Mercedes-benz ggn report

-

Upload

munish-saroch -

Category

Documents

-

view

41 -

download

1

Transcript of Mercedes-benz ggn report

T & T Motors Ltd.

INDUSTRIAL TRAINING REPORT

Submitted To:- Submitted By:-

Name –Munish Kumar

Name: Munish Kumar

1 | P a g e

College: L.R. Institute Of Engineering & Technology, Solan (HP)

University: Himachal Pradesh Technical University

Place Of Training : T & T Motors Ltd., New Delhi

KhasaraNo.-5/4/1/2, Village-Begampur, Khatola, Gurgaon-122001(Haryana)

Period From: July 14, 2015 to September 15, 2015

Duration: Two Month

Field Of Training : Automobile

TABLE OF CONTENTS

2 | P a g e

i. Introductiona) Historyb) Productionc) Quality rankingd) Models e) Cars Nomenclaturef) Logo historyg) Innovation

(Workshop)

ii. Turbocharger a) Turbocharger versus superchargerb) Operating principal

iii. Wheel alignmenta) Primary anglesb) Caster angelc) Camber angeld) Toe angel

iv. Importantv. Tools and machines

vi. Disc brakea) Whats the difference?b) Calipersc) Brake padsd) Piston and cylinders

vii. Parking brakeviii. EGR

ix. Service or Maintaincex. ABR

xi. Impotantxii. ABS

a) Componentsb) Speed sensorsc) Valves

3 | P a g e

d) Pumpe) Controller

xiii. Automatic transmissionxiv. Automatic transmission modesxv. Important

xvi. Shock absorberxvii. Intercooler

xviii. Radiatorxix. Condenserxx. Set up of belt over pulley

xxi. Steering systemxxii. Tools and machines used in workshop

(Bodyshop)

i. Substrate preparation guideii. Procedure of making paint

iii. Important

4 | P a g e

ACKNOWLEDGEMENT

It is always pleasure to remind the fine people in the engineering workshops and college for their sincere guidance to uphold my practical as well as theoretical skill in engineering .

I express my profound gratitude to our H.O.D and all the faculty members of the Mechanical Department for taking pains to guide me in the preparation of this industrial training report.

Firstly, I would like to thank Mr. Rajesh Gohan, Mr. Neeraj Jha and Mr. Mandeep Ahluwalia, Mr. Bikash Debnath which gives me to opportunity to work as a trainees in T & T Motors Ltd.

Secondly, I would like to thank my technician Mr. Jaswinder, Mr. Varinder, Mr. Vijay,and which gives support and guidance I received from them almost for all the work I did there.

Finally I apologize all other unnamed who helped me in various ways to have a good training.

5 | P a g e

Introduction

Mercedes- benz is a German automobile manufacture, a multinational division of the german manufacture Daimler AG. The brand is used for luxury automobiles, buses, coaches, and trucks. The headquarters of Mercedes-Benz is in Stuttgart, Baden-Wurttemberg, Germany.

The name first appeared in 1926 under Daimler AG but traces its origins to Daimler-Motoren-Gesellschaft’s 1901 Mercedes and Karl Benz’s 1886 Benz patent Motorwagen, which is widely regarded as the first automobile. Mercedes-Benz’s slogan is “Das Beste oder nichts”(English: ”The best or nothing”). Mercedes-Benz is part of the “German Big 3” luxury automakers, along with Audi and BMW, which are the best selling luxury automakers in the world.

History

Mercedes-Benz traces its origins to Karl Benz’s creation of the first petrol-powered car, the Benz Patent Motorwagen, financed by Bertha Benz and patented in January1886, and Gottlieb Daimler and engineer Wilhem Maybach’s conversion of a stagecoach by the addition of a petrol engine later that year. The Mercedes automobile was first marketed in 1901 by Daimler-Motoren-Gesellschaft’s. The first Mercedes- benz brand name vehicles were produced in 1926, following the merger of Karl Benz’s and Gottlieb Daimler’s companies into Daimler-Benz company. Throughout the 1930s, Mercedes-Benz produced the 770 model, a car that was popular during Germany ‘s Nazi period. Adolf Hitler was known to have driven these cars during his time in power, with bulletproof windshields. Most of the surviving models have been sold at the auction to private buyers. One of them is currently on display at the War Museum in Ottawa, Ontario. Mercedes-Benz has introduced many technological and safety innovations that later became common in the vehicles. Mercedes-Benz is one of the best known and established

6 | P a g e

automotive brands in the world, and is also one of the world oldest automotive brand still in existence today in 2014, having produced the first petrol-powered car.

Production

Factories: Besides its native Germany, Mercedes-Benz vehicles are also manufactured or assembled in:

Argentina –manufactures buses, trucks and the spinter van. This is the first Mercedes-Benz factory outside of Germany . Built in 1951.

Austria (G-Class) Bosnia and Herzegovina Brazil-manufacture trucks and buses. Established in 1956. The A-Class

(W168) was produced from 1999 to 2005 and the C-Class was produced until 2010 as well.

Canada China Egypt India, Bangalore(R&D) India(Pune) India, Chennai (Daimler India Commercial Vehicles Pvt. Ltd.)- Trucks &

Engine Manufacturing unit Indonesia Malaysia Mexico Nigeria Philippines Russia Spain South Africa South Korea United kingdom United states

7 | P a g e

Jordan: buses company factory Elba House, Amman

Quality ranking

Since its inception, Mercedes-Benz had maintained a reputation for its quality and durability. Objective measures looking at passenger vehicles, such as J.D. Power surveys, demonstrated a downturn in reputation in these criteria in the late 1990s and early 2000s. By mid-2005, Mercedes temporarily returned to the industry average for initial quality, a measure of problems after the first 90 days of ownership, according to J.D. power.

For 2008, Mercedes-Benz’s intial quality rating improved by yet another mark, to fourth place. On top of this accolade, it also received the Platinum Plant Quality Award for its Mercedes’s Sindelfingen, Germany assembly plant.

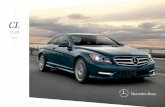

Models

A-Class-Hatchback B-Class-Multi Purpose vehicle(MPV) C-Class-Saloon, Estate &Coupe CL-Class-Luxury coupe CLA-Class-4 Door coupe CLS-Class-4 Door Coupe and Estate E-Class-Saloon, Estate, Coupe and Carbriolet G-Class-Sports Utility Vehicle (SUV) GL-Class-Sports Utility Vehicle (SUV) GLA-Class-Sports Utility Vehicle (SUV) GLB-Class-Sports Utility Vehicle (SUV) GLK-Class-Sports Utility Vehicle (SUV) M-Class-Sports Utility Vehicle (SUV) R-Class-Multi Purpose Vehicle (MPV) S-Class-Luxury Sedan SL-Class-Roadster SLK-Class-Roadster

8 | P a g e

SLS AMG- Coupe and Roadster Viano-Multi Purpose Vehicle (MPV) Citan-Mini MPV

Car Nomenclature

Until 1994, Mercedes-Benz used an alphanumeric system for categorizing their vehicles, consisting of a number sequence approximately equal to the engine’s displacement in liters multiplied by 100, followed by an arrangement of alphabetical suffixes indicating body style and engine type.

“C” indicates a coupe or cabriolet body style. “D” indicates the vehicle is equipped with a diesel engine. “E” (for “Einspritzung”) indicates the vehicles engine is equipped with

petrol fuel injection. In most cases (the 600 limousine being the exception), if neither “E” or “D” is present, the vehicle has a petrol engine with carburettor.

“G” indicates the Gelandewagen off-road vehicles. “K” was used in the 1930s, indicating a supercharger (“Kompressor”)

equipped engine. One exception is the SSK,where K indicates “Kurz”(short-wheelbase).

“L” indicates “Leicht”(lightweight) for sporting models, and “Lang”(long- wheelbase) for sedan models.

“R” indicates “Rennen”(racing), used for racing cars (eg. 300 SLR) “S” Sonderklasse “Special Class” for flagship models. “T” indicates “Touring” and an estate (or station wagon) body style.

Some models carry further designations indicating special features:

“4MATIC” indicates the vehicle is equipped with all-wheel-drive. “Blue TEC” indicates a desiel engine with selective catalytic reduction

exhaust aftertreatment. “Blue EFFICIENCY” indicates special fuel economy feature (direct

injection, start-stop system, aerodynamic modification, etc.) “CGI” (Charged Gasoline Injection) indicates direct gasoline injection. “CDI” (Common-rail Direct Injection) indicates a common-rail diesel

engine.

9 | P a g e

“Hybrid” indicates a gasoline or diesel-electric hybrid. “Kompressor” indicates a supercharged engine. “Turbo” indicates a turbocharged engine, only used on A-, B-, E- and GLK-

Class models. “AMG Line” indicates the interior or engine, depending which car, has been

fitted with the luxuries of their AMG sports cars.

Logo History

1902

1909

1916

1926

10 | P a g e

1980

1990

Innovations

Numerous technological innovations have been introduced on Mercedes –Benz automobiles throughout the many years of their production, including:

The internal combustion engine automobile was developed independently by Benz and Daimler & Maybach in 1886

Daimler invented the honeycomb radiator of the type still used on all water –cooled vehicles today.

Daimler invented the float carburetor which was used until replaced by fuel injection.

The first passenger road car to have brakes on all four wheels (1924) In 1936, the Mercedes –Benz 260 D was the first diesel powered passenger

car. Mercedes –Benz were the first to offer direct fuel injection on the Mercedes

–Benz 300SL Gullwing The “safety cage” or “safety cell” construction with front and rear crumple

zones was first developed by Mercedes –Benz in 1951. This is considered by many as the most important innovation in automobile construction from a safety standpoint.

An Anti-Lock Breaking System (ABS) was first offered on the W116 450SEL 6.9. They became standard on the W126 S-class starting production in 1979, and first sold in most markets in 1980.

11 | P a g e

Airbags were first introduced in the European market, beginning with model year 1981 s-class.

Mercedes –Benz was the first to introduce pre – tensioners will tighten the belt instantaneously, removing any ‘slack’ in belt, which prevents the occupant from jerking forward in a crash

In September 2003, Mercedes –Benz introduced the world’s first seven-speed automatic transmission called ‘7G-Tronic’

Electronic Stability Programme (ESP), brake assist, and many other types of safety equipment were all developed, tested, and implemented into passenger cars-first –by Mercedes –Benz. Mercedes –Benz has not made a large fuss about its innovation, and has even licensed them for use by competitors-in the name of improving automobile and passenger safety. As a result, crumple zones and anti-locks brakes (ABS) are now standard on all modern vehicles.

The (W211) E320 CDI which has a variable geometry turbocharger (VGT) 3.0-litre V6 common rail diesel engine (producing 224 hp or 167 kw), set three world endurance records.

Turbocharger

A turbocharger, or turbo (colloquialism), from Latin "turbo" ("spinning top"), is a turbine-driven forced induction device that increases an engine's efficiency and power by forcing extra air into the combustion chamber. This improvement over a naturally aspirated engine's output results because the turbine can force more air, and proportionately more fuel, into the combustion chamber than atmospheric pressure alone.

12 | P a g e

Turbocharger versus supercharger

In contrast to turbochargers, superchargers are mechanically driven by the engine. Belts, chains, shafts, and gears are common methods of powering a supercharger, placing a mechanical load on the engine By comparison, a turbocharger does not place a direct mechanical load on the engine, although turbochargers place exhaust back pressure on engines, increasing pumping losses. This is more efficient, because it uses the otherwise wasted energy of the exhaust gas to drive the compressor. In contrast to supercharging, the primary disadvantage of turbocharger is what is referred to as "lag" or "spool time". This is the time between the demand for an increase in power (the throttle being opened) and the turbocharger(s) providing increased intake pressure, and hence increased power.

Wheel alignment

Wheel alignment, sometimes referred to as breaking or tracking, is part of standard automobile maintenance that consists of adjusting the angles of the wheels so that they are set to the car maker's specification. The purpose of these adjustments is to reduce tire wear, and to ensure that vehicle travel is straight and true (without "pulling" to one side). Alignment angles can also be altered beyond

13 | P a g e

the maker's specifications to obtain a specific handling characteristic. Motorsport and off-road applications may call for angles to be adjusted well beyond "normal" for a variety of reasons.

Primary angles

The primary angles are the basic angle alignment of the wheels relative to each other and to the car body. These adjustments are the camber, caster and toe. On some cars, not all of these can be adjusted on every wheel.

These three parameters can be further categorized into front and rear (with no caster on the rear, typically not being steered wheels) so summarily the parameters are:

Front: Caster (left & right) Front: Camber (left & right) Front: Toe (left, right & total) Rear: Camber (left & right) Rear: Toe (left, right & total)

Caster angle

The caster angle or castor angle is the angular displacement from the vertical axis of the suspension of a steered wheel in a car, bicycle or other vehicle, measured in the longitudinal direction. It is the angle between the pivot line (in a car an imaginary line that runs through the center of the upper ball joint to the center of the lower ball joint) and vertical. Car racers sometimes adjust caster angle to optimize their car's handling characteristics in particular driving situations.

Camber angle

Camber angle is the angle made by the wheels of a vehicle; specifically, it

(From the front of the car, a right wheel with a negative camber angle)

14 | P a g e

is the angle between the vertical axis of the wheels used for steering and the vertical axis of the vehicle when viewed from the front or rear. It is used in the design of steering and suspension. If the top of the wheel is farther out than the bottom (that is, away from the axle), it is called positive camber; if the bottom of the wheel is farther out than the top, it is called negative camber.

Toe angle

Positive toe, or toe in, is the front of the wheel pointing in towards the centre line of the vehicle. Negative toe, or toe out, is the front of the wheel pointing away from the centre line of the vehicle. Toe can be measured in linear units, at the front of the tire, or as an angular deflection.

Important:-

Toe- Inward and outward or left and right Stearing rack

Camber-Shocker

Caster-lower arm

Tools and Machines:-

Target or Tire clamp adaptor:-fixed to all wheels helps to measure angel with help of sensors.

Turning angel gauge:-

Turning angel gauge plate helps to easily turn

Angel-(45-0-45) degree

Tire Changer:- changes tire from wheel easily and comfortably

Wheel or tire balance

Tire balance, also referred to as tire unbalance or imbalance, describes the distribution of mass within an automobile tire or the entire wheel to which it is attached.

15 | P a g e

(An automotive technician installing wheel weights on a wheel balancing machine)

(Zinc tire weight)

Tire + Rim= Wheel Tubeless wheel is used Tire pressure conversion with unit

1KPa=0.145PSI

Romess electronic –Airmatic height calibration-in wheel

Disc brake

A disc brake is a wheel brake that slows rotation of the wheel by the friction caused by pushing brake pads against a brake disc with a set of calipers. The brake disc is usually made of cast iron, but may in some cases be made of composites such as reinforced carbon–carbon or ceramic matrix composites. This is connected to the wheel and/or the axle. To stop the wheel, friction material in the form of brake pads, mounted on a device called a brake caliper, is forced

16 | P a g e

mechanically, hydraulically, pneumatically, or electromagnetically against both sides of the disc. Friction causes the disc and attached wheel to slow or stop. Brakes convert motion to heat, and if the brakes get too hot, they become less effective, a phenomenon known as brake fade. Compared to drum brakes, disc brakes offer better stopping performance, because the disc is more readily cooled.

Carbon ceramic brake- Carbon ceramic brake are used in Mercedes-Benz AMG

Parking brake

In cars, the parking brake, also called hand brake, erroneously called emergency brake, or e-brake, is a latching brake usually used to keep the vehicle stationary. It is sometimes also used to prevent a vehicle from rolling when the operator needs both feet to operate the clutch and throttle pedals. Automobile hand brakes usually consist of a cable directly connected to the brake mechanism on one end and to a lever or foot pedal at the driver's position. The mechanism is often a

17 | P a g e

hand-operated lever (hence the hand brake name), on the floor on either side of the driver, or a pull handle located below and near the steering wheel column, or a (foot-operated) pedal located far apart from the other pedals.

ABR

ADAPTIVE BRAKE extends the scope of ESP® to include a convenient Hill Start Assist feature and the HOLD function, which automatically prevents the vehicle from rolling forwards or backwards unintentionally from a stationary position.

ADAPTIVE BRAKE extends the scope of the familiar Electronic Stability Program (ESP®) to include Hill Start Assist and the HOLD function.

Braking is now even more safe and convenient – with ADAPTIVE BRAKE, which employs the ESP®-integrated control functions of the Antilock Brake System (ABS), Acceleration Skid Control (ASR) and BAS Brake Assist. With the aid of additional software components, new convenience- and safety-related features have been realised in the form of Hill Start Assist and the HOLD function. The HOLD function is activated when the driver steps briefly on the brake again while the vehicle is stationary. The vehicle is then held at a standstill – preventing it from rolling unintentionally forward or backward – without the driver having to keep his foot on the brake pedal.

Hill Start Assist takes the worry out of uphill starts. It prevents the car from rolling back in the opposite direction to the engaged gear as the driver moves his foot from the brake pedal to the accelerator pedal. This function comes into effect from a certain gradient.

Important:- ABR assists the driver in dangerous situations which occur suddenly and thus

serves active safety. In ABR, four pressure line filled with brake oil goes to all four wheels and

having two inlet line. 4MATIC permanent all-wheel drive provides for added dynamism, comfort and

safety on normal roads, too. Its lightweight design adds very little to the vehicle's overall weight.

18 | P a g e

Anti-lock braking system

Anti-lock braking system (ABS) is an automobile safety system that allows the wheels on a motor vehicle to maintain tractive contact with the road surface according to driver inputs while braking, preventing the wheels from locking up (ceasing rotation) and avoiding uncontrolled skidding. It is an automated system that uses the principles of threshold braking and cadence braking which were practiced by skillful drivers with previous generation braking systems. It does this at a much faster rate and with better control than a driver could manage.

ABS generally offers improved vehicle control and decreases stopping distances on dry and slippery surfaces for many drivers; however, on loose surfaces like gravel or snow-covered pavement, ABS can significantly increase braking distance, although still improving vehicle control.

The anti-lock brake controller is also known as the CAB (Controller Anti-lock Brake).Typically ABS includes a central electronic control unit (ECU), four wheel speed sensors, and at least two hydraulic valves within the brake hydraulics. The ECU constantly monitors the rotational speed of each wheel; if it detects a wheel rotating significantly slower than the others, a condition indicative of impending wheel lock, it actuates the valves to reduce hydraulic pressure to the brake at the affected wheel, thus reducing the braking force on that wheel; the wheel then turns faster. Conversely, if the ECU detects a wheel turning significantly faster than the others, brake hydraulic pressure to the wheel is increased so the braking force is reapplied, slowing down the wheel. This process is repeated continuously and can be detected by the driver via brake pedal pulsation. Some anti-lock systems can apply or release braking pressure 15 times per second. Because of this, the wheels of cars equipped with ABS are practically impossible to lock even during panic braking in extreme conditions.

The ECU is programmed to disregard differences in wheel rotative speed below a critical threshold, because when the car is turning, the two wheels towards the center of the curve turn slower than the outer two. For this same reason, a differential is used in virtually all roadgoing vehicles.

Components

There are four main components of ABS: speed sensors, valves, a pump, and a controller.

19 | P a g e

Speed sensors

A speed sensor is used to determine the acceleration or deceleration of the wheel. These sensors use a magnet and a coil of wire to generate a signal. The rotation of the wheel or differential induces a magnetic field around the sensor. The fluctuations of this magnetic field generate a voltage in the sensor. Since the voltage induced in the sensor is a result of the rotating wheel, this sensor can become inaccurate at slow speeds. The slower rotation of the wheel can cause inaccurate fluctuations in the magnetic field and thus cause inaccurate readings to the controller.

Valves

There is a valve in the brake line of each brake controlled by the ABS. On some systems, the valve has three positions:

In position one, the valve is open; pressure from the master cylinder is passed right through to the brake.

In position two, the valve blocks the line, isolating that brake from the master cylinder. This prevents the pressure from rising further should the driver push the brake pedal harder.

In position three, the valve releases some of the pressure from the brake.

The majority of problems with the valve system occur due to clogged valves. When a valve is clogged it is unable to open, close, or change position. An inoperable valve will prevent the system from modulating the valves and controlling pressure supplied to the brakes.

Pump

The pump in the ABS is used to restore the pressure to the hydraulic brakes after the valves have released it. A signal from the controller will release the valve at the detection of wheel slip. After a valve release the pressure supplied from the user, the pump is used to restore a desired amount of pressure to the braking system. The

20 | P a g e

controller will modulate the pumps status in order to provide the desired amount of pressure and reduce slipping.

Controller

The controller is an ECU type unit in the car which receives information from each individual wheel speed sensor, in turn if a wheel loses traction the signal is sent to the controller, the controller will then limit the brake force (EBD) and activate the ABS modulator which actuates the braking valves on and off.

Automatic transmission

An automatic transmission (also called automatic gearbox) is a type of motor

vehicle transmission that can automatically change gear ratios as the vehicle moves, freeing the driver from having to shift gears manually. Most automatic transmissions have a defined set of gear ranges, often with a parking pawl feature that locks the output shaft of the transmission stroke face to keep the vehicle from rolling either forward or backward.

21 | P a g e

Automatic transmission modes

Conventionally, in order to select the transmission operating mode, the driver moves a selection lever located either on the steering column or on the floor (as with a manual on the floor, except that most automatic selectors on the floor do not move in the same type of pattern as a manual lever; most automatic levers only move vertically). In order to select modes, or to manually select specific gear ratios, the driver must push a button in (called the shift lock button) or pull the handle (only on column mounted shifters) out. Some vehicles position selector buttons for each mode on the cockpit instead, freeing up space on the central console. Vehicles conforming to US Government standards must have the modes ordered P-R-N-D-L (left to right, top to bottom, or clockwise). Prior to this, quadrant-selected automatic transmissions often used a P-N-D-L-R layout, or similar. Such a pattern led to a number of deaths and injuries owing to driver error causing unintentional gear selection, as well as the danger of having a selector (when worn) jump into Reverse from Low gear during engine braking maneuvers.

22 | P a g e

Automatic transmissions have various modes depending on the model and make of the transmission. Some of the common modes include:

Park (P)

This selection mechanically locks the output shaft of transmission, restricting the vehicle from moving in any direction. A parking pawl prevents the transmission from rotating, and therefore the vehicle from moving. However, it should be noted that the vehicle's non-driven wheels are still free to rotate, and the driven wheels may still rotate individually (because of the differential). For this reason, it is recommended to use the hand brake (parking brake) because this actually locks (in most cases) the wheels and prevents them from moving. It is typical of front-wheel-drive vehicles for the parking brake to lock the rear (non-driving) wheels, so use of both the parking brake and the transmission park lock provides the greatest security against unintended movement on slopes. This also increases the life of the transmission and the park pin mechanism, because parking on an incline with the transmission in park without the parking brake engaged will cause undue stress on the parking pin, and may even prevent the pin from releasing. A hand brake should also prevent the car from moving if a worn selector accidentally drops into reverse gear while idling.

23 | P a g e

A car should be allowed to come to a complete stop before setting the transmission into park to prevent damage. Usually, Park (P) is one of only two selections in which the car's engine can be started, the other being Neutral (N). This is typically achieved via a normally open inhibitor switch (sometimes called a "neutral safety switch") wired in series with the starter motor engagement circuit, which is closed when P or N is selected, completing the circuit (when the key is turned to the start position). In many modern cars and trucks, the driver must have the foot brake applied before the transmission can be taken out of park. The Park position is omitted on buses/coaches (and some road tractors) with automatic transmission (on which a parking pawl is not practical), which must instead be placed in neutral with the air-operated parking brakes set.

Reverse (R)

This engages reverse gear within the transmission, permitting the vehicle to be driven backward, and operates a switch to turn on the white backup lights for improved visibility (the switch may also activate a beeper on delivery trucks or other large vehicles to audibly warn other drivers and nearby pedestrians of the driver's reverse movement). To select reverse in most transmissions, the driver must come to a complete stop, depress the shift lock button (or move the shift lever toward the driver in a column shifter, or move the shifter sideways along a notched channel in a console shifter) and select reverse. Not coming to a complete stop may cause severe damage to the transmission. Some modern automatic transmissions have a safety mechanism in place, which does, to some extent, prevent (but not completely avoid) inadvertently putting the car in reverse when the vehicle is moving forward; such a mechanism may consist of a solenoid-controlled physical barrier on either side of the Reverse position, electronically engaged by a switch on the brake pedal. Therefore, the brake pedal needs to be depressed in order to allow the selection of reverse. Some electronic transmissions prevent or delay engagement of reverse gear altogether while the car is moving.

Some shifters with a shift button allow the driver to freely move the shifter from R to N or D without actually depressing the button. However, the driver cannot shift

24 | P a g e

back to R without depressing the shift button, to prevent accidental shifting which could damage the transmission, especially at high speeds.

Neutral / No gear (N)

This disengages all gear trains within the transmission, effectively disconnecting the transmission from the driven wheels, allowing the vehicle to coast freely under its own weight and gain momentum without the motive force from the engine. Coasting in idle down long grades (where law permits) should be avoided, though, as the transmission's lubrication pump is driven by non-idle engine RPMs. Similarly, emergency towing with an automatic transmission in neutral should be a last resort. Manufacturers understand emergency situations and list limitations of towing a vehicle in neutral (usually not to exceed 55 mph and 50 miles). This is the only other selection in which the vehicle's engine may be started.

Drive (D)

This position allows the transmission to engage the full range of available forward gear ratios, allowing the vehicle to move forward and accelerate through its range of gears. The number of gear ratios within the transmission depends on the model, but they initially ranged from three (predominant before the 1990s), to four and five speeds (losing popularity to six-speed autos). Six-speed automatic transmissions are probably the most common offering in cars and trucks from 2010 in carmakers as Toyota, GM and Ford. However, seven-speed automatics are becoming available in some high-performance production luxury cars (found in Mercedes 7G gearbox, Infiniti), as are eight-speed autos in models from 2006 introduced by Aisin Seiki Co. in Lexus, ZF and Hyundai Motor Company. From 2013 are available nine speeds transmissions produced by ZF and Mercedes 9G.

EGR:- (Exhaust Gas Recirculation)

It is a Nitrogen oxide emission reduction technique . It recirculates a part of exhaust gas to the intake manifold It is located between inlet and exhaust manifold.

25 | P a g e

It provides passage for exhaust gases from exhaust to inlet manifold

Important:-

Electronic control unit (ECU)

In automotive electronics, electronic control unit (ECU) is a generic term for any embedded system that controls one or more of the electrical system or subsystems in a motor vehicle.

Engine control unit (ECU)

An engine control unit (ECU), now called the powertrain control module (PCM), is a type of electronic control unit that controls a series of actuators on an internal combustion engine to ensure optimal engine performance. It does this by reading values from a multitude of sensors within the engine bay, interpreting the data using multidimensional performance maps (called lookup tables), and adjusting the engine actuators accordingly.

Working of ECU

Control of Air/Fuel ratio Control of ignition timing Control of idle speed

26 | P a g e

Control of variable valve timing Electronic valve control

Common rail

Common rail direct fuel injection is a modern variant of direct fuel injection system for petrol and diesel engines

Shock absorber

A shock absorber is a mechanical device designed to smooth out or damp shock impulse, and convert kinetic energy to another form of energy (usually thermal energy, which can be easily dissipated). It is a type of dashpot. Pneumatic and hydraulic shock absorbers are used in conjunction with cushions and springs. An automobile shock absorber contains spring-loaded check valves and orifices to control the flow of oil through an internal piston.

(Air suspension air shocker or airmatic shocker)

Intercooler

An intercooler is any mechanical device used to cool a fluid, including

liquids or gases, between stages of a multi-stage heating process, typically a heat exchanger that removes waste heat in a gas compressor. Intercoolers increase the efficiency of the induction system by reducing induction air heat created by the supercharger or turbocharger and promoting more thorough combustion. This removes the heat of

27 | P a g e

compression (i.e., the temperature rise) that occurs in any gas when its pressure is raised or its unit mass per unit volume (density) is increased.

Radiator

Radiators are heat exchangers used to transfer thermal energy from

one medium to another for the purpose of cooling and heating. The majority of radiators are constructed to function in automobiles, buildings, and electronics. The radiator is always a source of heat to its environment, although this may be for either the purpose of heating this environment, or for cooling the fluid or coolant supplied to it, as for engine cooling.

Condenser (heat transfer)

In systems involving heat transfer, a condenser is a device or unit used to condense a substance from its gaseous to its liquid state, typically by cooling it. In so doing, the latent heat is given up by the substance, and will transfer to the condenser

coolant. Condensers are typically heat exchangers which have various designs and come in many sizes ranging from rather small (hand-held) to very large industrial-scale units used in plant processes. For example, a refrigerator uses a condenser to get rid of heat extracted from the interior of the unit to the outside air. Condensers are used in air conditioning,

28 | P a g e

industrial chemical processes such as distillation, steam power plants and other heat-exchange systems. Use of cooling water or surrounding air as the coolant is common in many condensers.

Set up of belt over pully

29 | P a g e

Steering System:-

Introduction

The steering system is the collection of component and linkages. It allows a vehicle to follow certain path desired by the driver through the

steering wheel.

Function

It helps to turn the vehicle. It converts the rotary motion of the steering wheel into angular turn of the

respective wheels. It multiplies the effort of the driver to turn the wheels.

Component

Steering wheel

30 | P a g e

Component of steering system-

Types of steering system-

Hydraulic Power system

Electric Power system

32 | P a g e

Service or Maintainance:-

Coolant Engine oil (check by deep stick) Wind shield washer Air filter Ac filter Brake fluid AC gas (used R134A gas ) Fuel filter ATF (60,000 km change) Tyre Tred (depth,change 1.5mm and checked by depth gauge) Disc thickness Brake pad thickness Battery level check Drain plug remove

Tools and Machines used in Workshop33 | P a g e

Piston puller Compressed-air blowgun with diffuser nozzle that reduces discharge air

pressure Computer wheel balancer Safety stand Floor jack Types of wrenches(i.e. box wrench, combination wrench, open-end wrench) Sets of sockets with handles, extension and universal joints(i.e. ratchet, nut

spinner) Torque wrench for wheel tight (130NM or 150NM) Air impact wrench or Gun for tight with reversing control Air ratchet for tight with reversing lever Computerized four wheel aligner for all wheels with same time with help of

sensors Tire changer Fill rise scissor for wheel alignment Oil management equipment or Bleeding machine(i.e. brake oil machine) Fully automatic A/C recycling machine Shocker puller(i.e. clamping plate, adapter plate, tensioning device) Jumper starter machine to charge, start battery Midtronics machine for checking battery voltage status(12 volts and 6cell) Jumping cables for connecting battery one to other charge. Inclinometer Injector puller Depth gauge Counter lock

Important:-

Clutch paddle is not present. Hand brake replaced by parking brake (present with brake paddle or on

dashboard with steering) Cruise control (sometimes known as speed control or autocruise, or

tempomat in some countries) is a system that automatically controls the

34 | P a g e

speed of a motor vehicle. The system takes over the throttle of the car to maintain a steady speed as set by the driver.

Adjustable electronic power steering with motor Xenon LED head light used. Front right side mirror absorbs light beams and show only objects likes car

etc. Oil level gauge to check the level of engine oil. In center, night view assist camera, rain light sensors and multifunction

camera in front interior mirror for adjusting beam of head lamp when turning or jumping.

In rear mirror,Upper coils for radio signals, telephone signal, interlock signal (radio signal)

Lower coils for removing fog by heating coils.

Interlock –infrared signal attached with lock handle only for some distance.

35 | P a g e

(Bodyshop)

Substrate preparation guide

i. Identify the damage.ii. Wash with water and soap.

iii. Degrease with 3919s preparation solution.iv. Identify colour.v. Select ecentric or planetary sanding machine 5 or 7mm for feather edges

(hard pad).vi. Bare metal-step1:- p80-180 original finish. Step2:-p120-180,p180-240

vii. Degrease again with 3920s degreaser.viii. Apply an anti-corrosion primer.820 wash primer filler or 830R Epoxy

primer depending on the substrate.ix. Apply a filling primer, 114xs universal 2k primer grey, LE 200x low

emission primer or 400xs ultra productive primer.x. Sand the primer.

xi. Dry sanding :-start with p320-400, end with p600.xii. Wet sanding:- start with p800-1000, end with p1000-1200.

xiii. Degrease again with 3920s degreaser.xiv. Apply DuPont centari Top coat, DuPont centari base coat and clear.

Procedure of making paint

i. See paint code of car near front right door.ii. Then checking the weight of color code in computer or booklet.

iii. Taking different color code or tenter (009,301-399) from mixing machine.iv. Then weighing each tenter in a flask according to requirement.v. Then mix it.

vi. And add hardner in it.

Important

Demineral water chemical added in paint. Clear chemical for shining.

36 | P a g e

Hardner chemical for dry. Clear + hardner (2:1) Double cone filter for filter chemicals. Silicon entferner remover used when oil or swet drops drop over painting

part before paint. Thinner used for cleaning spray gun. Dry for shining paint ,(5-10)min. and (18-22) degree Celsius. After paint in booth paint, heating upto (20-35)min. and (60-65)degree

Celsius. Sandar for removing denting paint Disc filter connected to sandar (p180 for plastic and p120 for metal) Soft spachtel (paste or putty) mixed with hardener. In Paint booth, floor filter, roof filter sucking small dust particals and send to

pocket filter to store. Infrared light machine having three rods used to remove moisture in outer

part only. Glass holder used to hold glass or metal by sucking the air. Adhesive sealant (Glazing), black paste used to fix mirror over it. Teflon is done for avoided sticking in outer body of car. Gas wielding only used for removing paint for cleaning.After this spot

wielding is used for repair dent by pulling denting place (earthing is necessary)

1.

37 | P a g e