Matching for Noisy Data of Multiple Types Gradient-based...

Transcript of Matching for Noisy Data of Multiple Types Gradient-based...

Gradient-based Pareto Optimal HistoryMatching for Noisy Data of Multiple TypesOleg Volkov (Stanford University), Vladislav Bukshtynov (Florida Tech),Louis J. Durlofsky, Khalid Aziz (Stanford University)

ABSTRACTThe advantages of the simultaneous integra-tion of production and time-lapse seismic datafor history matching (HM) have been demon-strated in multiple studies. Production dataprovide accurate observations at specific spa-tial locations (wells), while seismic data en-able global, though filtered/noisy, estimates ofstate variables. In this work we present an ef-ficient computational tool for bi-objective HM,in which data misfits for both production andseismic measurements are minimized using anadjoint-gradient approach. This enables us toobtain a set of Pareto optimal solutions definingthe optimal trade-off between production andseismic data conflicting misfits. The impact ofnoise structure and noise level on Pareto opti-mal solutions is investigated in detail. We dis-cuss the existence of the “best” trade-off solu-tion, or least-conflicting posterior model, whichcorresponds to the history matched model thatis expected to provide least-conflicting forecastof future reservoir performance. The overallframework is successfully applied in 2D and 3Dcompositional simulation problems.

PARETO OPTIMAL HMReservoir PDE (states x, model parameters u):

g(x,u) = 0, x(t0) = x0.

Multiobjective function to be minimized:

Jmo =α

J ∗prod

· JprodJ 0prod

+1− αJ ∗seism

· JseismJ 0seism

, α ∈ [0, 1],

production data (well rates q̃j,p)

Jprod(x,u) =Nobs∑k=1

Nqwell∑

j=1

Np∑p=1

Cj,p (qj,p − q̃j,p)2 ,

time-lapse seismic data (phase saturation s̃j,p)

Jseism(x,u) =Nobs∑k=1

Nblock∑j=1

Np∑p=1

Cp (sj,p − s̃j,p)2 .

CASE STUDY #1: 2D MODEL

1 2

3 4

5 6 7

8 9 10

11 12 13

10 20 30 40

5

10

15

20

25

30

35

40

45

1

2

3

4

5

6

7

8

9 Geometry: uniformgrid, 45× 45 blocksGeology: in SGeMS,spherical variogram& target histogramUncertain parame-ters: permeability

Parameterization: PCA on 1000 realizationsModel: compositional (6 components), 4 injec-tors + 9 producers (BHP controlled)History: 200 days, rates & seismic with noiseFluid components: same for 2D/3D models

Component CO2 C1 C2 C3 C4 C10

Initial (%) 1 20 20 15 10 34Injection (%) 100 – – – – –

ACKNOWLEDGMENTSStanford University Reservoir Simulation Research (SUPRI-B), Smart Fields Consortia, Tapan Mukerji (ERE, Stanford)

BI-OBJECTIVE HM RESULTS

10−3

10−2

10−1

10−2

10−1

production part

seis

mic

par

t

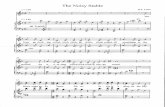

2% 5%

0%

15%

30%

50%

noise: 5% prod + 0% seismnoise: 5% prod + 30% seismnoise: 2% prod + 0% seismnoise: 2% prod + 15% seismnoise: 2% prod + 30% seismnoise: 2% prod + 50% seism

Noise in production and seismic data by stan-dard deviations of measurement error:

σq =

{σq,min, γq · qp < σq,min,

γq · qp, γq · qp ≥ σq,min,

σs = γs(1− φ)(1− strueg ).

Fig. 1: Pareto optimal solutions for different levelsof noise in production and seismic data (2D model).

Case study #1Predictions using HM models:• α = 0: only seismic data,• α = 0.5,• α = 1: only production data,• α = 0.826: best trade-off so-

lution determined at a pointwith the highest curvature

Fig. 2: (a-f) Predictions for CO2

injection (a, b) and production(c–f) rates with 2% noise inproduction and 50% in seismicdata. (g-i) Error in predicted sat-uration ‖sg − strueg ‖L2

/‖strueg ‖L2

with (g) no noise, (h) 5% noise inproduction data and (i) 2% noisein production and 50% in seismicdata.

(a) well #2 (injector)

0 100 200 300 400 500 6000

200

400

600

800

1000

days

CO

2 inje

ctio

n ra

te

(d) well #7 (producer)

0 100 200 300 400 500 6000

100

200

300

400

500

days

CO

2 pro

duct

ion

rate

(g) no noise

0 100 200 300 400 500 6000

0.1

0.2

0.3

0.4

0.5

days

satu

ratio

n fit

initialα = 0.0 (seism)α = 0.5α = 1.0 (prod)

(b) well #3 (injector)

0 100 200 300 400 500 6000

200

400

600

800

1000

1200

days

CO

2 inje

ctio

n ra

te

(e) well #9 (producer)

0 100 200 300 400 500 6000

100

200

300

400

500

600

700

days

CO

2 pro

duct

ion

rate

(h) noise 5% production & 0% seismic

0 100 200 300 400 500 6000

0.1

0.2

0.3

0.4

0.5

days

satu

ratio

n fit

initialα = 0.0 (seism)α = 0.5α = 1.0 (prod)best trade−off

(c) well #5 (producer)

0 100 200 300 400 500 6000

100

200

300

400

500

600

700

days

CO

2 pro

duct

ion

rate

(f) well #10 (producer)

0 100 200 300 400 500 6000

500

1000

1500

2000

2500

days

CO

2 pro

duct

ion

rate

trueinitialα = 0.0 (seism)α = 0.5α = 1.0 (prod)best trade−off

(i) noise 2% production & 50% seismic

0 100 200 300 400 500 6000

0.1

0.2

0.3

0.4

0.5

days

satu

ratio

n fit

initialα = 0.0 (seism)α = 0.5α = 1.0 (prod)best trade−off

10−1

100

10−0.4

10−0.2

100

100.2

production part

seis

mic

par

t

10−1

100

10−0.3

10−0.2

10−0.1

production part

seis

mic

par

t

Case study #2: A posteriori articulationfor Pareto optimal solutions.

Fig. 3: (left) Results of ten constrained op-timization runs with different colors used foreach solution trajectory. (right) Pareto front(filled circles) for the obtained solutions withbest trade-off point (blue circle).

(a) producer D-1CH

0 500 1000 1500 2000 2500 30000

0.5

1

1.5

2

2.5

3

3.5

4x 10

4

days

CO

2 pro

duct

ion

rate

trueinitialα = 0.0 (seism)best trade−offα = 1.0 (prod)

(b) producer D-2H

0 500 1000 1500 2000 2500 30000

2

4

6

8

10x 10

4

days

CO

2 pro

duct

ion

rate

(c) producer B-1H

0 500 1000 1500 2000 2500 30000

2

4

6

8

10x 10

4

days

CO

2 pro

duct

ion

rate

(d) noise 2% production & 50% seismic

0 1 2 3 4 5 6 7 8 90.4

0.45

0.5

0.55

0.6

0.65

0.7

0.75

years

satu

ratio

n fit

initialα = 0.0 (seism)best trade−offα = 1.0 (prod)

Fig. 4: (a-c) Predictions for CO2 production rates for three wells with 2% noise in production and 50% inseismic data. (d) Error in predicted saturation for the same noise in data.

CASE STUDY #2: 3D MODEL

E-4AH

permeability

E-4H

F-1H

F-2H

F-4H

D-4AHE-3BH

E-3HE-3CH

E-3AH

E-1H

E-2HE-2AH

F-3H

D-3H

B-4BH

D-3AH

B-4AHB-3H

D-3BH

C-4AHC-1HD-4H

B-1HC-4H B-4H

D-1CH

B-2H

B-1BHB-1AHK-3H

D-2HB-4DH

D-1H

C-3H

C-2H

0 250 500 750 1000 1250 1500 1750 2000 2250 2500

Geometry: mapped from corner-point grid ofNorne model, 49× 120× 66, 45,470 active cellsGeology: sampled from original modelUncertain parameters: permeabilityParameterization: PCA on 1000 realizationsModel: compositional (see 2D model), well lo-cation/schedule from original Norne modelHistory: 3 years, rates & seismic with noise

FORECASTING PARETO FRONTSA posteriori articulation treatment for α ∈ [0, 1]via constrained optimization:

• add α to the set of optimization variables

• define nonlinear constraints

sJ 0prod

J 0seism

≤(J 0prod + ε

)− Jprod(

J 0seism + ε

)− Jseism

≤ SJ 0prod

J 0seism

Jmin1 J ∗

1 J 01

Jmin2

J ∗2

J 02

α = 0

α = 1

initial

![Gradient-Based Multiobjective Optimization with Uncertaintiesindependently. In [DG05,DMM05,BZ06,SM08], evolutionary algorithms were developed for prob-lems with uncertain or noisy](https://static.fdocuments.in/doc/165x107/60e665dd86eb0748ed0ca20e/gradient-based-multiobjective-optimization-with-uncertainties-independently-in.jpg)