Merge MRT 3.3SelectionWeb

-

Upload

arturdvarela -

Category

Documents

-

view

242 -

download

0

Transcript of Merge MRT 3.3SelectionWeb

-

7/23/2019 Merge MRT 3.3SelectionWeb

1/23

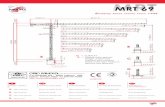

Modern Railway Track PREFACE

i

Digital Edition 2014

Version 3.1

Modern Railway Track

Coenraad Esveld

-

7/23/2019 Merge MRT 3.3SelectionWeb

2/23

Modern Railway Track PREFACE

ii

Modern Railway Track

Digital Edition 2014, version 3.1

Coenraad Esveld

Emeritus Professor of Railway EngineeringDelft University of Technology

Director of Esveld Consulting Services

This digital version of Modern Railway Track is published by

MRT-Productions

A subsidiary of Esveld Consulting Services BV

ISBN 978-1-326-05172-3SISO 696.3 UDC 625.1

Copyright 2001/2014 C. EsveldThis work is subject to copyright. All rights are reserved, whether the whole or part of the

material is concerned, specifically the right of translation, copying, reprinting, re-use ofillustrations, recitations, broadcastings, reproduction on microfilm or in other ways, and storagein data banks. Duplication of this publication or parts thereof is only permitted under the Dutch

Copyright Law.

The digital version 3 can be bought via www.esveld.com. The paper version of the secondedition can also be ordered from www.esveld.com.

MRT-Productions - Groenwal 25 - NL-5301 JJ Zaltbommel - The NetherlandsTel.: +31 6 543 683 60. Email: [email protected]

Internet: www.esveld.com

-

7/23/2019 Merge MRT 3.3SelectionWeb

3/23

Modern Railway Track PREFACE

iii

Preface to the Digital Edition

After more than 10 years, and with the upcoming digital techniques, I considered it the righttime to publish a digital version of this book. The present edition MRT-3 is just a digital copy ofthe original version of the Second edition, with all errata corrected and with some minorupdates.

It is my intension to update the book in the next couple of years to the actual state oftechnology, with emphasis on weld treatment and slab track. But also contact mechanics, trackcomponents and the new EN standards will be treated. That digital version will be published asMRT-4

It would be very much appreciated if the readers of this book will suggest any improvements orenhancements. Please dont hesitate to contact me at [email protected]. Actualinformation can be found on www.esved.comunder the heading Modern Railway Track. At theheading Downloads and then Additional Downloads you can find pdf files of my lectures,conference presentations and a basic railway course in Dutch.

Autumn 2014,

Coenraad Esveld

-

7/23/2019 Merge MRT 3.3SelectionWeb

4/23

Modern Railway Track PREFACE

xv

10.4.4 Thermit welding ............................................................................................. 345

10.4.5 Cooling rates.................................................................................................. 350

10.4.6 Improvement of weld geometry ....................................................................... 352

10.4.7 Weld geometry standards ............................................................................... 352

10.5 Rail failures .......................................................................................................... 353

10.5.1 Defects in rail ends ......................................................................................... 353

10.5.2 Defects away from rail ends ............................................................................ 354

10.5.3 Weld and resurfacing defects .......................................................................... 360

10.5.4 Rail defect statistics ........................................................................................ 363

11 SWITCHES AND CROSSINGS ....................................................................................... 370

11.1 The standard turnout ............................................................................................ 370

11.1.1 Set of switches ............................................................................................... 371

11.1.2 Common crossing ........................................................................................... 372

11.1.3 Closure rail .................................................................................................... 374

11.1.4 Rails and sleepers in turnouts .......................................................................... 374

11.2 Geometry of the turnout ....................................................................................... 374

11.3 High-speed turnouts ............................................................................................. 375

11.3.1 General ......................................................................................................... 375

11.4 Vehicle dynamic ................................................................................................... 375

11.4.1 Examples of modern high-speed turnouts ......................................................... 376

11.5 Notations used for switches and crossings .............................................................. 377

11.6 Types of turnouts and crossings ............................................................................ 377

11.7 Cross-overs .......................................................................................................... 379

11.8 Switch calculation ................................................................................................. 382

11.8.1 Relation between curve radius and crossing angle ............................................. 382

11.8.2 Calculation of main dimensions ........................................................................ 384

11.8.3 Geometrical design of switches and crossings ................................................... 385

11.9 Production, transport and laying of switches ........................................................... 386

12 TRACK MAINTENANCE AND RENEWAL ......................................................................... 387

12.1 Introduction ......................................................................................................... 387

12.2 General maintenance aspects ................................................................................ 388

12.3 Spot maintenance of track geometry ...................................................................... 388

12.4 Rail grinding and reprofiling .................................................................................. 390

12.4.1 Rail grinding machines .................................................................................... 390

12.4.2 Rail reprofiling machines ................................................................................. 392

-

7/23/2019 Merge MRT 3.3SelectionWeb

5/23

Modern Railway Track 1 INTRODUCTION

8

The contact line should be kept at a constant tension for a good and continuous contact withthe pantograph which is pushed against the wire by means of springs. The tension is obtainedby weights or by means of gas cylinders at the end of the wire. Given the material of the wire(copper), the length of the wire (about 1500 m), and temperature fluctuations, length variationsappear of about 50 cm. It is therefore of importance that the suspension points of the wires are

able to move with the expanding and contracting wire.

Regarding this two catenary systems can be distinguished:

a.

fixed suspension: for instance portal structures (Figure 1.2, left picture),

b. flexible suspension: for instance poles (Figure 1.2, right picture)

With a. the portals and carrying cables are fixed to each other. Because of this the carryingcables sag a little with warm weather and hence the contact wire as well. With b. the poles andcarrying cables are fastened to each other flexibly. The cantilevers of the poles are movable andwill change along with the carrying cables when temperature changes. The contact wire can

now stay completely flat. The single pole structure is used with speeds of 140 km/h and higher.At lower speeds portal structures can be used.

Concerning metro systems the so-called third rail takes care of the supply of the current. Thisrail is installed next to the two rails carrying and guiding the train. Because of this no catenarysystem is necessary. This leads to a smaller clearance and therefore a smaller and cheapertunnel construction is possible. When crossing over metro lines, the required height under thebridge can be lower. However, people should always be kept away from this third rail; the trackshould be inaccessible and without level crossings.

Figure 1.2: Catenary systems: fixed and flexible suspension

2.854.002.85

H- profile carrying cable (fixed)

BS

5.50+ BS

8.50+ BS

Catenary system via portal structure: V 140 km/h

contact wire (movable) )

8.60+ BS

7.02+ BS

5.50+ BS

carrying cable

(movable)

contact wire (movable)

BS

Catenary system via rotating lever: V > 140 km/h

-

7/23/2019 Merge MRT 3.3SelectionWeb

6/23

Modern Railway Track 1 INTRODUCTION

15

Tracks and switches areassets which will last forquite some years. Thechoice of a particulartrack system and thedecision to use this

system on certain lines,therefore, generallyinvolves a decisionwhich will hold good for20 to 50 years.Consequently, suchdecisions must be takenwith the future in mind,however difficult it maybe to make a validprediction. The only

sure factor is that a certain degree of objectivity must be maintained vis--vis the present daysituation, and not too much emphasis placed on random everyday events.

When choosing a track system, the above-mentioned requirements must all be given dueconsideration and it is clearly necessary to form some idea of the axle loads and maximumspeeds to be expected in the decades to come. After this the situation regarding the varioustrack components, such as rails, sleepers, fastenings, switches, and ballast should be examinedso that the optimum track design is obtained.

1.6.2 Load-bearing

function of the track

The purpose of track isto transfer train loadsto the formation.Conventional track stillin use consists of adiscrete system madeup of rails, sleepers,and ballastbed. Figure1.8 shows a principle

sketch with the maindimensions.

Load transfer works onthe principle of stressreduction, which meanslayer by layer, asdepicted schematicallyin Figure 1.9. Thegreatest stress occurs between wheel and rail and is in the order of 30 kN/cm2 (= 300 MPa).

Figure 1.8: Conventional track structure

Figure 1.9: Principle of load transfer

H = 100000 N/cmWheel/rail

rs = 250 N/cmRail/rail pad

/baseplate

sb = 30 N/cmSleeper

/ballastbed

bs = 70 N/cm

= 5 N/cmBallastbed/substructure

Ars = 200 cm

AH = 1 cm

Asb = 1500 cm

10000 cm

Abs = 750 cm

area

Wheel:

Axle: P = 200 kN

Q = 100 kN

Mean stress

(under rail 50 %)level

Baseplate

/sleeper

25 - 30 cm ballast (crushed stone 30/60)

Subgrade

10 cm gravel

Rail st = 900 N/mm

SleeperConcrete or Wood

Axle load = 225 kN max.

Fastening system

Spacing 0.6 m

-

7/23/2019 Merge MRT 3.3SelectionWeb

7/23

Modern Railway Track 2 WHEEL-RAIL INTERFACE

17

2 WHEEL-RAIL INTERFACE

2.1 Wheel-rail guidance

A rail vehicle basically consists of a body supported by secondary suspension on bogies in whichthe wheelsets are mounted and damped by means of primary suspension. Track guidance of

the wheel is achieved in principle by making the following two provisions:

The tires are conical instead of cylindrical which means that in straight track a centering

force is exerted on the wheelset if there is slight lateral displacement. The centering

effect promotes a better radial adjustment of the wheelset in curves. This leads to more

rolling, less slipping and hence less wear.

The tires have flanges on the inside of the track to prevent derailment. In case of more

considerable lateral displacement both in curves and on switches, the lateral clearance

between wheelset and track is often no longer sufficient to restrict lateral displacements

adequately by means of the restoring mechanism previously discussed. Should the

wheel flange touch the rail head face, this can result in high lateral forces and wear.

2.2 Wheelset and track dimensions

Generally the track gauge is used as a distance measured between the two rails, morespecifically the distance between the inside of the railheads measured 14 mm below the surfaceof the rail. By choosing 14 mm the measurement is less influenced by lipping or lateral wear onthe rail head and by the radius r = 13 mm of the rail head face. On normal track the gauge is1435+10-3 mm with a maximum gradient of 1:300. For new track, however, NS apply thefollowing standards:

Mean gauge per 200 m: 1435+3-1mm

Standard deviation within a 200 m section less than 1 mm.

70 mm

Track width 1500 (nominal)

Track distance 4.00 4.50 m

Track gauge 1435

Inside gauge 1360+3/3

Flange gauge 1426+0/16

Mean wheel circle

Track gauge

Flange gauge

14

10

Inclination1:20 (1:40)

Track width

+10/3

Figure 2.1: Wheelset and track dimensions for straight normal gauge track

-

7/23/2019 Merge MRT 3.3SelectionWeb

8/23

Modern Railway Track 2 WHEEL-RAIL INTERFACE

22

Here r1 - r2 is the instantaneous difference in rollingradius of the wheel treads; generally speaking this is anon-linear function of the lateral displacement y of thewheelset with respect to the central position. Thedifference between conical and worn profiles is given inFigure 2.7. To enable numerical comparisons e is at acertain lateral displacement y y=.

With a conical profile the conicity is constant and (2.8)becomes (see also):

In the next paragraph the effects resulting fromprogressive non-linear behavior of the effective conicityand its influence on the running stability of vehicles and

rail wear are dealt with in greater detail.

2.6 Worn wheel profiles

A perfectly conical wheel profile isunstable as far as its shape is concerned,but will take on a shape that is stable asthe effect of wear. In addition, conicalprofiles have the disadvantage that asubstantial lateral movement will, becauseof the two-point contact, lead directly to

an impact. If the profile of the rail andwheel tire at the point of contact isassumed to be circular, it can be deducedfrom

Figure 2.8 that in the case of lateraldisplacement y of the wheelset withrespect to the track, the contact point onthe rail will over a distance translate to:

Moreover, if the value of y is smallcompared to the radii, the followingrelationship holds true:

= = ( + ) ( )

= (2. 9)

=

(2. 10)

= tan 2 = 2 (2. 11)

Figure 2.7: y-r curves. Difference between conical andworn wheel profiles

Figure 2.8: Displacement of contact point on rail due to wheelsetdisplacement

r = r1 - r2

Worn profile

Flangeway clearance

Conic profile

2e

y y

y

y s

r

w

w

r

r

r

r= radius of rail= radius of wheelw

-

7/23/2019 Merge MRT 3.3SelectionWeb

9/23

Modern Railway Track 2 WHEEL-RAIL INTERFACE

30

give a stable equilibrium, but will instead induce a highly frequent jumping to and fro betweentwo points on the curve.

2.7.6 Spin

Apart from slip in thelongitudinal and lateraldirection a third quantity alsoexists: the so-called spin whichalso participates intransmitting the friction force.Spin or rotational slip arises ifthe small contact areabetween wheel and rail is notparallel to the rotation axis of

the wheelset. The rotationvector of the wheelset can

then be decomposed in acomponent parallel to the contact area (this is pure rolling), and a component perpendicular toit, which is the rotational slip or spin as indicated in Figure 2.23.

The spin is defined as:

It should be noted that the spin has adimension [1/m].

When spin takes place, the relativemovements between wheel and rail willalso partly be taken up by elastic distortionand partly by slip. The result will be that inthe contact area forces are generated withvarying magnitude and direction, theresultant of which produce a force in thelateral direction. This can be clarified bymeans of Figure 2.24.

In this picture, which was used innumerical considerations about contactmechanics, the contact ellipse is dividedinto a grid of small elements. Each elementshows the magnitude and direction of theslip regarding that element.

= sin =sin

(2. 16)

Figure 2.23: Effect of spin

Figure 2.24: Origination of pure spin

Force on Rail

Force on Wheel

Rotation Vector

Rolling

SpinRunning direction

Wheel

SlipAdhesion

Lea

din

g

edge

dy

dx

y

x

SlipAdhesion

Lea

din

g

edge

dy

dx

y

x

-

7/23/2019 Merge MRT 3.3SelectionWeb

10/23

Modern Railway Track 9 SLAB TRACK

285

After adjustment, the rail is made stress free by means of heating before the compound ispoured into the groove (Figure 9.52).

9.8.3 Experiences with embedded rail

Many pilot tracks of embedded rail have been applied over the last 30 years, 246 m paved-in as

well as main-line track. Nearby Deurne (The Netherlands) in 1976, a pilot was constructed inheavily used track with speeds up to 160 km/h. The track existed of a series of 6 meters ofprefabricated slabs containing the gullies supported underneath with old NP46 rails [201]. Theexperiences were qualified as positive. In 1994, the rails were renewed, but the wear of thoserails was considerably less compared to the adjacent track.

Another large pilot concerned 3 km track nearby Best (The Netherlands) which came intooperation in October 1999 and is currently being monitored.

The superstructure consists of a 42 cm thick slab with longitudinal reinforcement providing theslab with a high flexural strength. The slab lies on top of a concrete road bed and stabilized

subsoil. The cross section of this track structure is shown in Figure 9.48, while the constructionprocess of this test track is illustrated in Figure 9.49 up to and including Figure 9.54.

Figure 9.48: Cross section of the embedded rail superstructure near Best

Figure 9.49: Installing of the rails Figure 9.50: Positioning of the rails by means of wedges

Sand bed

Embedded Rail

2.5 m

0.6 m

Concrete slab

-

7/23/2019 Merge MRT 3.3SelectionWeb

11/23

Modern Railway Track 10 THE RAIL

309

A water-cooled oxygen lance is lowered into

the furnace and high-purity dry oxygen isblown onto the metal at very great speed.The oxygen combines with carbon and

other unwanted elements, thus eliminatingthese impurities from the molten charge.The carbon is blown down to less than0.1%. During the "blow" lime is added as aflux to help carry off the oxidized impuritiesas a floating layer of slag.

The positioning of the lances, thedetermination of the volume of oxygen tobe injected, the additions to be made and

Figure 10.3: Basic Oxygen Furnace (BOF) (Corus)

Figure 10.4: Filling process of converter

-

7/23/2019 Merge MRT 3.3SelectionWeb

12/23

Modern Railway Track 11 SWITCHES AND CROSSINGS

370

11 SWITCHES AND CROSSINGS

11.1 The standard turnout

Turnouts are used to divide a track into two, sometimes three tracks. The purpose of crossingsis to allow two tracks to intersect at the same level. If a complete train is to pass from one track

to another while moving and without being subdivided, turnouts are essential in the absence ofturntables or traversers.

It must be possible to run through switches and crossings in both directions. A normal or singleturnout, as shown in Figure 11.1, allows movement of traffic in a straight direction on thethrough track or in a divergent direction. A picture of the right-hand turnout is given in Figure11.2.

The turnout consists of three majorparts:

Set of switches (switch blades); Common crossing; Closure rail.

These parts will be discussedseparately below.

L

A B

R = . . . m1 : n

Half set of switch

Switch blade

Switch point

Stock rail

Front of turnout

Clamping (heel)

Check rail

Closure rail

Through rail

Rear of turnoutIntersection point

Crossing

Wing rail

Figure 11.1: Standard right-hand turnout

Figure 11.2: Picture of right-hand turnout

-

7/23/2019 Merge MRT 3.3SelectionWeb

13/23

Modern Railway Track 12 TRACK MAINTENANCE AND RENEWAL

422

Figure 12.61: Formation rehabilitation machine AHM 800 R

Figure 12.62: Example of tracks after formation rehabilitation with geotextile

-

7/23/2019 Merge MRT 3.3SelectionWeb

14/23

Modern Railway Track 16 INSPECTION AND DETECTION SYSTEMS

582

16.10.4 Quasi-static signals

In addition to the dynamic signals, quasi-static signals are produced for cant, curvature, andgauge. The measuring principles are presented schematically in Figure 16.84. Problems due todrift and lack of initial conditions mean that the quasi-static cant is not determined byintegration of the rate gyro signal, but by making use of the lateral car body acceleration,

curvature, and recording speed as indicated in Figure 16.84.

Two other transducers are, in addition to the two linear displacement transducers between carbody and bogie frame in the measuring bogie, installed in the second bogie to record curvature

according to the principle sketched in Figure 16.84. The quasi-static gauge is directly derivedfrom the line-scan camera signals.

All three quasi-static signals are low-pass filtered with a 3rd-order Bessel filter. The phaserelationship is linear and causes a distance delay of 27.5 m. As the curvature recorded in factcorresponds to the car center, the delay of the signal in relation to the measuring bogieamounts to 35 m or 20 m for forwards and backwards running respectively. With theintroduction of VRA this delay can be corrected.

16.10.5 Signal combination for determining track parameters

The track parameters produced by the former BMS system of NS are derived from a

combination of signals provided by 16 transducers, i.e. 1 rate gyro, 2 accelerometers, 10LVDTs, 2 line-scan cameras, and 1 tachometer. The location of the various transducers isindicated in Figure 16.85. The track parameters are derived from the following expressions:

Level:

= + 2 + (16.6)

Figure 16.84: Recording principle for BMS-1 quasi-static signals

Y

CANT

All signals low pass filtered with 3rd order Bessel filter

CURVATURE GAUGE

B

2 gvY

= B

B

2vBg

g

LR

1 =

21 +=

1 2

R

L

mm1435YYY RLS ++=

LY RY

-

7/23/2019 Merge MRT 3.3SelectionWeb

15/23

Modern Railway Track 16 INSPECTION AND DETECTION SYSTEMS

608

TEC for plain line track; TEE for switches; TET for tramway track.

Figure 16.106a: TEC Trolley Figure 16.106b: TEC Trolley with laser add-on to measure rail pr

Figure 16.106c: TEC control unit

Figure 16.107: Example of track geometry measurement results

-

7/23/2019 Merge MRT 3.3SelectionWeb

16/23

Modern Railway Track 16 INSPECTION AND DETECTION SYSTEMS

623

16.18 Weld geometry standards

Force geometry relationship

Dynamic components of the wheel rail contact force have a significant impact on trackdeterioration and should therefore be kept as low as possible. Weld geometry plays an

important role as a main contributor to high-frequency loads. At TU Delft this aspect was givenhigh priority in the early beginning of the 21 century, with a study aiming at developing atheory, with associating algorithm, to describe dynamic component of the vertical wheel railcontact force. The algorithm should be such that it could be implemented in a PDA, or hand-held computer, fast enough to make real time calculations within seconds.

The existing ways of weld

geometry assessment were

based on considering

measured versines which were

then tested against maximum

allowable values. From the

theory developed at TU Delft it

became apparent that the

versine approach was not

correct for representing forces,

but that instead the inclination

of the geometry, in fact the

first derivative of the

measured versines, should be

taken. All the filtering andanalyzes are made in a PDA

and presented to the user in a

normalized way via so-called

quality indices (QI). The

theory behind this concept was

documented in various publications, amongst others [309, 310]. The paper Force-based

Assessment of Weld Geometry [309] received the Best Paper Award for Infrastructure at the

WCRR in Montreal, Canada, June 2006.

The vertical wheel rail contact force is approximately proportional to the square of the speed. Inthis way the standards are speed dependent. Furthermore the contact force is linearly related tothe inclination (first derivative dy/dx of the geometry).

The inclination is determined from the versines measured with the RAILPROF on a base of 1 m,sampled at an interval of 5 mm. During data processing the samples are averaged (low-pass

=

(16.43)

Figure 16.131: Best Paper Award, WCRR Montreal 2006

-

7/23/2019 Merge MRT 3.3SelectionWeb

17/23

Modern Railway Track 16 INSPECTION AND DETECTION SYSTEMS

624

filtered) via a movingwindow of 5 samples. Thismeans that the shortestwavelength in the resultingsignal is 25 mm. This isdone to eliminate

irregularities with a shorterlength-scale.

The corresponding verticalcoordinate of the geometryis calculated as theaverage of the 2 verticalcoordinates of themeasuring positions atboth sides of themeasurement point and that of the measurement point itself (5 coordinates). At the boundaries

of the record 2 measurement points are added; their coordinates are determined by mirroring.At both edges the first filtered data point then coincides with the boundary of the originalrecord (Figure 16.133).

After filtering, the first geometrical derivative of the discrete filtered measurement signalis determined (Figure 16.134), via the formula:

where:

D(i): first derivative of the measurement;

y(i): level-coordinate of the record (after filtering);

dx: sample-interval after filtering (25 mm)

The calculated QI values are based on this signal, as depicted at the PDA screen presented inFigure 16.135.

() =( + 1) ()

(16.43)

Figure 16.132: Dynamic contact force versus inclination

Figure 16.133: Filtering and applied method at the record boundaries

Figure 16.134: Calculation of the 1st derivative of the filtered signal

Added data points Original data points

Filtereddata points

spaced 25 mm

Boundaryoriginal signal

y(i +1)y(i)

dx = 25 mm

-

7/23/2019 Merge MRT 3.3SelectionWeb

18/23

Modern Railway Track 16 INSPECTION AND DETECTION SYSTEMS

625

RAILPROF PDA screen.

On the RAILPROF screen (Figure 16.135) the blue line represents the vertical geometry, theorange line the QI. The person doing the finish grinding can immediately see where the QI isexceeding the norm (by definition QI = 1) - in this case 6 % - and which spots should beground. In the figure it is clearly seen that the slope right of the middle is too large and so thecenter part should be ground to decrease the inclination and thus the maximum QI.

Figure 16.136 shows maximum dynamic contact forces calculated with the program DARTS NLas a function of versine (geometry) and inclination (first derivative dy/dx of the vertical railgeometry). From the left-hand graph it is obvious that the contact force does not correlate (9%) with the versine (geometry), whereas the inclination (QI) in the right-hand graph very wellcorrelates (91 %) with the force. This means, amongst others, that a steel straightedge, as stillin use on a wide scale, is absolutely inadequate.

max

norm

InclinationQI = 1 OK

Inclination

Figure 16.135: Quality Index (QI) definition

Figure 16.136: Quality Index (QI) definition

-

7/23/2019 Merge MRT 3.3SelectionWeb

19/23

Modern Railway Track 16 INSPECTION AND DETECTION SYSTEMS

626

Rail geometry standards applied at ProRail in the Netherlands

The admissible QI in relation to the line speed is presented in Table 16.10, which values arepresently the official standards used by ProRail in The Netherlands and these standard havealso been adopted by the tram and metro companies in Holland. These are all based on the TUDelft studies referred to previously.

From a practical point of view the new standards have a number of advantages, amongstothers:

Negative welds are allowed;

Maximum versine at 140 km/h is 2 times larger than in the olds approach;

The standards are now speed dependent.

Cost savings

With the introduction of the new approach on force-based assessment of weld geometry andthe adoption of new QI-based standards, various estimates were made about the reduction inmaintenance cost which could be achieved if complying with the new standards. Theseestimates are presented in Figure 16.137, which shows that 1020 % reduction of the annualmaintenance budget could be achieved. According to ProRail figures, collected around 2010, theclaimed track maintenance cost reductions were too conservative and would be more in theorder of 20 - 40 % according to more recent maintenance experiences!

Standards vertical rail geometry

Speed [km/h] Inclination [mrad]

250 < V 300 1.0

200 < V 250 1.1

180 < V 200 1.3

160 < V 180 1.4

140 < V 160 1.6

120 < V 140 1.8

100 < V 120 2.0

90 < V 100 2.2

80 < V 90 2.3

70 < V 80 2.4

60 < V 70 2.6

50

-

7/23/2019 Merge MRT 3.3SelectionWeb

20/23

Modern Railway Track 17 HIGH-SPEED TRACKS

631

The TGV

After intensive tests with thegas-turbine "TGV 001" and theelectric "Zbulon", in 1977, theSNCF placed an order for 87TGV Sud-Est train sets. Theyused the "TGV 001" concept,with a permanently coupled setof eight cars, sharing "Jakobsbogies", and hauled by twoelectric power-cars, one at eachend.

In 1981, the first section of thenew Paris-Lyon High-Speed line was inaugurated, with a maximum speed of 260/270 km/h.With this much higher speed, this dedicated high-speed line, offered the ability to join

connected cities in a much shorter time. After the introduction of the TGV on some routes, airtraffic on these routes decreased, or even disappeared. At the same time, the TGV made historywith its multiple, highly publicized speed records: in 1981 with a record at 380 km/h, in 1990 at515 km/h, and then in 2007 at 574 km/h.

Figure 17.3 TGV_POS_Nuremberg_Ingolstadt.

Figure 17.4 European high-speed network as per ultimo 2013.

-

7/23/2019 Merge MRT 3.3SelectionWeb

21/23

Modern Railway Track 17 HIGH-SPEED TRACKS

634

The Chinese CRH3

State planning for China's high-speed railway began in the early 1990s, and the country startedconstruction of its first high-speed rail line, the QinhuangdaoShenyang Passenger Railway, in1999, which subsequently opened in 2003 with a design speed of 200 km/h.

The original goal of the Chinese Ministry of Railways (MOR) was to research and developdomestic technology to reach a world standard. The new high-speed rail line was used to testseveral Chinese developed prototypes. Although they were successful at creating a train setthat operated at 300 km/h, the trains performed poorly in regular service. Realizing thatdomestic high-speed technology was not sufficiently developed, the MOR purchased high-speed

trains from French, German, and Japanese manufacturers with technology transfer contracts toimprove its ability to build high-speed trains. In 2007 the first high-speed service using foreignhigh-speed trains, called China Railways High-Speed (CRH) was introduced.

Figure 17.7 Chinese CRH380B-6410L

Figure 17.8 Taiwan (THRR) high-speed train

-

7/23/2019 Merge MRT 3.3SelectionWeb

22/23

Modern Railway Track 17 HIGH-SPEED TRACKS

654

After this C1 and C2 can be computed. With C1 and C2 and the function of pe(t) provided for

instance by the program THERMATUN/5, pi(t) can be calculated.

The time for reducing of the inside air-pressure from 3.0 kPa to 0.1 kPa is 51 s. The factor k isestimated 0.07 based on a French TGV-R. With these values the constant factors C1and C2arethen 0.03408 and 0.02661 respectively. (Figure 17.16)

Figure 17.22: Characteristic pressure course in a leak test Figure 17.23: Static leak test: comparison of measuring/calculation

Figure 17.24: Proposed Dutch criterion for p in train bysolo trains in tunnels

Dp1

Dp2

Dp3

to t1 t2

Dp

10 20 30 40 50

Calculated

Measured

t0 = 0

t1

= 27.24 s

t2 = 56.00 s

Time [s]

Pressure

[kPa]

3.5

3

2.5

2

1.5

1

0.5

00

Proposal

Germany 1989

Germany 1996

Japan 1996

Japan 1993

C

B

A

50% 30% 10%

2,5%

Time period [s]

Pressure

variation

[kPa]

0 2 4 6 8 10 12 14 16 18 20

0

500

1000

1500

2000

2500

-

7/23/2019 Merge MRT 3.3SelectionWeb

23/23

Modern Railway Track CV Coenraad Esveld

Plasser & Theurer, Austria: Various consulting works on track maintenance applications;

SPOORNET, South Africa: Network inspection and advise on improving trackcomponents and maintenance strategy;

Metro Amsterdam: studies on wheel rail interface optimization and track maintenance

strategies; advices on design problems with new lines;

State Rail Authority of New South Wales, Australia: Studies carried out on track qualityassessment and track recording;

Europoint, The Netherlands: Organizing various conferences and seminars, such as Rail-Tech Europe;

UIC/ORE/ERRI: Project management of various research projects, such as D202 onTrack Stability and longitudinal forces;

Great Belt Bridge: Advisor to ARCADIS for the dynamic analysis of the bridge transitions;

MAIN ACTIVITIES OF ECS

Training and seminars

High Speed Operation

Heavy Haul and Heavy Axle Loads

Vehicle - Track Interaction

Track Dynamics

Track Maintenance Operations

Decision Support Systems

Life Cycle Costs

Development and Testing of Track Structures

Measuring and Recording Systems for Track Applications

Optimization techniques and applications

PUBLICATIONS

http://www.esveld.com/Download/TUD

http://www.esveld.com/RP_PDA.htm

ftp://213.127.130.218/ Lectures, presentations, railway videos.

http://www.esveld.com/Download/TUDhttp://www.esveld.com/Download/TUDhttp://www.esveld.com/RP_PDA.htmhttp://www.esveld.com/RP_PDA.htmftp://213.127.130.218/ftp://213.127.130.218/ftp://213.127.130.218/http://www.esveld.com/RP_PDA.htmhttp://www.esveld.com/Download/TUD