Mens Knit Brief Mtrs 10-29-09

Transcript of Mens Knit Brief Mtrs 10-29-09

-

8/13/2019 Mens Knit Brief Mtrs 10-29-09

1/12

New!ANECALCHelp GuideANECALC is a tool developed by American & Efird (A&E) toassist in estimating the amount of thread consumedin a sewnproduct. This information can then be used to calculate the ThreadCost per Garment and the estimated number of conesyou willneed for a quantity of sewn products you are planning onproducing.

You do not need to have any special software on your computerbecauseANECALC was developed using MicrosoftExcelspreadsheets.

TheANECALC workbook has Sheets shown as Tabs at thebottom used for the following:

INSTRUCTIONStab on how to use the program.

New! ISO STITCHES for identifying the correct stitch type.

New! WORKSHEETtab and THREAD COST Tabs have been

combined so you can see everything on one spreadsheet. Thisalso allows you to copy the entire worksheet to compare threadcost using other thread combinations.

mm to Inchestab that helps you convert fractions of an inch tomillimeters.

STARTING A NEWANECALCSPREAD SHEET

- To begin a newANECALC spreadsheet, you can either use anexisting Apparel GuidelinesANECALCspreadsheet for a similargarment and modify it for the garment you are doing the analysis

on; or you can decide to begin from scratch with a newSpreadsheet.

WHEN STARTING FROM SCRATCH

- When you are starting from scratch with a new Spreadsheet, iIt isimportant that you select the correct spreadsheet for the weight ofthe fabric being used in the garment. There are three basicANECALCspreadsheets:

Light Weight 2 to 4 oz weight fabricsMedium Weight 58 oz weight fabricsHeavy Weight 915 oz weight fabrics

The Weight of fabric determines the ratio of Needle to Bottomhread on the Thread Consumption Table that is used to estimatehe amount of thread consumed.

- For each sewing operation on the garment, list the name of thesewing operation, what ISO Stitch Type is being used, how manyrows of ISO Stitch there are, the Stitches Per Inch (SPI), and the

length of the seam.

AVERAGE SEAM THICKNESS

- At the top of eachANECALC spreadsheet is a cell for theaverage thickness of the seam in millimeters. This is based on

SELECTING THE ISO STITCH TYPE- If you are not family with the ISO 4915 stitch numbers, you

can look them up on the ISO4915 Tab below.

- For many stitches you must first measure the needle spacingor seam width before selection the stitch.

(Ex. 504 -1/83 Thd Overedge).

- It is important to select the correct ISO 4915 stitch becausethis will determine the amount of thread consumed in makingthe seam.

NUMBER OF ROWS OF STITCH

- Refers to the number of rows of ISO stitch used to make theseam. This does NOT refer to the number of needles or thenumber of pieces (i.e., pockets, etc.) being sewn, BUT thenumber of rows of the ISO stitch you selected in the previouscolumn to make the seam.

-

For example, a 406 stitch is a two needle bottom coverstitch.This two needle stitch type makes only one row of stitch.Rule: whenever the needles are connected with thread oneither the top or bottom side of the seam, one row of stitch isbeing produced.

- On the other hand, when you twin needle topstitch a pocketwith a 301 Lockstitch, then two independent rows of lockstitchare being used.

SPI- SPI refers to Stitches Per Inch and is the measurement of the

number of links of thread between needle holes in one inch.

- For example, a typical number of stitches per inch on denimwould be 8 spi. See A&Es technical bulletin on Selecting theProper Stitches Per Inch can be found on A&Es website.

LENGTH OF SEAM

- The length of seam is the measurement of the seam lengthincluding seam margins but does not include chain-off.- A&E hasANECALCspreadsheets available in either inches &

yards or centimeters & metres. The selection of the propersheet is normally dependent upon the international locationand what measurement system is used for the cone put-ups.To convert from meters to yards multiply times .91. To convertfrom meters to yards divide by .91.

- In the Americas., a typical cone of thread is wound on a 6,000yard put-up. In Europe or Asia, a typical cone is wound on a5,000 metre put-up.

Many sewing operations have mirror components on eachside of the garment. A right and left cuff, a right and leftpocket, etc.

-

8/13/2019 Mens Knit Brief Mtrs 10-29-09

2/12

ANECALCInstructions (continued)

the average seam thickness in the entire garment. In most cases,you will not have to change this if you are using the correctspreadsheet for Light, Medium or Heavy weight fabric.

- If the sewing operation includes sewing both of these parts, thendouble the measurement for the seam length.

BARTACK, BS, BH & EMBROIDERY

- If a bartack, buttonsew, buttonhole or embroidery selection ismade from the ISO Stitch Column, you should always enter the

number of tacks, buttons, etc. under Rows of Stitch, and 1under SPI and 1 under length of seam. (ex. Tack Belt Loops 10 tacks, 1 under SPI and 1 under Length of Seam).

HIDING ROWS

- A typicalANECALCspreadsheet has enough rows for 50operations but in many cases, you will not need all these rows.

- If you want to Hide the Rows between the last operation and theTotals at the bottom of the spreadsheet, Click in the left hand

margin and drag down the Row numbers until you are justabove the Totals.

- Next right click your mouse and select HIDE.

INSERTING A NEW ROW

- First, click in the row where you want to insert the new row.

- Next, right click and selectCopy.- Now right click again and selectInsert Copied Cells.- You will now have two identical rows of one above the other.- Next, right click on the Stitch Box in the new row you just

added.

- Then select Format Control from the pop-up menu.- Change the Cell Link to the proper Row Number. In this case,

change the D17 to D16 and then click on OK.

-

8/13/2019 Mens Knit Brief Mtrs 10-29-09

3/12

ANECALCInstructions (continued)

- Now you can change the operation numbers and the informationin the New Row you just inserted.

- If you change the Stitch Type, make sure that you put the rightthread type under Needle, and either Bobbin or Looper.

New! INSERTING THREAD SIZE, TYPE & COLOR

- New! To makeANECALC easier, we have added a section atthe top of the spreadsheet for putting the thread size / typedescriptions (column M). You can also change the ThreadGroup Description rather than using Thread type #1, #2, etc.(i.e., Topstitching #1, Looper threads, Serging threads)

- New! When you enter a thread Tex Size/Type/Clr (i.e, T-24Perma Core - Clrs), you will see this same thread identificationto the right in column O. This can then be copied and pasted inall operations using this particular SKU.

- ForANECALCto be able to calculate the cost per garment, theThread information for each operation must be inserted next tothe thread consumption calculation.

- Rule: There must be a thread description placed in theappropriate column for the Needle, Bobbin and Looper threadpositions where there is any thread consumed. IF AT THEBOTTOM OF THE SPREADSHEET UNDER TOTAL YARDSYOU SEE THE SAME NUMBER REPEATED, YOU MISSEDAN CELL FOR THREAD SIZE & TYPE.

- We strongly recommend that you copy and paste all threaddescriptions as mentioned above. Never type the same threadSize / Type multiple cells at the top asANECALC will double theconsumption.

CALCULATING TOTAL THREAD CONSUMPTION BY SKU

- Rule: The total amount of thread under the SKU Summary mustbe equal to the Total amount of thread found under theworksheet. If they are not the same, then you have missedcopying and pasting an SKU in the SKU Summary portion of thespreadsheet.

CALCULATING THREAD COST PER GARMENT

- To calculate the thread cost per garment, enter the thread put-up and price per cone. Example: 6,000 @ $6.00.

- Any currency can be used onANECALC.CALCULATING NUMBER OF CONES NEEDED

- To calculate the Number of cones required, type in theproduction requirement andANECALCwill calculate the numberof cones needed for the thread in the sewn products.

- If very small lots of production are to be produced, then morethread may have to be ordered to have the proper coverage on

there are coverage issues because there are too manyvariables that can affect this calculation.

- Ask aboutANECALC PLUSthat can help calculate the totalcones required to thread up a sewing production line.

- New!

If you have any questions, contact your local A&ETechnical Support Representative.

-

8/13/2019 Mens Knit Brief Mtrs 10-29-09

4/12

the sewing floor. By coverage, we mean the minimum numberof cones needed to thread up the machines on a production lineto run the work efficiently without delay. ANECALCwill notcalculate the minimum amount of cones you will need when

-

8/13/2019 Mens Knit Brief Mtrs 10-29-09

5/12

-

8/13/2019 Mens Knit Brief Mtrs 10-29-09

6/12

-

8/13/2019 Mens Knit Brief Mtrs 10-29-09

7/12

-

8/13/2019 Mens Knit Brief Mtrs 10-29-09

8/12

-

8/13/2019 Mens Knit Brief Mtrs 10-29-09

9/12

ISO 4915 STITCH MATRIX

-

8/13/2019 Mens Knit Brief Mtrs 10-29-09

10/12

-

8/13/2019 Mens Knit Brief Mtrs 10-29-09

11/12

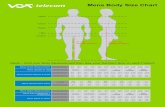

ANECALCAvg. Seam Thickness

Fill in the information highlighted in 'yellow' 1.2 mm

Company Name:Thread Description (ex. Tex Size /

Brand / Clr)

Copy & Paste from column "M" to

Column "O"

XYZ Mfg. Company T-27 Perma Spun = T-27 Perma Spun

T-18 Widcat Plus = T-18 Widcat Plus

Garment Description: =

Men's Knit Brief =

=

=

Cost Per Garment =

US $

Rows Seam Needle Needle Bobbin Bobbin Looper Looper / Cover Total

Oper ISO of Length Thread Thread Thread Thread Thread Thread Metres /

# Name of Operation Stitch Stitch SPI CM Metres Tex / Type / Color Metres Tex / Type / Color Metres Tex / Type / Color Oper.

1 Bind Fly Panels 301 1 10 36 1.76 T-27 Perma Spun 1.62 T-18 Widcat Plus 3.38

2 Join & Tape Front 1 12 38 4.08 T-27 Perma Spun 3.34 T-18 Widcat Plus 7.42

3 Bind Leg Openings 1 10 117 5.71 T-27 Perma Spun 5.27 T-18 Widcat Plus 10.99

4 Close Crotch 1 12 19 2.44 T-27 Perma Spun 2.98 T-18 Widcat Plus 5.42

5 Close Elastic Waistband 1 12 3 0.39 T-27 Perma Spun 0.47 T-18 Widcat Plus 0.86

6 Set Elastic Waistband 1 10 86 6.52 T-27 Perma Spun 7.96 T-18 Widcat Plus 14.48

7 Set Label to WB 1 10 10 0.15 T-27 Perma Spun 0.14 T-27 Perma Spun 0.29

8 Bartack 2 1 1 0.18 T-27 Perma Spun 0.06 T-27 Perma Spun 0.24

SUBTOTALS 21.23 0.20 21.65 TOTALS 43.08

43.08 Total Metres/Garment Consumed

10% 4.31 Metres/Garment - Waste

47.39 Total Metres/Garment w Waste

Program Sz (units)

Copy & Paste Thread SKU's TOTAL Put-Up Price Thread Price Thread Price 10,000

From Above METRES (5000M) Per Yard Per Garment # of Cones needed

1 T-27 Perma Spun 23.57 5000 -$ -$ 47.1

2 T-18 Widcat Plus 23.82 10000 -$ -$ 23.8

3

4

5

6

Percent Waste

ANECALC THREAD COST ANALYSIS

Photo

Thread #2

Thread #3

Thread #4

American & Efird Thread Consumption Calculator - Light Wt. Fabrics

Ok to change (ie, Topstitching)

Thread #1

Thread #5

Thread #6

Size: Large

Page 11 of 12

-

8/13/2019 Mens Knit Brief Mtrs 10-29-09

12/12

![HEARTLINE KNIT WRAP | KNIT · 2018. 5. 11. · HEARTLINE KNIT WRAP | KNIT 2 of 2 HEARTLINE KNIT WRAP | KNIT CAK0126-010003M measures approx 58" [147.5 cm], ending on a WS row with](https://static.fdocuments.in/doc/165x107/5fd034989f28e2726c32dbf7/heartline-knit-wrap-knit-2018-5-11-heartline-knit-wrap-knit-2-of-2-heartline.jpg)