Metal hydride hydrogen storage tank for fuel cell utility...

Transcript of Metal hydride hydrogen storage tank for fuel cell utility...

Metal hydride hydrogen storage tank for fuel cell utility vehicles

Mykhaylo Lototskyy, Ivan Tolj, Yevgeniy Klochko,

Moegamat Wafeeq Davids, Dana Swanepoel and

Vladimir Linkov

Fuel cell utility vehicles (incl. forklifts): Motivation

HyLIFT-DEMO Project Showcases Hydrogen Powered Fuel Cell Forklift Trucks at CeMAT logistics Fair May 2-6, Press release, Hannover, May 2, 2011

Hydrogen powered utility vehicles including material handling units with fuel cells combine the advantages of diesel / LPG and battery powered vehicles:• Constant power during the

entire shift;• Short refuelling time;• Zero emission electric

propulsion.

Lototskyy M. et al, Progress in Natural Science: Materials International 27 (2017) 3

Metal hydrides for heavy-duty FC powered utility vehicles incl. forklifts: Motivation

CGH2

•Approved technology, prototypes

available (Plug Power, H2Logics,

Proton Motor, PearlHydrogen);

•Fast refuelling;

•Safety and refuelling infrastructure

(filling H2 pressure ~350 bar);

•Space constrains;

•Additional counterbalance required

(forklift operation safety).

MH

H2

•Compact + heavy: intrinsic solution

of the counterbalance problem;

•Safety (lower standby H2 pressure);

•Simpler refuelling infrastructure

(filling H2 pressure <200 bar);

•Limitations of charge / discharge

rates (heat transfer issues).

Lototskyy M. et al, J. Power Sources, 316 (2016)Lototskyy M. et al, Progress in Natural Science: Materials International 27 (2017) 3

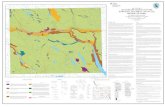

Background: MH hydrogen storageon-board fuel cell utility vehicles

• Low weight H2 storage capacity in MH is not drawback but advantage for this application. • Main challenge of conventional solutions (MH containers in a water tank) is still insufficient system

weight / too big size of the H2 storage system.

Prototype FC power module with integrated MH hydrogen storage (Hawaii Hydrogen Carriers)A. Narvaez. Presentation at US DOE Annual Merit Review Meeting, June 18, 2014, Project ST 095

➢ The MH tank (L=470 mm; W=700 mm; H=370 mm) stores ~2 kg (20 Nm3) H2 and has a weight ~500 kg when filled with water.

➢ For sufficient counter-balancing, all the components are assembled within rectangular metal casting body, and the most of its internal volume was occupied by the MH tank.

MH tank FC power moduleMine locomotive

FC powered mine locomotive with

integrated MH hydrogen storage (Vehicle Projects, Inc. & Anglo American

Platinum)P. Valicek, F. Fourie, 6th Int.

Platinum Conf, ‘Platinum–Metal for the Future’, The Southern

African Institute of Mining and Metallurgy, 2014

FC forklift with commercial FC power module and MH extension tank

AC Motors

DC / AC DC / DC

Battery

Auxiliaries

CGH2

+MH

H2 storage:

FC

MH H 2 purification

& compression

system H 2 ; P~50 bar

H2

HEAT

AIR

HP buffer

A

C

Cooling water

Steam Condensate

Pure H 2 P≤200 bar

80 VDC MAX 300 ADC

Forklift equipment

Power module components

Original developments

within this project

B

• In 2012-2015, HySA Systems integrated a MH H2 storage extension tank in a commercial GenDrive 1600-80CEA fuel cell power module (Plug Power Inc.) which was installed in a 3 tonne STILL electric forklift.

• Main performances (VDI-60):➢ Energy consumption 11.15 kWh/h.➢H2 fuel consumption 689 NL/kWh

(CGH2 31%, MH 69%).

• The prototype is in operation at Impala Platinum refineries in Springs, South Africa, since September 2015.

Lototskyy M. et al, Int. J. Hydrogen Energy, 41 (2016) 13831Lototskyy M. et al, J. Power Sources, 316 (2016)

MH extension tank: details

CGH2

11 Nm3 H2

@ 185 bar

T1

F1

CV1RECEPTACLE

V1 V2

MH

10 Nm3 H2

GenDrive 1000 160X-80CEA

Extension

FC

stack

➢Assembly of 20x MH containers connected in parallel to gas manifold.➢The assembly is submersed in external

water / glycol tank providing thermal control during the charge (cooling with ambient air) and discharge (heating from the FC stack).➢Dimensions 950 (L) x 120 (W) x 700 (H)

mm; weight ~200 kg.➢The tank is fitted in the forklift in the

space remaining vacant after the installation of the GenDrive power module.➢The total weight of the power module

and the extension tank is ~1800 kg that provides sufficient counter-balance for the safe forklift operation when lifting up to 3 tons.➢Only minor changes in high-pressure

H2 system of the GenDrive power module.➢21 Nm3 H2 total capacity at charge

pressure of 185 bar (for CGH2 only ~19 Nm3 @ 350 bar).

➢Next step: full integration of the MH H2 storage in fuel cell power module

HySA Systems power module for forklift: concept

Coolant Pump

DI Filter

Electronically

Controlled

Proportional Valve

Expansion

tank

Membrane

humidifier

Air

compressor

Air inlet

CGH2

MH

H2

H2 recirculation

pumpPressure regulator

Purge valve

-

+

Batt

ery

pack

CV

M

-

+

El.

outp

ut

A

V

Liq

uid

to l

iqu

id h

eat

exch

an

ger

Expansion

tankPump

Condenser

Anode

Cathode

F

Fuel supply

Air supply

FC cooling

MH heating/cooling

T

T

P

FP

P

PE

M F

C

110 c

ells

TT

T T

T T

BoP design• The BoP designed

around Ballard 9SSL / 75 Cell FC Stack.

• Main subsystems include:o The Cathode, Air

Subsystem;o The Anode, H2

Subsystem;o The Closed Circuit

Water cooling (stack) / heating (MH) subsystem.

• Challenges:o Component selection

constraints (availability, functionality & performance, size);

o Insufficient weight (ballast required);

o Alignment of the communication protocols

AIR MASS FLOW

METERAIR FILTER

A

N

O

D

E

T1

MANUAL SHUT-

OFF VALVE

P8C

O

O

L

A

N

T

M

M

AIR Scroll

COMPRESSOR

Cathode Heat

Exchanger

GAS – GAS

HUMIDIFIER

HYDROGEN

PURGE VALVE

HYDROGEN

RECIRCULATION

PUMP

O2 IN

CHECK

VALVE

H2 Line

H2 Supply

from Metal

HYDRIDE

Bed

SV

AIR STOICHIOMETRY = 1.8

H2

STOICHIOMETRY = 1.6

CHECK

VALVE

O2 OUT

H2 IN

From Cooling

System

Cooling

System Return

From Cooling

System

Cooling System

Return

Compressor

Motor Drive

H2 Buffer Tanks

MANUAL SHUT-

OFF VALVE

H2 Charge

Input

From Cooling

System

Cooling System

Return

CHECK

VALVELIQUID H2O

KNOCKOUT

LIQUID H2O

KNOCKOUT

H2O DRAIN

EXHAUST

MANUAL SHUT-

OFF VALVE

CHECK

VALVE

Metal

Hydride

Bed

Ba

llard

9S

SL

/ 75

Ce

ll Fu

el C

ell S

tack

H2

H2 Leak

detector

H2

H2

Concentration

Sensor

Pressure

Reducing Valve

AIR REFERENCE

PRESSURE

H2 OUT

P1

T2P2

T4P4

C

A

T

H

O

D

E

T3P3

T5P5

ISOLATION

VALVE

V-41

T6P6

P7

Air Reference

Pressure

V-43

ISOLATION

VALVE

RH

1

RH

2

Thermal Insulation

Thermal InsulationTherm Insu

Th

erm

al In

su

latio

n

Thermal InsulationThermal Insulation

H2

Air

Temperature control

Stack cooling / MH heating system• Stack cooling system is coupled with the

system of heating the MH tank

Patent ZA 2014/08640

Gas supply system

MH bed

• CGH2 buffer tank(s) provide stable H2 supply during the FC operation (H2 purging impulses)

Buffer tanks

Patent ZA 2014/08640

Fuel Cell Stack

H2 Leak Detector

System Controller

MH bed in a water tank

H2 Buffer Tanks

Anode Humidifyer

Air Intake Filter

Back Pressure Regulator

Water Trap

Cathode Air Compressor

Cathode Heat Exchanger

20kW Synchronous DC-DC Converter

Air Compressor Motor Drive

Cooling Radiator and FAN

8.4 kWh SLA Battery Bank

Hydrogen Recirculation Pump

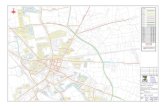

HySA Systems power module for forklift: Specification and preliminary design

➢ Stack: closed cathode FC;➢ H2 storage: integrated MH

storage unit, 20 Nm3;➢ Battery bank: deep cycle

lead-acid, 8…10 kWh.

• Donor vehicle: STILL RX60-30L;

• Bus voltage (VDC): 80;• Output power (kW): ~15

(average), up to 30 (peak);

• Dimensions (mm): 840 (L) x 1010 (W) x 777 (H);

• Weight (kg): 1800…1900

• The total weight of the power module ~650kg. Addition of 1150 kg of a ballast is required to achieve the target weight.

• The size of the MH bed and water tank is almost 40% of the total space in the power module compartment. CGH2 buffer tanks do not fit in the available space

HySA Systems power module for forklift: Updated design

Fuel Cell Stack

MH Bed Encased in

Lead

Anode Humidifier

Air Intake Filter

Compressor Motor Drive

Cathode Air Compressor

8.4 kWh SLA Battery Bank

Cooling Radiator and fan

Cathode Heat Exchanger

System Control Electronics

H2 Recirculation Pump

H2 Reducer

MH hydrogen storage: material

Ti0.55Zr0.45(Cr,Mn,Fe,Ni)2 + 10 wt% La0.8Ce0.2Ni5

0 50 100 150 200

1

10

100

113 NL/kg (discharge @ 2 bar / -10 oC)

T= -10 oC

T=50 oC

T=30 oC

P(H

2)

[bar]

C [NL (H2) / kg]

T=10 oC

165 NL/kg (discharge @ 5 bar / 50 oC)

Charge @ 150 bar / 30 oC

0 50 100 150 200

1

10

100

176 NL/kg (discharge @ 2 bar / -10 oC)

T= -10 oC

T=50 oC

T=30 oC

P(H

2)

[bar]

C [NL (H2) / kg]

T=10 oC

198 NL/kg (discharge @ 5 bar / 50 oC)

Charge @ 150 bar / 30 oC

Ti0.85Zr0.15(Mn,V,Ni,Cr,Fe)2

Alloy 1: imported from CN (custom order)

Alloy 2: manufactured by HySA Systems

➢ C-14 AB2-type intermetallides; A=Ti+Zr, B=Mn+Cr+Ni+V+Fe

MH hydrogen storage: container

Alloy 1 (3.1 kg): 503 NL H2 Alloy 2 (2.9 kg): 624 NL H2

H2 charge performance

➢ Standard SS pipe with pressed-in perforated copper fins➢ Addition of expanded natural graphite to the MH powder

0 10 20 30 40 50 60

-10

0

10

20

30

40

50

60

70

H2Flow Rate

Pressure

Time (minutes)

H2F

low

Rate

(L/m

in),

Pre

ssure

(bars

)

20

22

24

26

28

30

32

34

36

38

40

Temperature Centre

Temperature Front

Temperature End

Tem

pera

ture

(oC

)

0 10 20 30 40 50 60

-10

0

10

20

30

40

50

60

70

H2Flow Rate

Pressure

Time (minutes)

H2F

low

Ra

te (

L/m

in),

Pre

ssu

re (

ba

rs)

20

22

24

26

28

30

32

34

36

38

40

Temperature Centre

Temperature Front

Temperature End

Te

mp

era

ture

(oC

)

➢ Rated up to 190 bar / 100 °C➢ External heating / cooling

Patent application WO 2015 189758 A1; patent ZA 2016/08250

MH hydrogen storage: tank (general layout)

• Main challenge of conventional solutions (MH containers in a water tank) is insufficient system weight.

• Suggested approach: assembly of cassettes each comprising several MH containers encased in lead.

✓ Patent application UK1806840.3; 26.04.2018

10 – metal hydride cassette: 11 – metal hydride container12 – gas manifold13 – external pipeline of the gas manifold14 – heating / cooling means15, 16 – external heating / cooling pipelines17 – filling body (lead alloy)18 – pre-assembly of the MH cassette

MH cassette MH cassette pre-assembly before lead encasing

11

1412

13

18

• Special procedure of lead encasing which allows to simultaneously activate the MH material in the MH cassette has been developed.

• When heated with running water to T=40–50 °C, the cassette releases more than 60% of its full capacity (~2.5 Nm3) at the H2 flow rate of 25 NL/min.

• 8 MH cassettes have been manufactured and installed in the frame of forklift power module to form, together with 9L buffer cylinder, a hydrogen storage tank.

• The tank is characterised by H2 storage capacity above 20 Nm3 (1.8 kg) and has a weight ~1.2 tonnes that allows to provide counterbalancing weight (1850 kg for the whole power module within the space constrains) necessary for the safe operation of 3 tonne forklift.

• The tank can provide >2 hour long H2 supply to the FC stack operated at 11 kWe (H2 flow rate of 120 NL/min).

• The refuelling time of the MH tank (T=15–20 °C, P(H2)=150–180 bar) is about 15–20 minutes.

Lead encasing

Left: two ready-to-use MH cassettes. Right: MH tank for forklift power module comprising 8 MH cassettes

0 20 40 60 80 100 120

0

10

20

30

40

50

H2 flow rate [NL/min]

H2 pressure [bar]

T(MH) [oC]

T(in) [oC]T

, P

, F

R

Time [min]0 20 40 60 80 100 120

0

10

20

30

40

50

60

H2 pressure [bar]

H2 flow rate [NL/min]

T(MH) [oC]

T, P

, F

R

Time [min]

T(in) [oC]

MH hydrogen storage: tank

H2 charge (left) and discharge (right) performance of the MH cassette; water flow (T=T(in)) ~4 L/min

FC power module: Assembling on-board prototype

• Optimised BoP configuration (FC stack + SLA battery pack + supercapacitors) and control algorithms.

• Integration of the heating circuit of the MH tank with the stack cooling system.

• Optimisation of the fuel supply and purging strategy to reduce H2

consumption and increase efficiency is in progress.

MH tank

CGH2 buffer

Conclusions• The use of fuel cells in heavy duty utility vehicles, including material handling

units / forklifts or underground mining vehicles, has a number of advantages over similar diesel / LPG or battery-driven vehicles.

• Most of vehicular FC power systems have utilised compressed H2 stored in gas cylinders at pressures up to 350 bar. This solution, however, results in too light weight of the FC power modules for the utility vehicles which require additional ballast for a proper counterbalancing to provide vehicle stability.

• Intermetallic hydrides with H storage capacities below 2 wt% can provide compact H2 storage simultaneously serving as a ballast. However, further weight increase is necessary for the sufficient counterbalancing within strict space constrains.

• New engineering solution of a MH hydrogen storage tank for FC utility vehicles which combines compactness, adjustable high weight, as well as good dynamics of hydrogen charge / discharge has been developed.

• The developed MH tank comprises plurality of MH cassettes made as assemblies of externally heated / cooled MH containers staggered together with the heating / cooling tubes and encased in molten lead followed by the solidification of the latter.

• The MH tank has been successfully integrated in a prototype fuel cell power module for electric forklift.

Acknowledgements

• Impala Platinum Limited – co-funder;

• Department of Science and Technology (DST) via HySA Programme (projects KP3-S02 and KP3-S03) – co-funder;

• European Commission, Grant Agreement number: 778307 – HYDRIDE4MOBILITY –H2020-MSCA-RISE-2017 “HYDRIDE4MOBILITY” – support of international collaboration.

• Hot Platinum (Pty) Ltd – integration of the power module