: 4.5 Establishing acoustic-based measurement protocol

D: 4.5 Establishing acoustic-based measurement protocol

Test plan for on-line SW measurement in the processor head

Laser measurements for longitudinal axial modes analysis with the resonance method

D: 4.5 Establishing acoustic-based measurement protocol

Test plan for on-line SW measurement in the processor head

Time of flight (ToF) measurements

Conclusions

Many factors influence SW propagation in wood.

Parameters measured with the other NDT methods will be incorporated in the SW prediction models

Multiple linear regression analysis will be implemented for the definition of the importance of the different parameters (regression t-values) for the model.

The further development of Task 4.4 is based on the implementation of the lab scanner (i.e. purchase of sensors)

For the implementation of the methodology in the real case scenario, some practical issues(e.g. coupling-decoupling of sensors, etc.) have to be considered in combination with activity of Task 3.4

TASK 4.5Evaluation of cutting process (CP) for the

determination of log/biomass “CP quality index”

Work Package 4: Multi-sensor model-based quality control of mountain

forest production

Task leader: Jakub Sandak (CNR)

Task 4.5: cutting process quality indexObjectives

The goals of this task are:• to develop a novel automatic system for measuring of the cutting resistance of wood processed during harvesting• to use this information for the determination of log/biomass quality index

Task 4.5: Cutting Process (CP) for the determination of

log/biomass “CP quality index”

Task Leader: CNRTask Partecipants: Compolab

Starting : October 2014Ending: November2015Estimated person-month = 4.00 (CNR) + 2.00 (Compolab)

CNR : will coordinate the research necessary, develop the knowledge base linking process and wood properties, recommend the proper sensor, develop software tools for computation of the CP quality index

Compolab: will provide expertise in regard to sensor selection and integration with the processor head + extensive testing of the prototype

Task 4.5: cutting process quality index

Deliverables

D.4.06 Establishing cutting power measurement protocolReport: This deliverable will contain a report and recommended protocol for collection of data chainsaw and delimbing cutting process.

Delivery Date: January 2015 (M.13) DONE

D.4.11 Estimation of log quality by cutting power analysisPrototype: Numerical procedure for determination of “CP quality index” on the base of cutting processes monitoring

Delivery Date: December 2015 (M.24)

T4.5: Evaluation of cutting process (CP) for the determination of log/biomass CP quality index

Laboratory scale tests for delimbing energy needs

CNR:

Develop CP quality indexCNR:

T4.5 cutting power quality

D04.11

D04.06

CNR

CNR

Determine optimal set-up for the measurement of cutting forces on the processor headCNR:

D01.04Laboratory scale tests for chain saw energy needs

CNR:

Develop models linking CP in delimbing and quality

CNR:

Develop models linking CP in chain sawing and quality

CNR:

Develop report on using CPCNR:

the resources planned: 6.0 M/Mthe resources utilized:PROBLEMS: Delay related to the processor head and final sensor selection/designSOLUTIONS: LAB scanner + collaboration with engineers + list of sensor(s) for purchase ready

31.12.2015

!

!

draft: January 2014

accepted: July 2015

• load cell: indirectly measuring the cutting force• strain gauge: rough estimation of cutting forces on the base of machine parts

deformation • pressure sensor: continuously measure oil pressures both in the hydraulic motor

and feed pistons• oil flow meter: indirect evaluation of the cutting speed and its changes due to

cross-cutting progress• electrical multimeter: electrical analogy for measuring the oil pressure• other: dedicated to determine if emission generted while cutting out braches

contain any signal features useful for detection of the branch presence and/or its size and health status

• Acoustic emission (AE): (signal frequency > 50kHz) • Microphone: cutting sound (signal frequency < 20kHz)

Task 4.5: cutting process quality indexsensors for cutting process monitoring

• working time of the cutting tools (knifes and chain):• estimation of the tool wear and correction of the cutting forces

• position of the saw bar while cross-cutting: • monitoring of the cutting progress• correction factors related to the determination of the cutting forces and material

characteristics• log diameter (combined with position of the saw bar):

• determination of the cutting length at each moment of the cross-cutting• position of the main hydraulic actuator while cutting-out branches:

• monitoring of the de-limbing progress• determination/mapping of the detailed knot position

Task 4.5: cutting process quality indexother sources of information

sensor type sim

plic

ity

relia

bilit

y

info

rmat

ion

qual

ity

easy

inte

rpre

tatio

n

low

cos

t

suita

ble

for

SLO

PE

labo

rato

ry te

sts

suita

ble

for

SLO

PE

in-f

ield

app

licat

ion

load cell

strain gauge

electric multimeter

oil pressure

oil flow

AE

microphone

Task 4.5: cutting process quality indexcomparison of sensors

• a process where several cutting edges are involved in the cutting at the same time. The angle between the main cutting edge and fibre direction is ~0°, while the angle between feed direction and grain angle is ~90°.

• rather difficult to direct monitoring due to peculiarities related to the processing in the field/forest (suitable sensors, capability for acquisition of the proper energetic effects of cutting)

• relatively resistant to various sources of noise• great effect of the tool sharpness changing along the processing time• cutting speed and/or feed speed changes considerably between (and within) cutting cycles. • cutting power is related to the quantity of the material to split (log diameter) and variation

within the material itself:• reaction wood• knots• small ring width • decayed/rooted wood

Task 4.5: cutting process quality indexcross-cutting with the chain saw

Depends on:• wood density• cutting conditions• selected mechanical properties

of wood (such as fracture toughness, shear strength, MOE...)

Task 4.5: cutting process quality indexcutting forces in (chain) sawing

hydraulic pressure sensors , load cell , strain gauges , AE sensors , microphone

Task 4.5: cutting process quality indexschematic of the log cross-cutting system of the ARBRO1000

electric chain saw , feeding actuator of the chain saw , load cell , strain gauges , AE sensors , microphones , electric multimeter

Task 4.5: cutting process quality indexthe laboratory log cross-cut simulator

• one cutting edge is involved in the branch cutting-out. • the most demanding cutting configuration as the cutting forces foreseen in that arrangement are the

highest: the angle between the main cutting edge and fibre direction is ~90°, and between feed direction and grain angle is also ~90°.

• the cutting angle is very small• simpler to asses than of cross-cutting with a chain saw: due to the peculiar design of the processor head

where the cutting knife if fixed to the machine body and not any high-frequency changes to the process occurs

• depending on the processor design, the log may be moved against knives or alternatively the knives may be shifted along the trunk

• the fixed knifes system is relatively resistant for external sources of noise allowing measuring of the cutting power by means of various sensors

• an important issue to be considered is an effect of the tool geometry and sharpness• de-branching forces depend on:

• branch size• health state and moisture

Task 4.5: cutting process quality indexprocess of tree de-branching

source: Benjamin Hatton et. al (2015) Experimental determination of delimbing forces and deformations in hardwood harvesting,Croat. j. for. eng. 36-1:43-53

dimensionless displacement

forc

e, k

N

0.0 0.5 1.00

10

20

30

40 ɸ=85.7mm

ɸ=62.5mm

branch area, cm2m

axim

um fo

rce,

kN

0

10

20

30

40

30 40 50 60

low cutting speed

high cutting speed

Task 4.5: cutting process quality indexcutting forces in delimbing

hydraulic pressure sensors , load cell beside the cutting knives , strain gauges , AE sensor(s) , microphone(s)

Task 4.5: cutting process quality indexschematic of the instrumented de-branching system of the ARBRO1000

feeding system of the scanner frame , instrumented cutting knife , load cell , strain gauges , AE sensors , microphones , electric multimeter

Task 4.5: cutting process quality indexlaboratory de-branching simulator

Cutting process chain saw de-branching Surface of sample laboratory processor

laboratory processor

knots resin pocket twist eccentric pith compression

sweep taper shakes insects dote rot W

ood

defe

cts a

ccor

ding

to E

N

1927

-1:2

008

stain chemical

heartwood/sapwo

density mechanical

moisture content Oth

er w

ood

prop

ertie

s/ch

ara

resonance wood

Task 4.5: cutting process quality indexapplications for detection defects in logs

two quality indexes (numbers in the range from 0 to 1) associated to wood/log properties are determined:

• CP quality index #1: reflects the estimation of the “wood density” as related to the cutting resistance during cross-cutting of log by chain saw. The quality index #1 value is unique for the whole log.

CP quality index #1 = f(wood moisture content, tool wear, cutting speed, feed speed, log diameter, ellipsoid shape, presence of defects)

• CP quality index #2: reflects the “brancheness” of the log along its length and is estimated by means of signals associated with cutting out branches. The quality index #2 is spatially reolved.

CP quality index #2 = f(hydraulic pressure changes along the log length, changes of cutting forces in time, number of AE events or sound pressure level)

Task 4.5: cutting process quality indexalgorithms for data mining

• to plot a quality map – suport operator in taking decision - that is mostly affecting the whole following transformation chain!!!

• to grade the log• (to optimize cut-to-length)

Concept of the “quality map” indicating as a pattern sections of selected log properties, geometries and presence of various defects derived from the cutting-power analysis.

Task 4.5: cutting process quality indexuse of quality indexes

Task 4.5: cutting process quality indexChallengesSome additional delay with prototype developing: the equipment ordered and soon ready for installation

How to physically install sensors on the processor?

How reliable will be measurement of cutting forces in forest?

What is an effect of tool wear?

How to link cutting force (wood density) with recent quality sorting rules?

Delimbing or debarkining?

Thank you very much

TASK 4.6Implementation of the log/biomass grading

system

Work Package 4: Multi-sensor model-based quality control of mountain

forest production

Task leader: Jakub Sandak (CNR)

Task 4.6: Implementation of the log/biomass grading system

Task Leader: CNRTask Participants: GRAPHITECH, COMPOLAB ,MHG, BOKU, GRE, TRE

Starting : June 2014Ending: July 2016Estimated person-month = 1.50 (GRAPHITECH) + 2.0 (CNR) + 1.00 (COMPOLAB) + 1.00 (MHG) + 1.00 (BOKU), 0.50 (GRE) + 1.00 (TRE)

CNR: will coordinate the research necessary, develop the software tools (expert systems) and integrate all available information for quality gradingTRE, GRE, COMPOLAB: incorporate material parameters from the multisource data extracted along the harvesting chainGRAPHITECH: integration with the classification rules for commercial assortments, linkage with the database of market prices for woody commoditiesMHG: propagate information about material characteristics along the value chain (tracking) and record/forward this information through the cloud database BOKU: validation of the grading system

Task 4.6: Implementation of the grading system

Objectives

The goals of this task are:• to develop reliable models for predicting the grade (quality class) of the harvested log/biomass.• to provide objective/automatic tools enabling optimization of the resources (proper log for proper use)• to contribute for the harmonization of the current grading practice and classification rules

• provide more (value) wood from less trees

Task 4.6: Implementation of the grading system

Deliverables

D.4.01 Existing grading rules for log/biomassReport: This deliverable will contain a report on existing log/biomass grading criteria and criteria gap analyses

Delivery Date: October 2014 (M.10) DONE

D.4.12 Implementation and calibration of prediction models for log/biomass quality classes and report on the validation procedurePrototype: This deliverable will contain a report on the validation procedure, and results of the quality class prediction models, and integration in the SLOPE cloud data base

Delivery Date: June 2016 (M.30)

T4.6: Implementation of the log/biomass grading system

Link in-field data with cloud database

CNR:

Compare automatic and visual grading resultsBOK, CNR:

Determine threshold valuesCNR:

Develop grading expert systemCNR:

Develop algorithm for data fusionCNR, COM, TRE:

In field visual quality assessment CNR, BOK:

Develop data base for prices of woody commodities

CNR, BOK:

Reliability studiesBOK:

Economic advantage studiesBOK, CNR:

T4.6 quality implementation

D04.01

CNR

D04.12

CNR

Identify grading rules for standard and niche productsCNR:

Prepare state-of-the-art report on grading rulesCNR:

the resources planned: 8.0 M/Mthe resources utilized:PROBLEMS: Delay related to other tasks – difficulties with implementationSOLUTIONS: LAB scanner + prototype software developed in lab + algorithms ready

31.06.2016

draft: October 2014

accepted: July 2015

!

!

Task 4.6: Implementation of the grading system

Deliverable 4.01 - content

• Wood market within and beside legal norms and regulation• “Quality of wood” from perspectives of various players• Potential advantages of wood from mountain areas • List of legal norms, standards and regulations in relation to log grading• General overview on the recent wood market in relation to SLOPE

• Global level• European Union level• Specific countries

• Specific regulations in various wood industries• Currently used log grading practices• Procedures for estimation of the log’s geometrical characteristics and volume• Visual grading procedures• Machine grading systems of logs

Currently used logs grading practice

• Detailed criteria of Norway spruce (Picea abies) quality sorting are provided in European Standard EN 1927-1:2008– List of wood/log defects: knots, resin pocket, twist (or spiral grain), eccentric

pith, compression wood, sweep, taper, shakes, checks and splits, insect or worm holes, dote, rot, stain

– Round wood quality classes according to EN 1927-1:2008– Criteria of classification

Wood defects and possibilities of their detection/identification (focus on SLOPE sensors)

Sensor type

Multispectral cameras for remote sensing (satellite)

Multispectral cameras for remote sensing (UAV)

3D laser scanner and cloud of points

Near Infrared spectrometer (laboratory)

Near Infrared spectrometer (in-field)

Hyperspectral imaging VIS

Hyperspectral imaging NIR

Ultrasound sensor

Free vibrations meter

Cutting forces meters (de-branching)