Md-03 Stress and Deformation

Transcript of Md-03 Stress and Deformation

-

8/8/2019 Md-03 Stress and Deformation

1/24

330:148 (g)

Machine Design

Nageswara Rao Posinasetti

September 17, 2010 Rao, P.N. 1

-

8/8/2019 Md-03 Stress and Deformation

2/24

3. Stress and Deformation

Objectives

Review the types of stresses caused from axial,

bending, shear, and torsion loading. Review the relationship between stresses in the

part and the strength or stress-carrying ability ofthe part, and begin to appreciate the relationshipbetween the two.

Distinguish between the ability of a material tocarry loads in shear versus axial loading, and therelationship between these types of stresses.

Contd

September 17, 2010 Rao, P.N. 2

-

8/8/2019 Md-03 Stress and Deformation

3/24

3. Stress and Deformation

Objectives (contd..) Review the principles of deformation

and whether those levels ofdeformation are acceptable to thedesign being analyzed.

Review beam deflection formulas and

their use in design problems.

September 17, 2010 Rao, P.N. 3

-

8/8/2019 Md-03 Stress and Deformation

4/24

Introduction to Failure Analysis

Failure definition A part fails whenever it no longer

fulfils its required function

September 17, 2010 Rao, P.N. 4

-

8/8/2019 Md-03 Stress and Deformation

5/24

Failure Analysis

Type of failures Static loads

Dynamic loads

fatigue failure Modes of failure

Ductile appreciable deformation Brittle relatively no deformation

Wear due to friction Creep elevated temperatures

September 17, 2010 Rao, P.N. 5

-

8/8/2019 Md-03 Stress and Deformation

6/24

Modes of failure

Stress Deformation Wear Corrosion Vibration Environmental damage

Loosening of fastening devices

September 17, 2010 Rao, P.N. 6

-

8/8/2019 Md-03 Stress and Deformation

7/24

Fig. 3.2 Tension, Compression and Shear

September 17, 2010 Rao, P.N. 7

-

8/8/2019 Md-03 Stress and Deformation

8/24

Static Force

September 17, 2010 Rao, P.N. 8

Direct tensile force

-

8/8/2019 Md-03 Stress and Deformation

9/24

Static Force

September 17, 2010 Rao, P.N. 9

Direct compressive force

-

8/8/2019 Md-03 Stress and Deformation

10/24

-

8/8/2019 Md-03 Stress and Deformation

11/24

Tensile Strength

A

F

Area

Force

September 17, 2010 Rao, P.N. 11

Stress, S =

Strain,

= lengthOriginal

lengthinChange

-

8/8/2019 Md-03 Stress and Deformation

12/24

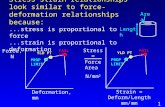

Deformation

September 17, 2010 Rao, P.N. 12

lengthOriginal

nDeformatio

Strain

E

StressStrain

Area

ForceStress

AE

lF

AreaE

lengthOriginalForcen,Deformatio

-

8/8/2019 Md-03 Stress and Deformation

13/24

Poissons Ratio

September 17, 2010 Rao, P.N. 13

Axialexpansion

Lateralcompression

-

8/8/2019 Md-03 Stress and Deformation

14/24

Poissons Ratio

Axial strain =

Lateral strain =

Poissons ratio =

September 17, 2010 Rao, P.N. 14

dimensionAxial

nDeformatioAxial

dimensionLateral

nDeformatioLateral

StrainAxialStrainLateral

-

8/8/2019 Md-03 Stress and Deformation

15/24

Stresses and Deflections due to Bending

Beam must be primarily in purebending (no axial and shear loads)

Beam is not subjected to torsion

Beam material has the samemodulus of elasticity in tension andcompression

Beam is not subjected to localizedbuckling

September 17, 2010 Rao, P.N. 15

-

8/8/2019 Md-03 Stress and Deformation

16/24

Bending moment

Reference is to a beam, assumed forconvenience to be horizontal and loadedand supported by forces, all of which lie in

a vertical plane. The bending momentat any section of the

beam is the moment of all forces that acton the beam to the left of that section,

taken about the horizontal axis of thesection.

September 17, 2010 Rao, P.N. 16

-

8/8/2019 Md-03 Stress and Deformation

17/24

Bending moment

The bending moment is positive whenclockwise and negative whencounterclockwise; a positive bending

moment therefore bends the beam so thatit is concave upward, and a negativebending moment bends it so that it isconcave downward.

September 17, 2010 Rao, P.N. 17

-

8/8/2019 Md-03 Stress and Deformation

18/24

Shear Force

September 17, 2010 Rao, P.N. 18

Negative

Counterclockwise

-

8/8/2019 Md-03 Stress and Deformation

19/24

3.5 Shear Force

September 17, 2010 Rao, P.N. 19

PositiveClockwise

-

8/8/2019 Md-03 Stress and Deformation

20/24

Shear force sign convention

September 17, 2010 Rao, P.N. 20

Positive

Clockwise

NegativeCounter clockwise

-

8/8/2019 Md-03 Stress and Deformation

21/24

Direct shear stress, SS

Force tends to cut through amember Punch and Die

Shear on a key in a shaft

Similar to calculating direct

tensile stressSS = Shear force / Area in shear

September 17, 2010 Rao, P.N. 21

-

8/8/2019 Md-03 Stress and Deformation

22/24

3.6 Torsional Shear Stresses

Torsional shear stress, SS =

J = Polar moment of inertia = c = radius of the shaft

T = Torque d = diameter of shaft

September 17, 2010 Rao, P.N. 22

Torque

J

cT

32

d4

-

8/8/2019 Md-03 Stress and Deformation

23/24

Shear Stress in a shaft

Shear stress, SS =Where T = torque d = diameter of the shaft

September 17, 2010 Rao, P.N. 23

Torque

3

16

d

T

-

8/8/2019 Md-03 Stress and Deformation

24/24

Angular Deformation in a shaft

Angular twist, =

Where T = torque l = length of the shaft G = Modulus of rigidity of shaft material J = Polar moment of inertia of the shaft

=

September 17, 2010 Rao, P.N. 24

Torque

GJ

lT

32

4d