METHODS FOR SYNTHESIS OF CNT

-

Upload

anusree1993 -

Category

Education

-

view

878 -

download

2

Transcript of METHODS FOR SYNTHESIS OF CNT

CARBON NANO TUBES

1CARBON NANO TUBES

PREPARATION – METHODS

ANUSREE

CBPST,KOCHI

TYPES OF CARBON NANO TUBES: Single walled CNT (SWCNT)

Multi walled CNT (MWCNT)

Can be metallic or semi conducting

single walled -Most single-walled nanotubes (SWNTs) have a diameter of close to 1

nanometer,with a tube length that can be many millions of time longer -The structure of a SWNTs can be conceptualized by wrapping a one-

atom-thick layer of graphite called graphene in to a seamless cylinder

multi walled

• Multi-walled nanotubes (MWNTs) consist of multiple rolled layer( concentric tubes) of graphene

• The way the graphene sheet is wrapped is represented by a pair of indices (n,m) called the chiral vector.

• The integers n and m denote the number of unit vectors along two directions in the honeycomb crystal lattice of graphene

• If m = 0, the nanotubes are called "zigzag". If n = m, the nanotubes are called "armchair". Otherwise, they are called "chiral".

CNT: Rolling-up a graphene sheet to form a tube

Schematic of a CNT

SEMimage of CNT

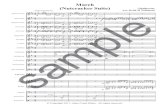

CNT Synthesis Methods Overview

1 Arc discharge synthesis2 Laser ablation synthesis3 Thermal synthesis

3.1 Chemical vapor deposition3.2 High-pressure carbon monoxide

synthesis3.3 Flame synthesis

4 PECVD synthesis

Arc Discharge Method:

3 Electric-Arc Method – Experimental Devices

Sketch of an electric arc reactor. It consists of a cylinder of about 30 cm in diameter and about 1m in height.

After the triggering of the arc between two electrodes, a plasma is formed consisting of the mixture of carbon vapor, the rare inert gas (helium or argon), and the vapors of catalysts. The vaporization is the consequence of the energy transfer from the arc to the anode made of graphite doped with catalysts.

ARC DISCHARGE•CNT production requires 3 elements ,

I. Carbon feedII. Metal catalystIII. Heata) Two Graphite electrodes placed in an inert Helium

atmosphere .b) When DC current is passed anode is consumed and material

forms on cathode.c) For SWNT mixed metal catalyst is inserted into anoded) Pure iron catalyst + Hydrogen-inert gas mixture gives 20 to

30cm long tube.e) The nanotubes were initially discovered using this technique, it

has been the most widely-used method of nanotube synthesis.

Arc evaporation technique involves evaporation of graphite anode rod and condensation of the deposit on the cathode rod under inert atmosphere.

A plasma is achieved by making a gas to conduct electricity by providing a potential difference across two electrodes

Electrodes are made of conducting materials In arc discharge method, two high purity graphite

electrodes as anode and cathode are held a short distance apart under a helium atmosphere.

Inert atmosphere/Gas

Inert gas is meant for cooling / condensation of the sample.

The chamber must be connected both to a vacuum line with a diffusion pump and to helium supply.

Important parameters of gas

• Pressure Material 1000 torr Soot/ Carbon onions 500 torr Carbon nanotubes 100 torr Fullerenes• 20 torr Amorphous carbon/soot Therefore pressure & type of inert gas used

determines the structure of carbons to be obtained.

Electrodes:In arc evaporation method, graphite rods are

used as electrodes.Graphite rods with 99.99% purity are used.Major impurities in graphite are sulphur atoms

as Sulphur changes the morphology of CNTs.The anode is a long rod of 6mm diameter & the

cathode is a short rod of 9mm diameter

Cooling of ElectrodeEfficient cooling of the electrodes & the chamber

are essential to produce good quality nanotubes and also to avoid excessive sintering.

Without proper cooling-sintering occurs-with a hard deposit of mass

With proper cooling-sintering does not occurs- forms a uniform deposit i.e., Homogeneous deposit with aligned bundles of nanotubes.

Current & VoltageDC power supply is given in the range of 50-100mA

and the discharge voltage is between 20 – 50 V.

DISTANCE BETWEEN ELECTRODESThe position of the anode can be adjustable from outside the chamber.Distance between the electrodes must be constant to obtain a stable current.The two electrodes are maintained at constant distance for obtaining CNTsWhen two electrodes are in contact / not at a particular distance - fullerenes can be formed.

ARC DIS CHARGE PROCESS• It is the most common and perhaps easiest way to produce CNTs, as it

is rather simple.• However, it is a technique that produces a complex mixture of

components, and requires further purification - to separate the CNTs from the soot and the residual catalytic metals present in the crude product.

• This method creates CNTs through arc-vaporization of two carbon rods placed end to end, separated by approximately 1mm, in an enclosure that is usually filled with inert gas at low pressure.

• A direct current of 50 to 100A, driven by a potential difference of approximately 20 V, creates a high temperature discharge between the two electrodes.

• The discharge vaporizes the surface of one of the carbon electrodes, and forms a small rod-shaped deposit on the other electrode.

• Producing CNTs in high yield depends on the uniformity of the plasma arc, and the temperature of the deposit forming on the carbon electrode.

Arc Discharge Method Parameters of SWNTs:

In the arc discharge production method sulfur functions as a SWNTs growth promoter and surfactant when added together with Ni/Fe/Co, Ni/Co, Ni/Y/Fe or Ni/Ce/Fe catalysts into the anode.

The metal-sulfur interactions change surface tension and melting point of small droplets of metals. This can support the creation of SWNTs for metals which in pure form catalyze badly.

The highest yield of web product containing the smallest concentration of metals was obtained for the sample C where the composition of the anode is Fe:Y:S:C at6.6%:1.1%:1.6%:90.7%.

SEM images of the samples which were synthesized (a) in an air atmosphere at 300 Torr and (b) in the helium atmosphere at 500 Torr

SEM images of MWNT’s produced by arc discharge (Kunsan National Univ)

Synthesis of Carbon Nanotube1 Laser Ablation – Experimental Devices

- graphite pellet containing the catalyst put in an inert gas filled quartz tube; -oven maintained at a temperature of 1,200 ◦C;-energy of the laser beam focused on the pellet;-vaporize and sublime the graphiteSketch of an early laser vaporization apparatus

The carbon species are there after deposited as soot in different regions: water-cooled copper collector, quartz tube walls.

2 Synthesis with CO2 laser

Fig. 3.10 Sketch of a synthesis reactor with a continuous CO2 laser device

Vaporization of a target at a fixed temperature by a continuous CO2 laser beam (λ = 10.6μm). The power can be varied from 100Wto 1,600 W.

The synthesis yield is controlled by three parameters: the cooling rate of the medium where the active, secondary catalyst particles are formed, the residence time, and the temperature (in the 1,000–2,100K range) at which SWNTs nucleate and grow.

Laser ablation process Another method to grow SWNTs using laser ablation was demonstrated

in 1996 by Smalley's group and has prompted a lot of interest. The synthesis could be carried out in a horizontal flow tube under a flow

of inert gas at controlled pressure. In the laser ablation process, a pulsed laser vaporizes a graphite target in

a high-temperature reactor while an inert gas is bled into the chamber. Nanotubes develop on the cooler surfaces of the reactor as the

vaporized carbon condenses. A water-cooled surface may be included in the system to collect the

nanotubes. The laser ablation method yields around 70% and produces primarily

single-walled carbon nanotubes with a controllable diameter determined by the reaction temperature.

it is more expensive than either arc discharge or chemical vapor deposition.

Chemical Vapor Deposition

• Carbon is in the gas phase• Energy source transfers

energy to carbon molecule• Common Carbon Gases

– Methane– Carbon monoxide– Acetylene (C2H2)

http://neurophilosophy.files.wordpress.com/2006/08/multiwall-large.jpg

Chemical Vapor Deposition

• Carbon is in the gas phase• Energy source transfers energy to

carbon molecule• Usually a silicon plate coated with

iron particles is the substrate.• Common Carbon Gases

– Methane– Carbon monoxide– Acetylene

Chemical Vapor Deposition• After energy transfer, the

carbon molecule binds to the substrate

• Temperature between ~1300⁰F• Carbon nanotubes stick to each

other due to Vander walls force.• When tubes are extracted , cling

on to each other and pull each other out of substrate

• Yield is usually about 30%• One of the most common

methods of carbon nanotube synthesis

Chemical vapor deposition (cvd): During CVD, a substrate is prepared with a layer of metal catalyst articles, most

commonly nickel, cobalt, iron, or a combination. The diameters of the nanotubes that are to be grown are related to the size of

the metal particles. The substrate is heated to approximately 700°c. To initiate the growth of nanotubes, two gases are bled into the reactor: a

process gas (such as ammonia, nitrogen or hydrogen) and a carbon-containing gas (such as acetylene, ethylene, ethanol or methane).

Nanotubes grow at the sites of the metal catalyst; The carbon-containing gas is broken apart at the surface of the catalyst

particle, and the carbon is transported to the edges of the particle, where it forms the nanotubes.

Chemical Vapor Deposition

Advantages

Disadvantages

• Easy to increase scale to industrial production

• Large length• Simple to perform• Pure product

http://endomoribu.shinshu-u.ac.jp/research/cnt/images/cat_cnt.jpg

• Defects are common

Arc Discharge Method Chemical Vapor Deposition Laser Ablation (Vaporization)

Connect two graphite rods to a power supply, place them

millimeters apart, and throw switch. At 100 amps, carbon

vaporizes in a hot plasma.

Place substrate in oven, heat to 600 C, and slowly add a carbon-bearing gas such as

methane. As gas decomposes it frees up carbon atoms,

which recombine in the form of NTS

Blast graphite with intense laser pulses; use the laser

pulses rather than electricity to generate carbon gas from

which the NTS form; try various conditions until hit on one that produces prodigious

amounts of SWNTS

Can produce SWNT and MWNTs with few structural

defects

Easiest to scale to industrial production; long length

Primarily SWNTS, with a large diameter range that can be

controlled by varying the reaction temperature

Tubes tend to be short with random sizes and directions

NTS are usually MWNTS and often riddled with defects

By far the most costly, because requires expensive lasers

References:

http://en.wikipedia.org/wiki/Carbon_nanotube http://www.nanocyl.com/en/CNT-Expertise-Centre/Carbon-N

anotubes http://www.sciencedaily.com/articles/c/carbon_nanotube.ht

m https://www.youtube.com/watch?v=B4VTfgaKLAM&hd=1 http://www.azonano.com/article.aspx?ArticleID=1561

Thanks for your listening…