MICROVENT MACHINING

Transcript of MICROVENT MACHINING

Atrenne Integrated Solutions | 10 Mupac Drive | Brockton, MA 02301 | 508-588-6110 | www.atrenne.com

MICROVENT® MACHININGDATASHEET

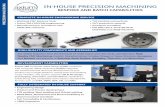

WHAT IS MICROVENT® MACHINING?MicroVent® technology addresses the need for more efficient thermal management in custom, electromechanical enclosures across many industries. The MicroVent® pattern incorporated in an extruded or sheet metal front panel design provides additional airflow to the system, for thermal management requirements, while meeting system EMI/RFI requirements.

MicroVent technology is a sophisticated machining process yielding hexagonal apertures with up to 86% open area in thick panel applications. The highly configurable features can be easily oriented to maximize cooling in close proximity to I/O openings for precise targeting of heat generating components, producing an accurate, repeatable, aesthetic, robust and cost effective perforation method.

MicroVent technology may be used to augment front panels and other products in a wide range of applications. The advanced MicroVent® machining pattern provides a cosmetic, integrated component in next generation telecommunications, computing and data storage systems that require increased airflow cooling and EMI attenuation.

MicroVent Machining offers measurable performance improvements in airflow, reduced back pressure, and EMI shielding, maintaining structural integrity, and reducing assembly costs. This proven technology is currently being utilized in a wide variety of customer applications and industries, including global Fortune 500 companies.

COMMON FEATURE DIMENSIONSHex (flat) Radii Web % Open

mm In mm In mm In

3.0 0.118 0.8 0.030 0.3 0.013 79.3

3.5 0.138 0.8 0.030 0.3 0.013 82.1

4.0 0.157 0.8 0.030 0.3 0.013 84.2

Material : Aluminum; extruded shape or sheet stock

Material Thickness: 2-3mm optimal; Contact Atrenne for thicker material options.

Atrenne Integrated Solutions | 10 Mupac Drive | Brockton, MA 02301 | 508-588-6110 | www.atrenne.com

MICROVENT® MACHININGDATA SHEET

EMI AND AIRFLOW TEST RESULTS

Dynamic Range

.113 [2.86] hex, .010 [.25} web, .08 [2] thick

.121 [3.08] hex, .019 [.30] web, .08 [2] thick

.126 [ 3.2] hex, .019 [.30] web, .08 [2] thick

.126 [3.2] hex, .013 [.30] web, .08 [2] thick

Dynamic Range = TRP signal ceiling - TRP noise floor

SE vent panel =TRP signal ceiling - TRP with panel

© 2

016

Atr

enne

Inte

grat

ed S

olut

ions

• A

ll R

ight

s R

eser

ved.

A

IS-D

S-M

icro

vent

-610

713A

CONTACT [email protected] or 800.926.8722The information in this document is subject to change without notice and should not be construed as a commitment by Atrenne Integrated Solutions. While reasonable precautions have been taken, Atrenne Integrated Solutions assumes no responsibility for any errors that may appear in this document. All products shown or mentioned are trademarks or registered trademarks of their respective owners.

0

0.005

0.01

0.015

0.02

0 100 200 300 400 500 600 700

dp in

ches

H2O

Velocity ft/min

Airflow Test Data .118 [3] hex, .013 [.33] web, .197 [5] thick

.118 [3] hex, .013 [.33] web, .098 [2.5] thick

.138 [3.5] hex, .013 [.33] web, .098 [2.5] thick

AtrenneIntegrated Solutions