Mass Transport in a Spaceflight Plant Growth Chamber · Mass Transport in a Spaceflight Plant...

Transcript of Mass Transport in a Spaceflight Plant Growth Chamber · Mass Transport in a Spaceflight Plant...

Mass Transport in a Spaceflight Plant Growth Chamber

A. Hoehn, J. Clawson, A.G. Heyenga, P. Scovazzo, K.S. Sterrett, L.S. Stodieck, P. Todd

BioServe Space Technologies, University of ColoradoM.H. Kliss

NASA Ames Research Center

SAE paper 98-1553 28th International Conference on Environmental Systems, ICES, July 12-16, 1998, Danvers,

MA.

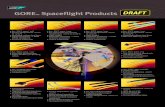

Spaceflight Plant Growth Chambers

Biomass Production System, BPS

Astroculture™

Commercial Plant Biotechnology Facility, CPBF

Astro-Plant Generic Bioprocessing Apparatus, PGBA Plant Growth Facility, PGF

Mass Flows to/from Plant Chamber

Light Intensity (fluorescent) ≈ 350 µmol⋅m-2⋅s-1 PARAir Temperature Range 18-25°CHumidity Range (dew point) 60-100% r.H.Chamber Air Volume 28.3 literUsable Growth Area, 25x30 cm2 0.075 m2

Max. Theoretical Dehumid. Rate 17.28 liter⋅day-1 H2OMax. Water Supply to Roots 17.28 liter⋅day-1 H2OChamber CO2 Range 250 – 3,000 ppmCabin Air max. Intake Rate 2 liter⋅min-1

Max. CO2 Supply Rate for 500ppm Target / 3,000 ppm externalCO2 Concentration

7.2 liter⋅day-1 CO2

(14 gram⋅day-1 CO2)

CO2

O2

Light

H2O

PressureTemperatureRelative Humidity

MixingCirculation

PGBA Performance Limits:

Sealed Plant Chamber Due to:• containment of hazardous samples.• orbiter environment not suitable for

reproducible scientific conditions.• water recycling.• plant performance measurements.

Temperature Profiles

STS-94: independent day / night setpoints:• day 25°C / night 22°C• 20 minutes (heat) / 60 minutes (cool) to reach new setpoint

Humidity Control

STS-94: dew point control limited by available power:• humidity controlled by dew point temperature only.• cooled porous plate maintained under suction to separate condensate.• condensate supplied to root re-hydration system.

Mission Temperature Profile

• Independent day/night temperature setpoint.• Temperature exceedance on return due to hot ambient temperatures.

Mission Humidity Profile

• flight vs. ground reasonably tracked.• ground control exceedance on day 9 due to flow controller failure.• elevated humidity on mission beginning / end due to elevated ambient temperatures.

Water Recovery from Air Humidity

Water condensate pumped from humidity control to nutrient delivery:•3,000 ml H2O in 17 days ~ 175 ml/day ≈ 2,350 ml m-2 day-1

Atmosphere Composition

C 3 P lan t

Rat

e of

Pho

tosy

nthe

sis

L igh t In tensity

C om pensation P o in t20 -80 µm ol*m -2s -1 P A R

N et C O 2re lease

N et C O 2 up take

D ark R esp ira tion

0

Need to control oxygen:

(Keeton, 1979)

Light limited

Trace Contaminants

Flight Unit Ground UnitCompound PPB PPBethylene 1.88 0.91acetylene 1.06 0.71ethane 5.99 7.2propylene 0.93 0.13propane 5.82 4.65i-butane 0.8 1.07n-butane 1.58 1.59i-pentane 1.18 1.03n-pentane 1.13 1.07

Atmosphere Contaminant Analysis

Flight Unit Ground Unit BaselineCompound nL/gram nL/gram nL/gramDichlorodifluoromethane 8.7 5.8 9.3Bromotrifluoromethane 0.9 ND NDChlorodifluoromethane 1.5 ND NDMethylene Chloride 277 320 NDBenzene 2.9 6.3 3Octamethylcyclotetrasiloxane 11.3 14 11.3Hexamethulcyclotrisiloxane 0.5 0.2 0.2Phenylphenol 0.9 1.1 0.1Biphenyl ND ND 0.1Trichlorotrifluoroethane ND ND 10

Activated Carbon Contaminant Analysis

SummaryImproved Plant Research Facilities Available:•better characterized environment / instrumentation.•improved environmental control:

•higher light intensities / higher rates of photosynthesis.•better thermal / humidity control.•atmosphere control challenging.

•flight vs. ground deviation:•master-slave configuration for simultaneous ground controlsminimizes flight / ground differences.

•Atmosphere control anomaly requires further study / moresophisticated control strategies.

•future research:•anomaly analysis continued.•single crop characterization / advanced life support studies.•environmental control enhancements.