MD T,D,E-iom En

-

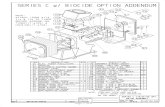

Upload

mihai-constantinescu -

Category

Documents

-

view

223 -

download

1

Transcript of MD T,D,E-iom En

-

8/12/2019 MD T,D,E-iom En

1/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D-E - BDE

Rev 4.2. 29-09-00 EN 1 (50)

PRECISION AIR CONDITIONING UNITS

MDT / MDD / MDE

0651 - 0702 - 0902 - 1002 - 1302

BDE

2002 - 2402

INSTRUCTION MANUAL

GB

The contents of this document are subject to revision without notice due to continued

progress in methodology, design and manufacturing.

Read this manual before using the unit and keep it in a safe place for future reference.

-

8/12/2019 MD T,D,E-iom En

2/48

INSTRUCTION MANUAL UNIFLAIRTM

MD.T-D-E - BDE

2 (50) Rev 4.2. 29-09-00 EN

UNIFLAIR ITALIA S.r.l.Via dellindustria, 10

35020 BRUGINE (Padova) ItalyTel. +39 (0)49 9713211

Fax +39 (0)49 5806906Internet: www.uniflair.comE-mail: [email protected]

Release: 4.2 Date: 29 - 09 - 2000

Checked by:

-

8/12/2019 MD T,D,E-iom En

3/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D-E - BDE

Rev 4.2. 29-09-00 EN 3 (50)

INDEX

PageImportant warnings 5

GENERAL DESCRIPTION 6Documentation enclosed with the unit 6Description of the unit and intended use 6MDT: aircooled twin-cool units 7MDD: watercooled twin-cool units 7MDE/BDE: energy-saving units 7

Access to main components 8Data Plate 9

INSTALLATION GUIDE 10

Transport and movement 11Dimensions and weights 11Positioning the unit 12

Air distribution 13Suction plenum 15Fresh air filter 16Refrigerant connections (MDT) 17Water connections (MDD) 19Water connections (MDD-MDE/BDE) 20Humidifier connections 23Connecting the condensate drain 24Electrical connections 26Recommended sizes of power supply cables and line fuses 28

START-UP AND TESTING 29Evacuation of refrigerant circuit and refrigerant charging (MDT) 29Thermostatic expansion valve regulation (MDT) 30Remote control 31Start-up procedure 31

FUNCTION & REGULATION 32Water-cooled units (MDD) 32Electrical connection and control of remote radiators (MDE/BDE) 33Measurement and alarm devices 35Regulation of condensation pressure (remote air-cooled condenser) 36Setting the pressostatic valve (optional - water-cooled models only) 36

Setting the regulation and safety devices 37Setting the airflow sensor 37Setting the dirty filter sensor (optional) 37Valve and servomotor 38

-

8/12/2019 MD T,D,E-iom En

4/48

INSTRUCTION MANUAL UNIFLAIRTM

MD.T-D-E - BDE

4 (50) Rev 4.2. 29-09-00 EN

Page

TECHNICAL DATA 39General characteristics 39Electrical data 41

MAINTENANCE 42Regular checks 42Changing the Low Pressure pressostat 42Humidifier 43

PROBLEM SOLVING 46Temperature control 46Humidity control 46

Fans 47Refrigerant circuit 47Compressors 48Electric heaters 48

IMPORTANT: the description of the Control System and the operating logic of the unit are given in the

MP20 Control System Instruction Manual.

-

8/12/2019 MD T,D,E-iom En

5/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D-E - BDE

Rev 4.2. 29-09-00 EN 5 (50)

This unit has been subjected to risk analysis under EC Directive 98/37/EEC (89/392/EEC).The technical solutionsimplemented during the design phase are described in the units technical documentation.

This unit is built to perform the functions for which it was designed without risk as long as the installation,

operation and maintenance of the unit are all carried out according to the instructions in this manual and

on the labels on the unit. There are however some residual risks, particularly regarding maintenance.

The risks which are particularly important for the safety of the user are marked with the danger symbol:

IMPORTANT WARNINGS

This unit contains refrigerant gas circuits under pressure, live electrical components, hot surfaces, sharp edges(such as the coil) and rotating devices such as the fans. Before accessing the inside of the unit, disconnect it

from the electrical power supply.

All service and maintenance operations must be performed when the unit is off and must be done by

qualified and experienced personnel who are aware of the necessary precautions.

In any case, all safety legislation of the installation location must be followed.

In the event of fire,water and other conductive substances must not be used to put out the fire near live electricalcomponents. This warning must be displayed on notices in the unit installation location.

If the refrigerants used come into contact with fire they decompose, forming acids and other irritants. The smell ofthese substances, even at concentrations below danger levels, gives enough warning to allow evacuation of thearea at risk.

Make sure that the power supply voltage corresponds to the value shown on the data plate.

-

8/12/2019 MD T,D,E-iom En

6/48

INSTRUCTION MANUAL UNIFLAIRTM

MD.T-D-E - BDE

6 (50) Rev 4.2. 29-09-00 EN

GENERAL DESCRIPTION

DOCUMENTATION ENCLOSED WITH THE UNIT

Every MD*-BD* air conditioning unit is supplied complete with the following documents:

Unit instruction manual;

MP20 Microprocessor control instruction manual

Electrical diagrams;

Spare parts list

CE declaration listing the directives and norms which the unit conforms

Guarantee certificate.

UNIT DESCRIPTION AND INTENDED USE

MD*-BD* downflow air conditioning units are designed for high-technology applications such as computer rooms,telephone exchanges, control rooms, laboratories and clean rooms. Air-cooled direct-expansion units must beconnected to UNIFLAIR CAL-series condensers. Water-cooled direct-expansion units must be connected toUNIFLAIR RAL-series radiators. All the units are fully assembled and tested in the factory and are built forapplications where safety and reliability cannot be compromised.

ACTIVE SAFETYcontrol systems provide monitoring and prevention functions via:

Function status indication Continuous reading and display of the temperature measured by the sensors.

Indication of fault and alarm situations

Automatic stopping of unit components in the event of risk;

Compressor management to reduce the start-up frequency of each compressor and to avoid compressorsbeing started at the same time.

PASSIVE SAFETYThe essential functions of air conditioning units are protected against faults and potentially dangerous conditions thecontrol systems which includes:

High and low-pressure pressostats to protect the refrigerant circuit (HP with manual re-set)

Safety valve

Low airflow differential pressostat

Safety thermostat on units with electric heater

Liquid shut-off valve to protect the compressor against migration of liquid refrigerant when the unit is off

Compressor electric motor protection.

PERSONAL SAFETYThe design and wiring of air conditioning units conform to IEC electrical norms. The electrical panels, are equippedwith an auxiliary 24V circuit and include individual short circuit protection using automatic circuit breakers. Fans arefitted with metals grilles conforming to IEC safety norms.

-

8/12/2019 MD T,D,E-iom En

7/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D-E - BDE

Rev 4.2. 29-09-00 EN 7 (50)

MDT: AIRCOOLED TWIN-COOL UNITSMDT TWIN-COOL units include two independent cooling systems:- direct expansion with air-cooled condensers;

- chilled water.

The unit is connected to the remote condensers with refrigerant tubes and to the chilled water piping system.The microprocessor automatically maintains room temperature by controlling:- switch over between the two cooling systems;- compressor operation during direct expansion function when the chilled water supply is unavailable;- the modulating motorised valve during chilled water function.For further details please refer to the microprocessor manual.

MDD: WATERCOOLED TWIN-COOL UNITSMDD Twin-Cool units have 2 independent cooling systems:- direct expansion with water-cooled condensers;

- chilled water.

The unit is connected to the condenser cooling water supply as well as to the chilled water piping system. Themicroprocessor automatically maintains room temperature by controlling:- switch over between the two cooling systems;- compressor operation during direct expansion function, when chilled water supply is unavailable;- the modulating motorised valve during chilled water function.For further details please refer to the microprocessor manual.

MDE/BDE: ENERGY-SAVING UNITSENERGYSAVING units include two independent cooling systems:- direct expansion with water-cooled condenserssupplied with water pumped in closed circuit and cooled by

external radiators;

- chilled watercoil (economiser), connected in to the closed circuit glycol loop between the condensers and theexternal radiators.Whenever the outside temperature falls below the room temperature, the ENERGYSAVING unit starts to takeadvantage of the free cooling effect i.e.: cooling without the need to operate compressors.During warm weather the unit operates like a conventional glycolcooled system (diagram A) with the 3way valvebypassing the economiser coil. In cooler weather or at night when the outside temperature drops and thewater/glycol mixture leaving the radiator becomes colder than the room, the economiser coil is fed via the 3wayvalve to provide a freecooling effect and reduce the amount of direct expansion cooling required (diagram B).When the outside temperature falls further there comes a point at which the free-cooling effect provided by theeconomiser is sufficient to meet the entire heat load and no direct expansion cooling is required at all.In this mode an ENERGY-SAVING unit operates like a chilled water unit with the 3way valve controlling the flowthrough the economiser coil (diagram C).The microprocessor provides fully automatic control of the unit (for further details please refer to the mP20

microprocessor manual).Fig. 1.A Fig. 1.B Fig. 1.C

-

8/12/2019 MD T,D,E-iom En

8/48

-

8/12/2019 MD T,D,E-iom En

9/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D-E - BDE

Rev 4.2. 29-09-00 EN 9 (50)

DATA PLATE

The data plate is in the electrical panel housing and shows:

- Unit model and serial number

- Power supply (voltage, number of phases and frequency)

- Power absorption of the unit and of the main components;

- Current absorption of the unit and of the main components: OA (Operating current), FLA (Full load current) andLRA (Locked rotor current);

- Setting values of the refrigerant circuit pressostats (high and low pressure) and of the other regulation and safetydevices;

- Refrigerant type and charging of refrigerant circuit.

MODEL SERIAL No.

POWER SUPPLY VOLTAGE

ELECTRICAL CURRENT

OA FLA LRA KW TOTALI

SETTING OF SAFETY DEVICES

REFRIGERANT Fig. 4.

-

8/12/2019 MD T,D,E-iom En

10/48

INSTRUCTION MANUAL UNIFLAIRTM

MD.T-D-E - BDE

10 (50) Rev 4.2. 29-09-00 EN

INSTALLATION GUIDE

TRANSPORT AND MOVEMENTThe unit should not be turned on its back or upside-down, or exposed to the weatherand should be taken as near as

possible to the installation location before removing the cardboard packing and the pallet .

The unit can be lifted:

- with a fork-lift, placing the forks in the appropriate slots of the pallet;

- with straps passed under the unit, making sure that they do not put pressure on the upper rim of the unit.The unit must be stored, preferably in its packing, under cover and protected from excessive humidity (< 90% R.H.) and

temperature (< 50C).The dimensions and weight of the unit with packaging are given below:

MD*

mm 0651 0702 0902 1002 1302

M 1510 1740 1740 2440 2440

N 2135 2135 2135 2135 2135

O 720 720 720 720 720

kg 475 535 545 640 650

N

M

O

BDE

mm 2002 2402

M 2710 2710

N 2135 2135

O 920 920

kg 900 930

Fig. 5.

The symbols applied to the units packaging conform to ISO7000; they are explained in the table below.

SYMBOL MEANING SYMBOL MEANING

FRAGILE: handle with care. THIS SIDE UP shows theorientation of the unit.

PROTECT AGAINST MOISTURE:the packaged unit must be storedin a dry place.

TEMPERATURE LIMITS: the unitmust not be stored outside theselimits.

CENTRE OF GRAVITY: shows thecentre of gravity of the packagedunit.

NO HOOKS: do not use hooks tolift the packed unit.

KEEP AWAY FROM HEAT: theunit must be kept away from heatsources.

DO NOT STACK

RECEIVING THE UNITWhen the unit arrives, check that it is complete and in perfect condition; notify the carrier immediately in writing of any

damagethat might have been caused in transit.

-

8/12/2019 MD T,D,E-iom En

11/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D-E - BDE

Rev 4.2. 29-09-00 EN 11 (50)

DIMENSIONS AND WEIGHTS

MD*mm 0651 0702 0902 1002 1302

A 1440 1670 1670 2370 2370A1 1400 1630 1630 2330 2330

B 1970 1970 1970 1970 1970

C 650 650 650 650 650

C1 645 645 645 645 645

D*) 700 700 700 700 700

E**) 900 900 900 900 900

kg 450 500 510 600 610

NOTE: Maximum tolerance on height B is 5 mm*)Free space for maintenance**)Free side access in the unlikely event of coil replacement

C

DA

A1

B

C1

60

Fig. 6.

E

BDE

mm 2002 2402

A 2640 2640

A1 2600 2600

B 1970 1970

C 850 850

C1 845 845

D(1) 700 700

E(2)

900 900F1

(3) 700 700

F2(4) 2500 2500

kg 850 880

NOTE: Maximum tolerance on height B is 5 mm(1)

Free space for maintenance(2)

Free space for access to the compressors(3)

Free space for access to water connections(4)

Free space for coil repalcement

Fig. 7.

60

AA1

B

D

C1

EF2

C

F1

-

8/12/2019 MD T,D,E-iom En

12/48

-

8/12/2019 MD T,D,E-iom En

13/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D-E - BDE

Rev 4.2. 29-09-00 EN 13 (50)

WORKING SPACE MD*0651-1302To facilitate maintenance, leave at least 700mm free space in front of the unit as shown in the diagram (fig. 6. -pointD). Side access may be necessary in the unlikely event of coil replacement.

WORKING SPACE BDE 2002-2402To facilitate maintenance, leave at least 700mm free space in front of the unit as shown in the diagram (fig. 7. -

pointD). With BDE 2002-2402 units1 metre free space must also be left clear to the right of the unit (fig. 7. - E) inorder to allow access to the compressors for refrigerant charging and other maintenance operations and 700 mmfree space must also be left clear to the left of the unit ( fig. 7. - F1) in order to allow access to water connections.Side access from the left side may be alsonecessary in the unlikely event of coil replacement; leave around 2.5metre free space for this purpose (fig. 8. - F2).

AIR DISTRIBUTION

Treated air is delivered into the raised floor cavity and distributed through it into the room. Since the cooling capacityof the unit depends on the air flow, pay particular attention to:

a) the hole in the raised floor under the unit; this must have the dimensions labelled G and H and the unit mustbe positioned exactly over the centre. The gap must not be even partially obstructed be sections of panels,stringers, pipes; fit an elastic gasket around the base of the unit to avoid the transmission of noise andvibrations.

30

G

H

BDE

mm 2002 2402

G 2540 2540

H 790 790

MD*

mm0651 0702 0902 1002 1302

G 1340 1570 1570 2270 2270

H 590 590 590 590 590

Fig. 9.a.

Without optional Mounting Frame

b) free air flow in the raised floor cavity; the cavity under the raised floor must be at least 200-250 mm high, not

including the thickness of raised floor panels and stringers and free from obstructions, especially near the unit;

c) grilles and holes for air distribution in the room;the air comes out of grilles or holes in the floor; the locationand dimensions of these vents must correspond to the room heat load pattern.

The air velocity out of the raised floor should be between 1 and 2.5 m/s

The total free area (the sum of the sections of the air outlets) necessary for each model is calculated by dividing thetotal air flow rate (in m

3/s) by the required airflow velocity (in m/s).

The nominal airflow for each model is given in the technical data section of this manual. The location anddimensions of the outlets must correspond to the room heat load pattern and to the layout of the units.

IMPORTANT: An insufficient outlet area reduces the airflow and the cooling capacity of the units: keep theair outlet completely clear.

-

8/12/2019 MD T,D,E-iom En

14/48

INSTRUCTION MANUAL UNIFLAIRTM

MD.T-D-E - BDE

14 (50) Rev 4.2. 29-09-00 EN

The exact dimensions of the air delivery sectionare shown in the diagrams below.

MD*Model 0651 0702-0902 1002-1302

A 60 275 275

B 1320 1335 2035

A B 60

45

215

390

Fig. 9.b.

BDEModel 2002 2402

265 562 401 562 850

47

484

314

Fig. 9.c.

-

8/12/2019 MD T,D,E-iom En

15/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D-E - BDE

Rev 4.2. 29-09-00 EN 15 (50)

SUCTION PLENUM

The air intake can be ducted with a connection via an optional plenum to the suspended ceiling or a return air duct.

This plenum is available in a sound-absorbing version and with a removable front panel for removing the filter.

MD*

mm 0651 0702 0902 1002 1302

A 1400 1630 1630 2330 2330

C 610

H1 600

H1

25

A

F

10.b.

20

5

FRONT OFUNIT

25

10.a.C

BDE

mm 2002 2402

A 2600

C 810

H1 600

Fig. 10.

Fit optional plate F (see fig 10.) in front of the recirculation air filter housing to guarantee air tightness.

Details of the top edge for fastening the return air extension hood are shown in figs. 10.a. and 10.b. .

-

8/12/2019 MD T,D,E-iom En

16/48

INSTRUCTION MANUAL UNIFLAIRTM

MD.T-D-E - BDE

16 (50) Rev 4.2. 29-09-00 EN

FRESH AIR FILTER(optional)

The optional fresh air filter must be fitted to the left-hand side of the unit during installation, over the hole whichallows air into the fan section (see fig. 11.).

Connect the lower opening of the module to the nearest external air intake via a circular flexible tube with minimumdiameter 80mm; secure the tube to the module with a band or tie.

The flexible tube must be kept as short as possible; if the length is more than 6/7 metres, the optional forcedventilation module (external fan) should be fitted on the tube.

To change the fresh air filter:

1) slide the cover of the module upwards;

2) take out the filter cartridge

3) put the new cartridge in and replace the cover.

MODELS MD*0651 - 1302 MODELS BDE 2002 - 2402

FIG. 11.a

125

150

100 mm

Model 0651only

Models0702-1302

Fig. 11.b

90

100 mm

-

8/12/2019 MD T,D,E-iom En

17/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D-E, BDE

Rev 4.2. 29-09-00 EN 17 (50)

REFRIGERANT CONNECTIONS (MDT)

Each refrigeration circuit must be connected to its remote air-cooled condenser with one copper pipe for the gasoutput and one for the liquid return.

Sealant is used on the threaded compressor intake and output connections: AREXONS 35A42 for diameters up to and AREXONS 35A72 for larger diameters.

The figure below shows the base of the unit with the holes for the liquid line L and the gas output G ..

LG

W1

W2100***

W3100 Fig. 12.

G L

*** 80 mm on model 0651 only

MDT 0651 0702 0902 1002 1302

W1 70

W2 770 195

W3 - 895

W4 170

W5 460

W6 70

L 3/4

G 3/4

G: Gas discharge lineL: Liquid return line

REFRIGERANT PIPING: SUGGESTED SIZES

The table shows recommended diameters for output and liquid lines for distances up to 20 metres.

MODEL: 0651 0702 0902 1002 1302

Number of lines 1 2

Gas discharge pipe 18 mm( 3/4)

16 mm( 5/8)

18 mm( 3/4)

Liquid return pipe 16 mm( 5/8)

The table shows recommended diameters for output and liquid lines for distances up to 30 metres.

MODEL: 0651 0702 0902 1002 1302

Number of lines 1 2

Gas discharge pipe 22 mm( 7/8)

18 mm( 3/4)

22 mm( 7/8)

Liquid return pipe 18 mm( 3/4)

16 mm

( 5/8)

22 mm

( 7/8)

Pipes should have a total length of less than 30 metres and must be laid byan expert refrigeration technician in accordance with the instructions in fig. 13.

Pay special attention to:- insulationof the gas piping in the raised floor;- protection of the liquid piping against the sun and other heat sources.

De

1 mm

The values shown in the table refer to externaldiameter; pipe wall thickness is 1mm.

-

8/12/2019 MD T,D,E-iom En

18/48

INSTRUCTION MANUAL UNIFLAIRTM

MD.T-D-E, BDE

18 (50) Rev 4.2. 29-09-00 EN

LIQUIDO

OUTPUT

1/100

MAX 30 METRES

LIQUID

OUTPUT

1/100

N.B.: piping must be protected from sunlight

Fig. 13.c

MAX 5METRES

MAX 15METRES

MAX 5METRES

SYPHON

Fig. 13.a

Fig. 13.b

LIQUID

OUTPUT

1/100

MAX 5METRES

THERMALINSULATION

THERMALINSULATION

THERMALINSULATION

-

8/12/2019 MD T,D,E-iom En

19/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D-E, BDE

Rev 4.2. 29-09-00 EN 19 (50)

WATER CONNECTIONS (MDT)

Check chilled water pipe size and pump characteristics: insufficient water flow affects unit performance.Connect the unit to the piping system making sure that chilled water flows into the unit through the lower connection

and comes out from side connection; seal the holes where the pipes pass through the base of the unit in order toavoid bypass of air.For all hydraulic connections (except the condensate drain) use:

flexiblepipes to avoid the transmission of vibrations and to enable the unit to be moved;

3 piece junctions, near the connections to enable the unit to be removed if necessary;

shut-off valves to isolate the unit from the water circuit: if possible use full flow sphere valves to minimisepressure drop.

Insulate all the chilled water pipes with closed cell insulating material (e.g. Armaflex or equivalent) to avoidcondensation; insulation must allow access to valves and joints.

Install a mechanical filter in the section of tubing near the intake of the unit to prevent the fouling of the

heat exchanger with pieces of welding or flakes of oxidised metal from the water mains.

MDT 0651 0702 0902 1002 1302

I1 330 190 210

I2 90 30 60

I3 35 45 35

U1 330 95 120

U2 285 105 185

U3 245 260 245

I 1 G.f 1. G.f 1. G.f.

U 1 G.f 1. G.f 1. G.f.

I: chilled water intakeU: chilled water output

U3I3

I

U

SIDE

IU

Fig. 14.a.

U1I1

I

U

I2

U2

-

8/12/2019 MD T,D,E-iom En

20/48

INSTRUCTION MANUAL UNIFLAIRTM

MD.T-D-E, BDE

20 (50) Rev 4.2. 29-09-00 EN

WATER CONNECTIONS (MDD-MDE/BDE)

WATER CONNECTIONS - MDDCheck chilled waterpipe size and pump characteristics: insufficient water flow affects unit performance.

Connect the unit to the piping system making sure that chilled water flows into the unit through the lower connectionand comes out from side connection; seal the holes where the pipes pass through the base of the unit in order toavoid bypass of air.For all hydraulic connections (except the condensate drain) use:

flexiblepipes to avoid the transmission of vibrations and to enable the unit to be moved;

3 piece junctions, near the connections to enable the unit to be removed if necessary;

shut-off valves to isolate the unit from the water circuit: if possible use full flow sphere valves to minimisepressure drop.

Insulate all the chilled water pipes with closed cell insulating material (e.g. Armaflex or equivalent) to avoidcondensation; insulation must allow access to valves and joints.

Install a mechanical filter in the section of tubing near the intake of the unit to prevent the fouling of the

heat exchanger with pieces of welding or flakes of oxidised metal from the water mains.

MDD 0651 0702 0902 1002 1302

I1 330 190 210

I2 90 30 60

I3 35 45 35

U1 330 95 120

U2 285 105 185

U3 245 260 245

I 1 G.f 1. G.f 1. G.f.

U 1 G.f 1. G.f 1. G.f.

I: chilled water intakeU: chilled water output

U3 I3

I

U

SIDE

IU

Fig. 14.b.

U1I1

I

U

I2

U2

-

8/12/2019 MD T,D,E-iom En

21/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D-E, BDE

Rev 4.2. 29-09-00 EN 21 (50)

The water-cooled condensermust be connected to the cooling water piping system, making sure that water flows

into the condenser through the lower connection I and leaves through the upper connection U .Use:

- flexiblehoses to avoid transmission of vibrations;- 3 piece unions, close to the connections, to permit possible removal of the unit;- shut-off valvesto isolate the unit from the water circuit: if possible use full flow ball valves to minimise the waterpressure drop.If the water temperature may drop below the dew point of the treated air, insulate the water pipes with closed cell insulatingmaterial (e.g. Armaflex or equivalent) to avoid condensation; insulation must allow access to valves and joints.Seal the holes where the pipes pass through the base of the unit in order to avoid by-pass of air.N.B.: cooling water pressure should not exceed 1000 kPa (10 bar).If the cooling water temperature is uncontrolled and may drop below 25C, the use of a pressure operated waterregulating valve (available as an optional extra) for each condenser is required; in this case the water pressureshould not fall below 200 kPa (2 bar).IMPORTANT: the use of an evaporating cooling tower without efficient water treatment is not recommended sincescale build-up could rapidly clog the condensers.

MDD 0651 0702 0902 1002 1302

W1 70

W2 770 195

W3 - 895

W4 170

W5 460

W6 70

Iw 1 G.f 1. G.f 1. G.f.

Uw 1 G.f 1. G.f 1. G.f.

I: Condenser water intakeU: Condenser water output

A

A

Uw

Iw

Uw

Iw

W5

W4

W6

SECTION. A-A

MDD units only

Iw*Uw*

W1

W2100***

W3100 Fig. 15.

*MDD units onlyUw* Iw*

***80 mm on model 0651 only

-

8/12/2019 MD T,D,E-iom En

22/48

INSTRUCTION MANUAL UNIFLAIRTM

MD.T-D-E, BDE

22 (50) Rev 4.2. 29-09-00 EN

WATER CONNECTIONS - MDE/BDE

MDE BDE0651 0702 0902 1002 1302 2002 2402

E1 330 190 210 200 200

E2 195 75 135 110 110

E3 280 280 550 515 515

E4 70 70 70 105 105

Ie 1 G.f 1. G.f 1. G.f.

Ue 1 G.f 1. G.f 1. G.f.

E1 Ie

E2

E3

UeE4

Fig. 16.a.

MDE 0651 - 1302

Fig. 16.b.

C-(D)F 55 120

70 195

Ie

Ue

E1

645

E2 E4

E3

BDE 2002 - 2402

IMPORTANT: the units should operate with a mixture of water and ethylene glycol (containing passivating inhibitorsto prevent corrosion) in proportion to the external minimum design temperature. To prevent freezing duringdehumidification, the circuit must always contain at least 10% glycol.

Percentage in weight of ethylene glycol 10% 20% 30% 40% 50%

Freezing temperature -4C -10C -17C -25C -37C

-

8/12/2019 MD T,D,E-iom En

23/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D-E, BDE

Rev 4.2. 29-09-00 EN 23 (50)

HUMIDIFIER CONNECTION

Connect the humidifier intake (fig. 17. F ) to the building water supply using the 6 mm internal diameter flexible

plastic tube included with the unit and a shut-off valve.

OPTIONAL Humidifier(versions Dand Honly)Fig. 17.a.

F

C

D

C2

C1F1

F2

F

C

C-(D)

F

C1F1

C2

F2

Fig. 17.b.

355

SIDE(section)

C2F

C

MD* BD*0651 0702 0902 1002 1302 2002 2402

C1 95 70 65 65

C2 160 225 265 265

F1 185 220 120 120

F2 15 65 195 195

C (D) 25 25 25F 6 6 6

C(D): Condensate / Humidifier drainF: Humidifier feed

-

8/12/2019 MD T,D,E-iom En

24/48

INSTRUCTION MANUAL UNIFLAIRTM

MD.T-D-E, BDE

24 (50) Rev 4.2. 29-09-00 EN

The characteristics of the water supply must be within the following limits:

MINIMUM MAXIMUM

Mains pressure 1 bar 10 bar Electrical conductivity at 25C 125S/cm 1250 S/cm

Dimensions of impurities - 0.1mm

A mechanical filter with a mesh less than 50m should be used.Do not use water from de-mineralising or water softening plants.

The figure below represents connection of the condensate drain for unit versions D and H.At the condensate collection tray of the evaporating coil two corrugated siphoned tubes are connected (B1e B2)and meet at the "T" form (B3) from which leaves the connection to the humidifier drain.

During instalation, the water drain attachment (C-(D)) is connected to the buildings waste water drain by means of arubber or plastic tube with a resistance to temperatures reaching 100 C.A siphon must be provided on the piping on the outside of the unit, to avoid that water levels can rise and

overflow the humidifier tray.At the end of the siphon the pipe should have an inclination that is sufficient to provide water discharge (at leastequal to 1%).

B1

B2

C -(D)

1

1

B3

B1 B2

B3

Sez. 1-1

C -(D)

B3

Sez. 2-2

-

8/12/2019 MD T,D,E-iom En

25/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D-E, BDE

Rev 4.2. 29-09-00 EN 25 (50)

CONNECTING THE CONDENSATE DRAIN

The figure represents connection of the condensate drain for unit versions C and T.

At the condensate collection tray of the evaporating coil two corrugated siphoned tubes are connected (B1and B2)and meet at the "T" form (B3)

B1

B2

C (-D)

B3

During installation, the water drain (C-(D)) is connected to the the buildings waste water drain by means of a rubberor plastic tube with an internal diameter of 25 mm with a resistance to temperatures reaching 100 C.A siphon must be provided on the piping on the outside of the unit, to avoid that water levels can rise and

overflow the condensate tray.At the end of the siphon the pipe should have an inclination that is sufficient to provide water discharge (at leastequal to 1%).

If used, the optional condensate pump should be placed at a lower level than the output connection; the pump headpressure must be sufficient to deliver the condensate to the drain.

C-(D)

> 1 %Syphone

Minimum inclination

-

8/12/2019 MD T,D,E-iom En

26/48

INSTRUCTION MANUAL UNIFLAIRTM

MD.T-D-E, BDE

26 (50) Rev 4.2. 29-09-00 EN

ELECTRICAL CONNECTIONS

Correct and accurate electrical connections, carried out in compliance with localregulations, are extremely important for the prevention of accidents and for ensuring

long, trouble-free operation.

ACCESS TO THE ELECTRICAL PANELBefore working on the electrical parts of the unit, make sure that there is no power supply to the unit and that theswitch on the electrical panel is off (in the O position);The power section of the electrical panel is protected by a plastic cover; to remove this cover, turn off the mainswitch to release the lock and then undo the four screws.

CONNECTION TO THE MAINS - CABLE SECTIONS - FUSES

Check that the mains voltage corresponds to the nominal data of the unit (voltage, phases, frequency) shown on the

electrical panel.

Power supply voltage must be within 6% of the nominal value. In tri-phase units the difference between the phasesmust be less than 2%: unit operation with power supplies outside these limits may invalidate the guarantee.

Pass the electrical supply cable through the hole in the bottom of the unit. The cable can also be passed throughthe sides or back of the base frame after opening the pre-cut holes.See also the table Recommended cable sections and line fuses .

Take the cable up to terminal box A (fig.18.) containing the terminals of the 3 phase wires and of the yellow-green

earth wire (detail B ).

Fix the ends of the power supply cable to the top terminals of the general switch in the electrical panel and tightenthe screws.

N.B.in MD*0651 and BDE units the neutral wire must also be connected (detail C ).

L1 L2 L3

B

L1 L2 L3 N

C

70

70FIG. 18.

A

MD* 0651 - 1302

-

8/12/2019 MD T,D,E-iom En

27/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D-E, BDE

Rev 4.2. 29-09-00 EN 27 (50)

Fig. 19.

A

L1 L2 L3 N

B

BDE 2002 - 2402

INSTALLATION AND CONNECTION OF CONTROL PANEL

The control is not installed on the unit when it is shipped to prevent damage during transport. The packagecontaining the control is in the fan housing on the right hand side of the unit.

Fix the control panel(s) in accordance with the enclosed instructions and insert the cable connectors in therespective slots without forcing them (see control panel instruction manual).

IMPORTANT: the connection of the control panel must always be carried out when the power is off (electrical

panel switch in position O).

-

8/12/2019 MD T,D,E-iom En

28/48

INSTRUCTION MANUAL UNIFLAIRTM

MD.T-D-E, BDE

28 (50) Rev 4.2. 29-09-00 EN

RECOMMENDED POWER SUPPLY CABLE SECTIONS AND LINE FUSES

UNIT - VERSION C UNIT - VERSION T UNIT - VERSION D UNIT - VERSION H

MODEL LINE FUSES LINE FUSES LINE FUSES LINE FUSES

MD...0651 4x2.5 + 2.5PE 40A 4x2.5 + 2.5PE 40A 4x4 + 4PE 40A 4x6 + 6PE 50A

MD...0702 3x2.5 + 2.5PE 40A 3x2.5 + 2.5PE 40A 3x4 + 4PE 50A 3x4 + 4PE 50A

MD...0902 3x4 + 4PE 40A 3x4 + 4PE 40A 3x10 + 10PE 50A 3x10 + 10PE 50A

MD...1002 3x4 + 4PE 40A 3x4 + 4PE 40A 3x10 + 10PE 50A 3x10 + 10PE 50A

MD...1302 3x6 + 6PE 50A 3x6 + 6PE 50A 3x10 + 10PE 63A 3x10 + 10PE 63A

BD...2002 4x25+16PE 125A 4x25+16PE 125A 4x25+16PE 125A 4x25+16PE 125A

BD...2402 4x25+16PE 125A 4x25+16PE 125A 4x25+16PE 125A 4x25+16PE 125A

-

8/12/2019 MD T,D,E-iom En

29/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D.E, BDE

Rev 4.2. 29-09-00 EN 29 (50)

START-UP AND TESTING

EVACUATION OF REFRIGERANT LINES AND REFRIGERANT

CHARGING (MDT)

The unit is supplied pre-charged with refrigerant R22 or R407C.

Check the type of refrigerant to use on the unit data plate and on the compressor.

Create a vacuum in the refrigerant lines and the remote condenser; maintain pressure below 100 Paabsolute (0,7 mmHg) for several hours (preferably overnight) in order to evacuate air and any moisturetraces.Start the compressor and then slowly charge the system with refrigerant through the special valve

downstream of the thermostatic valve. Charge the system until the pressure in the lines is stable and thebubbles in the sight glass have disappeared.

The charging must be done under normal room conditions and with an output pressure of around 18 bar(equivalent to a saturation temperature of 48C in the case of R22); If the unit has on-off condensationcontrol, make sure that the condenser fan does not keep switching on and off, if necessary by partiallyobstructing the intake area.Check that the subcooling of the liquid at the thermostatic valve intake is between 3 and 5C less than thecondensation temperature reading on the manometer scale and that the superheating of the vapour at theevaporator output is between 5 and 8C.The dilution ratio of the system is around 5% by weight of oil to refrigerant. In the event that it is necessaryto top up the oil use only these types:

COPELAND COMPRESSORSRefrigerant Recommended Oil

R22(Mineral oil) Suniso 3 GS Texaco WF 32 Fuchs KM

R407C(POE) Mobil EAL Arctic 22 CC ICI EMKARATE RL 32S

MANEUROP COMPRESSORS

Refrigerant Recommended Oil

R22(Mineral oil) Maneurop 160P

R407C(POE) Maneurop 160SZ

-

8/12/2019 MD T,D,E-iom En

30/48

INSTRUCION MANUAL UNIFLAIRTM

MD.T-D.E, BDE

30 (50) Rev 4.2. 29-09-00 EN

THERMOSTATIC EXPANSION VALVE REGULATION (MDT)

The thermostatic expansion valve is set using the regulation screws shown in the diagram below (fig. 20.).On MDD and MDE/BDE models the regulation is pre-set in the factory.

NOTICE: The instructions as below must be done when the unit is operating in Cooling function,under the following operating conditions:

- Indoor temperature: 24C.

- Outdoor temperature: 32C.

NOTICE: Observe the glide with refrigerant R407C.

Check that liquid subcooling at the condenser output is around 3-5C (against bubble point for R407C);

Check that thermostatic expansion valve superheating is around 5-10C (against dew point for R407C);

Check that the sensor bulb of the valve is correctly positioned, fixed and insulated.

If superheating is higher than the correct level, increase the valve opening; if it is lower, reduce theopening.

Bulb Expansion valve

Equaliser tube

Evaporatorcoil

Regulation screw

Fig. 20.

The table below shows the approximate changes in superheating resulting from one full turn of thethermostatic expansion valve regulation screw.

Model Valve Refrigerant Evaporation temperature

Pressure change per turn (bar) -10C 0 +10CChange in superheating from one turn (Kelvin)

0702 TI(E) R22 0.58 4.4 3.5 2.8

R407C 0.58 4.5 3.5 2.70651 - 0902 TCLE R22 0.05 0.4 0.3 0.31002 - 1302

2002 - 2402R407C 0.05 0.3 0.2 0.2

-

8/12/2019 MD T,D,E-iom En

31/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D.E, BDE

Rev 4.2. 29-09-00 EN 31 (50)

REMOTE CONTROL

MP20 control systems feature as standard the automatic management of two units, one operating and one

in stand-by, without the need for additional devices. To enable this, connect terminals NC10-C10on the 2nd

level alarm relay on the first unit to remote control terminals 20-50on the second unit, and vice versa. Theelectrical diagram included with the unit shows the terminals for the interconnection of the units.

20

0

Fig. 21.

20

50

Remotecontrol

ID1

IDCM1 NO10 C10 NC10

2n

level alarm

START-UP PROCEDURE

Checkthat the auxiliary transformer is supplied through the terminal (220/240/380/415) corresponding tothe effective mains voltage.Connectthe power supply to the electrical panel, set the auxiliary automatic circuit breakers, turn on thecurrent and check that the yellow LINE LED on the control board is on.Armall the automatic switches on the electrical panel.

Do notstart the unit for at least 12 hours to allow the preheating element to evaporate any liquid refrigerantwhich may have accumulated in the compressor.Open all chilled water shut-off valves (chilled water models: MDT-MDD-MDE/BDE).

Open all condensation water shut-off valves (water-cooled models: MDD-MDE/BDE).

Openall shut-off valves on the refrigerant circuits (air-cooled models: MDT)

Checkthat power is on to the remote air-cooled condensers (MDT units)

Checkthat power is on to the remote radiators (MDD-MDE/BDE units)

Checkthat the cooling water circulating pump is working and power is on to the external radiators (water-

cooled models).

AT LEAST 12 HOURSAFTER TURNING ON THE POWER SUPPLY:

Start the unit by pressing the button on the control terminal; after a short delay the fan will start andthe green LED on the control panel will come on.If there is an alarm shown by the red ALARM LED and the buzzer, consult the microprocessor controlmanual.

-

8/12/2019 MD T,D,E-iom En

32/48

INSTRUCION MANUAL UNIFLAIRTM

MD.T-D.E, BDE

32 (50) Rev 4.2. 29-09-00 EN

FUNCTION AND REGULATION

WATER-COOLED UNITS (MDD)

OPEN WATER CIRCUITIf the cooling water temperature is not controlled and may go below 28C, a pressostatic valve must befitted for each condenser; in this case the supply pressure must not go above 200 kPa (2 bar).IMPORTANT: do not use water cooled by an evaporating tower since the condensers would quicklybecome blocked with scale.

CLOSED WATER CIRCUITThe condensers are supplied with water in a closed circuit cooled by external radiators; check that thesection of the piping and the performance of the pump are sufficient. An inadequate water flow reduces theperformance of the air conditioning unit.The cooling water temperature must be controlled so that it does not go below 28C (fig. 22).The microprocessor control system performs this function; it measures the water temperature with optional

sensor A , adjusting the fans C of the external radiators (see mP20 instruction manual - analogue output"Y1").

If the temperature of the cooling water is not controlled, a constant water flow condensation pressureregulation system must be used (available as an option) on each cooling circuit.IMPORTANT: the cooling water must contain a percentage of ethylene glycol (of the passive, non-corrosive type) in proportion to the likely minimum outdoor temperature.

Percentage of glycol by weight 10% 20% 30% 40% 50%

Freezing temperature -4C -10C -17C -25C -37C

T

C

A

28 C

Fig. 22.

Limit of equipmentsupplied by UNIFLAIR

-

8/12/2019 MD T,D,E-iom En

33/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D.E, BDE

Rev 4.2. 29-09-00 EN 33 (50)

ELECTRICAL CONNECTION AND CONTROL OF REMOTE RADIATORS

(MDE/BDE)

The room units need to be wired to the radiators only for transmitting the signal required to control theradiator operation, as described hereafter.The remote radiators - electrically supplied from the nearest power point, independently from the room unit- must be provided with a fan contactor whose coil shall be energised with a 24 V AC signal to start thefans.In MDE units the microprocessor measures and compares the return air temperature and the outdoortemperature and, when feasible, switches from the mechanical cooling mode to the energy-saving mode.The microprocessor measures also the coolant temperature and, when this is lower than the return airtemperature, opens the 3-way valve to feed the free cooling coil (analogue output Y0).The water/glycol coolant temperature is kept at two different levels:- at approx. 28-34C, to be set according to the design conditions, during the warm weather mode

(operation with mechanical cooling only);- between 8 and 10C during the energy-saving mode (free-cooling operation).

The microprocessor has the capability of controlling the coolant temperature (with the NO contact 13placed in the interface card: refer to the mP10/mP20 microprocessor manual) according to one of thefollowing systems.

WATER CIRCUIT WITH ONLY ONE ROOM UNIT (see fig. 23.a.)

The ENERGY-SAVING unit measures with its own sensor the coolant temperature and controls it byenergising the contactor of the radiator (max 2 pieces) through the contact 13of the interface card.The radiator can be alternatively of the type:- without thermostatic control. The microprocessor of the room unit controls at any time the coolant

temperature providing an on-off signal to start the radiator fan(s)- with thermostatic fan speed control by regulating fan speed.

During the mechanical cooling mode the radiator controls the coolant temperature with its built-inthermostatic fan speed control.During the Energy-Saving cycle the microprocessor controls the coolant temperature providing an on-offsignal to start the radiator fan(s).

WATER CIRCUIT WITH MULTIPLE ROOM UNITS AND RADIATORS IN PARALLEL (see fig. 23.b.)

In multiple installations, with several room units (each one capable of fully independent operation) andseveral radiators connected in parallel in the same water circuit, the control system is more flexible.The coolant temperature is controlled by the RADIATOR MANAGER (RM in fig. 23.b.), a separateelectrical panel with an independent multi-step solid state temperature controller with two different andindividually programmable set points (Summer & Energy-Saving).The RADIATOR MANAGER (available in 4-step and 8-step version) is connected with a double wire:- to each MDE room unit which, by closing the contact 13 of its interface card, has the capability to switch

the operation from the mechanical cooling mode to the energy-saving mode;- to the contactor coil of each radiator to start and stop its fans.In this case too, the radiators can be either:- without thermostatic control: The RADIATOR MANAGER keeps the coolant temperature at the set

value by controlling the number of operating radiators;- with thermostatic fan speed control: During mechanical cooling, each radiator controls coolant

temperature with its own fan speed control.

During the Energy-Saving cycle The RADIATOR MANAGER keeps the coolant temperature at the setvalue with the step control of the number of operating radiators

N.B.: The mP10/mP20 microprocessor provides a 0-10V DC modulating signal to control radiator fans viaspecific fan speed control (analogue output Y1); further information is available on request.

-

8/12/2019 MD T,D,E-iom En

34/48

INSTRUCION MANUAL UNIFLAIRTM

MD.T-D.E, BDE

34 (50) Rev 4.2. 29-09-00 EN

T

FIG. 23.a

A

T

FIG. 23.b.

A

T

A

RM

S

-

8/12/2019 MD T,D,E-iom En

35/48

UNIFLAIRTM

DIRECTION FOR USE

MD.T-D.E, BDE

Rev 4.2. 29-09-00 EN 35 (50)

MEASUREMENT AND ALARM DEVICES

The unit is equipped with the following devices (see fig 24.):

- STU: room temperature and humidity sensor;- FS: air flow sensor (differential pressostat)

- PFS: dirty filter sensor(differential pressostat);

- AP: high pressure p-stat with manual reset

- BP: low pressure p-stat witchwith automatic re-set

- TSR:electric heater safety thermostat; the re-set button is in the coil housing

- Chilled water temperaturesensor (for reading and controlling CW operation in MDT and MDD models) installedon the chilled water supply pipe to the unit

- SE: external air temperaturesensor (in MDE/BDE models) to be installed outdoors in the shade

- SCW: closed circuit water temperaturesensor (in MDE/BDE models for reading and control of glycoled watersupply temperature): installed on the water supply pipe to the unit

The following optional devices can be connected to the microprocessor control:

- Underfloor flooding detectorconsisting of:a) SAS deviceinserted in the appropriate socket of the electrical panel;

b) RAS sensor(or sensors, connected in parallel) installed at the points to be monitored;

- ATA and BTA: high/low room temperature sensors: to be installed close to the unit;

- AUA and BUA: high/low room humidity sensors: to be installed close to the room unit;

- SFF: fire and smoke sensors: to be installed in the room or under the raised floor, in a low air-speed zone.

RAS

FS

PFS

Fig. 24.a.

SAS

TSR

STUSI

mP20

BP

AP

RAS

Fig. 24.b.

SAS

TSR

BP

AP

FS PFS

MP20

MDT / MDD / MDE 0651 - 1302 BDE 2002 - 2402

-

8/12/2019 MD T,D,E-iom En

36/48

DIRECTION FOR USE UNIFLAIRTM

MD.T-D.E, BDE

36 (50) Rev 4.2. 29-09-00 EN

REGULATION OF CONDENSATION PRESSURE(Remote air-cooled condenser)

Unit condensation temperature must be between:- minimum 40C (for correct thermostatic expansion valve function and to avoid freezing of the coil in partial

operation)

- maximum 63C.

For this purpose there are condensation pressure regulation devices which should be set as follows.

Condensation pressure is controlled by regulation of the condenser fan by one of these options which must be

chosen when the REMOTE CONDENSER is ordered (see CAL Instruction Manual):

1) pressostat PV which measures condensation pressure and activates the fan of the air-cooled condenser;

2) regulator RV which modulates the speed of the fan as a function of condensation pressure.

The table below shows the settings of the two systems.

Description Intervention Differential Re-set

PV standard Fan Pressostat 18 bar (closing) 4 bar 14 bar

RV optional Speed regulator 20 bar (maximum speed) 4 bar 16 bar (minimum speed)

When setting the pressostat or the regulator, check the condensation pressure with a manometer connected to thepressure connector of the gas output valve.

SETTING THE PRESSOSTATIC VALVE(Optional - water cooled models only)

The pressostatic valve controls the water flow to prevent condensation pressure from falling too low and to reducewater consumption.

Set the pressostatic valve with the regulation knob (clockwise to increase the pressure) until the pressure is stableat the recommended value of 17 bar (equivalent to a saturation temperature of around 45C in the case of R22).Check the pressure with a manometer on the pressure connector of the output valve.

-

8/12/2019 MD T,D,E-iom En

37/48

UNIFLAIRTM

DIRECTION FOR USE

MD.T-D.E, BDE

Rev 4.2. 29-09-00 EN 37 (50)

SETTING THE REGULATION AND SAFETY DEVICES

After starting the unit, make the following settings:

- Room temperature:see control manual;- Room relative humidity (D and H versions): see control manual;

- Fan speed:see section on Fan Speed Regulation;

- Dirty filter differential pressostat:see section on setting the dirty filter sensor.

Check that safety devices are set at the values shown in the table below.

The regulation and safety devices are set in the factory as shown in the table below and must not be changedwithout good reason.

SETTING VALUES

Description Intervention Differential Re-set

ALL MODELSAP HP Pressostat 27.5 bar (opening) - Manual reset

BP LP Pressostat 2.0 bar (opening) 1.5 bar 3.5 bar

TSR Safety Thermostat (optional) 320 C (opening) - Manual reset

VS Safety valve 29 bar - -

WATER-COOLED MODELS

VP Pressostatic valve 15 bar - -

SETTING THE AIRFLOW SENSOR

The FS differential pressostat should intervene if the fan is not working (if the unit has one fan only) or if one of thefans is not working (in the case of multiple fans).The setting of the airflow differential pressostat is 1.0 mbar (100 Pa). Since the difference in pressure between thefan intake and delivery depends on the airflow, it is necessary to set the pressostat after installation, making surethat the contact closes when the fan is in normal operation. To set the pressostat:

set the fan speed regulator at the required value (see Fan Speed Regulation);

simulate a fan fault (stop the fan, or one of the fans if multiple); check that the pressostat intervenes

if the pressostat does not intervene, gradually lower the setting until it doesThe FS differential pressostat can be set on a scale from 0.5 to 5.0 mbar (from 50 to 500 Pa).

SETTING THE DIRTY FILTER SENSOR(Optional)

The PFS pressostat must be set as a function of the pressure drop; this depends not only on how dirty the filter isbut also on the airflow and therefore on the setting of the fan speed regulator. The setting must be done when thefilter is clean:- set the fan speed regulator at the desired value (see Fan Speed Regulation);- set the pressostat intervention at 1.5 mbar;

- gradually cover the surface of the air filter and check that the pressostat intervenes when the filter is about 50-60% covered;

- if the pressostat does not intervene, gradually lower its setting; if it cuts in too soon, increase the setting.

-

8/12/2019 MD T,D,E-iom En

38/48

DIRECTION FOR USE UNIFLAIRTM

MD.T-D.E, BDE

38 (50) Rev 4.2. 29-09-00 EN

VALVE AND SERVOMOTOR

The instructions for the valve and servomotor are on the enclosed sheet included with the unit.

IMPORTANT: Disconnect the power supply before working on the servomotor.

With 24V AC power supply the servomotor moves in proportion to the control signal which varies between 0 and10V DC.

The servomotor automatically stops:

at the end of its travel; in the position corresponding to the control signal;

in the position in which it is situated whenever power is disconnected.

OPERATION OF SERVOMOTOR MVB

If there is a problem with the servomotor or thecontrol system, the valve can be moved manually by turning controlknob A(fig. 25.).If necessary:1. Pull control knob Aout2. Turn the knob clockwise to lower the valve stem, anti-clockwise to raise it.

A Manual control knob

Locking nut

Valve steam

A

1.Pull out

2. Turn clockwise to open (the valve stemmoves up)

2.Turn anti-clockwise to close (the valve stemmoves down)

Fig. 25.

-

8/12/2019 MD T,D,E-iom En

39/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D-E, BDE

Rev 4.2. 29-09-00 EN 39 (50)

TECHNICAL DATA

GENERAL CHARACTERISTICS

These characteristics refer to standard units and may be different for special or modified units.

MD* BD*0651 0702 0902 1002 1302 2002 2402

TWIN COOLdirect expansion function

MDT- air-cooled (1)Condensing temperature: 48C

total - kWsensible - kW

22.822.8

28.628.6

35.232.9

38.438.4

44.644.6

MDD- water-cooled (1)Condensing temperature: 40C

total - kWsensible - kW

24.424.4

30.930.9

38.034.0

41.141.1

47.647.6

MDD- glycol-cooled (2)Condensing temperature: 52C

total - kWsensible - kW

22.0

22.0

27.6

27.6

33.7

32.4

37.0

37.0

43.0

43.0

TWIN COOL chilled water function (3)Cooling capacity total - kW

sensible - kW30.326.2

32.532.5

32.532.5

54.550.7

54.550.7

Chilled water flow rate l/h 5220 5620 5620 9400 9400

Pressure drop- coil only kPa 62 47 47 74 74

Pressure drop - valve kPa 37 16 16 20 20

ENERGY SAVING direct expansion function

MDE-BDE- Cooling capacity (1)Condensing temperature: 52C

total - kWsensible - kW

22.022.0

27.627.6

33.732.4

37.037.0

43.043.0

65.965.9

79.975.6

ENERGY SAVING free cooling function (2)

Cooling capacity with inlet watertemperature = 7C

total - kWsensible - kW

24.724.7

30.030.0

30.630.6

46.246.2

46.946.9

66.266.2

73.673.6

Cooling capacity with inlet watertemperature = 10C

total - kWsensible - kW

20.520.5

24.924.9

25.425.4

38.338.3

38.938.9

54.954.9

60.960.9

Cooling capacity with inlet watertemperature = 12C

total - kWsensible - kW

17.617.6

21.421.4

21.921.9

33.033.0

33.533.5

47.247.2

52.452.4

Chilled water flow rate l/h 4500 6000 6500 8000 8500 13000 15500

Pressure drop kPa 130 135 130 130 130 115 155

(1) With room at 24C, 50% rH;(2) With room at 24C, 50% rH; data refer to unit with 30% ethylene glycol in water circuit;(3) With room at 24C, 50% rH; inlet/outlet water temperature: 7/12C

-

8/12/2019 MD T,D,E-iom En

40/48

INSTRUCTION MANUAL UNIFLAIRTM

MD.T-D-E, BDE

40 (50) Rev 4.2. 29-09-00 EN

MD* BD*0651 0702 0902 1002 1302 2002 2402

FANS

Fan drive direct direct direct direct direct belt drive belt drive

Number 2 2 2 3 3 2 2

Nominal air volume (6) l/s 1.94 2.58 2.58 3.89 3.89

m3/h 6980 9290 9290 14000 14000

COMPRESSORS

Number 1 2 2 2 2 2 2

Cooling power ARI (each) kW 19.5 11.0 14.7 15.8 19.5

Absorbed power ARI (each) kW 7.1 3.8 5.1 5.7 7.1 8.9 11.1

AIR FILTERS

Number 2 2 2 3 3 3 3

Frontal Dimensions mm 625x500 750x500 750x500 750x500 750x500 680x750 680x750

EU4 Filter thickness (standard) mm 100 100 100 100 100 150 150

EU5 Filter thickness (optional) mm 300 300 300 300 300 300 300

THREE-WAY VALVE

Valve size 1 1.1/4 1.1/2" 1.1/2" 1.1/2" 2" 2"

kvs coefficient 8.6 14 21 21 21 40 40

ELECTRICAL HEATERS

Total power kW 9 9 9 9 9 18 18

Number of elements 3 6 6

Number of stages 3 3 3

HUMIDIFIER

Nominal steam production kg/h 4.5 9.6 9.6 9.6 9.6 9.6 9.6

Nominal absorbed power kW 3.3 6.6 6.6 6.6 6.6 6.9 6.9

(6) Static head pressure: 20Pa

-

8/12/2019 MD T,D,E-iom En

41/48

UNIFLAIRTM

INSTRUCTIONMANUAL

MD.T-D-E,

BD.T-D-E

Rev4.2.29-09-00EN

41(50

)

ELECT

RICALDATA

COMPONENTS

COMPLETEUNIT

DIRECTDRIVE

FANSMOTORS(a)

HERMETICTYPE

COMPRESSORS(a)

ELECTRIC

HEATERS

ELECTRODE

HUMIDIFIER

ROOM

UNIT

VERS

IONC

ROOMUNIT

VERSIONT

ROOMUNIT

VERSIOND

ROOMUNIT

VERSIONH

MODEL

VOLTAGE

No.

kW

OA

FLA

L

RA

No.

kW

OA

FLA

LRA

kW

OA

kW

OA

OA

(c)

OA(c)

OA(c)

OA(c)

MD...0651

4

00V/3N

50HZ

2(b)

0.55

5.0

5.5

8.7

1

7.1

12.0

13.2

69

9.0

13.7

3.3

5.0

17.0(c)

18.7(c)

22.0(c)

30.7(c)

MD...0702

400V/3

50HZ

2

1.2

2.5

3.3

7.2

2

3.8

6.5

7.1

38

9.0

13.7

6.6

10.0

18.0

18.0

28.0

28.0

MD...0902

400V/3

50HZ

2

1.2

2.5

3.3

7.2

2

5.7

9.7

10.8

63

9.0

13.7

6.6

10.0

24.4

24.4

34.4

34.4

MD...1002

400V/3

50HZ

3

1.2

2.5

3.3

7.2

2

5.7

9.7

10.8

63

9.0

13.7

6.6

10.0

26.9

26.9

36.9

36.9

MD...1302

400V/3

50HZ

3

1.2

2.5

3.3

7.2

2

7.1

12.0

13.2

69

9.0

13.7

6.6

10.0

31.5

31.5

41.5

41.5

KEY

kW:nominalpower

VERSIONC:c

oolingonly;

NOTES

OA:nominaloperatingcurrent

VERSIONT:c

ooling+electricheating

(a):datareferstoeachp

iece;

FLA:fullloadc

urrent

VERSIOND:c

ool.+humiditycontrol(humid.anddehum

.)

(b):singlephaseat230V

LRA:lockedro

torcurrent

VERSIONH:c

ool.+electricreheating+humiditycontrol.

(c):maxcurrentofthem

ostloadedphaseatnominaloperatingcondition.

COMPONENTS

COMPLETEUNIT

FANSMOTOR

COMPRESSOR

ELECTRIC

ELECTRODE

UNITVERSION

(c)

(a)

(a)

RE-HEAT

HUMIDIFIER

C

T

D

H

MODEL

VOLTAGE

No.

kW

OA(/1)

FLA(/1)

LRA(/1)

No.

kW

OA(/1)

FLA(/1)

LRA(/1

)

No.

kW

OA

kW

OA(/1)

kW

OA(c)

kW

OA

kW

OA

kW

OA

BDE2002

400V/3N

50HZ

2

2.6

4.7

5.2

26.0

2

8.9

16.5

18.4

127

.0

3

6.0

8.7

6.9

10.0

23.0

42.4

23.0

42.4

29.9

52.4

29.9

52.4

BDE2402

400V/3N

50HZ

2

3.5

6.1

6.9

38.0

2

11.1

20.3

23.4

159

.0

3

6.0

8.7

6.9

10.0

29.2

52.8

29.2

52.8

36.1

62.8

36.1

62.8

KEY

NOTE

kW:currentabsorption;

VERSION

C:coolingonly;

(a):singledevice;

OA:currentabso

rptioninnominalconditions;

VERSION

T:cooling+electricre-heat;

FLA:currentabs

orptioninmaximumconditions;

VERSION

D:cooling+hum

iditycontrol;

(c):Maximumcurrentabsorptionofthem

ostheavily

LRA:start-upcu

rrent;

VERSION

H:temperaturea

ndhumiditycontrol

loadedphaseinoperationalconditions

-

8/12/2019 MD T,D,E-iom En

42/48

INSTRUCTION MANUAL UNIFLAIRTM

MD.T-D-E, BDE

42 (50) Rev 4.2. 29-09-00 EN

MAINTENANCE

REGULAR CHECKS

The following maintenance operations should be done regularly:

WEEKLY:

- check that room conditions on the control panel display are normal;

- check the refrigerant charge; the sight glass should be clear (however the presence of a few bubbles is normal);

- check normal temperature and noise levels of compressor and fans;

- check the air filters; clean or change the filters when the dirty filter alarm comes on;

- check that power supply voltage is within design limits;

MONTHLY:

- check normal condensation and evaporation pressures;- check the cylinder and the feed and drain valves of the humidifier: replace the cylinder when the specific alarm

comes on (see microprocessor instruction manual);

- check the flow of condensate to the drain;

- check remote condensers or external radiators: remove all foreign objects (leaves, seeds, dust, etc.) with a jet ofcompressed air or water;

- check that electrical terminals are tight and in good condition;

- check correct pressostatic valve operation (option on MDD water-cooled models).

YEARLY:

- check that the concentration of ethylene glycol and passivating inhibitor complies with the suppliers instructions

(MDD-MDE/BDE models).

CHANGING THE LOW PRESSURE PRESSOSTAT

The refrigerant circuits of M-series air conditioningunits have schrader needle valves for connectingmanometers or transducers and for refrigerantcharging.

All schrader valves are fitted with needles except thevalve for connecting the High Pressure pressostat.

If there is a fault, the refrigerant circuit must be drainedto change the High Pressure pressostat (AP).

To change the Low Pressure pressostat (BP), simplyundo the capillary connection shown at (2) in thediagram.

IMPORTANT:DO NOT UNDO THE PRESSOSTAT SHOWN AT (1)

IN THE DIAGRAM THIS WOULD ALLOW GAS TO ESCAPE FROM THE REFRIGERANT CIRCUIT.

BP PRESSOSTAT

Fig. 26.

Connectionn.1Pressure connector

Connectionn.2Schrader valve

-

8/12/2019 MD T,D,E-iom En

43/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D-E, BDE

Rev 4.2. 29-09-00 EN 43 (50)

HUMIDIFIER

SYSTEMS COMPONENTS

On request, Dand Hversions of the unit can be fitted with an immersed-electrode humidifier. The steam productiongroup consists of the following components.

1. Humidifier interface board: SIU;

2. Current transformer TAMfor measuring the currentflowing between the electrodes in the boiler cylinder;

3. Water supply filling tray;

4. High water level detector electrodes in the

boiler cylinder;5. Overflow pipe;

6. Boiler cylinder;

7. Feed water solenoid valve: EVC;

8. Boiler cylinder drain solenoid valve: EVS.

9. Control board: MP20;

10. Temperature and humidity probe: STU;

2

3

4

6

8

5

7

1

Fig. 27.a.

9. MP20

2.TAM

4

6.

8.EVS7.EVC

5

3

1. SIU

10. STU

Fig. 27.b. CU

-

8/12/2019 MD T,D,E-iom En

44/48

INSTRUCTION MANUAL UNIFLAIRTM

MD.T-D-E, BDE

44 (50) Rev 4.2. 29-09-00 EN

OPERATING PRIINCIPLE OF THE HUMIDIFIER

In the electrode boiler humidifier, the current flowing between the electrodes in the water in the cylinder generatesthe heat necessary to boil the water (see fig. 27.).

The rate of current flow, and therefore of steam production measured by the transformer (2.), is controlled by

controlling both the water level and the concentration of salts in the cylinder (6.) by means of the fill- (7.) and drain

(8.) solenoid valve.

On a call for humidification, the CU humidifier contact (see electrical diagram) is closed, providing power to the immersedelectrodes. When the current falls below the value required as a result of a fall in the water level, the feed water solenoid valve

(7.) is opened.

The drain solenoid valve (8.) is opened at intervals depending upon the characteristics of the feed water supply, in

order to mantain the optimum concentration of dissolved salts in the water in the cylinder (6.).

The only maintenance required is periodic inspection and cleaning of the steam boiler components.This should be carried out at least once a year, preferably before summer holiday shutdown.

BOILER CYLINDER

Scale deposits must be cleaned periodically from the electrodes andparticles of scale must be removed from the filter in the base of thecylinder.To dismantle the cylinder:

- drain all the water from the cylinder (see the section on ManualControls in the microprocessor control instruction manual).

- cut the power supply by opening the main isolator on the electricalpanel;- disconnect the steam distributor hose from the top of the cylinder;- disconnect the power connections to the electrodes by unscrewingthe terminal connectors and pull off the connectors of the high levelelectrodes;- unclip the cylinder fixing bracket;- pull the cylinder (1.) vertically upwards out of its seat as shown infig. 28.

Unscrew the retaining ring (5.) (see fig. 28.) from the base of the

cylinder (1.) and remove the filter (2.). Flush loose scale depositsfrom the filter and the inside of the cylinder with water. Clean scale deposits from the electrodes mechanically orchemically (normal commercially available descaling products can be used ).

The boiler cylinder can be re-used many times after cleaning of the electrodes. However it will eventually requirereplacement when the electrode meshes are too worn to make further cleaning worth while. The standard sparepart comprises only the cylinder itself (1.) and the gasket (3.): the filter (2.), retaining ring (5.) and connecting piece

(4.) are items which are not normally subject to wear and can be re-used with the new cylinder.

1

2

3

4

5

Fig. 28.

Manual OverrideHumidifier Drain Valve Y

-

8/12/2019 MD T,D,E-iom En

45/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D-E, BDE

Rev 4.2. 29-09-00 EN 45 (50)

FILL AND DRAIN CONNECTIONS

Periodic inspections of the fill and drain connections are also advisable in order to guarantee trouble-free operationof the humidifier.Proceed as follows:- drain all the water from the cylinder using the manual control on the microprocessor control ;- cut the power supply by opening the main isolator on the electrical panel;- disconnect the feed line at the connection to the inlet solenoid valve connection;- extract, clean and replace the filter located inside the solenoid valve connection;- remove the drain solenoid valve assembly (shown in fig. 29.), clean out the water pathways and remove anyparticles of scale from the drain syphon.

1Fig. 29.

-

8/12/2019 MD T,D,E-iom En

46/48

INSTRUCTION MANUAL UNIFLAIRTM

MD.T-D-E, BDE

46 (50) Rev 4.2. 29-09-00 EN

PROBLEM SOLVINGProblem solving is made easier by the microprocessor control display; if there is an alarm, consult the control panelinstruction manual.

If necessary, call the nearest service centre describing the nature of the fault displayed on the control.

PROBLEM POSSIBLE CAUSE CHECK / REMEDY

NO POWER A) No power to the unit electrical panel Check that power is on and the unit mainswitch on the electrical panel is closed.

(The yellow LED on the mP3 controlpanel or the mP20 board is off)

B) No power to the auxiliary circuit 1) Check that the IM automatic circuit breakeron the AUX circuit is set.

2) Check the auxiliary circuit 24V fuse; checkthe fuse on mP20 board.

THE UNIT DOES NOT WORK A)The control panel does not start theunit.

Check that the control panel connectors arecorrectly located in their sockets; see control

panel instruction manual.B) Check the control panel for alarms See the control panel instruction manual

ROOM TEMPERATURE TOO The unit does not work. See The unit does not work.

HIGH(high room temperature alarm)

A) The parameter settings on thecontrol panel are not correct

Check the room temperature setting; seecontrol panel instruction manual.

B) Lack of air flow. See Lack Of Air Flow.

The compressor does not work whencalled by the control panel.

See The Compressor Does Not Work.

C) Insufficient compressor output See Compressor High Output Pressure,Compressor Low Intake Pressure.

E) The control system is not working. See control panel instruction manual; check thatcontrol panel and/or sensors work properly.

E) Heat load higher than expected. Check: fresh air conditions and volume,

external air infiltration and latent load,particularly with dehumidification.

B) 3-way valve is stuck open Check 3-way valve function (see Valve andServomotor).

I) No chilled water flow. Check chilled water supply and shut-off valves

L) High chilled water temperature withrelated alarm on mP20 control

Check water chiller function

ROOM TEMPERATURE TOO LOW A) The parameter settings on thecontrol panel are not correct.

Check room temperature setting; see thecontrol panel instruction manual

(Low room temperature alarm) B) 3-way valve is stuck open Check 3-way valve function (see Valve andServomotor).

C) Electric heater (if fitted) does not 1) Check electric heater operation

work. 2) Check electric heater power supply

3) If there is a heater alarm, remove thecause and re-set the safety thermostat

E) The control system is not working. See control panel instruction manual; checkthat control panel and/or sensors workproperly.

F) Thermal leakage higher thanexpected

Check thermal leakage and entry of externalair.

ROOM HUMIDITY TOO HIGH(High room humidity alarm)

A) The parameter settings on thecontrol panel are not correct.

Check room humidity settings; see the controlpanel instruction manual.

B) Latent load higher than expected Check: latent load, fresh air conditions andvolume, external air infiltration

C) The compressor does not functionduring dehumidification.

See The Compressor Doesnt Work

D) Dehumidification valve does notclose.

Check the function of the dehumidificationcircuit solenoid valve.

E) The control system is not working. See control panel instruction manual; checkthat control panel and sensors work properly.

-

8/12/2019 MD T,D,E-iom En

47/48

UNIFLAIRTM

INSTRUCTION MANUAL

MD.T-D-E, BDE

Rev 4.2. 29-09-00 EN 47 (50)

PROBLEM POSSIBLE CAUSE CHECK / REMEDY

ROOM HUMIDITY TOO LOW(Low room humidity alarm)

A) The parameter settings on the controlpanel are not correct.

Check the room temperature setting; see also thecontrol panel instruction manual.

B) Latent load lower than expected. Check: quantity of the latent load, fresh airconditions and volume, external air infiltration

C) The humidif ier is not working. 1) Check water supply pressure

2) Check function of manual control system andsteam production group (see microprocessorcontrol manual).

D) The control system is not working. See control panel instruction manual; check thatcontrol panel and/or sensors work properly.

LACK OF AIRFLOW A) No power to the fans Check power supply to the fan motors

B) The filters are dirty Shake dust out of the cartridge and clean with avacuum cleaner. Change filter if blocked. Checkcorrect setting of the dirty filter pressostat.

C) The fans are rotating in the wrong

direction

Swap two power supply phases and check

correct rotation direction. (See electricaldiagrams, RSF phase sequence relay).

D) The airflow is obstructed Read the section on Air Distribution

E) Intervention of fan thermal protection. Check the resistance of the fan windings. Re-setthen measure voltage and current.

HIGH COMPRESSOROUTPUT PRESSURE

A) Non-condensable air or gas in thecircuit, with bubbles in the flow sightglass; supercooling of the liquid is high.

Evacuate the refrigerant circuit and re-charge

B) Airflow is insufficient or air in theremote condenser is too warm.

1) Check fan operation and rotation direction inthe remote heat exchanger. (Seecondenser/radiator instruction manual).

2) Remove any obstructions from the remotecondenser with compressed air or water.

3) Check pressure drop if air output is ducted4) Check for obstructions to unit airflow and forrecirculation of air;

5) Check that the temperature of the cooling air iswithin the projected limits

C) Water flow to remote condenserinsufficient or too warm.

1) Check condensation water flow, pressure andtemperature (MDD)

2) Check closed circuit water flow, pressure andtemperature (MDE/BDE);

3) Check setting and function of watertemperature regulation system (MDE/BDE).

D) Too much refrigerant in the circuit;condenser partially flooded. Refrigerantsupercooling too high at condenser

output

Remove some refrigerant from the circuit.

E) High-pressure valves partially closed Check the opening of the valves..

F) Intake pressure too high. See "High compressor intake pressure.

HP COMPRESSOR OUTPUTPRESSOSTAT INTERVENES

A) The condensation pressure controlsystem is not functioning efficiently (MDTair-cooled models)

1) Check condenser fan and fuses; re-set orreplace the faulty fans

2) Check setting and function of the condenserfan pressostat and the speed regulator

B) The HP pressostat is incorrectly set. Re-set the pressostat to the value shown on theunit data plate.

C) System output pressure is too high. See High Compressor Output Pressure

-

8/12/2019 MD T,D,E-iom En

48/48

INSTRUCTION MANUAL UNIFLAIRTM

MD.T-D-E, BDE

PROBLEM POSSIBLE CAUSE CHECK / CORRECTIVE ACTION

LOW COMPRESSOR OUTPUTPRESSURE

A) Condensation pressure control systemis not working (see microprocessor

1) Check the function and setting of the condenserfan pressostat and speed regulator(MDT)

control instruction manual). 2) Check the setting and function of the

pressostatic valve (MDD);3) Check the function and setting of the closedcircuit water temperature regulation system (MDD).

B) Intake pressure too low See Low Compressor Intake Pressure.

HIGH COMPRESSOR INTAKEPRESSURE

A) Thermal load higher than expected Check: room thermal load especially duringdehumidification; the flow and conditions ofexternal air; external air leaks

B) System output pressure is too high See High Compressor Output Pressure

C) Too much refrigerant in the circuit Remove some refrigerant from the circuit.

D) Liquid refrigerant return tocompressor intake

Check correct thermostatic valve superheating(around 5-8C); Check that the valve sensor bulbis correctly positioned, fixed and insulated

LOW COMPRESSOR A) Room temperature too low See Room temperature too lowINTAKE PRESSURE B) Low or zero airflow See Lack of airflow

(possible freezing of the coil) C) Liquid receiver output valve not fully open Check the opening of the valve

D) Refrigerant filter blocked Check the refrigerant filter

E) Thermostatic valve incorrectly set ordefective

Check correct thermostatic valve superheating(around 8-10C); Check that the valve sensorbulb is correctly positioned, fixed and insulated.

F) Insufficient refrigerant charge Check for leaks and re-charge the unit untilsupercooling at the condenser output is 3-5C.

G) Output pressure too low See Low compressor output pressure

COMPRESSOR INTAKE LPPRESSOSTAT INTERVENES

A) Thermostatic valve incorrectly set ordefective

Check that superheating of the thermostaticvalve is correct (around 5-8C).

B) Low liquid refrigerant flow to the

thermostatic valve.

Check the opening of the liquid receiver output

valve; check the function of the refrigerant shut-off solenoid valve.

C) The filter dryer cartridge is dirty Check whether the cartridge needs to bechanged; temperature difference before and afterthe cartridge should be less than 2C.

D) low pressure pressostat is incorrectly set. Re-set low pressure pressostat.