Metric Bolt Data - Torque - Thread Strength Rev 02

Transcript of Metric Bolt Data - Torque - Thread Strength Rev 02

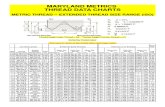

BOLT DATA - TORQUE - THREAD STRENGTH CALCULATION ISO METRIC COARSE SCREW THREADS TO AS 1275 BOLT DATA

BOLTING STANDARD PROPERTY CLASS DIAMETER PITCH CORE AREA TENSILE STRESS AREA SHANK AREA MINIMUM TENSILE STRESS YIELD STRESS PROOF STRESS #N/A #N/A #N/A #N/A #N/A #N/A #N/A mm mm mm2 mm2 mm2 MPa MPa MPa

PREFERRED BOLT TORQUE

BOLT UTILISATION BASED ON PREFERRED BOLT UTILISATION BOLT CONDITION TORQUE COEFFICIENT (NUT FACTOR) BOLT LOAD BASED ON PREFERRED BOLT LOAD PREFERRED BOLT TORQUE

% OF YIELD STRESS #N/A #N/A #N/A kN Nm

NUT DATA (NOT APPLICABLE IF USING A COMPATIBLE NUT)NUT MATERIAL NUT PLATE THICKNESS NUT MATERIAL ULTIMATE TENSILE STRESS NUT MATERIAL YIELD STRESS #N/A #N/A mm MPa MPa

THREAD STRENGTH (NOT APPLICABLE IF USING A COMPATIBLE NUT)

ULTIMATE BOLT LOAD THREAD ENGAGEMENT TO DEVELOP FULL BOLT STRENGTH THREAD ENGAGEMENT TO YIELD THREADS AT FULL BOLT STRENGTH #N/A FORCE REQUIRED TO STRIP mm LENGTH OF THREADS FORCE REQUIRED TO YIELD mm LENGTH OF THREADS

#N/A #N/A #N/A #N/A #N/A

kN mm mm mm kN kN

SELECTED BOLT LOAD & TORQUE (NOT APPLICABLE IF USING A COMPATIBLE NUT)

REQUIRED SAFETY FACTOR ON THREAD YIELD RECOMMENDED BOLT LOAD RECOMMENDED BOLT LOAD AS A % OF YIELD STRESS RECOMMENDED BOLT TORQUE SELECTED BOLT TORQUE SELECTED BOLT LOAD SELECTED BOLT LOAD AS A % OF YIELD STRESS #N/A

#N/A #N/A #N/A #DIV/0! #DIV/0!

kN % Nm Nm kN %

TORQUE VALUES CALCULATED USING FORMULA T = KDP WHERE T = TORQUE (Nm), K = TORQUE COEFFICIENT, D = NOMINAL DIAMETER (mm), P = BOLT CLAMP LOAD (kN)

97960814.xls.ms_office

BOLT STDS & CLASSES 1 AS 1110.1 AS 1110.2 AS 1111.1 AS 1111.2 AS 1252 0 2 3 4 8.8 10.9 12.9 8.8 10.9 12.9 4.6 4.6 8.8 ### #N/A #N/A

BOLT DIAMETERS 1 AS 1110.1 AS 1110.2 AS 1111.1 AS 1111.2 AS 1252 0 2 5 5 5 5 16 3 6 6 6 6 20 4 8 8 8 8 22 5 10 10 10 10 24 6 12 12 12 12 27 7 14 14 14 14 30 8 16 16 16 16 36 9 18 18 18 18 10 20 20 20 20 11 22 22 22 22 12 24 24 24 24 13 27 27 27 27 14 30 30 30 30 15 33 33 33 33 16 36 36 36 36 17 39 39 39 39 18 42 42 42 42 19 45 45 45 45 20 48 48 48 48 21 52 52 52 52 22 56 56 56 56 23 60 60 60 60 24 64 64 64 64

BOLT PITCHES & AREAS 1 BOLT SIZE (mm) 5 6 8 10 12 14 16 18 20 22 24 27 30 33 36 39 42 45 48 52 56 60 64 0 2 PITCH

### ### ### ### ### ### ### ### ### ### ### ### ### ### ### ### ### ### ### ### ### ### ###

(mm) 0.8 1 1.25 1.50 1.75 2.00 2.00 2.50 2.50 2.50 3.00 3.00 3.50 3.50 4.00 4.00 4.50 4.50 5.00 5.00 5.50 5.50 6.00 #N/A

MECHANICAL PROPERTIES 1 2 BOLT MIN TENSILE STRESS GRADE (MPa) d16 mm 4.6 8.8 10.9 12.9 400 800 1040 1220

0 0

#N/A #N/A

STRENGTH OF METRIC THREADS BOLT TORQUE COEFFICIENTS 4 5 AREAS (mm2) TENSILE SHANK STRESS 14.2 19.6 20.1 28.3 36.6 50.3 58.0 78.5 84.3 113 115 154 157 201 192 254 245 314 303 380 353 452 459 573 561 707 694 855 817 1018 976 1195 1121 1385 1306 1590 1473 1810 1758 2124 2030 2463 2362 2827 2676 3217 #N/A #N/A 1 BOLT CONDITION 2 K

T PITCHES & AREAS 3

TENSILE STRENGTH OF THE BOLT MA

CORE 12.7 17.9 32.8 52.3 76.2 105 144 175 225 282 324 427 519 647 759 913 1045 1224 1377 1652 1905 2227 2520 #N/A

CHANICAL PROPERTIES 3 4 5 6 7 MIN TENSILE STRESS YIELD STRESS PROOF STRESS (MPa) (MPa) (MPa) d>16 mm d16 mm d>16 mm d16 mm d>16 mm 400 830 1040 1220 240 640 940 1100 240 660 940 1100 225 580 830 970 225 600 830 970

1px1 (MOLY)V 0.18 AS RECEIVED 0.20 AS RECEIVED OR LIGHTLY OILED & LOCTITE 771 0.13 BOWMAN ANTI-SEIZE 0.12 CADMIUM PLATED 0.17 CADMIUM PLATED (DEGREASED) 0.20 CADMIUM PLATED (LIGHTLY OILED) 0.14 CADMIUM PLATED (LIGHTLY OILED & LOCTITE 243) 0.13 CLEAN, NONPLATED, AS RECEIVED 0.20 COPPER BASED ANTI-SEIZE 0.16 DEGREASED & LOCTITE 243 0.20 DRY 0.30 EXPOSED TO ELEMENTS, BEGINNING TO OXIDISE0.30 GALVANISED (DEGREASED) 0.42 GALVANISED (LIGHTLY OILED) 0.22 GENERAL MACHINE OIL 0.20 GREASE 0.16 GREASE (HEAVY) 0.14 HOT DIPPED GALVANISED 0.25 INORGANIC SILICATE (IOZ) 0.17 LIGHTLY OILED 0.20 LIGHTLY OILED & LOCTITE 243 0.14 LOCTITE MOLY PASTE 0.11 LOW FRICTION OIL 0.15 MOLYBDENUM DISULPHIDE BASED GREASE 0.14 MOLYBOND GA50 0.14 MOLYKOTE 0.18 MOLYKOTE P74 0.14 NICKEL BASED ANTI-SEIZE 0.15 NEVER-SEIZE (PASTE) 0.17 NONPLATED, BLACK FINISH 0.30 PHOSPHATED (LIGHTLY OILED) 0.14 PHOSPHATED (LIGHTLY OILED & LOCTITE 243) 0.11 PHOSPHATED (DEGREASED) 0.24 PHOSPHATED (DEGREASED & LOCTITE 243) 0.14 SOLID PTFE FILM 0.12 TEFLON 7630 0.09 WAXED 0.10 XYLAN 0.10 ZINC PLATED 0.22

ULTIMATE TENSILE STRENGTH OF THE NUT M

LENGTH OF THREAD ENGAGEMENT REQUIRED TO DEVELOP FULL STRENGTH:

LENGTH OF THREAD ENGAGEMENT REQ'D TO DEVELOP FU

LENGTH OF THREAD ENGAGEMENT REQUIRED TO YIELD THREAD AT FULL STRE

LENGTH OF THREAD ENGAGEMENT REQ'D TO DEVELOP FU

#N/A #N/A

#N/A #N/A

#N/A

#N/A #N/A

#N/A

ZINC PLATED (DRY) ZINC PLATED (DEGREASED) ZINC PLATED (DEGREASED & LOCTITE 243) ZINC PLATED (LIGHTLY OILED) ZINC PLATED (LIGHTLY OILED & LOCTITE 243) 0

0.29 0.14 0.15 0.18 0.16 #N/A

LENGTH OF THREAD ENGAGEMENT REQUIRED TO YIELD THREAD AT FULL S SELECTED LENGTH OF THREAD ENGAGEMENT

SELECTED LENGTH OF THREAD EN

RECOMMENDED BOLT TORQUE

SELECTEDED BOLT TORQUE

NUT PLATE MECHANICAL PROPERTIES BOLT STANDARD = BOLT PROPERTY CLASS = TENSILE STRENGTH OF THE BOLT MATERIAL, Sst = YIELD STRESS OF THE BOLT MATERIAL = 0.0 0.0 #N/A MPa #N/A MPa 0 0 mm MPa MPa 1 MATERIAL 2 ULTIMATE TENSILE STRESS (MPa) 300 410 430 450 480 #N/A 430 460 490 3 4 5 6 7 8 YIELD STRESS (MPa)

40 50 80 40 50 80 50 80 50 80 50 80 50 50 80 50 80 50