METALNI I NEMETALNI MATERIJALI proizvodnja – … · The precipitation kinetics of rapidly...

Transcript of METALNI I NEMETALNI MATERIJALI proizvodnja – … · The precipitation kinetics of rapidly...

Univerzitet u Zenici University of Zenica

Bosnia and Herzegovina FAKULTET ZA METALURGIJU I MATERIJALE

FACULTY OF METALLURGY AND MATERIALS SCIENCE

VIII Naučno/stručni simpozijum sa međunarodnim učešćem

8th Scientific/Research Symposium

with International Participation

METALNI I NEMETALNI MATERIJALI proizvodnja – osobine – primjena

METALLIC AND NONMETALLIC MATERIALS

production – properties – application

KNJIGA ABSTRAKTA sa elektronskim izdanjem Zbornika radova BOOK OF ABSTRACTS with electronic edition of Proceedings

Zenica, April 2010.

UREDNIK/EDITOR Dr Sulejman Muhamedagić IZDAVAČ/PUBLISHER Univerzitet u Zenici Organizaciona jedinica Fakultet za metalurgiju i materijale Travnička cesta 1, 72000 Zenica Tel: ++ 387 401 831, 402 832, Fax: ++ 387 406 903 KOMPJUTERSKA OBRADA TEKSTA TECHNICAL ASSISTANCE AND DTP Diana Ćubela Almaida Gigović-Gekić Hasan Avdušinović Adnan Mujkanović ŠTAMPA/PRINTED BY EURO COPY M.S. Serdarevića 27, Zenica TIRAŽ/ISSUE: 120 primjeraka/copies

VIII Naučno/stručni simpozijum sa međunarodnim učešćem „Metalni i nemetalni materijali“, Zenica, BiH, 27. – 28. april 2010.

ORGANIZACIONI ODBOR / ORGANIZING COMMITTEE

Dr Sulejman Muhamedagić, President

Dr Hasan Avdušinović, secretary Mr Almaida Gigović-Gekić, technical secretary

Mr Adnan Mujkanović, technical secretary Dr Fuad Begovac

Dr Jusuf Duraković Dr Diana Ćubela

Dr Marina Jovanović Dr Ilhan Bušatlić Larisa Omerović

NAUČNI ODBOR

INTERNATIONAL SCIENTIFIC/RESEARCH COMMITTEE

Dr Anžel Ivan, SI Dr Begovac Fuad, BA Dr Beroš Ana, BA Dr Bikić Suada, BA Dr Bikić Farzet, BA Dr Bizjak Milan, SI Dr Brdarević Safet, BA Dr Burzić Zijah, SP Dr Bušatlić Ilhan, BA Dr Chumbley Scot, US Dr Ćubela Diana, BA Dr Delijić Kemal, CG Dr Dolinšek Slavko, SI Dr Drljević Sulejman, BA Dr Duraković Jusuf, BA Dr Durman Mehmed, TR Dr Džonlagić Nusreta, BA Dr Ekinović Sabahudin, BA Dr Fidančevska Emilija, MK Dr Gojić Mirko, HR Dr Hessling Goetz, DE, Dr Hodolič Janko, SP

Dr Holger Frenz, DE Dr Ibrahimefendić Salih, BA Dr Ivanković Hrvoje, HR Dr Jovanović Marina, BA Dr Kosec Borut, SI Dr Kurtović Azra, BA Dr Lamut Jakob, SI Dr Lazić Dragica, BA Dr Mahmutović Aida, BA Dr Mirjanić Dragoljub, BA Dr Mamuzić Ilija, HR Dr Muhamedagić Sulejman, BA Dr Mujezinović Aziz, BA Dr Oruč Mirsada, BA Dr Ostojić Milinko, BA Dr Pašalić Zakir, BA Dr Pašić Sead, BA Dr Pašić Zijad, BA Dr Petković Darko, BA Dr Petrovski Petar, BA Dr Ranogajec Jonjaua, SP Dr Rizvanović Mirsada, BA

Dr Rusell Alen, US Dr Salihović Senaid, BA Dr Senk Dieter, DE Dr Spužić Sead, AU Dr Sredojević Jovan, BA Dr Stanojlović Rodoljub, SP Dr Subašić Kemal, BA Dr Šestić Mediha, BA Dr Šetrajčić Jovan, BA Dr Tomašević Sreto, BA Dr Uzunović Faik, BA Dr Vitez Ivan, HR Dr Volkov-Husović Tatjana, SP Dr Vukojević Dušan, BA Dr Yalcin Senay, TR Dr Zelić Jelica, HR Dr Zlokolica Miodrag, SP Dr Žigić Izet, BA Dr Živković Dragana, BA Dr Živković Živan, BA

i

VIII Naučno stručni simpozijum sa međunarodnim učešćem „Metalni i nemetalni materijali“, Zenica, BiH, 27. – 28. april 2010.

SADRŽAJ/CONTENTS

stranica/page

UVODNA PREDAVANJA/KEYNOTES PAPERS 1. Metal expansion penetration on casting components of grey cast iron

Izudin Dugić, Attila Diószegi, Ingvar L Svensson ...................................................... 3

2. Porous ceramic materials Emilija Fidančevska................................................................................................. 13

SEKCIJA METALNI MATERIJALI/SESSION METALLIC MATERIALS 1. Prednost proizvodnje visokokvalitetnih bakrenaca u topionicama koje prerađuju

sulfidne koncentrate bakra Lj. Misic, T. Apostolovski-Trujic, S. Ivanovic.......................................................... 23

2. Review of thermodynamic simulation models in copper matte production -The impurities behaviour analysis E. D. Požega, L. D, Gomidželović, D. T. Živković, V. K. Trujić .............................. 24

3. Dobijanje srebra i bakra visoke čistoće iz istrošene posrebrene bakarne žice S. Dimitrijević, S. Dragulović, S. Ivanović, D. Marković, R. Todorović ................ 25

4. Experimental investigation and thermodynamic predicting of phase equilibria in Ga-GeSb0.855 system A. Kostov, D. Živković, D. Manasijević, D. Minić, Ž. Živković ............................... 26

5. Experimental investigation and thermodynamic calculation in Pb-Zn-Ag system D. Živković, D. Minić, D. Manasijević, A. Mitovski, Lj. Balanović, Ž. Živković ..... 27

6. Thermal analysis of the ternary system Bi-Cu-Sn D. Manasijević, D. Minić, D. Živković, N. Talijan, A. Grujić, S. Marjanović......... 28

7. Numerical study of the chill wheel cooling during continuous free jet melt-spinning B. Karpe, B. Kosec, M. Bizjak, T. Kolenko .............................................................. 29

8. The precipitation kinetics of rapidly solidified Al based alloys M. Bizjak, G. Dražič, L. Kosec, B. Karpe ................................................................ 30

9. Microstructure and characterisation of rapidly solidified Au-La ribbons T. Zupančič Hartner, R. Rudolf, B. Kušić, K. Mahrabi, I. Anžel ............................ 31

10. Uticaj sadržaja δ-ferita na mehanička svojstva austenitnog nehrđajućeg čelika A. Gigović-Gekić, M. Oruč ...................................................................................... 32

11. Faktori koji utiču na toplootpornost legure na bazi nikla – IN.100 R. Todorović, A. Kostov, Lj. Todorović ................................................................... 33

12. Mikrostruktura, mehaničke i električne osobine legura ternarnog Bi-Cu-In sistema A Aljilji, D. Minić, V. Čosović, M.Kolarević, D. Manasijević, D. Živković............. 34

13. Mikrostruktura, mehaničke i električne osobine legura ternarnog Cu-In-Sb sistema D. Minić, A. Aljilji, J. Stajić-Trošić, D. Manasijević, D. Živković .......................... 35

14. Uticaj aluminija i titana na temperaturu rekristalizacije Superlegure Nimonic 80A O. Beganović,B. Muminović, B.Fakić, F. Uzunović ................................................ 36

15. Recrystallization temperatures of cold deformed Au- 0,5La alloy B. Kušić, T. Zupančič Hartner, I. Anžel................................................................... 37

16. Uticaj vremena izotermalnog poboljšanja na mikrostrukturne karakteristike uzoraka od austemperovanog nodularnog liva H. Avdušinoviæ, S. Tomašević. F. Begovac.............................................................. 38

17. Inductive heating and quenching of planetary shafts for the automotive industry B. Kosec, B. Karpe, A. Nagode, M. Ličen, G. Kosec ............................................... 39

18. Eksperimentalna ispitivanja tvrdoće zavarenog spoja čelika Fadil Islamović, Fatka Kulenović, Dženana Gačo, Esad Bajramović .................... 40

19. Procena preostalog veka trajanja materijala bubnja kotla sa aspekta mikrostrukture Z. Karastojković, R. Popović, Z. Kovačević, Z. Janjušević .................................... 41

20. Kontrola atmosfere u pećima za termičku obradu J. Duraković, D. Ćubela, A. Gigović-Gekić............................................................. 42

21. Modifikovani bakar: ekološka alternativa za Cu-Cd leguru A. Ivanovic, S. Dimitrijevic, V. Marjanovic, V. Cvetković - Stamenkovic ............... 43

22. Uticaj indijuma na osobine nekih bezolovnih lemnih legura A. Milosavljević, D. Živković, N. Talijan, A. Grujić ................................................ 44

23. Korozija hirurških instrumenata u dezinfekcionim sredstvima M. Cacan, S. Islamović, S. Gojak, S. Gutić.............................................................. 45

24. Uticaj polianilinske prevlake na korozione karakteristike visokolegiranog nehrđajućeg čelika M. Cacan, F. Lutvić, S. Gutić, S. Islamović, S. Gojak ............................................. 46

ii

25. Uticaj koncentracije 1-fenil 5-merkapto tetrazola na elektrohemijsko ponašanje mesinga u rastvoru boraksa Z. Ljubomirović, M. Antonijević, M. Petrović, M. Radovanović ............................. 47

26. Plemeniti metali kao materijali za električne kontakte V. Marjanović, V. Cvetković-Stamenković, A. Ivanović........................................... 48

27. Čelici za poboljšavanje prema europskim standardima I. Vitez, V. Marušić, D. Krumes, A. Milinović ......................................................... 49

28. Savremeni trendovi u proizvodnji nehrđajućih čelika Š. Žuna ..................................................................................................................... 50

29. Prilog strategiji razvoja novih materijala u BiH M. Oruč, M. Rimac, N. Šehić-Mušić ........................................................................ 51

SEKCIJA NEMETALNI MATERIJALI /SESSION NONMETALLIC MATERIALS 1. Uloga karakteristika stijenskih materijala u metodološkim tokovima izbora

drobilica i mlinova I. Šišić, N. Alić ......................................................................................................... 55

2. Ispitivanje i karakterizacija glina Srednje Bosne M. Jovanović, J. Zelić .............................................................................................. 56

3. Ispitivanje kvaliteta gline i mogućnosti njene eksploatacije sa lokaliteta „Ulice“ D.Lazić, J.Penavin-Škundrić, S.Sladojević, Lj.Vasiljević, R. Smiljanić, D.Kešelj, D. Smiljanić.............................................................................................................. 57

4. Potencijalnost ležišta dolomita „Tunel“ kod Konjica i mogućnosti njihove primjene M. Operta, N. Škripić, S. Salihović .......................................................................... 58

5. Keramičko-tehnološke osobine opekarske gline „Čavka“ A. Šeper, A. Kobilica, M. Jovanović ........................................................................ 59

6. Mineraloško-petrografska i tehnološka svojstva gline ležišta „Golo brdo“ kod Visokog A. Hamzabegović, M. Stević, Dž. Alijagić ............................................................... 60

7. Geološka građa, potencijalnost i kvalitativne odlike glina ležišta “Kečkovac” po bušotini B-9 A. Baraković, P. C. Katanić, D. Baraković.............................................................. 61

8. Activated sintering of magnesium oxide from seawater with TiO2 addition V. Martinac, T. Maleš, M. Labor ............................................................................. 62

iii

9. Promjena energetskih karakteristika aktivne mase olovnih baterija dodatkom H3PO4 u elektroit N. Avdić .................................................................................................................... 63

10. Kemijska reaktivnost i vezivanje hidrauličnog vapna praćeni procesima njegove hidratacije P. Krolo, T. Kosor, P. Dabić.................................................................................... 64

11. Optimizacija klasiranja dekompozirane suspenzije natrijum aluminatnog rastvora R. Smiljanić, D. Lazić, D. Smiljanić, Ž. Živković..................................................... 65

12. Ispitivanje adsorpcionih mogućnosti CaFeO3 perovskita S. Sladojević, J. Penavin-Škundrić, D. Lazić, B. Škundrić, D. Bodroža, S.Zeljković66

13. Uticaj površinski aktivne materije – PAM na adsorpcione osobine Mordenita Z. Levi, D. Bodroža, S. Sladojević, D. Lazić, J. Penavin-Škundrić, P. Dugić ......... 67

14. The effect of MgO addition on the synthesis of mullite from rice husk ash and technical alumina R. Adziski, E. Fidancevska, D.Milovski ................................................................... 68

15. Fabrication of magnezite-chromite refractory using different binders D. Milovski, V. Jovanov, R. Adziski, E. Fidancevska............................................... 69

16. Primjena ekspandiranog polistirena za proizvodnju izolacionih i ambalažnih materijala i upravljanje nastalim otpadom P. Dugić, Z. Petrović, V. Aleksić, V. Mićić, M. Perušić .......................................... 70

17. Internal stresses in polymeric materials based on aminoplast N. Vukas, I.Horman ................................................................................................. 71

18. Ispitivanje uticaja koncentracije SiO2 i temperature precipitacije na deaglomerabilnost precipitiranog SiO2 metodom raspršavanja laserske svjetlosti A. Mujkanović, P. Petrovski, Lj. Vasiljević, G. Ostojić ........................................... 72

19. Ispitivanje uticaja dodatka elektrofilterskog pepela na proces hidratacije mjerenjem specifične električne provodnosti cementnih pasti I. Bušatlić, P. Dabić , M. Rizvanović, N. Bušatlić .................................................. 73

20. Geopolymeric binders prepared by using the Croatian coal-fly ash J. Zelić , D. Jozić, M. Nikola Mužek , D. Krpan-Lisica ........................................... 74

21. Kinetika hidratacije PC i svojstva nastalog cementnog kompozita uz dodatak zeolitnog otpada koji sadrži Zn2+-ione P. Krolo, R. Bulat, P. Dabić .................................................................................... 75

22. Crveni mulj kao baza za sintezu željezovitih cemenata J. Mikić, M. Sudar.................................................................................................... 76

iv

23. Uticaj silicijske prašine na osobine cementa tipa Cem II/B – W 42,5N u Tvornici cementa Kakanj N. Merdic, Z. Pašić, N.Haračić, I. Bušatlić ............................................................. 77

24. Korištenje pećne prašine za proizvodnju cementa u Tvornici cementa Kakanj N. Merdic, Z. Pašić, N. Haračić, I. Bušatlić ............................................................ 78

25. Karakterizacija EFP iz TE Gacko i mogućnosti njegove primjene P.Petrovski, I.Bušatlić , S.Govedarica i D.Miloševic, N.Bušatlić .......................... 79

26. Uticaj agregata, za proizvodnju asfalta, na hrapavost kolovoznih konstrukcija E. Softić, N. Alić, A. Softić ..................................................................................... 80

27. Primjena DPV i DPASV metoda kod određivanja cinka F. Bikić, M. Rizvanović ............................................................................................ 81

28. Kvalitativna analiza motornog ulja FT-IR spektrofotometrijom F. Bikić ..................................................................................................................... 82

29. Konduktometrijska metoda određivanja prihvatljivog dodatka otpadnog mulja i zasićenog zeolita iz pogona pocinčavanja u cementu P. Dabić, P. Krolo, D. Barbir, M. Maretić ............................................................. 83

30. Primjena kalibracionih etalona u XRF (x-ray fluorescence) spektrometrijskoj analizi N.Haračić, P. Petrovski, M. Rizvanović, N. Merdić, I. Bušatlić ............................. 84

31. On-line kontrola kvaliteta pomoću PGNAA analizatora i XRF spektrometra N.Haračić, P. Petrovski, M. Rizvanović, N. Merdić, I. Bušatlić ............................. 85

32. Implementation of image analysis of surface on thermal shock and cavitation resistance testing of low cement high alumina castable S. Martinovic, M. Dojcinovic, J. Majstorovic, T. Volkov-Husovic .......................... 86

33. Stanja elementarnih pobuđenja u superrešetkama kristalnih organskih materijala S.M.Vučenović, S.Pelemiš, B.Škipina, J.P.Šetrajčić ................................................ 87

34. Uticaj mehaničkih karakteristika materijala na stabilnost i sigurnost konstrukcije zidanih sakralnih tornjeva A. Čaušević .............................................................................................................. 88

35. Vakumirana ostakljenja A. Salihbegović ........................................................................................................ 89

36. Energetska učinkovitost u zgradarstvu uz primjenu domaćih materijala N. Rustempašić......................................................................................................... 90

v

SEKCIJA ZAŠTITA RADNE I ŽIVOTNE SREDINE I ODRŽIVI RAZVOJ /SESSION ENVIROMENT PROTECTION AND SUSTAINABLE DEVELOPMENT 1. Tehnologija prerade čeličanske troske u ArcelorMittal Zenica

S. Muhamedagić, Ć.Talam, ..................................................................................... 93

2. Menadžment recikliranja u procesu proizvodnje gvožđa i čelika A. Mahmutović, L. Torlaković, S. Vilić, F. Vardo, A. Jusufović, E. Merdić, S. Omić94

3. Japanski model održivog razvoja D. Ćubela ................................................................................................................. 95

4. Korišćenje sirovog drvnog otpada kao goriva u tehnološke svrhe V. Đukić.................................................................................................................... 96

5. The GAP analysis of the wood processing sector in Bosnia and Herzegovina I. Alagić.................................................................................................................... 97

6. Rješavanje okolinskih problema u eksploataciji i pripremi stijenskih masa dijabaza na površinskim kopovima D. Vejzović, N.Vejzović, A. Mahmutović, ............................................................... 98

7. Upravljanje građevinskim otpadom u skladu sa EU standardima N. Rustempašić......................................................................................................... 99

8. Environmental labeling of products with eco-labels type I I. Budak, B. Kosec, M. Soković, J. Hodolič, Š. Goletić.......................................... 100

9. Štetni efekti saobraćaja na životnu sredinu V. Đukić.................................................................................................................. 101

vi

VIII Naučno/stručni simpozij sa međunarodnim učešćem „METALNI I NEMETALNI MATERIJALI“ Zenica, BiH, 27-28. april 2010.

EKSPANZIJSKA PENETRACIJA METALA NA ODLIVCIMA OD SIVOG LIJEVA

METAL EXPANSION PENETRATION ON CASTING COMPONENTS

OF GREY CAST IRON

Izudin Dugic*, Linnaeus University, School of Engineering, Växjö, Sweden, Attila Diószegi and Ingvar L Svensson, Jönköping University, School of

Engineering/Component Technology and Casting, Jönköping

*Corresponding author: [email protected] Key words: Grey cast iron, solidification, graphite expansion, casting simulation, inoculation, metal expansion penetration, eutectic cell size, primary austenite. ABSTRACT Cast irons are a family of sophisticated design materials with precise engineering properties.

In some grey cast iron components which are cast in sand moulds, the metal sometimes penetrates into

the mould producing defects which cause difficulty when cleaning the components. Metal penetration

is a casting surface condition resulting from either physical, mechanical and/or thermo chemical

reactions or a combination of these at the mould–metal interface.

The present work will summarize research efforts to understand the mechanisms of metal expansion

penetration performed in collaboration with Swedish foundries. The main parts of the experimental

works are based on some casting components.

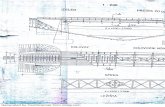

1. INTRODUCTION One of the most important factors in the production of cast iron is the production of cast components without any defects. In some grey cast iron components which are cast in sand moulds, the metal sometimes penetrates into the mould producing difficulties in cleaning the components. Penetration is often so severe that castings are beyond the point of economical rework and must be scrapped. Machining of castings that exhibit this defect is often difficult and may result in excessive tool wear. Metal penetration is a casting surface condition resulting from various physical, mechanical and/or thermo–chemical reactions either singly or in combination at the mould–metal interface. The metal penetrates into the voids between the sand grains to various depths without displacing the grains, thus yielding a phase of sand grains surrounded by metal and frequently by mould-metal reaction products. The general definition for metal penetration, accepted by the foundry industry, as proposed by Draper and Gaindar [1], is the condition in which cast metals has entered the inter–granular space of the moulding material, up to and beyond the first layer of sand grains. In the published literature, numerous names have been given to the various types of penetration. During eutectic solidification, cast iron solidifying with an austenite–graphite eutectic has been demonstrated to expand, significantly. The expanding metal exerts a significant pressure on the mould walls. If the mould is rigid, and if the metal cannot be pushed back in the riser or the gates because they have solidified, this pressure results in metal penetration, called expansion penetration. This type of penetration was first identified by Levelink and Julien [2] who called it exudation penetration. They indicated that expansion occurring during eutectic solidification may result in exudation of eutectic in locations where a solidifying metal shell does not obstruct it. This is especially so at “hot spots”, such as “L”, “T” and “Y”, where the metal is still liquid at the time expansion occurs due to eutectic solidification. Eutectic exudation penetration appears to occur mostly in grey cast iron and very seldom in ductile iron. Expansion penetration depends upon the metallurgical characteristics of the solidifying metals and alloys. Metal penetrations have been discussed by many authors [3,4,5,8] and lot of works have been done in the industries to understand how to avoid metal penetration. To give an increased knowledge of the metal penetration mechanism and the influence from different factors, a series of test castings was performed at the different foundries. 2. INFLUENCE OF CHEMICAL COMPOSITION The influence of chemical composition has been discussed by many authors [6] and suggestions for improvements have been made. In order to analyze how the chemical composition of the casting iron have an influence on metal expansion penetration, a series of test castings were made on casting components in a production scale. The experiments work was carried out at the foundry of ITT Flygt AB with a Seiatsu production line. The casting component studied was “Styrklo” (figure 1a) and eight castings were mounted on the pattern plate (figure 1b). The weight of each “Styrklo” is 7.8 kg and the total casting weight is 78 kg. The castings were made in green sand moulds with a typical moulding hardness of 80 to 85 GF. Melting was done in a high frequency furnace with a charge composition of 40 % recycled metal, 20 % pig iron and 40 % steel. After melting, the melt is transported in a 1 ton pouring

ladle to a production line. The casting temperature was 1430 °C with a variation of ±10 °C. The chemical composition of the base melt for each casting experiment is shown in table 1. Table 1. The chemical composition of the base melts. Cequ = % C + % Si / 4.

Element in wt % Experi-ment C Si Mn P S Cr Cu Cequ A 3.45 1.78 0.66 0.082 0.091 0.05 0.24 3.895 B 3.41 1.88 0.64 0.084 0.092 0.05 0.24 3.880 C 3.33 2.02 0.62 0.075 0.089 0.04 0.25 3.835 D 3.27 1.99 0.62 0.123 0.087 0.05 0.21 3.767 E 3.30 2.04 0.60 0.102 0.074 0.07 0.26 3.810

The inoculant used in these experiments was of a ferro-silicon-strontium type. The inoculant had a particle size between 1.0 and 6.0 mm and inoculation was made in the stream when pouring the melt from the high frequency furnace to the pouring ladle. The amount of inoculant added was 0.15 % for all experiments, and the time between inoculation and casting in the mould flasks was 2 minutes. After blasting, all casting components were documented by an ocular inspection. The metal penetration often occurs in two places on this casting. These are shown in figure 1a and the places are called “side” and “beneath” respectively. On most castings, other types of surface defects had also formed; e.g. scabs and surface shrinkage. The following parameters have been calculated for each chemical composition: percentage of castings having metal penetration defects and percentage of castings having scab defects. These results are shown in table 2.

Figure 1a. The casting component Figure 1a. The geometry of the casting “Styrklo”. The circles show the areas components – upper part. where surface defects usually occur. The microstructures close to the penetration areas were analysed in an optical microscope. Etching was performed in the following etching solution: 10 g NaOH, 40 g KOH, 10 g C6H3N3O7 and 50 ml H2O. The etching time was 5 minutes at a temperature of 80 °C. In figures 2a and 2b, micrographs are shown of the some microstructures (before and after etching) close to the metal penetration areas.

Table 2. Statistical listing of different surface defects found on the castings.

Experiment Casting defect A B C D E

Metal penetration (%) 100 91.0 16.0 0.0 0.0 Scab (%) 0.0 0.0 50.0 100 85.0

Figure 2a. Experiment A, microstructure Figure 2b. Experiment A, microstructure before etching, (magnification 150 X). after etching, (magnification 150 X). 3. INFLUENCE OF THE INOCULATION AND CASTING TEMPERATURE The primary reason to inoculate [7,9] cast iron is to improve the mechanical properties and machinability of iron castings. It is carried out by adding a material called an inoculant to molten iron for the purpose of establishing nucleation centres (sites) for the precipitation (formation) of graphite. Inoculation in grey cast irons results in an increase in the temperature where the eustenite-flake graphite eutectic forms, most often associated with an increase in the number of nucleation sites for this eutectic. The aims of the experiments were to investigate the effect of inoculants, inoculant amount and casting temperature on the metal expansion penetration in grey cast iron using a same commercial casting component and at the same foundry (ITT Flygt AB). Two series of experiments were done. In the first experimental series, five different inoculants were investigated. The inoculant which gave the best results with regards to (minimum) metal penetration in an earlier investigation was chosen for this study: inoculant H, containing silicon, aluminium and zirconium. The inoculation was made in the stream during pouring the melt from the holding furnace to the pouring ladle. The amounts of inoculant added were 0.05 %, 0.15 % and 0.30 %. The results from an ocular inspection of the castings are summarised in Table 3. Table 3. The chemical composition of the inoculants. Inoculant % Si % Ca % Al % Zr % Mn % Ba % Sr % Ti A 72-78 max 0.1 max 0.5 - - - 0.6-1.0 - B 73-78 0.09 0.48 - - - 0.6-1.0 - D 59-65 1.5-3.0 1.0-1.5 - 9.0-11.0 4.0-6.0 - - E 51-55 1.0 1.0-1.3 - - - - 9.0-11.0H 44-50 2.5-3.5 1.0 1.5-2.0 - - -

After sand blasting, the penetration severity in all castings was investigated by an ocular inspection. The results are given in tables 4 and 5. Table 4. The average casting defects calculated for the first experimental series.

Inoculants A B D E H

Metal penetration in mm2 45.30 97.93 86.08 112.23 22.18 Metal penetration in % 46.03 76.78 59.57 64.58 34.09 Shrinkage in % 3.17 8.93 12.77 4.16 13.63 Table 5. The average casting defects calculated for the second experimental series.

The amount of inoculant and casting temperature 0.05 % 0.15 % 0.30 %

Casting defects 1440°C 1410°C 1390°C 1420°C 1390°C 1370°C 1420°C 1400°C 1370°C Metal pene-tration (mm2)

0 0 0.81 23.16 5.50 1.16 81.12 4.40 0

Metal pene-tration (%)

0 0 3.25 34.37 10.00 3.22 75.00 6.67 0

Bulb (mm2) 0 0 9.84 9.06 12.50 8.06 6.25 22.50 11.72 Bulb (%) 0 0 35.48 31.25 46.66 32.26 25.00 66.67 40.62 Shrinkage (%) 0 0 0 0 0 0 0 0 0 The penetration areas were analysed metallographically in an optical microscope. Etching was performed in “Steads etching solution” (10 g copper chloride, 40 g magnesium chloride, 20 ml hydrochloric acid dissolved in 1000 ml 95 % ethyl alcohol). The etching time was 5 min at room temperature. After etching, the samples were rinsed in ammonium hydroxide to remove the precipitated copper. In figures 3a and 3b, micrographs are shown of the microstructure and eutectic cell size close to the metal penetration using inoculants H and E.

Figure 3a. The microstructure close to the Figure 3b. The microstructure close to the metal metal penetration area, the best case of metal penetration area, the worst case of metal penetration, using inoculant (H). penetration, using inoculant (E).

0.5 mm 0.5 mm

4. SIMULATION OF THE SOLIDIFICATION OF GREY CAST IRON COMPONENTS A series of simulations were performed with the casting simulation program MAGMASOFT® using the add-on module MAGMAiron®, especially developed for cast iron simulation. MAGMASOFT® is designed to simulate heat and fluid flow and optionally simulate stress/strain and microstructure formation phenomena in the casting process. Cast iron simulations require an accurate consideration of the microscopic phase separation, of the melt analysis, and other information such as the type and effect of melt inoculation. The MAGMAiron® module utilises a microscopic kinetic growth model to predict the solidification sequence of cast iron alloys. Before any pattern was built, a simulation of mould filling and solidification supplied basic information for the comprehensive optimisation of casting design and parameters. A series of simulations were performed for a commercial casting component with its gating system. The mould filling sequence and the solidification were considered in the simulations. During the solidification simulation, MAGMASOFT® calculated the heat flow in the casting and the mould and took the effect of feeding and casting shrinkage into account. Some results from the simulation are shown in Figures 4a and 4b. These pictures show the location of the pores. The geometry is clipped in the z- and y-directions. It is relevant to note that the predicted porous areas perfectly match the areas where surface defects occurred in the experiments.

Figure 4a. 3-D result from the simulation Figure 4b. 3-D result from the simulation showing the location of pores. The geometry showing the location of pores. The geometry is clipped in the z-direction. is clipped in the y-direction.

Figure 5a. Results from 3-D simulation of Figure 5b. Results from the 3-D simulation, the liquid fraction, when 5 % liquid in total showing the location of the pores. The geometry remains. The x-ray option is used is clipped in the z-direction.

No. 5 No. 5

A complete mould with 8 components and associated gating system was modelled. In the simulation, the mould filling sequence and the solidification process were considered. In Figure 5a the last areas to solidify are shown using the x-ray option when 5 % liquid remains. In Figure 5b the location of the pores is shown. The geometry is clipped in the z-direction. These areas perfectly match the defect areas found experimentally. 5. THE MECHANISMS OF METAL EXPANSION PENETRATION A cylindrical test cup with an internal core has been designed and optimized to obtain a hot spot at the metal-mould interface, see figure 6a and figure 6b. For optimisation of the test cup geometry the MAGMASOFT® simulation program was used. The diameter of the test cup is 80 mm, and the height is 80 mm. The internal core diameter is 30 mm, and is rounded at the end in contact with the bulk metal with a radius of 15 mm. The experiments were carried out at the Volvo Foundry in Skövde. The melt was poured from a holding furnace to a small ladle holding approximately 30 kg metal. Inoculants were added in the bottom of the ladle before pouring. The liquid metal was immediately poured into the test cup after which the cover containing the thermocouple was placed on top of the cup. Two test cups were poured from each charge. One sample was allowed to cool under normal conditions (as cast) and the other was DAAS-treated. The direct austempering after solidification (DAAS) technique was introduced by Sikora [10] to investigate the macrostructure of grey cast iron. The principle of the DAAS method is that using a special thermal process the austenite phase is retained and keeps the crystalline orientation defined during solidification. This method is very suitable for examination of the macrostructure of austenite grains. The procedure involves shaking out the casting at approximate 950 ºC, transferring the casting into a furnace held at 900 ºC, holding for 30min, quenching in a molten salt bath held at 360 ºC, and holding there for 90min before finally air-cooling to room temperature.

Figure 6a. Test cup for investigation of metal expansion penetration mechanism.

Figure 6b. Solidification time of the test cup.

It has been demonstrated that expansion penetration appears both before and after the columnar to equiaxed transition.The penetration phenomenon before columnar to equiaxed transition is shown in Figure 7a. The investigated microstructure at the metallic interface for this type of penetration is presented in Figure 7b.

Figure 7a. The metallic interface and Figure 7b. Microstructure of the penetrated penetrated metallic strip. strip containing exclusively eutectic phase The penetration phenomenon after columnar to equiaxed transition presents the largest amount of adhered sand grains, Figure 8a. The microstructure at the metallic interface for this type of penetration is presented in Figure 8b.

Figure 8a. Distorted metallic interface Figure 8b. Microstructure of the distorted and penetrated metallic strip. metallic interface. To compare the observations that expansion penetration appears both before and after the columnar to equiaxed transition a series of experiments were done on cylinder head cast in grey cast iron. The cylinder heads, see Figure 9a, studied were prepared on a standard moulding line using green sand as moulding material at the Skövde Foundry of Volvo Truck Component Corporation. The specimens for study were cut out from the areas where metal penetration had occurred. Some of these specimens are shown in figures 9b. The specimens were ground and polished in order to investigate the graphite morphology by optical microscopy. After a first inspection the specimens were he etched in a picric acid-based reagent at 110 ºC in order to investigate the primary austenite and eutectic cells. The microstructure of the casting surface in connection with the penetrated particles for the metal expansion penetration before the columnar to equiaxed transition (Figure 10a) consists of a eutectic strip with graphite lamellas oriented mainly perpendicularly to the mould

surface. This combination of microstructure in the penetrated and the casting surface is identical to that observed by earlier experiments.

Figure 9a. A sectioned cylinder head. Figure 9b. The investigated specimens showing metal expansion penetration. Behind the penetrated areas of eutectic composition there was observed a second type of microstructure in connection to the mould surfaces. This type of microstructure indicates a normal fraction of primary phase behind the casting surface (Figure 10b) and a much less dense primary phase in connection with the casting surface. The normal fraction of primary phases refers to the chemical composition.

Figure 10a. Microstructure of the first Figure 10b. Microstructure at metal-mould group of expansion penetration. interface with sparse fraction primary phase austenite and an anomalous interdendritic phase. 6. CONCLUSIONS These experiments on the castings components showed that carbon and phosphorus levels had an important influence on metal penetration and shrinkage behaviour. Metal penetration decreases when decreasing the carbon content and increasing the phosphorus content. The experiments with different inoculants show that the type and amount of inoculation of grey cast iron will influence the tendency towards metal penetration in areas with late solidification times and where the melt is in contact with the sand mould.

Experiments using different inoculants show that the best results regarding reduced metal penetration have been obtained when using an inoculant which contains silicon, aluminium and zirconium. For this inoculant, the average penetration area was only about 20 % of that which was found using the worst inoculant. The worst cases of metal penetration were obtained using an inoculant containing titanium. A large number of small eutectic cells and a high volume of the small cells were observed, which leads to severe metal penetration. By simulation it is possible to detect the areas where porosities are likely to be formed. Simulation results show that expansion penetration generally occurs in the same regions as shrinkage depending on the freezing rate if the area is close to a surface. The freezing parameters will give a change in the excess or deficiency of the metal versus the precipitation of the graphite, giving rise to either expansion or shrinkage. Cylinder heads have an extremely complex shape with large areas of concave casting surfaces. Investigation of cylinder heads cast under industrial production conditions reveal the same mode of expansion penetration mechanisms as found an experimental test cups cast at the same foundry and under same metallurgical conditions. The metal expansion penetration before and after columnar to equaixed transition is observed to dominate. 7. ACKNOWLEDGMENTS This study is based on experimental work performed in collaboration between Jönköping University, Linnaeus University in Växjö, ITT Flygt AB Foundry and Volvo Powertrain Foundry in Skövde. Both the Universities and the Foundries are warmly acknowledged. 8. REFERENCES

1. A. B. Draper and J. L. Gaindhar, ”Metal penetration–a critical literature review,” AFS Transactions, vol. 85, pp. 163–199, 1977.

2. H. G. Levelink and F. P. M. A. Julien, “Penetration and shrinkage by interaction of solidifying cast iron and casting mould–Part 2”, AFS Cast Metals Research Journal, vol. 9 (2), pp 105-109, 1973.

3. P. J. Thorpe, “Avoidance of metal penetration and sand burn–on in iron castings,” Brit. Foundryman, vol. 64, pp. 38–396, 1971.

4. Kagawa, A; Kiguchi, S; Osada, M, “Volumetric change in freezing cast irons”, Transactions of the Japan Foundrymen's Society. Vol. 14, pp. 18-23. Dec. 1995

5. D.M. Stefanescu, T.S. Piwonka, S. Giese, and A. Lane, “Cast Iron Penetration in Sand Moulds, Part I: Physics of Penetration Defects and Penetration Model”, AFS Transactions, vol. 104, (1996), pp 1233-1248.

6. Srivatsan, T S; Sudarshan, T S, “The influence of phosphorus on shrinkage porosity in cast irons”, Materials Letters. Vol. 41, no. 4, pp. 186-191. Nov. 1999

7. Carl R Loper Jr and R. Gundlach: ‘Inoculation, what is it and how does inoculation work’, International inoculation conference, Illinois, USA, 1998.

8. G. F. Ruff and J. F. Wallace: ‘Effects of solidification structure on the tensile properties of grey iron’, AFS Transactions, 1977, 85, pp. 179-202.

9. A. T. Rushworth: ‘The effect of holding time on various inoculants in flake and nodular graphite irons’, M. Sc. Thesis, Birmingham University, 1965.

10. G.L. Riviera, R.E. Boeri and J.A. Sikora, “Solidification of Gray Cast Iron”, Scripta materialia, Paper 50, pp 331-335, 2004.

8 th Scientific/Research Symposium with International Participation „Metallic and Nonmetallic Materials“ Zenica, B&H, 27-28. April 2010

POROUS CERAMIC MATERIALS

Emilija Fidancevska Ss Cyril and Methodius University, Faculty of Technology and Metallurgy

Ruger Boskovic 16, 1000 Skopje Republic of Macedonia

Keywords: porosity, biomaterials, wastes, glass, glass ceramics

ABSTRACT Creation of porous ceramic materials based on hydroxyapatite, titania and alumina for biomedical application is the first approach of this paper and on the other hand porous materials made of wastes i.e. fly ash and metallurgical slag is the other point which this paper deals with. Different methods for creation of porous structure are discussed manly using polyurethane foam, H2O2 and C-fibers as porogens. 1. INTRODUCTION Recently, there has been an increasing interest in the applications of porous ceramics for variety of applications. Porous ceramics may be classified into four basic structures: (1) tangle fibre networks, (2) closed cell structures, (3) open cell structures, and (4) membranes. The application of these ceramics is obviously determined by their unique structure [1]. Different manufacturing processes for cellular ceramics have been proposed, including replica of polyurethane foam, direct bowing of ceramic suspension, and the use of sacrificial fillers, extrusion or the bonding of fibres [2]. This method allows the direct adjustments of porous characteristics by the amount, size, shape and distribution of the pore-forming agents [1, 3]. Porous ceramics find numerous applications in various engineering fields, including filtration (molten metals, particulate from diesel exhausting gases), radiant burners, catalyst supports, biomedical devices, kiln furniture, reinforcement for metal matrix composites, bioreactors, thermal protection systems, supports for space mirrors, components in solid oxide fuel cells, lightweight sandwich structure, heat exchangers etc. [4]. The present paper deals with the creation of porous materials for biomedical applications and on the other hand the paper presents the usage of wastes (metallurgical slag, fly ash and waste glass) for creation of porous structure. A proper bone substitute besides being bioactive, it should also be able to guide bone regeneration into the defect. For this reason bone substitute materials and tissue engineering scaffolds are designed in macro porous form in order to provide a correct blood supply inside the implant as well as satisfactory bone in-growth and osteointegration [5,6,7]. On the other hand the paper presents the usages of wastes (metallurgical slag, fly ash and waste glass) for creation of porous structure. Their recycling is one of the tasks in the field of the environment protection which should be solved in near future. This industrial waste material as the main oxide constituents contains Fe203, Al203, Si02, Mg0, Na20 as well as small amounts of ecologically hazardous oxides such as Cr203, Ni0, and Mn0. By means of multi barrier system [8, 9] and the combinations of different types of industrial toxic waste and non-toxic waste (glasses), ecologically compatible products, could be developed by powder technology. Using waste glass, the sintering temperature is significantly reduced due

to the presence of liquid phase. Ecologically hazardous components are fixed at the molecular level in the silicate phase and inserted additionally in the matrix based material, which either has no toxic components or contains them in ecocompatible concentration. The obtained new glass-ceramics possess significantly lower leaching behaviour (leaching rate) and significantly higher mechanical properties. 2. EXPERIMENTAL PROCEDURE 2.1. Materials In this investigation materials used for creation the porous structures for biomedical application were: biohydroxyapatite, titania and alumina. Commercial biohydroxyapatite powder (Merck Company, Darmstadt, Germany) with particle size 1±0.5 μm and the ratio Ca/P=1.63 was used for this investigation, and Ti02 was synthetized by hydrolysis procedure using C12H28TiO4 as precursor for titania. Transitional nano aluminium oxide powder (99.88wt.%; IBU-tech Company, Germany) was synthetized by pulse reactor technique at 8500C from aluminium tri-sec-butylat. Porous glass ceramics from wastes were created by using fly ash (thermal power plant REK Bitola, Republic of Macedonia), ferrochromium slag (Ferroalloys Work, Dugi Rat, Croatia; coded as Dalmacija) and waste glass from TV monitor using the multi barrier principle. 2.2. Methods for creation of porous structures 2.2.1 Creation of a porous structure using hydrogen peroxide H202 with concentration of 4% was used as a creator of porous structure. A slip consisted of powder, deflocculant Dolapix CE64 and H202 (10:4:3) was continuously mixed at room temperature. During the mixing a visible formation of bubbles of free oxygen was not noticed. The slip was then poured into aluminium frames. After drying at room temperature for 24h and at 105oC/6h, the porous (foam) material was sintered. Hydroxyapatite was sintered at 1200oC/1h and titania at 1300oC/ 3h . 2.2.2. Creation of a porous structure by use of C-fibre In a very dense pulp (consisted of powder, water and deflocculant Dolapix CE64), C-fibres (Toko Rayon C Ltd) with diameter of 500 μm have been embedded as bundles. After drying of the systems using the same procedure described in 2.2.1, sintering was performed within the temperature range from 20 to 1200oC with heating rate of 1oC/min and holding time at 1200oC for 2h. 2.2.3 Creation of a porous structure by use of polyurethane foam Open-celled macrostructures were fabricated by coating the skeletons of polyurethane foam with ceramic slurry followed by firing the resultant structure to pyrolyse the substrate and sinter the ceramic body. Polyurethane with density of 30 kg/m3 was used as substrate which was coated with slurry of the powder system. Dispersed, aqueous slurry was produced using Dolapix CE 64 as a deflocculant. The slurry containing 30% solid, 35% Dolapix CE 64 and the rest distilled water, coherently coats the polyurethane substrates. The foam was squeezed and dipped into the slurry, looking in that case like a sponge. During the expansion to the original shape and size, the foam was impregnated by the mentioned slurry. After drying of the system using the same procedure described in 2.2.1, the coated substrates were heated up to 1100oC in a schedule which minimized disruption during pyrolysis and allowed the ceramic body to reach full density. The heating schedule consisted of a heating rate of

0.5oC/min up to 800oC and rapid heating of 10oC/min from 800 to 1100oC, 0.5h soak time at 1100oC, and cooling in the furnace. 2.2.4. Creation of a porous structure by using industrial waste Based on the multi barrier concept [9], ferrochromium slag with granulation (-0.125 + 0.063mm) was mixed with 20wt.% TV glass, pressed at 20 MPa and sintered at 950oC/2h. Fly ash waste with 50wt.% TV glass was used as material for creating porous structure. Polyurethane foam was used as porogen (load was 0.5 g suspend./cm3) and the porous sample was sintered at 950oC/0.5h 2.3. Characterization Powder morphology and microstructure of the sintered porous samples were determined by scanning electron microscopy (Leica S 440i). Specific surface area of the powders was determined by 5-point-BET measurements (Micromeritics Gemini 2370). X-ray diffraction method (Philips PV 15-1 difractometer, operating at CuKα-radiation) was used for determination of phase composition. Cold isostatic pressing (Weber Pressen KIP 3010) was used for pressing transitional nano alumina powder. Sintering was realized in chamber furnace according to the schedule characteristic for appropriate porous material. Density of the sintered samples was determined by Archimedes method. Mechanical properties (E-modus and bending strength) were determined by three point bending tester (NETZSCH 401). 3. RESULTS AND DISCUSSION 3.1. Hydroxyapatite porous structure The porous structure of hydroxyapatite produced by the method described in 2.2.1 is presented in Fig.1. The macrostructure was seen to be partially heterogeneous, i.e. regions of high and low densities were observed. The total porosity of this system was 68±5%. The pores are interconnected among each other and with a size of 100 to 3000μm. The microstructure of the pore wall–skeleton is shown in Fig.2. E-modulus, bending strength and compressive strength of this system were 1.6±0.4 GPa, 2±0.3 MPa and 7±2 MPa, respectively. The value of bending strength is close to that one presented in [10]. Ioku et al [11] refers to the value of compressive strength of 12.5 MPa for hydroxyapatite with porosity of 60±5%. Table I presents the values of E-modulus, bending strength and compressive strength of cortical and cancellous bone [12,13] and Fig. 3 shows the pores morphology of human cancellous bone.

Figure 1. Hydroxyapatite porous structure Figure 2. Microstructure of the densified created by H202 (4 mas.%) as porogen , skeleton (bar 1μm) sintered at 1200oC/1h (bar 1mm)

Table 1. E-modulus, bending strength and compressive strength of cortical and cancellous bone

Properties

Cortical bone Cancellous bone

E-modulus, GPa 7-25 0.05-0.5 Bending strength, MPa 50-150 / Compressive strength, MPa 130-180 2-12

Fig.3 Macrostructure of cancellous human bone (bar 1 mm) Based on the mechanical properties presented in Table I could be concluded that porous hydroxyapatite obtained by H202 as a pores creator, could be ranged between cortical and cancellous bone and potentially applied in medicine. Using procedure described in 2.2.2, the porous compacts with total porosity of 50±5% were obtained. The diameter of the pore channel was in the range 300-500 μm as shown in Fig. 4 (a and b). E-modulus, bending strength and compressive strength of this system were E=5±0.4 GPa, σ= 4±0.3 MPa and K= 11±2 MPa, respectively. a b c

Figure 4. Macrostructure of cell foam, using C-fibres Figure 5. Porous structure created as pores creator (a) axial (b) radial by polyurethane foam (bar 1mm)

Pores with dimensions in the range 200-400 μm were obtained by using the polyurethane foam, as shown in Fig.5. Total porosity of the compact was 65±4%. E-modulus, bending strength and compressive strength of this system were: E= 1.3±0.4 GPa, σ=1.6±0.3 MPa, K=5±1 MPa, respectively. Part of the porosity was open and interconnected, but the largest porosity was composed of closed pores. 3.2. Titania porous structure Titania produced by hydrolysis method has a specific surface area of 8.3 m2/g.The powder was agglomerated, the agglomerate size was in the range 0.5-2 μm and the primary particles had dimensions of 6-100 nm. Figure 6 (a) presents the porous structure of titania fabricated by applying the procedure described in 2.2.1. The integral porosity of 58±5% was obtained and the E-modulus, bending

strength and shear modulus of this system were: E=20GPa, σ=18MPa, G=17GPa, respectively. Titania porous structure was obtained by applying the procedure 2.2.2. The diameter of the pore channel was in the range of 200-400 μm as shown in Fig.6(b) and total porosity of 55±5% was obtained. E-modulus, bending strength and shear modulus of this system were: E=23GPa, σ=21MPa, G=19GPa, respectively. There was no interconnection between the formed tubular pores. Pores with dimensions in the range of 600-800 μm were obtained by using the polyurethane foam, Fig.6(c). Total porosity of the compact was 51±4%. E-modulus, bending strength and shear modulus of this system were: E= 26GPa, σ=23MPa, G=21 GPa, respectively. Part of the porosity was open and interconnected, but the largest porosity was composed of closed pores. This particular kind of pore structures with low pore interconnectivity is of relatively low interest in functional ceramics.

a b c Fig.6 . Ti02 porous structure created by usages of: a. H202 as porogen (x100), b. C-fibres as porogen ( bar 20μm) and c. polyurethane foam (bar 200 μm) 3.3. Alumina porous structure The specific surface area and tap density of the alumina powder was 111,5 m2/g and 37.55 g/dm3

, respectively. The size of the particles was 10-60 nm. XRD shows that the powder is consisted of δ, θ, γ and α phases. After cold isostatic pressing at 500 MPa and sintering in the interval RT-1500oC/30 min, density of 0.73TD was obtained. Open porosity of the compacts was 28%. The microstructure, Fig.7 is of a vermicular network [14] in which both, the pores and the pore channels are the same scale as α-Al203 grains. The elongated pores have a size of 0.5-1.0 μm. E-modulus and bending strength of this porous system were 140 GPa and 91 MPa, respectively. The presence of vermicular microstructure, geometry and interconnection of the pores as well as the bioinert properties of alumina allows whole spectrum of potential application in the functional ceramics. Using the procedure described in 2.2.2, the porous compact with total porosity of 53±5% was obtained. The diameter of the pore channel was in the range 2000-4000 μm as shown in Fig.8. Part of the porosity was open and interconnected, but the largest porosity was composed of closed pores. E-modulus, bending strength and shear modulus of this system were: E= 93±8GPa, σ=21±6MPa, G= 19±4GPa, respectively. This particular kind of pore structure with low pore interconnectivity is of low interest for medical purpose, in particular for tissue engineering scaffold applications.

Figure 7. SEM micrograph of the fractured Figure 8. Structure of alumina created by surface of α-Al203, sintered at 1500oC, H2O2 as porogen (x50) (bar 1μm)

3.4. Porous glass ceramics obtained from industrial waste Typical open pore structure created of fly ash and 50wt.% TV glass by using polyurethane foam as porogen is shown in Fig.9 [15]. Pores with dimensions in the range 600-1500 μm were obtained. The pores are interconnected. Integral porosity of the porous glass ceramics system was 74±5%. Mechanical properties of the porous system were: E-modulus 1.6±0.5 GPa and bending strength 3.4±1.1 MPa.

Figyre 9. Porous structure created Figure 10. SEM micrographe of the composite of fly ash-glass composite by using Dalmacija (-0.125+0.063mm)-20wt.% TV glass, polyurethane foam as porogen,(bar 2mm) sintered at 9500C/2h (bar 100 μm) Figure 10 illustrates porous structure of the composite consisted of 20wt.% TV glass and slag Dalmacija with granulation (-0,125+0.063mm) sintered at 9500C/2h. The porosity of the composite was 26.8±3.5%. The mechanical properties of the composite i.e. bending strength and E-modulus were σ = 35±3,5MPa and E=25.4±3,4GPa. The durability (expressed as mass lost) of the composite was determined after 24, 168 and 720h in 0,1M HCl and the values were 0.202, 0.471 and 0.662%, respectively. The fabricated porous composite was further examined for the purpose to be used as diffuser for water purification.

4. CONCLUSION - Porous hydroxyapatite fabricated by H202 as a pores creator (porosity 68±5%, E-modulus:1.6±0.4 GPa, bending strength: 2±0.3 MPa and compressive strength: 7±2 MPa) could be ranged between cortical and cancellous bone and potentially applied in medicine; - Porous alumina with vermicular microstructure (open porosity of 28%) and mechanical properties (E-modulus 140 GPa and bending strength 91 MPa) presents potential material with a whole spectrum of application in the functional ceramics. - Porous composite Dalmacija (-0.125+0.063mm)-20wt. % TV glass, sintered at 9500C/2h with porosity 26.8±3.5% and mechanical properties (σ = 35±3,5MPa and E=25.4±3,4GPa) presents potential material which can be used as diffuser for water purification.

5. REFERENCES [1]. Hirschfeld D.A., Li T.K., Liu D.M.: Processing of Porous Oxide ceramics, Key Eng. Mater., 1996, 115, 65-80 [2]. Colomo P.: Conventional and novel processing methods for cellular ceramics, Philos. Trans.R.Soc. A, 2006, 364(1838), 109-124 [3]. Liu D.M: Influence of porosity and pore size on the compressive strength of porous hydroxyapatite ceramic, 1997, 23(2), 135-139 [4]. She J.H, Ohji T.: Fabrication and characterization of highly porous mullite ceramics, Mater. Chem.Phys., 2003, 80, 610-614 [5]. Tsuruga E., Takita H., Itoh H., Wakisaka Y., Kuboki Y., Pore size of porous hydroxyapatite as the cell-substratum controls BMP-induces osteogenesis, J.Bioche, 1997, 121, 317-324 [6]. Hing K.A., Annaz B., Saeed S., Ravell P.A., Buckland T.: Microporosity enhances bioactivity of synthetic bone draft substitutes, J.Mater.Sci.:Mater.Med., 2005, 16, 467-475 [7]. Chang B.S., Lee C.K., Hong K.S., Youn H.J., Ryu H.S., Chang S.S., Park K.W.: Osteoconduction at porous hydroxyapatite with various pore configurations, Biomaterials, 2000, 21, 1291-8 [8]. Fidancevska E., Mangutova B., Milosevski D., Milosevski M., Bossert J.: Obtaining of dense and highly porous ceramic materials from metallurgical slag, Sci.Sint., 2003, 35, 85-91 [9]. Ondracek G.:Berg- und Huttenmannische Monatshefte, 1994, 139, 273 –279 [10]. Slosarczyk A., Higly porous hydroxyapatite material, Powder.Met.Int., 1989, 21(4), 24 [11]. Ioku K., Kurosawa H., Shibuya K., Yokozeki H., Hayashi T., Bioceramics,Vol7 Ed.O.H.Anderson and Yli-Urpo,Butterford-Heinemann,1994, p.97 [12]. Hench L.: Bioceramics: from concept to clinic, J. Am. Ceram. Soc., 1991, 74(7), 1487 [13]. Ravaglioli A., Krajewski A., Bioceramics, Chapman & Hall, London, 1996, p.44 [14]. Fidancevska E., Bossert J., Vassilev V., Adziski R., Milosevski M., Design of ceramic microstructure of nanoscaled transitional alumina, Nanostructuresd materials for advanced technological application, J.P.Reithmaier et al.(eds.), Nanostructured Materials for Advanced Technological Applications, Springer Science+Business Media B.V. 2009 [15]. Fidancevska E., Milosevski M., Technical report of INCO Copernicus project 2003

VIII Naučno/stručni simpozij sa međunarodnim učešćem „METALNI I NEMETALNI MATERIJALI“ Zenica, BiH, 27-28. april 2010

PREDNOST PROIZVODNJE VISOKOKVALITETNIH BAKRENACA U

TOPIONICAMA KOJE PRERAĐUJU SULFIDNE KONCENTRATE BAKRA

ADVANTAGE OF HIGH GRADE MATTE PRODUCTION IN SULFIDE

COPPER CONCENTRATES SMELTERS

Ljubiša Mišić, dipl.ing.met. Tatjana Apostolovski-Trujić, dipl.ing.met.

Saša Ivanović, dipl.ing.met. Institut za rudarstvo i metalurgiju

Zeleni bulevar 35, Bor, Srbija

REZIME U ovom radu dat je uporedni pregled količina energije sumpora i kiseonika za proizvodnju visoko kvalitetnih bakrenaca (65-70% bakra) iz koncentrata bakra, u zavisnosti od sastava različitih koncentrata bakra. Sumpor i kiseonik kreiraju visok potencijal za egzotermalanu toplotu tokom procesa oksidacije sa povećanjem sadržaja FeS2. Ali ovu prednost degradira povećanje količine šljake i gasa, što uključuje potrebu za dodatnom energijom i troškovima. Suprotan efekat stvaraju halkozin Cu2S ili bornit Cu5FeS4 u koncentratu. To znači da se količine produkata prerade: šljaka i otpadni gas moraju smanjiti. Manja količina produkata prerade rezultira manjim zahtevima za fosilnim gorivima i industrijskim kiseonikom. Sve prednosti / posledice upoređivane su u zavisnosti od rezultatih mineraloških sastava koncentrata iz Rusije, Latinske Amerike, Afrike i domaćih koncentrata. ABSTRACT This paper compares how energy of sulfur and oxygen requirement for production high grade matte (65-70 % Cu) from sulfide concentrates of copper vary with their composition. There are created high potential for exothermal heat during oxidation process from concentrates of increasing FeS2 content. But this benefit of energy is degraded with increasing slag and off-gas production, which involve extra treatment energy and cost. The opposite of that is more chalcocite Cu2S or bornite Cu5FeS4, in concentrates. This means that furnace products: slag and off-gas which is evolved must also decrease. As а benefit of small amounts of furnace products result in a lessened requirement for fossil fuel and industrial oxygen. All benefits/consequences result as a different mineralogical composition of Russian, Latin American, African and domestic concentrates are also compared.

8th Scientific/Research Symposium with International Participation „Metallic and Nonmetallic Materials“ Zenica, B&H, 27-28. April 2010

REVIEW OF THERMODYNAMIC SIMULATION MODELS IN COPPER MATTE PRODUCTION -

THE IMPURITIES BEHAVIOUR ANALYSIS

Emina D. Požega, Mining and metallurgy institute

Zeleni bulevar 33, 19210 Bor J 12, 19210 Bor, Serbia

Dragana T. Živković, University in Belgrade,

Tehnical faculty in Bor, Serbia

Lidija D. Gomidželović, Mining and metallurgy institute

Zeleni bulevar 33, 19210 Bor, Serbia

Vlastimir K. Trujić, Mining and metallurgy institute

Zeleni bulevar 33, 19210 Bor, Serbia Keywords: modeling, copper metallurgy, simulation, thermodynamics, software ABSTRACT Modeling and simulation, including computer simulation/calculation software or program and mathematical representations of physics and chemistry of complex metallurgical systems, have been increasingly used to assist: process development and design, process evaluation and optimization, production scheduling and planning, process control, and business evaluation. Review of thermodynamic simulation models for copper matte production in the conventional copper smelting process were presented in this paper, with special emphasize on thermodynamic analysis of impurities behavior in copper metallurgy.

VIII Naučno/stručni simpozij sa međunarodnim učešćem „METALNI I NEMETALNI MATERIJALI“ Zenica, BiH, 27-28. april 2010

DOBIJANJE SREBRA I BAKRA VISOKE ČISTOĆE IZ ISTROŠENE POSREBRENE BAKARNE ŽICE

REFINMENT SILVER AND CUPRUM HIGH PURITY FROM SPENT SILVER OVER CUPRUM WIRE

Silvana Dimitrijević,dipl.inž.met

Dragan Marković, dipl.inž.met.

Suzana Dragulović, dipl.inž.tehn.

Radiša Todorović dipl.inž.met

Saša Ivanović, dipl.inž.met.

Institut za rudarstvo i metalurgiju, Zeleni bulevar 35, Bor, Srbija

e-mail: [email protected]

Ključne reči: posrebrena bakarna žica, prerada, srebro, bakar REZIME U novije vreme povećan je interes za recikliranjem metala čime se smanjuje količina otpada kao i troškovi tretiranja otpadnih voda. Cilj ovog rada bio je da se iz istrošene posrebrene bakarne žice valorizuju srebro i bakar a da se nečistoće, kao što su olovo, kalaj, antimon, kadmijum uklone. Srebro i bakar visoke čistoće (99,99%) iz istrošene žice dobijeni su kombinacijom pirometalurških, elektrometalurških i hemijskih postupaka u laboratorijama i poluindustrijskim postrojenjima Instituta za rudarstvo i metalurgiju u Boru.

Key words: recrystalization temperature, tin and tellurium low-alloyed copper

ABSTRACT Recycling of secondary raw’materijals recently become more interesting, mainly due to reduced quantities of waste and price of waste water treatment. Aim of this work was recycling and production of copper ana silver from rub out copper wire plated with silver. Silver and copper high purity (99,99%) from rub out copper wire realized by combining pyro-metallurgy, electro-metallurgy and chemical treatment in laboratory and pilot production in Institute of Mining and Metallurgy Bor.

VIII Naučno/stručni simpozij sa međunarodnim učešćem „METALNI I NEMETALNI MATERIJALI“ Zenica, BiH, 27-28. april 2010.

EXPERIMENTAL INVESTIGATION AND THERMODYNAMIC PREDICTING OF PHASE EQUILIBRIA IN Ga-GeSb0.855 SYSTEM

Ana Kostov1, Dragana Živković2, Dragan Manasijević2, Duško Minić3, Živan Živković2

1 Mining and Metallurgy Institute Bor, Serbia, E-mail: [email protected] 2 University of Belgrade, Technical Faculty Bor, Serbia

3 University of Priština, Faculty of Technical Sciences Kosovska Mitrovica, Serbia

Keywords: DTA, phase diagram, Ga-Ge-Sb system ABSTRACT Experimental investigation and thermodynamic predicting of phase equilibria in Ga-GeSb0.855 system, which is of a practical importance in electric - semiconductors industry, are presented in this paper. Results of experimental investigation are done by different thermal analysis (DTA) and SEM-EDX analysis, and thermodynamic predicting is done by PANDAT thermo-chemical software. The experimental and calculated values are shown a good agreement as well as the obtained phase diagram of the investigated system.

8 th

Scientific/Research Symposium with International Participation „Metallic and Nonmetallic Materials“ Zenica, B&H, 27-28. April 2010

EXPERIMENTAL INVESTIGATION AND THERMODYNAMIC CALCULATION IN Pb-Zn-Ag SYSTEM

Dragana T. Živković1, Duško M. Minić2, Dragan M. Manasijević1, Aleksandra M. Mitovski1, Ljubiša T. Balanović1, Živan D. Živković1

1 – University of Belgrade, Technical Faculty, Bor, Serbia

2 – University of Priština, Faculty of Technical Sciences, Kosovska Mitrovica, Serbia

Keywords: extractive metallurgy of lead, desilverizing, Pb-Zn-Ag system, thermodynamics, phase equilibria ABSTRACT Ternary Pb-Zn-Ag system is typical for some physicochemical processes going on in refining phase in the extractive metallurgy of lead. Therefore, investigation of mentioned system is important from both theoretical and practical research of the phenomena occurring during the lead desilverizing process.The results of experimental investigation (DTA) and thermodynamic calculation of phase equilibria in Pb-Zn-Ag system (CALPHAD method + PANDAT software) are presented in this paper.

8 th

Scientific/Research Symposium with International Participation „Metallic and Nonmetallic Materials“ Zenica, B&H, 27-28. April 2010

THERMAL ANALYSIS OF THE TERNARY SYSTEM Bi-Cu-Sn

Dragan M. Manasijević1, Duško M. Minić2, Dragana T. Živković1, Nadežda M. Talijan3, Aleksandar S. Grujić3, Saša R. Marjanović1

1 – University of Belgrade, Technical Faculty, Bor, Serbia 2 – University of Priština, Faculty of Technical Sciences, Kosovska Mitrovica, Serbia

3Institute of Chemistry, Technology and Metallurgy, Belgrade, Serbia

Keywords: Lead-free solders, Bi-Cu-Sn ternary system, Thermal analysis, DTA, DSC ABSTRACT Interaction of lead-free solders with copper substrate represents an important phenomenon in the issue of reliability of solder joints and is typical for the Bi-Cu-Sn system, as one the high-temperature solder system recently suggested in literature and soldering practice. New experimental results on thermal analysis of the Bi-Cu-Sn alloys, including DTA and DSC measurements for two isopleths from bismuth corner with molar ratio of copper and tin equal to 1/3 and 1/1 and three isopleths from tin corner with molar ratio of bismuth and copper equal to 3/1, 1/1 and 1/3, are presented in this paper.

8 th Scientific/Research Symposium with International Participation „Metallic and Nonmetallic Inorganic Materials“ Zenica, B&H, 27.-28. April 2010

NUMERICAL STUDY OF THE CHILL WHEEL COOLING DURING

CONTINUOUS FREE JET MELT-SPINNING

Blaž Karpe, Borut Kosec, Milan Bizjak, Tomaž Kolenko University of Ljubljana, Faculty of Natural Sciences and Engineering

Ljubljana Slovenia

Keywords: rapid solidification, metallic materials, heat transfer balance, heat transfer coefficient, numerical modeling

ABSTRACT New method for determining contact resistance through variable heat transfer coefficient is introduced which takes into account physical properties of the casting material, process parameters and contact time/length between metal melt or metal ribbon and substrate and enables cooling and solidifying rate prediction before the experiment execution. The calculations show that contact resistance between metal melt and chilling wheel has a great influence on melt cooling and wheel heating rate, and must not be neglected in numerical calculations, even if its value is very low. Influence of process parameters on cooling and solidifying rate and consequently on microstructure development over ribbon thickness are outlined. It can be concluded from the results, that process parameters which determine the thickness of the melt puddle in the downstream have major influence on cooling and solidifying rate of the ribbon. Among thermal properties, the thermal diffusivity of the metallic melt, solidified ribbon and wheel material has major influence on cooling and solidifying rate of the melt and solidified ribbon respectively. In the case of continuous casting, heat balance of the wheel is calculated and influence of the chill wheel cooling mode on cooling rate of metallic ribbon is analyzed.

8 th Scientific/Research Symposium with International Participation „Metallic and Nonmetallic Inorganic Materials“ Zenica, B&H, 27.-28. April 2010

THE PRECIPITATION KINETICS OF RAPIDLY SOLIDIFIED Al - BASED ALLOYS

Milan Bizjak, Ladislav Kosec, Blaž Karpe

University of Ljubljana, Faculty of Natural Science and Engineering Ljubljana, Slovenia

Goran Dražič

Jožef Stefan Institute, Jamova 39 Ljubljana, Slovenia

Keywords: Rapid solidified Al alloys, Kinetics of precipitation, In-situ measurement of electrical resistivity

ABSTRACT

Aluminium alloys are widely used as an industrial material, usually for lower temperature applications. For synthesis of new aluminium alloys with good mechanical properties at elevated temperatures, combine development of powder metallurgy and rapid solidification was necessary. This article describes the synthesis and analysis of rapidly solidified Al-TM alloys produced by melt spinning method. As cast alloys were rapidly solidified in the form of thin ribbons, thicknesses between 30 and 75 microns and heat threaded at a constant heating rate in argon or vacuum atmosphere up to 600°C. Kinetics and sequence of microstructural changes during heating was analyzed by in-situ measurements of electrical resistivity. This method allows accurate detection of transformations between metastable and stable phases of rapidly solidified Al-TM alloys at a given temperature. After determining the temperature of transition points, quenched microstructures were analyzed with transmission electron microscopy. It can be concluded from the results of investigation that precipitation from supersaturated solution is the most frequent reaction in these types of alloys. Its kinetics is highly dependent upon solidification rate achieved through the cross-section of as cast ribbon, which is in direct connection with ribbon thickness.

8

th Scientific/Research Symposium with International Participation

„Metallic and Nonmetallic Materials“ Zenica, B&H, 27-28. April 2010

MICROSTRUCTURE AND CHARACTERISATION OF RAPIDLY SOLIDIFIED Au-La RIBBONS

T. Zupančič Hartner1,2, R. Rudolf1,2, B. Kušić1, I. Anžel1

1Faculty of Mechanical Engineering, University of Maribor, Slovenia

2Zlatarna Celje d.d., Department for technological Development, Slovenia

ABSTRACT In this research influence of lanthanum as a micro-alloying element in pure gold was investigated. Rapidly solidified ribbons of Au-0.5 wt.% La have been made by melt spinning technique. On prepared samples microstructure was investigated and micro-hardness was measured. Microstructure analysis in cross-section of the melt-spun ribbons reveals three different regions from wheel to air side: fine equiaxed grains, zone with a columnar microstructure and coarse equiaxed grains. Very fine precipitates inside the grains, the eutectic micro-segregation at the grain boundaries and some other features have been observed in the metastable rapidly solidified microstructure. Non-homogeneous microstructure in cross section was accompanied with significant differences in micro-hardness values. This indicates strong influence of changeable solidification conditions during melt spinning on the microstructure evolution and mechanical properties. Microstructure and corresponding strengthening achieved by lanthanum and by rapid solidification is discussed.

VIII Naučno/stručni simpozij sa međunarodnim učešćem „METALNI I NEMETALNI MATERIJALI“ Zenica, BiH, 27-28. april 2010

UTICAJ SADRŽAJA δ-FERITA NA MEHANIČKA SVOJSTVA

AUSTENITNOG NEHRĐAJUĆEG ČELIKA

INFLUENCE OF DELTA FERITE ON MECHANICAL PROPERTIES OF AUSTENITE STAINLESS STEEL

Mr.Sc. Almaida Gigović-Gekić1, Dr. Sc. Mirsada Oruč2

1.Univerzitet u Zenici, Fakultet za metalurgiju i materijale, 72 000 Zenica 2. Univerzitet u Zenici Metalurški institut“Kemal Kapetanović“, 72 000 Zenica

Ključne riječi: austenitni nehrđajuči čelik, delta ferit, mehanička svojstva REZIME Zahvaljujući karakterističnim svojstvima kao što su duktilnost, otpornost prema habanju, otpornost prema visoko temperaturnoj koroziji, otpornost prema puzanju i dr. austenitni nehrđajuči čelici su našli široku primjenu u industriji. U austenitnim čelicima osim osnovne austenitne mikrostrukture može bit prisutan i delta ferit. Delta ferit nastaje u toku solidifikacije i ostaje prisutan u mikrostrukturi i na sobnoj temperaturi. Prisustvo delta ferita ima negativan uticaj na svojstva, posebno deformabilnost čelika kao i na osjetljivost prema interkristalnoj koroziji. U ovom radu su predstavljeni rezultati ispitivanja mehaničkih svojstava za austenitni nehrđajući čelik u zavisnosti od sadržaja delta ferita. Key words: austenite stainless steel, delta ferrite, mechanical properties ABSTRACT Thanks to the characteristic properties such as ductility, resistance to abrasion, resistance to high temperature corrosion, resistance to creep and other properties, austenitic stainless steels have found wide application in industry. The delta ferrite can be a second phase in austenite stainless steel. The delta ferrite occurs during solidification and remains present in the microstructure at room temperature. The presence of the delta ferrite has a negative impact on properties, especially the deformability of steel as well as sensitivity to intercrystal corrosion. This paper presents the results of testing of mechanical properties for austenitic stainless steel depending on the content of delta ferrite.

VIII Naučno/stručni simpozij sa međunarodnim učešćem „METALNI I NEMETALNI MATERIJALI“ Zenica, BiH, 27-28. april 2010

FAKTORI KOJI UTIČU NA TOPLOOTPORNOST LEGURE NA BAZI NIKLA – IN.100

FACTORS INFLUENCE ON HEAT RESISTANCE OF IN-BASED

ALLOY – IN.100

Radiša Todorović, dipl.ing.met, Dr Ana Kostov, dipl.ing.met. LjubinkaTodorović,dipl.hem.

Institut za rudarstvo i metalurgiju Bor 19210 Bor, Srbija, E-mail:[email protected]

Ključne reči: legura IN.100 , intermetalni talog γ’ , veličina čestica , trajna čvrstoća REZIME Granica puzanja i trajnja čvrstoća su dve najznačajnije mehaničke karakteristike toplootpornih materijala na osnovu kojih se može izvesti ocena toplootpornosti specijalnih legura koje su namenjene za rad na povišenim temperaturama pri odgovarajućim složenim opterećenjima. Navedene karakteristike su u direktnoj zavisnosti od makro i mikrostrukture, karbidne faze kao i odgovarajućih mikrokonstituenata. U radu je naveden uticaj prisustva legirajućih elemenata, uslova topljenja i livenja kao i očvršćavanja na veličinu i raspored izlučenih čestica prisutnih faza i morfologiju karbida, a što se skupa odražava na granicu puzanja i trajnu čvrstoću a time i na toplootpornost legure. ABSTRACT Creep limit and long-time strength areth two most significant mechanical propertise of high-temperature resistant materials. On the basis of these properties, one can estimate high-temperature resistance of special alloys intendend for service at elevated temperatures under the corresponding complex loads. The above mentioned properties are directly related to macro and micro structures, carbide phase, as well as to the relevant micro constituents. The paper discusses the effect of the presence of alloying elements, the conditions of melting and casting, as well of herdening on both the siye and arrangement which all together the high-temperature resistance of an alloy.

VIII Naučno/stručni simpozij sa međunarodnim učešćem „METALNI I NEMETALNI MATERIJALI“ Zenica, BiH, 27-28. april 2010

MIKROSTRUKTURA, MEHANIČKE I ELEKTRIČNE OSOBINE

LEGURA TERNARNOG Bi-Cu-In SISTEMA

Ajka Aljilji1, Duško Minić1, Vladan Čosović2, Milan Kolarević3, Dragan Manasijević4 i Dragana Živković4

1- Univerzitet u Prištini, Fakultet tehničkih nauka, Kos. Mitrovica, Srbija

2 – Institut za Hemiju, Tehnologiju i Metalurgiju, Beograd, Srbija 3 – Univerzitet u Kragujevcu, Mašinski fakultet, Kraljevo, Srbija

4 - Univerzitet u Beogradu,Tehnički fakultet, Bor, Srbija Ključne reči: Bi-Cu-In sistem, mikrostruktura, tvrdoća, električna provodljivost REZIME Bezolovne lemne legure na bazi bakra posebno predstavljaju moguću zamenu za standardni olovno-kalajni lem. Za kompletno definisanje osobina ternarnog Cu-In-Bi sistema izvedena su ispitivanja mikrostrukture, tvrdoće po Brinelu i električne provodljivosti legura datog sistema. Ispitano je vići broj legura za tri kvazibinarna preseka, sa molarnim odnosom Bi:Cu=1, Cu:In= 1:3, Bi:In=1. Pomoću optičke mikroskopije određene su mikrostrukture legura na sobnim uslovima. Primenom CALPHAD metode izvršen je proračun izotermalnog preseka na 250C . ABSTRACT Lead free solder alloys based on copper are possible substitution for standard Pb-Sn solders. For the completed definition of the properties of ternary Cu-In-Bi system there were conducted microstructure investigations, hardness by Bruinell and electric conductivity of alloys. Numerous alloys were investigated for three quasi binary cross sections with molar ratio Bi:Cu=1, Cu:In= 1:3, Bi:In=1. By the application of optical microscopy there were defined micro structures of the alloys on ambient temperature. By application of CALPHAD method a calculation of isothermal cross section is made at 250C

VIII Naučno/stručni simpozij sa međunarodnim učešćem „METALNI I NEMETALNI MATERIJALI“ Zenica, BiH, 27-28. april 2010

MIKROSTRUKTURA, MEHANIČKE I ELEKTRIČNE OSOBINE LEGURA TROJNOG Cu-In-Sb SISTEMA

Duško Minić1, Ajka Aljilji1, Milan Kolarević2, Jasna Stajić-Trošić3

Dragan Manasijević4 i Dragana Živković4

1- Univerzitet u Prištini, Fakultet tehničkih nauka, Kos. Mitrovica, Srbija 2- Univerzitet u Kragujevcu, Mašinski fakultet, Kraljevo, Srbija

3- Institut za Hemiju, Tehnologiju i Metalurgiju, Beogradu, Srbija 4 – Univerzitet u Beogradu,Tehnički fakultet, Bor, Srbija

Ključne reči: Cu-In-Sb trojni sistem, mikrostruktura, tvrdoća i električna provodljivost.