Metal Alloys Making

-

Upload

ravi-chaurasia -

Category

Documents

-

view

16 -

download

0

description

Transcript of Metal Alloys Making

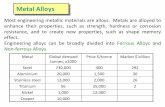

METAL ALLOYSMaking Process

Iron and Steel

Making Process

From Iron Ore and Limestone

Blast Furnace

Iron Ore Pig IronMelting

Iron

Blast Furnace

Steel is produced in the furnace of steel

from pig iron, either in the form of solid,

liquid, scrap metal and some metal

alloys.

Some of steel-making process:• Basic oxygen furnace

• Electric furnace

Steel Making

The liquid metal is inserted into the combustion chamber (tilted and enforced)

Oxygen (+ 1 000 ˚C) is blown through the Oxygen Lance into the combustion chamber at high speed with pressure 1400kN/m2

Added powdered lime (CaO) to reduce levels of P and S

Advantages of the Basic Oxygen Furnace:• Using the pure CO2 without Nitrogen

• The process was only + 50 minutes

• Phosphorous and sulfur expelled earlier than Carbon

• low operating costs

Basic Oxygen Furnace

Basic Oxygen Furnace

Conducted in high temperature and using the arc light electrodes and electric induction

Advantages:• Easy to reach high temperatures in a short time

• Temperature can be set

• kitchen high thermal efficiency

• The liquid iron is protected from dirt and environmental influences, so the quality is good

• The loss due to evaporation is very small

Electric Furnace

Electric Furnace

Aluminum Making Process

Step 1: crushing and grinding

alumina recovery begins by passing the bauxite through screens to sort it by size

The ore is then fed into large grinding mills and mixed with a caustic soda solution

The material finally discharged from the mill is called slurry.

Step 2 : digesting

1. The slurry is

pumped to a

digester where the

chemical reaction to

dissolve the alumina

takes place.

Step 3- Settling

The liquor at the top

of the tank (which

looks like coffee) is

now directed through

a series of filters

Step 4 : precipitation

The clear sodium aluminate from the settling and filtering operation is pumped into these precipitators. Fine particles of alumina -called "seed crystals" (alumina hydrate) - are added to start the precipitation of pure alumina particles as the liquor cools.

Calcination is a heating process to remove the chemically combined water from the alumina hydrate.

The result is a white powder like that shown below: pure alumina. The caustic soda is returned to the beginning of the process and used again.

Stage 2: converting alumina to

alumunium

Electrolysis reduction by Hall-Herault

process

Reacted in a melted of kriolit (Na3AlF6)

in a steel vessel 950oC.

Alumunium Making

Titanium Making

Thanks for your attention