MASS Balances With Page Numbers

-

Upload

tanavi-rana -

Category

Documents

-

view

95 -

download

4

Transcript of MASS Balances With Page Numbers

1

1. Historical Profile

1.1 Introduction to Ethyl Benzene (EB):

Ethyl benzene is an organic chemical compound which is an aromatic hydrocarbon

(HC). Its major use is in th petrochemical industry as an intermediate compound for

the production of styrene, which in turn is used for making polystyrene, a commonly

used plastic material. Although often present in small amounts in crude oil, ethyl

benzene is produced in bulk quantities by combining the petrochemicals benzene and

ethylene in an acid-catalyzed chemical reaction. Catalytic hydrogenation of the ethyl

benzene then gives hydrogen gas and styrene, which is vinyl benzene. Ethyl benzene

is also an ingredient in some paints.

Ethyl Benzene is used almost exclusively as intermediate in the production of styrene

monomer. It is produced by liquid phase alkylations or vapour phase alkylation’s of

benzene with ethylene. Commercial production started in the 1930s and has grown to

over 23 million metric annually (MTA)

1.2 History of Ethyl Benzene:

The alkylation of HC with olefins in the presence of AlCl3 catalyst was first practiced

by M.Balsohn in 1879. However, Charles Friedel & James M. Crafts pioneered much

of early research on alkylation & AlCl3 catalyst .Over a century later, the process that

employ the classic Friedel-Crafts reaction chemistry remain a dominant source of EB.

Ethyl benzene was first produced on a commercial scale in the 1930s by Dow

Chemical in US and by BASF in the Federal Republic of Germany.

Until 1980s , almost all ethyl benzene was manufactured with an aluminium chloride

catalyst using a Freidal Crafts reaction mechanism . A few EB production units

employed a different Freidal-Crafts catalyst, boron trifluoride. Small amount of EB

also recovered as a by product from mixed xylenes streams using a very intensive

distillation process. In 1980s ,the first commercial facility using a zeolite based

process and the absence of maintenance and environmental problems associated with

the Freidal-Crafts catalyst have allowed zeolite catalyst and to completely displace the

order catalyst in all modern production facilities. The4first zeolite process was based

on vapour –phase reactor at temp. of over 4000C. In this temperature range, reaction

such as isomerisation/cracking and hydrogen transfer produce a number of by

products that contaminate the EB product.

Efforts were made to reduce by-product formation by changing reaction condition, but

it was not until the advent of liquid phase processes operating at temperatures lower

than 2700C that zeolite –catalysed processes were truly capable of producing high

2

purity EB . The first high purity zeolite based on technology developed by UOP and

ABB Lummus Global , started up in the 1990.

The Ethyl benzene- Styrene industry remained relatively insignificant until World

War 2. The tremendous demand for synthetic SBR during world war prompted

accelerated technology improvements and tremendous capacity expansion. This

enormous wartime effort led to the construction of several large scale factories,

turning styrene production quickly in to a giant industry. In 1965, 10% of EB

production was from super fraction of on a commercial scale in the 1930s by Dow

Chemical in US and by BASF in the Federal Republic of Germany.

1.3 Natural Occurrences:

Ethyl benzene is a colourless, flammable liquid that smells like gasoline. It is naturally

found in coal tar and petroleum and is also found in manufactured products such as

inks, pesticides, and paints.

3

2. Applications

2.1 Current Applications:

All commercial EB production is captive consumed for the manufacture of styrene

monomer Styrene is used in the production of poly styrene and a wide range of other

plastics. Of the other minor applications, the most significant in the paint industry as a

solvent.

Even smaller volumes go towards the production of acetophenone, diethyl benzene &

ethyl anthraquinone.

2.2 Product Specification

The product specification on EB is set to provide a satisfactory feedstock to the

associated styrene unit.

Objectionable impurities in the EB can be grouped in to two categories:

a) Halides

b) Diethylbenzene

Purity 99.5 wt% min.

Benzene 0.1-0.3%

Toluene 0.1-0.3%

O-xylene+cumene 0.02% max

m,p-xylene 0.02% max

Allylbenzene 0.2%

Diethylbenzene 20mg/kg max

Total chlorides 1-3 mg/kg max

Total original sulphur 4 mg/kg max

Reactivity density@150 C 0.869-0.872

APHA color 15 max

4

Manufacturing Capacities:

PRODUCER CAPACITY*

BP Chemicals, Texas City, TX 1,100

Chevron, St. James, LA 1,800

Cos-Mar, Carville, LA 2,200

Dow, Freeport, TX 1,900

Huntsman, Odessa, TX 350

Lyondell Chemical, Channelview, TX 3,000

Nova, Bayport, TX 1,400

Sterling, Texas City, TX 2,000

Westlake, Lake Charles, LA 380

Total 14,130

*Millions of pounds per year of Ethyl benzene (EB).

In INDIA

From Chemical Weekly Buyers Guide 2005- Vol.3

Pashim Petrochem Ltd.

Amol Chemicals & Polymers

Chemaroma Drug House

Chemico

Forum Enterprizes

Ganesh Trading Co.

Manish Chemicals

Mikit Chemicals

Om Chemi Pharma

Perfect Chemicals

Solvchem

Tanay Corporation

5

3. MARKET SURVEY

3.1 Current & Projected Demand:

Demand ( till 2004):

1999: 13,193 million pounds

2000: 13,444 million pounds

2004: 14,552 million pounds

Growth

Historical (1995 - 2000): 0.7 percent per year.

Strength

EB demand runs parallel to that of styrene, and styrene is a mature and stable

commodity, used in many homo-polymer, copolymer and ter-polymer applications.

These applications cover a wide scope in industrial, consumer and medical products.

Weakness

EB’s major shortcoming is that it is essentially a one market segment product -

styrene. Moreover, as the styrene is produced with captive EB there is not much

noticeable market activity.

3.2 Price & Price Variations:

PRICE

Historical (1995 - 2000):

High, $0.25 per pound, bulk, f.o.b. Houston, TX, list ($ 0.5511 / Kg)

By Friday 8 August, 2008:

EB was valued at $1,554-1,570/tonne FOB NWE ($ 1.554—1.570 / Kg)

Price Variations:

The US unit sales value of EB in $/Kg from 1960 – 1986:

Year Sales ( $/Kg)

1960 0.13

1965 0.09

1970 0.09

1973 0.11

6

1974 0.37

1975 0.20

1978 0.24

1979 0.35

1980 0.50

1983 0.51

1986 0.48—0.51

3.3 Application wise Consumption Pattern:

Application Consumption ( in % )

Styrene Production 99 %

Paint industry as a solvent < 1%

Production of Acetophenone,

Diethylbenzene,Ethyl

anthraquinone

< 1%

3.4 Site Considerations:

Before any site selection work begins the company should be organized for expansion

planning in a way that depends on the size of the firm. A company may want to utilize

a standing committee, a special project team or planning by one person. In any event

the planning function must be clear cut responsibility of one individual.

Site Selection Factor:

1. Markets

2. Work force

3. Unionization

4. Transportation

5. Energy

6. Business climate

7. Water and waste systems

8. Living conditions

9. Topography

7

The basic aim of the site selector is to choose a location that maximizes income and

minimizes cost compromises usually have to be made. No site is ever perfect, and it is

the mission of the site selection team to weigh the alternatives and compromises on

the best choice.

Plant layout:

Plant layout involves developing physical equipment for a processing facility. The

development must affect a balance of equipment spacing and integration of specific

systems related to facility as a whole. Some of the factors to be considered for

designing the plant layout are:

1. Process

2. Economics

3. Client requirements

4. Operation

5. Erection and maintenance

6. Safety

7. Environment

8. Appearance

9. Expansion

In-line plant layouts are made in various arrangements which often are referred to by

letter designation. Various configurations are formed based on the main artery of the

process unit i.e. the pipe rack, which contains long process and the utility lines that

connect distant equipment and product piping entering and leaving the plant. Space

for instrument and electrical feeders is allocated in the pipe rack such that they are

connected to the related equipment. This area is kept free of piping and its related

supports.

Generally an I shaped plot is used for small process and an H-shape plot for larger

units. In developing the plant layout for a chemical plant, it is essential that the firm

decisions are made early as to equipments arrangement. This eliminates changes,

which cost man-hours as the job progresses through engineering and design. The

distillation sections are based on a grade-level process plant layout configuration. The

steam generation and power facilities are housed in a building. The basic arrangement

follows the equipment spacing charts and clearance tables. Based on all above factors

8

we have selected Mumbai as our plant site due to good availability of raw materials as

well as for better market.

The word ―Utilities‖ is now generally used for the ancillary services needed in the

operation of any production process. These services will normally be supplied from a

central site facility; and will include:

1. Electricity.

2. Steam, for process heating.

3. Cooling water.

4. Water for general use.

5. Demineralised water.

6. Compressed air.

7. Inert-gas supplies.

8. Refrigeration.

9. Effluent disposal facilities.

A Typical Site Plan

9

4. Properties

4.1 Physical Properties:

Under ordinary conditions, EB is a clear liquid with a characteristic aromatic odor. EB

is an irritant to the skin & eyes and is ordinary toxic by ingestion and skin adsorption.

The properties are as follows:

IUPAC Name Ethylbenzene

Other names Ethylbenzol, EB, Phenylethane

Identifiers [100-41-4]

CAS Number DA0700000

RTECS Number c1ccccc1CC

SMILES C8H10

Molecular Formula 106.167 g/mol

Molar Mass Colourless liquid

Appearance 0.87139 g/cc

Density (at 150 c) 0.8669 g/cc

Density ( at 200 c) 0.86262 g/cc

Density ( at 250 c) -94.949 0 c

M.P. 136.860 c

B.P. ( at 101.3 K Pa) 1.49588

Refractive index (at 200 c) 1.49320

Refractive index ( at 250 c ) 3609 K Pa (36.09 bar)

Critical pressure 344.02 0 c

Critical temperature 150 c

Flash point 4600 c

Auto ignition temperature 1.0%

Flammability limit ( lower) 1.5%

Flammability limit ( Upper) -----

Latent heat ( fusion) 86.3 j/kg

Latent heat ( vaporization) 335 j/kg

Heating value ( gross) 42999 j/kg

Heating Value ( net) 40928 j/kg

Kinematic viscosity (at 37.8 0 c ) 0.6428 * 10 -6 m2 / s

Kinematic viscosity (at 98.90 c ) 0.390 * 10 -6 m2 / s

10

Surface Tension 28.48 mN/m

Specific heat capacity ( ideal gas, 250 C) 1169 kg-1 K-1

Specific heat capacity ( liquid, 250 C) 1752 kg-1 K-1

Acentric factor 0.311

Critical compressibility 0.264

LEL 1.2 %

UEL 6.8 %

4.2 Chemical Properties:

The most important chemical reaction of EB is its dehydrogenation to Styrene.

The reaction is carried out at:

1. High temprature ( 600-6700 c)

2. Usually over an iron oxide catalyst

3. Steam is used as dilutent

Commercially, selectivities to styrene range from 89-96%with per rpass conversion 65-70%.

Another reaction of commercial importance is the oxidation of EB by air to

hydroperoxides C6H5CH(OOH)CH3

The reaction takes place in the liquid phase , with no catalyst required. With a suitable

catalyst EB can be converted to xylenes. Commercial processes for isomerizing

xylenes usually involve the catalytic isomerization or dealkylation of EB. EB may be

dealkylated catalytically or thermally to benzene.

11

4.3 Environmental & Health Effects:

Emergency Overview:

Clear, colourless liquid with a characteristic, sweet, gasoline-like, aromatic odour.

Flammable liquid and vapour. Liquid can accumulate static charge by flow, splashing

and agitation. Vapour is heavier than air and may spread long distances. Distant

ignition and flashback are possible. Liquid can float on water and may travel to distant

locations and/or spread fire. Closed containers may rupture and explode in heat of fire.

TOXIC. May be harmful if inhaled. Central nervous system depressant. Vapour may

cause headache, nausea, dizziness, drowsiness, confusion, unconsciousness and

possibly death. SKIN IRRITANT. May cause skin irritation. Aspiration hazard.

Swallowing or vomiting of the liquid may result in aspiration (breathing) into the

lungs. POSSIBLE CANCER HAZARD - may cause cancer, based on animal

information.

Potential Health effects:

Effect of short Term Exposure:

Inhalation:

Ethylbenzene readily forms high vapour concentrations and should be considered

toxic by this route of exposure. Inhalation of the vapour or mists can irritate the nose

and throat and produce symptoms of central nervous system depression such as mild

unsteadiness, headache, nausea, dizziness and a feeling of drunkenness at

approximately 100-200 ppm. Much higher concentrations can cause more severe

symptoms including unconsciousness and death. Human volunteers exposed to 85

ppm for 8 hours reported no adverse health effects. Above 100 ppm, mild

unsteadiness, sleepiness and headache were reported. In another report, approximately

100 ppm (cited as 400 mg/m3) produced a slight irritating effect on the respiratory

tract, occasional headaches, sleepiness, slight drowsiness after 8 hours. More

pronounced irritation, frequent headaches, sleepiness and a feeling of drunkenness

were observed at 200 ppm (860 mg/m3). At 1150 ppm (5000 mg/m3), irritation of

nose and throat was experienced. Exposure to 1000-2000 ppm (0.1-0.2%) for 6

minutes caused irritation of the nose and throat, fatigue and increasing unsteadiness,

chest constriction and dizziness in 4-6 male volunteers. Exposure to 5000 ppm (0.5%)

was considered intolerable.

Skin Contact:

The liquid can cause moderate irritation, based on animal information. Ethylbenzene

is absorbed through the skin to a small extent, but harmful effects are not expected to

occur by this route of exposure.

12

Eye Contact:

The liquid can cause mild to moderate irritation, based on limited animal information.

Volunteers reported that exposure to approximately 100 ppm was slightly irritating to

the eyes. At 1000 ppm (0.1%) the vapour was very irritating to the eyes of 4-6

volunteers, producing smarting and burning, accompanied by profuse tearing. This

irritation, gradually decreased until, after a minute or two, it was barely noticeable. At

2000 ppm (0.2%), the irritation was almost intolerable upon first exposure, but again

became less irritating upon continued exposure, while 5000 ppm (0.5%) was

considered intolerable.

Ingestion:

Ethylbenzene has relatively low toxicity following ingestion. As a central nervous

system (CNS) depressant, it can cause nausea, vomiting, headache and dizziness. Very

large amounts may cause unconsciousness and death. Ethylbenzene can cause severe

lung damage or death if the liquid is accidentally breathed into the lungs (aspirated),

based on physical properties. There are no reports of aspiration occurring in humans.

Ingestion is not a typical route of occupational exposure.

Effects of Long-Term (Chronic) Exposure:

Nervous System:

A number of human population studies involving painters and other occupational

groups exposed to a wide range of solvents, including ethylbenzene, have led to some

investigators to conclude that long-term exposure to solvents may cause permanent

effects on the central nervous system (CNS). The signs and symptoms are ill-defined

and include headaches, memory loss, fatigue and altered emotional reactivity. This

syndrome is commonly known as Organic Solvent Syndrome. There are no specific

studies that implicate ethylbenzene as a causal agent, although it is present in many of

the paints and other solvent-containing products. The available studies tend to have a

number of deficiencies including concurrent exposure to many different chemicals,

and lack of exposure data. In a limited study, most workers exposed to up to 11.5 ppm

(cited as 0.05 mg/L) complained of headaches, irritability and of tiring rapidly.

Functional nervous system disturbances were found in some workers employed for

over 7 years.

13

Skin:

Repeated or prolonged contact may cause dry, red, chapped skin (dermatitis).

Skin Sensitization:

No allergic skin reaction was observed among 25 volunteers exposed to 10%

ethylbenzene in petrolatum.

Hearing:

Studies in rats have shown that simultaneous exposure to ethyl benzene and noise

increases the potential for hearing damage above that for noise exposure alone.

Guinea pigs do not appear to be sensitive to these effects.(54,55) The relevance of

these observations to human exposures is not known.

4.4 Handling, Storage & Transportation:

EB is a flammable liquid.

It is stored & transported in steel containers.

The US DOT identification number is UN 1175.

Foam, Carbon dioxide, dry chemical, halon & water ( fog pattern) are used in fighting

EB fires.

The use of NIOSH approved respirators is recommended at high concentration.

Skin contact should be avoided.

14

5. Manufacturing Processes:

Currently, the primary source of ethyl benzene is the alkylation of benzene with

ethylene. The only other source, the super fractionation of mixed C8 aromatic streams,

supplies only a small portion of the ethyl benzene produced. Two distinct types of

ethyl benzene alkylation processes are currently used commercially: liquid- phase

alkylation and vapor-phase alkylation.

5.1 Liquid Phase Alkylation:

Liquid phase aluminum chloride processes have been the dominant source of

ethylbenzene since the 1930s. Several companies have developed variations of this

technology. Processes currently in use include those of Dow chemical, BASF, shell

chemical, Monsanto, societe chimique des cahrbonnages, and union carbide/ badger.

The Monsanto process is currently the most modern commercially licensed aluminum

chloride alkylation technology. Alkylation of benzene with in the presence of an

aluminum chloride catalyst complex is exothermic (∆H-114 kJ/mol); the reaction is

very fast and produces almost stoichiometric yields of ethy lbenzene. In addition to

AlCl3, a wide range of Lewis acid catalysts, including AlBr3, FeCl3, and BF3, have

been used. Aluminum chloride processes generally use ethyl chloride or hydrogen

chloride as a catalyst promoter. These halide promoters reduce the amount of AlCl3

required. The reaction mechanism has been studied in detail

Alkylation:

In the conventional AlCl3 process (see Fig 1), three phases are present in the reactor.

Aromatic liquid, ethylene gas, and a liquid catalyst complex phase (a reddish brown

material called red oil). A mixture of catalyst complex, dry benzene, and recycled

polyalkyl benzenes is continuously fed to the reactor and agitated to disperse the

catalyst complex phase in the aromatic phase. Ethylene and the catalyst promoter are

injected into the reaction mixture through spargers, and essentially 100% of the

ethylene is converted. Low ethylene: Benzene ratios are used to give optimum overall

yield of ethylbenzene.

Commercial plants typically operate at ethylene: because molar ratios of ca.0.3-0.35.

As the ratio is increased, more side reactions, such as transalkylation and isomeric

rearrangement, occur. Further alkylation of ethylbenzene leads to the reversible

formation of lower molecular mass polyalkylbenzenes. The loss in net yield due to

residue is minimized by recycling this material to the alkylation reactor. In addition,

because the reaction occurs close to thermodynamic equilibrium, the traditional

processes use a single reactor to alkylate benzene and transalkylate

polyalkylbenzenes.

15

The reaction temperature is generally limited to 1300C; a higher temperature rapidly

deactivates the catalyst and favors formation of non aromatics and

polyalkyllbenzenes, which are preferential absorbed by the highly acidic catalyst

complex, resulting in byproduct formation. Sufficient pressure is maintained to keep

the reactants in the liquid phase. High –alloy materials of construction are also

required for the piping and handling systems. The liquid reactor effluent is cooled and

discharged into a settler, where the heavy catalyst phase is decanted from the organic

liquid phase and recycled. The organic phase is washed with water and caustic to

remove dissolved AlCl3 and promoter. The aqueous phase from these treatment steps

in first neutralized and then recovered as a saturated aluminum chloride solution and

wet aluminum hydroxide sludge.

Removal of dissolved catalyst from the catalyst from the organic stream has long been

a problem for ethylbenzene producers. Recently CdF chime found that more complete

recovery of AlCl3 could be achieved by first contacting the organic phase with

ammonia instead of sodium hydroxide.

Separation: Purification of the ethyl benzene product is usually accomplished in a

series of three distillation columns. The unreacted benzene is recovered by the first

columns as an overhead distillate. The second column separates the ethyl benzene

product from the heavier polyalkylated components. The bottoms product of the

second column is fed to a final column, where the recyclable polyalkylbenzenes are

stripped from non recyclable high molecular mass residue compounds. The residue or

flux oil, consisting primarily of polycyclic aromatics, is burned as fuel. Because the

alkylation mixture can tolerate only minor amounts of water, the recycled benzene and

fresh benzene must be dried thoroughly prior to entering the reactor. Water not only

increases corrosion, but also decreases catalyst activity. Benzene dehydration is

accomplished in a separate column.

The improved Monsanto process has distinct advantages compared to conventional

AlCl3 processes. The most of these is a significant reduction in the AlCl3 catalyst use,

thus lessening the problem of waste catalyst disposal. Monsanto found that by an

increase in temperature and by careful control of ethylene addition, the required AlCl3

concentration could be reduced to the solubility limit, thereby eliminating the separate

catalyst complex phase. Therefore, alkylation occurs in a single homogeneous liquid

phase instead of the two liquid phases is earlier processes.

Monsanto claims that a separate catalyst complex phase may actually prevent the

attainment of maximum reactor yields. With a few exceptions, the flow scheme of the

Monsanto process is nearly the same as that of more traditional processes. The process

is also capable of operating with low- concentration ethylene feed. The process is also

capable of operating with low concentration ethylene feed. Typically, the alkylation

16

temperature is maintained at 160-1800C. This higher operating temperature enhances

catalyst activity, with the additional benefit that the heat of reaction can be recovered

as low- pressure steam. Whereas the traditional process accomplishes alkylation and

transalkylation in a single reactor, the homogenous catalyst system must employ a

separate transalkylation reactor. At lower catalyst concentrations, the recycle of

substantial amounts of polyalkylbenzenes terminates the alkylation reaction.

Therefore, only dry benzene, ethylene, and catalyst are fed to the alkylation reactor.

The recycle polyethylbenzene stream is mixed with the alkylation reactor effluent

prior to entering the transalkylation reactor. The transalkylation reactor is operated at

much lower temperature than the primary alkylation reactor. After transalkylation, the

reaction products are washed and neutralized to remove residual AlCl3. With the

homogenous process, all of the catalyst remains in solution. The catalyst-free organic

reaction mixture is then purified using the sequence described previously for the

conventional AlCl3 process. As with other AlCl3 process, the organic residue is used

as fuel and the aluminium chloride waste streams are usually sold, or sent to treatment

facilities.

5.2 Vapor Phase Alkylation:

Vapor-phase alkylation has been practiced since the early 1940s, but at that time

processes were unable to compete with liquid-phase aluminum chloride based

technology. The alkar process developed by UOP, based on boron trifluoride catalyst,

had modest success in the 1960s, but fell from favor because of high maintenance

costs resulting from the severe corrosion caused by small quantities of water.

Nevertheless, some ethylbenzene units continue to use this process.

The Mobil –badger ethylbenzene process represents the latest and most successful

vapor phase technology to be introduced. The process was developed in the 1970s

around Mobil’s versatile ZSM-5 synthetic zeolite catalyst. Earlier attempts at using

zeolite or molecular sieves for benzene alkylation had suffered from rapid catalyst

deactivation because of coke formation and poor transalkylation capabilities. The

Mobil catalyst combines superior resistance to coke formation with high catalytic

activity for both alkylation and transalkylation by American Hoechst Corp. at their

408x10-3/t/a Bayport, Texas plant. Currently nine commercial plants have been

licensed, representing ca. 3x10106 t/a of production capacity.

ALKAR PROCESS:

This process produces a high purity ethylbenzene product and can use dilute ethylene

feed stock. If the entry of water into the process is strictly prevented, the corrosion

problems associated with aluminum chloride processors are avoided. However, even

small amounts of water (<1mg/kg) hy6drolze the BF, catalyst. The alkyation reaction

17

takes place at high pressure (2.5-3.5 Mpa; 25-35 bar) and low temperature (100-

1500C). Dehydrated benzene, ethylene, and make up BF3, catalysts are fed to the

reactor. Typically, ethylene; benzene molar ratios between 0.15 and 0.2 are used. The

reactor inlet temperature is controlled by recycling a small portion of the reactor

effluent.

Transalkylation takes place in a separate reactor. Dry benzene, BF3 catalyst, and

recycled polyethlybenzene are fed to the transalkylation reactor. The effluent streams

from the two reactors are combined and passed to a benzene recovery column, where

benzene is separated for recycle to the reactors. Boron trifluoride and light

hydrocarbons are taken over head as a vapour stream from which the BF3, is

recovered for recycle. The bottom for the benzene recovery column is sent to a

product column, where ethyl benzene of > 99.9% purity is taken overhead.

A final column serves to recover polyethylbenzenes for recycle to the transalkylation

reactor. The alkar process can operate with ethylene feed containing as low as 8-10

mol% ethylene, enabling a variety of refinery and coke-oven gas streams to be used.

However, purification of these streams is necessary to remove components that poison

the BF3 catalyst, e.g., trace amounts of water sulfur compound, and oxygenates.

Mobil-Badger Process:

The fixed –bed ZSM-5 catalyst promotes the same overall alkylation chemistry as

those used in the other processes; however, the reaction mechanism is different.

Ethylene molecules are adsorbed onto the Bronsted acid sites within the catalyst,

which activates the ethylene molecule and allows bonding with benzene molecules to

occur. Hence, the range of higher alkylated aromatic byproducts formed by the Mobil

– Badger process is somewhat different than that for the Friedel Crafts processes.

These components do not affect the ethyl benzene product purity and are recycled to

the reactor for transalkylation or dealkylation. The Mobil-Badger heterogeneous

catalyst system offers several advantages when compared to the other commercially

available processes.

The most important are that it is noncorrosive and non-polluting. The catalyst is

essentially silica – alumina, which is environmentally inert. Because no aqueous waste

streams are produced by the process, the equipment for waste treatment and for

catalyst recovery is eliminated. In addition, carbon steel is the primary material of

construction, high-alloy materials and brick linings are not required. The reactor

typically operates at 400-4500C and 2-3 MPa (20-30 bars). At this temperature >99%

of the net process heat input and exothermic heat of reaction can be recovered as

steam.

18

The reaction section includes two parallel multi-bed reactors, a fired heater, and heat

recovery equipment. The high-activity catalyst allows transalkylation and alkylation to

occur simultaneously in a single reactor. Because the catalyst slowly deactivates as a

result of coke formation and requires periodic regeneration, two reactors are included

to allow uninterrupted production: one is on stream while the other is regenerated.

Regeneration takes ca. 36h and is necessary after 6-8 weeks of operation. The catalyst

is less sensitive to water, sulfur, and other poisons than the Lewis acid catalysts. The

reactor effluent passes to the purification section as a hot vapor. This steam is used as

the heat source for the first distillation column, which recovers the bulk of the

unreacted benzene for recycle to the reactor. The remaining benzene is recovered from

a second distillation column.

The ethybenzene product is taken as the overhead product from the third column. The

bottoms product from this column is sent to the last column, where the recyclable

alkylbenzenes and polyalkylbenzenes are separated from heavy nonrecyclable residue.

The low-viscosity residue stream, consisting mainly of diphenylmethane and

diphenylethane, is burned as fuel. The Mobil-Badger process also can use dispute

ethylene feedstocks. In semi commercial applications, the process has operated on

streams containing as little as 15 mol% ethylene.

5.3 New Developments:

Dow Chemical and Snamprogetti are developing a process for making ethyl

benzene/styrene from ethane and benzene. The process combines the dehydrogenation

of ethane and ethyl benzene in one unit and integrates the processes for preparing

ethylene, ethyl benzene and styrene. This process is claimed to have lower costs than

the conventional route to styrene, largely stemming from the low cost of ethane in

relation to ethylene. A pilot plant has been operating since 2002 and

commercialisation could be possible by the end of the decade.

5.4 Comparison between Processes:

Although both the alkylation process i.e. liquid phase & vapor phase are of equal use

commercially. Yet there are some differences:

1. In vapour phase alkylation, the reactors operates at higher temperatures(400—4500

c) which causes catalytic deactivation by fouling as a result catalyst required periodic

regeneration.

2. In vapour phase alkylation process two reactors will be required so that processing

and regeneration can proceed alternatively without interrupting production.

3. All the ethylene feedstock is reacted completely in the liquid benzene, thus

eliminating off gas recovery equipment.

19

4. Ethyl benzene yield is 99.7% in liquid phase alkylation process while in vapour

phase alkylation it is around 98%.

5. Zeolite as a catalyst can be used in any of the processes.

6. Up to 99.95wt% product purity in the with no xylene formation, in liquid phase

alkylation process.

20

6. Selected Process:

We have selected liquid phase alkylation process for ethyl benzene production, now

we will discuss process under the followings:

Introduction to process:

Efforts were made to reduce by-product formation by changing reaction condition but

it was not until the advent of liquid phase at temperature lower than 2700 c that zeolite

–catalyzed processes were truly capable of producing. The first high purity zeolite

based EB plant , based on technology developed by UOP & ABB Lummus Global

started up in 1990.

Technology Supplier: UOP & ABB Lummus Global

Current Status: Currently 16 plants are using this technology.

Raw Materials: Ethylene & Benzene

Product quality achievable: 99.95wt% pure EB can be produced.

Catalyst: Zeolite

Material of construction: Carbon Steel

Process Effluents: Inert component of ethylene feed which will appear as benzene

column vent.

6.1 Process Chyemistry:

EB made by the alkylation of benzene with ethylene in the presence of zeolite

catalyst. Successive alkylation also

occurs to minor extent, producing diethylbenzens, collectively termed polyethylene

benzene (PEB)

Benzene + Ethylene → EB (Ethyl benzene)

EB + Ethylene →DEB (Di- ethyl benzene)

Process Description:

Benzene alkylated with the ethylene to yield a mixture of alkylated benzenes. This

mixture is distilled to recover product EB, and higher ethylated benzenes (PEB). The

liquid phase alkylation reactor consists of multi[le beds of zeolite catalyst operating

adiabatically. Process conditions are selected to keep the aromatic reaction mixture in

the liquid phase. Excess benzene is used, and ethylene is injected before each bed.

21

Multiple ethylene injection points improve selectively and enhance catalyst stability.

In the alkylation reactor, ethylene reacts completely, leaving only the inert

constituents of the feed, such as ethane. These inters pass through the reactor and are

from the plant at a convenient point.

The alkylation effluents are fed to the benzene column, where benzene is taken as the

over head product for recycle to the reactor. The benzene column bottoms feed the

ethyl benzene column. Here EB is taken as the overhead product.

The reboiler of the distillation columns may used hot oil, high-pressure steam, or

direct firing. Overhead vapors are condensed in waste heat boilers, generating

valuable steam useful in a downstream SM or propylene oxide/styrene monomer

plant. The EB unit has considerable flexibility to mmet a verify of local site conditions

in an efficient manner. If no stream export is required, the net heat import can be

reduced considerably

6.3 Plant Capacity:

The Ethyl benzene plant capacity is 1000MTPY(109 kg per year) based on:

er capacities of other Ethyl benzene operating plants (or projected

plan

22

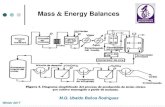

7.Mass & Energy Balances

7.1 Process information:

1. Stream (1) – Benzene is pure

2. Stream (2) – ethylene contains 7 mole % ethane as impurity. Ethane dose not react

but moves in the process as inerts and vent in the light column.

3. Stream (3) – B: E ratio is adjusted to control reaction selectivity , 8:1.

4. Reactor (R-1) – the limiting reactant achivees 100% conversion.

5. Stream (8) –composition is;

Inerts – 45% mole

Benzene - 55% mole

6. Efficiency of T – 1 is such that 99.9% of benzene that is fed is in the overhead.

7. Stream(11) –

Ethyl benzene = 99.9% wt

Benzene= 0.1% wt

8. All the EB fed in to the EB column (T—2) is in overhead.

7.2 Mass balance Calculations:

The plant capacity for ethyl benzene plant = 1000 MTPA

For which we are suppose to produce the product as follows:-

The product ethyl benzene which we will produce will contain:-

1190 mol/hr ethyl benzene

and 1.6 mol/hr benzene

Since we are using liquid phase alkylation process for ethyl benzene production, for

which yield and conversion are as follows:

Yield=99.7%

23

Conversion=100% (w.r.t ethylene)

Now consider PFD for ethyl benzene plant

Stream (11)

Ethyl benzene=1190 mol/hr

Benzene = 1.6 mol/hr

Now we are coming to the reaction part, here we have reactor:-

Now we know that:-

Yield = [{(moles of product produced)*(stochiomertric coefficient)} /(moles of

reactant converted)]/100

=99.7/100=1190/moles of reactant converted

Moles of reactant converted (ethylene)= 1193.5 mol/hr

Now the reactions in the reactor are:-

C6H6 + C2H4 → C6H5-C2H5

benzene ethylene Ethyl benzene

C6H5-C2H5 + C2H4 → C6H4-(C2H5)2

Ethyl benzene ethylene Diethyl benzene

here, For 1 mole of Ethyl benzene = 1 mole of ethylene needed

24

and For 1 mole of diethyl benzene = 2 moles of ethylene needed.

Now after reactor 1190 mol of ethyl benzene produced

So ethylene consumed is = 1190 mol

Thus rest ethylene is = 1193.5 - 1190

= 3.5 mol of ethylene

Since conversion is 100%

It means that all ethylene had converted in to ethyl benzene and rest ethylene

converted in to diethyl benzene.

Now

2 moles of ethylene will produce = 1 moles of diethyl benzene

So, 3.5 mol will produce = 3.5/2

= 1.75 mol/hr of diethyl benzene (DEB)

Now, to minimize the production of DEB we have chosen high B : E ratio i.e. 8:1

Thus total benzene requirement is = 8 *1193.5

= 9548 mol/hr

Since Ethylene is not pure it is having only 93mole % ethylene

Thus total ethylene stream (ethylene+ ethane) requirement is:-

=1193.5/0.93 = 1283.3 mol/hr

Inert = 1283.3– 1193.5

= 89.8 moles/ hr

After reactor will also have un-reacted benzene which will be :-

=Benzene fed – benzene consumed

= 9548-1193.5-1.75

= 8356.25 mol /hr (unreacted)

25

Now consider reactor-1 (R-1) again:-

Inputs:

Benzene = 9548 mol

Ethylene = 1193.5 mol

Inert = 89.8 mol

Outputs:

Ethyl benzene = 1190 mol

Benzene = 8356.25 mol

Inert = 89.8 mol

Diethyl benzene = 1.75 mol

Stream:-(6)

Ethyl benzene = 1190 mol/hr

Benzene = 8356.25 mol/hr

Inert = 89.8 mol/hr

Diethyl benzene = 1.75 mol/hr

26

Thus Consider Flash Column: Stream -6

Material Balances of Benzene Column

27

Now consider Ethyl benzene (EB) column:

Stream no :(10)

Stream 10 will contain:

EB= 1188.8 mol/hr DEB= 1.75 mol/hr Benzene= 2.352 mol/hr

Now as we already know that stream (11) will be:

Stream (11):

EB = 1188.7 mol/hr

Benzene= 2.352 mol/hr

Stream (12):

DEB = 1.75 mol/hr

EB = 0.123 mol/hr

28

Mass balance at a Glance:

For Reactor

Input :

Stream:

Component Kg/hr mol//hr

Ethylene (E) 33.418 1193.5

Benzene (B) 744.744 9548

Inert (I) 2.694 89.8

Total 780.856

Output:

29

Stream:

Component Kg/hr mol//hr

Ethyl Benzene (EB) 126.140 1190

Di-ethyl Benzene (DEB) .234 1.75

Benzene (B) 651.788 8356. 25

Inert (I) 2.694 89.8

Total 780.856

For Flash Column:

Input:

Stream: 6

Component Kg/hr mol//hr

Ethyl Benzene (EB) 126.140 1190

Di-ethyl Benzene (DEB) .234 1.75

Benzene (B) 651.788 8356.25

Inert (I) 2.694 89.8

Total 780.856

Output:

Stream: 7

Component Kg/hr mol//hr

Inert (I) 1.234 41.151

Benzene (B) 4.608 59.074

Ethylbenzene (EB) 0.106 1

Total 5.948 101.225

30

&

Stream: 8

Component Kg/hr mol//hr

Ethyl Benzene (EB) 126.304 1189

Di-ethyl Benzene (DEB) .234 1.75

Benzene (B) 647.179 8297.176

Inerts (I) 1.460 48.649

Total

For Benzene Column:

Input:Stream: 8

Component Kg/hr mol//hr

Ethyl Benzene (EB) 126.304 1189

Di-ethyl Benzene (DEB) .234 1.75

Benzene (B) 647.179 8297.176

Inerts (I) 1.460 48.649

Total 775.178

Output:

Stream: 9

Component Kg/hr mol//hr

Benzene (B) 647 8294.824

Ethyl Benzene (EB) 0.0525 0.5

Di-ethyl Benzene (DEB) 0 0

Inerts (I) 1.460 48.649

Total 648.51

Stream: 10

Component Kg/hr mol//hr

Ethyl Benzene (EB) 126.013 1188.8

Di-ethyl Benzene (DEB) .234 1.75

Benzene (B) 0.184 2.352

Total 126.43

31

For Ethyl Benzene Column:

Input:

Component Kg/hr mol//hr

Ethyl Benzene (EB) 126.013 1188.8

Di-ethyl Benzene (DEB) .234 1.75

Benzene (B) 0.184 2.352

Total 126.43

Output:

Stream : 11

Component Kg/hr mol//hr

Ethyl Benzene (EB) 126.002 1188.7

Benzene (B) 0.184 2.352

Total 126.186

&

Stream: 12

Component Kg/hr mol//hr

Di-ethyl Benzene (DEB) .234 1.75

Ethyl Benzene (EB) .013 0.123

Total 0.248