Mew introduction-ppt (17.05.16)

-

Upload

maxpromotion -

Category

Engineering

-

view

141 -

download

0

Transcript of Mew introduction-ppt (17.05.16)

“Achieve Excellence Through TPM

Manish Engineering WorksUnit – I & II

Wel-come01

“Achieve Excellence Through TPM

► Company Vision

►TPM Organization Structure:

►Vision, Mission & TPM Policy

2

TPM FacilitatorMr. Vijay Shiradkar

Mr. M. D. Rawke

08

“Achieve Excellence Through TPM

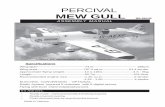

Established Year: 1999 - 2000

► Company Profile – Unit-I

● Sheet Metal Press Parts.- 10T-60T Mech. Press : 5 Nos.● TIG Welding : 3 Nos.

● CO2 Welding : 2 Nos.

● Brazing : 2 Set

● Riveting : 3 Nos.

► Press Parts & Assemblies

● CNC Machines : 12 Nos.● VMC : 3 Nos.● Cy. Grinder : 1 Nos.● Center. Grinder

: 1 Nos.● Pre machining Set Up

- Drilling : 3 Nos.- Lathes : 1 Nos.- Traub M/c : 3 Nos.

► Turned Components

Dedicated Surface Treatment Facilities for All Types of Yoke only:

● Plating.

● Powder Coating

► Surface Treatment

“An ISO 9001 :2008 Certified Company”

► Existing Set Up: Precise set up under one roof for manufacturing

02

“Achieve Excellence Through TPM 03

Products • Precise CNC / VMC Parts, Press Parts & Sub Assymblies like M. Bkt.Assy & D. Shaft Assy.

Works • K-161,MIDC,WALUJ,AURANGABAD.

Processes • Precision Machining,Press Parts,Sub Assy,Surface Treatment as Powder Coating

Area

• Plot - 600 Sq. Mtr.• Machine Shop 320 Sq. Mtr.• Assy. & Powder Coating - 200 Sq. Mtr.• Q.A. & office - 79 Sq. Mtr.

Employee• Skilled - 36 Nos,• Semi-Skilled - 20 Nos,• Casuals - 10 Nos.

Business Growth • 20 % Average annual Growth

► Manish Engineering Facts:- Unit-I

“Achieve Excellence Through TPM 04

Company started in the year 1999-2000 with press part manufacturing set up

Existing Set UpPrecise set up in one roof for manufacturing components like

1. Sheet Metal Press Parts :- Press Capacity in the range of 10 – 50 MT

2. Turned Components :- 12 CNC + 3 VMC + Precise Premachining Set Up like Lathes ,Drilling , Milling, Traub Machines

3. Grinding :- Cylindrical Grinding, Centerless Grinding

4. Welding & Brazing Assy. : - TIG / ARC / CO2 Welding , Brazing & Riveting

5. Surface Treatment :- Dedicated Set up of Surface Treatment like Powder Coating for Yoke

► Manish Engineering Works – Unit-I

“Achieve Excellence Through TPM

Established Year: 2014 - 15

► Added Plant - (UNIT-II)

● CNC Machines : 14 Nos.● VMC : 02 Nos.● Broach Machine : 01 Nos. ● Contracer Mitutoyo : 01 Nos. ● Pre Machining Set Up

- Drilling : 6 Nos.- Lathes : 5 Nos.- Hy. Band Saw :

4 Nos.

► Turned Components

“L-33, MIDC, Waluj, Aurangabad-431 133”

► Existing Set Up: Precise set up under one roof for manufacturing

05

Plot -1004 Sq. Mtr. Machine Shop - 320 Sq. Mtr. QA.+ Assy. & Office - 320 Sq. Mtr. Pre-M/c Area -220 Sq. Mtr.

► Area

“Achieve Excellence Through TPM 06

Products • Precise CNC / VMC Parts, Gear - 735/742, GPD, HMSI Parts.

Works • L-33, MIDC,WALUJ,AURANGABAD.

Processes • Precision Machining,

Area• Plot - 1004 Sq. Mtr.• Machine Shop -502 Sq. Mtr.• 1st Floor - 320 Sq. Mtr.

Employee• Skilled - 22 Nos,• Semi-Skilled - 15 Nos,• Casuals - 05 Nos.

Business Growth • Newly Started. Add New Customers

► Manish Engineering Facts:- Unit-II

“Achieve Excellence Through TPM

Other18%

Varroc Group82%

SOB

Varroc Engineering

2 Wh.

3 Wh.

Pulsar

Royal Enfield

Yamaha

Suzuki

Yoke: 90K

Yoke: 45K

3W4S

Yoke: 40k

Yoke: 40K

BSC 384: 35K

Gear HD : 20K

Gear1082/83: 10K

Gear 561/1059 : 30K

Lay Shaft: 20K

Sleeve Gear: 20K Sleeve: 10K

M.B. Assy.: 15K

Pinion Assy.: 5K

D.S. Assy. (New): 15K

D.S. Assy. (Old): 15K

► Our Product Range & Customers – (Unit- I & II)

07

Other

“Achieve Excellence Through TPM TPM: Way Towards Manufacturing Excellence 9

BasicRestoration

Reactive &ProactiveImprovements

Sustenance Excellence

Step - 1

Step - 2

Step - 3

Step - 4

► Improvement Journey

09

“Achieve Excellence Through TPM TPM: Way Towards Manufacturing Excellence 10

o Streamline & Optimization of 4M1T Resources

● Single piece flow● No metal to metal contact

● Min motion losses● Unidirectional Material flow

● Cell layout

● Well defined (Based Process FMEA)

● Optimised cycle time● Excellent Man/Machine Balancing

●IPO (Operational level 4M1T condition well defined

● Process

● JH-3: M/cs basic condition restored

● M/cs PM/TBM : Well addressed and Practiced

● Equipment/ m/cs + Tools jigs & fixtures

● Lean organization Structure● Production Operation-1S,2S,JH-3,Quality Inspection ,Production norms , Material Handling.● Maint. Operations.- PM, TBM,M/c b/d Why why analysis● Tool fixt Maint.- PM,TBM of tools & Fixt.● Inspectors- Final inspection in process inspection.● Supervisors- DWM, Driving cell for TPM way improvements

● Manpower

►Excellent Performance & Smooth Delivery - Zero break down , Zero defect, Zero Accident , Zero cost loss, Zero line loss

► Technology Up gradation / Low cost automation ► Engineering Expertise (Product knowledge) ► Optimized Inventory ► SMED (Single minute exchange of Dies) ► Proactive in Response.

● Must Required

► Approach

10

“Achieve Excellence Through TPM

Series10

5

10

15

20

25

30

8.5513.6

15.6718.89

24

2012-13 2013-14 2014-15 2015-16 2016-17 (Projected)

► Turnover Growth Year on Year :-

25

“Achieve Excellence Through TPM

Thank You…I

32