Masport Manual H HXL

-

Upload

michael-rice -

Category

Documents

-

view

268 -

download

7

Transcript of Masport Manual H HXL

-

8/12/2019 Masport Manual H HXL

1/47

PRICE: $5.00 90343

MASPORT INCORPORATED

Toll Free 1(800) 228-4510

www.masportpump.com

Masport Incorporated All Rights Reserved

Phone (402) 466-8428

Fax (402) 466-8355

6140 McCormick Drive

Lincoln, NE 68507

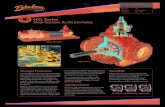

Masport Air CooledH and HXL-Series and Series II

Vacuum / Pressure Pumps

Series II Pump Models:

HXL75V II, HXL75F II,

HXL15V II, HXL15F II

Includes Series I Pump Models:

H5F, H5V, HXL5F, HXL5V,

H75F, H75V, HXL75F, HXL75V,

-

8/12/2019 Masport Manual H HXL

2/47

-

8/12/2019 Masport Manual H HXL

3/47

I. LIMITED WARRANTY..........................................................................

II. APPLICATION...................................................................................... A. TYPE OF APPLICATION................................................................

B. APPROXIMATE TRUCK SIZE........................................................

C. VALVE OPTIONS...........................................................................

III. PUMP LOCATION............................................................................... A. HV - SERIES..................................................................................

B. HF - SERIES..................................................................................

IV. DRIVE SYSTEMS................................................................................ A. HORSE POWER REQUIREMENTS...............................................

B. BELT DRIVE SYSTEMS................................................................. 1. Belt Type..............................................................................

2. Pulley Sizing.........................................................................

3. Pulley Horsepower Transfer Requirement Equations..........

4. Drive Ratio Equations...........................................................

5. Pump Rotation......................................................................

6. Belt Tension and Alignment..................................................

C. POWER TAKE OFF INSTALLATIONS...........................................

D. HYDRAULIC SYSTEM INSTALLATIONS.....................................

V. PLUMBING REQUIREMENTS..........................................................

A. PIPE SIZE RECOMMENDATIONS............................................... B. HOSE SIZE AND TYPE RECOMMENDATIONS..........................

C. HF - SERIES INSTALLATION RECOMMENDATIONS.................

D. HV - SERIES INSTALLATION RECOMMENDATIONS.................

VI. PUMP PROTECTIONCOMPONENTS........................................... A. PRIMARY AND SECONDARY TRAP SYSTEMS.........................

B. INLET FILTER...............................................................................

C. VACUUM RELIEF VALVE.............................................................

D. PRESSURE RELIEF VALVE.........................................................

E. PRESSURE/VACUUM GAUGE.................................................... F. OIL SEPARATOR.........................................................................

G. REMOTE 4-WAY VALVE..............................................................

H. SWING CHECK VALVE................................................................

TABLE OF CONTENTS

pg. 1

pg. 22

2

3

pg. 33

3

pg. 44

44

5

8

8

9

9

9

10

pg. 10

1011

11

11

pg. 1212

12

12

12

1313

13

13

I. Table of contents continued next page

-

8/12/2019 Masport Manual H HXL

4/47

VII. LUBRICATOR SYSTEMS..................................................................... A. THEORY OF OPERATION.................................................................

1. Pump Pressure Actuated..........................................................

2. Air Brake Pressure Actuated.....................................................

3. XL - Lubricator...........................................................................

B. MOUNTING OPTIONS........................................................................

C. INSTALLATION RECOMMENDATIONS.............................................

D. LUBRICANT RECOMMENDATIONS..................................................

E. LUBRICANT FLOW RATE..................................................................

1. Pump Pressure Actuated..........................................................

2. Air Brake Pressure Actuated.....................................................

3. XL - Lubricator...........................................................................

VIII. COMPONENT CHECK LIST................................................................

IX. OPERATION INSTRUCTIONS............................................................... A. NORMAL SUMMER CONDITIONS....................................................

B. COLD WEATHER CONDITIONS.......................................................

X. PUMP MAINTENANCE.......................................................................... A. PERIODIC MAINTENANCE...............................................................

B. STORAGE..........................................................................................

C. VANE WEAR CHECK........................................................................

D. PUMP REPAIR KITS..........................................................................

XI. INSTALLATION DIAGRAMS AND PARTS LISTS..................................

INSTALLATION DIAGRAM 90417...........................................................

INSTALLATION DIAGRAM 90414...........................................................

DIMENSIONAL DATA..............................................................................

H5V,H75V PARTS LIST...........................................................................

MASPORT XL LUBRICATOR..................................................................

INSTALLATION DIAGRAM 90412........................................................... INSTALLATION DIAGRAM 90411...........................................................

TABLE OF CONTENTS (continued)

II.

pg. 1414

14

14

14

15

15

16

16

16

17

17

pg. 17

pg. 1818

19

pg. 2020

20

20

21

pg. 22

22

23

24

25

26

2728

Table of contents continued next page

-

8/12/2019 Masport Manual H HXL

5/47

INTEGRAL 3 FEED LUBRICATOR (13451)............................................

INTEGRAL 3 FEED LUBRICATOR (13452)............................................

INTEGRAL 3 FEED LUBRICATOR (13471)............................................

REMOTE 3 FEED LUBRICATOR (13459)..............................................

REMOTE 3 FEED LUBRICATOR (13462)...............................................

3 POINT SIGHT FEED ASSEMBLY (25320)...........................................

XII. SERIES II PUMPS................................................................................ HXL75V II PARTS LIST...........................................................................

HXL75F II PARTS LIST...........................................................................

HXL15V II PARTS LIST...........................................................................

HXL15F II PARTS LIST...........................................................................

OIL RESERVOIR KIT PARTS LIST......................................................... RECOMMENDED OIL LIST.....................................................................

TABLE OF CONTENTS (continued)

III.

Do Notattempt to install, operate, or service this pump without reading and understanding the

corresponding section in this manual.

29

30

31

32

33

34

pg. 3535

36

37

38

3940

-

8/12/2019 Masport Manual H HXL

6/47

PURCHASER - KEEP FOR RECORD

TERMS OF LIMITED WARRANTY: 12 MONTHS

DATE PURCHASED:

SERIAL NUMBER:

1

I. LIMITED WARRANTYManufacturer warrants defects in workmanship, materials or parts for a period of twelve

months from date of sale. The limited warranty is restricted to repair or replacement of

parts or pumps at Masport Incorporateds discretion. Masport Incorporated neither

assumes, nor authorizes any person to assume any other obligation or liability in

connection with Masport Incorporateds products, parts or services sold or delivered.

Masport Incorporated shall not be liable for injury or damage to property other than the

products or parts themselves, nor for incidental, consequential or special damages.

1. The product must be returned to Masport Incorporated. The limited warranty does

not cover the cost of collection or delivery.

2. Any claim under this limited warranty must be made in writing and received within

twelve months from date of sale. Claims should be addressed to Masport

Incorporated. Masport Vacuum/Pressure Pump Warranty Claims Department,

6140 McCormick Drive, Lincoln, NE 68507-3296.

3. This limited warranty will not apply to any malfunction, defect, or damage of any

product resulting from repair or alteration other than by Masport Incorporated.

4. This limited warranty excludes the following: damage during shipment, damage

from other than normal or intended use, normal wear, any defects arising frominstallation or operation of the products other than in accordance with the operating

instructions provided, or any product which has been subject to misuse, neglect, or

accident.

5. This limited warranty is not transferable and shall extend only to the original

purchaser.

Masport Air Cooled Vacuum Pressure PumpOwner/ Operator Manual

-

8/12/2019 Masport Manual H HXL

7/47

II. APPLICATION

A. TYPE OF APPICATION

Masport Air Cooled H-Series Vacuum/Pressure Pumps are designed for continuous dutyoperation to 20Hg or 20 PSIG. Applications for H-Series pumps include liquid waste

transport, oil eld service work, septic tank cleaning, car wash or grease trap cleaning,

and many other industrial applications. When pressure off-loading, pump lubricant will be

discharged into the product being off-loaded. This is a consideration when the product

being transported cannot tolerate small quantities of oil, as in the case of food grade

materials and some types of chemicals.

B. APPROXIMATE TRUCK SIZE

The following information regarding application of a Masport pump model to a particular

truck is provided as a general guide. Individual installation requirements may vary

from those provided. Pumps may be applied to larger or smaller trucks than those

recommended to better suit the application.

When selecting the correct pump, consideration must be given to the type of product to

be moved (weight, viscosity), tank size, desired evacuation time, height of lift, elevation

at which the pump will operate, and the quantity of air admitted with the product. In

skimming operations, large quantities of air enter the tank with the product, lowering the

vacuum level. In such a case, a large pump on a relatively small tank may be desirable.

The below chart gives the airow and recommended tank size for Masport Air Cooled

Vacuum/Pressure H and HXL-Series Pump models. For more specic information

regarding application of Masport Pumps to a particular application, consult the localMasport Representative or contact Masport Incorporated.

2

SPECIFICATIONS

MASPORT VACUUM/PRESSURE PUMP

H5V, H5FHXL5V,

HXL5F

H75V,

H75F

HXL75V,

HXL75F

HXL15V,

HXL15F

DISPLACEMENT

C.F.M.

120 152 180 204 314

TANK SIZE -GALLONS

1000-2200 1000-2400 1800-3800 1800-4000 1800-4000

-

8/12/2019 Masport Manual H HXL

8/47

3

C. VALVE OPTIONS

The HV-Series Pumps are equipped with an integrally mounted pressure change over

valve and a built in anti-backspin check valve. The integral change over valve allows

switching from vacuum operation to pressure operation by turning the control lever. The

built in check valve prevents the pump from spinning backwards when the drive system

is shifted into neutral with either pressure or vacuum in the tank. A HV-Series pump is

desirable when the pump can be located in an area on the truck that allows easy access to

the valve control lever. An example of an installation using an HV-Series pump is shown in

the INSTALLATION DIAGRAM 90417 onpage 22.

The HF-Series Pumps are equipped with a threaded porting plate and can be used

with vacuum only or pressure only operation or with a remote 4-way valve to allow both

pressure and vacuum operation. An example of an installation using a Masport Four Way

Remote Valve is shown in the INSTALLATION DIAGRAM 90414 on page 23.

III. PUMP LOCATION

A. HV-SERIES LOCATION

The HV-Series pump should be mounted to allow easy access to the control lever on the

top of the pump for valve operation. Consideration should also be given to the type of

lubricator to be used. If a pump mounted (integral) lubricator is used, the pump should be

placed to allow a visual check of the oil ow rate. If the pump is a HXL-Series the pump

should be placed so that the reservoir sight glasses are visible to check lubricant level.

The pump mounting surface should be reasonably level to prevent stress on the casting

and uneven loading on the bearings. The pump should be placed to allow accuratealignment of the drive system with the pump drive shaft.

B. HF-SERIES LOCATION

HF-Series pumps are used in applications where the truck design prevents mounting in an

area accessible to the operator. They are particularly suited for use on direct PTO drives

where the pump is mounted under the frame of the truck making access for lubricator and

or valve operation impossible. As with the HV-Series, the HF-Series mounting surface

should be reasonably level to prevent stress on the casting and uneven loading on the

bearings.

The HF-Series can be used with the supplied porting plate for vacuum only or pressure

only operation, or for pressure and vacuum operation with the addition of the Masport

Remote 4-Way Valve.

Lubrication for the HF-Series can be provided by a Masport Remote Lubricator System.

Remote lubricator systems are available in pump pressure or air brake pressure actuated

models. (Refer to the Lubrication Sectionpg. 14 for details.)

-

8/12/2019 Masport Manual H HXL

9/47

4

A. HORSEPOWER REQUIREMENTS

When selecting a drive system for the pump, it is rst necessary to determine the

maximum vacuum level the pump will operate at, if it is to be used in a vacuum only

operation, or the maximum pressure level if the pump is to be used for pressure only or

vacuum and pressure operation.

If used for pressure and vacuum operation, the drive system should most often be

designed to transfer the horsepower required for pressure operation because the pump

requires signicantly more horsepower at pressure than at vacuum.

The horsepower gures shown in the chart below are the minimum amount required at the

pump shaft to adequately power the pump. Failure to install a properly sized drive system

will result in the pump slowing during operation. This loss of RPM will result in vane oat

causing damage to the pump. Vane oat occurs when the centrifugal force holding the

vanes in contact with the cylinder is overcome by the pressure the pump is producing.Vane oat caused the vane to bounce or hammer on the cylinder wall rather than sliding

smoothly, causing corrugation of the cylinder wall and damage to the vane tips.

If a belt driven system is to be used to power the pump, horsepower gures should be

multiplied by 1.3 to allow a service factor. The following gures represent the horsepower

required by the pump at various speeds at maximum vacuum and various pressure levels.

IV. DRIVE SYSTEMS

B. BELT DRIVE SYSTEMS

1.) Belt Type

The type of belt drive system that is best for a particular application is affected by a

number of factors. Some of these are shaft speed, available pulley space, horsepower to

be transferred and availability of replacement parts.

HORSEPOWER REQUIREMENTS

PUMPMODEL

RPMMAX

VACUUM

PRESSURE

5 10 15 20 25

H5VH5F 1100 5.9 4.9 6.9 8.7 10.7 12.4

HXL5VHXL5F

1100 5.9 4.9 6.9 8.7 10.7 12.4

1400 7.5 6.2 8.8 11.0 13.6 15.7

H75VH75F

1100 9.6 8.6 11.1 13.8 16.3 19.2

HXL75VHXL75F

1100 9.6 8.6 11.1 13.8 16.3 19.2

1250 10.9 9.8 12.6 15.7 18.5 21.8

HXL15VHXL15F

1100 13.5 17.4 22.2 26.5 30.8 34.7

1250 15.6 20.1 25.7 30.7 35.7 40.2

-

8/12/2019 Masport Manual H HXL

10/47

5

The most common type of belts used to drive this type of equipment are the standard B

section and the BX sometimes referred to as cog belts. Other possible belt drive options

are the 3V and 5V type drives. A 3V or 5V drive is desirable on systems requiring greater

amounts of horsepower to be transferred on installations where spare for large diameter

pulleys is not available.

B and BX belts differ only in the fact that the BX type has notches around the inside

circumference of the belt. These notches allow the belt to wrap tighter around a small

diameter pulley, providing more surface contact between the belt and pulley and increased

horsepower transfer capability. The increased horsepower transfer capability of the BX

belt will, in many cases, allow fewer belts to be used, decreasing the cost of the drive

system and simplifying installation.

The 3V and 3VX belts provide a relatively high horsepower transfer because they are

narrower than the B type belts and a larger number of belts can be used without the pulley

becoming too wide for the available shaft.

5V belts have higher horsepower transfer rates due to the large amount of surface areathat contacts the pulley. The 5V belt is the same width as the B section belt but it is

deeper and provides more belt to pulley contact.

When considering a 3V or 5V drive system, keep in mind that this type of belt is not

available in the wide variety of lengths that the B section is available in. Attention must be

given to mounting the pump a distance from the drive shaft that works with the available

belt sizes.

2.) Pulley Sizing

In the following section on pulley sizing we have provided a guide to help understand the

effects of pulley diameter and speed on the horsepower transfer capabilities of a drive

system. This information is provided due to the fact that belt drive suppliers can sometimes

be more concerned with selling a drive system they stock than one that is properly suited to

the application. The charts provided do not take into account variables such as belt length

correction factors and additional horsepower transfer due to drive ratio variations but they

are helpful as a general guide to ensure the success of the system.

In the end result, belt type will be dictated mainly by the pulley diameters that are used in

the installation.

Two major factors affect horsepower transfer capabilities of a belt drives system, the

diameter of the smallest pulley and the speed at which it is turning. A smaller diameterdecreases the amount of belt surface area actually touching the pulley and consequently

decreases horsepower transfer. The other factor affecting power transfer is shaft speed.

The slower a shaft is turning the less power a given diameter pulley can transfer.

The following chart on horsepower transfer characteristics lists a number of shaft speeds,

pulley diameters and the maximum amount of horsepower per groove that pulley can

transfer. Pulley sets should be chosen to allow adequate horsepower transfer using no

-

8/12/2019 Masport Manual H HXL

11/47

6

more than a four groove pulley with B or BX type belts, six grooves on a 3V drive, and no

more than four grooves on a 5V drive.

The outside diameter of a B section pulley is the pitch diameter plus .35

HORSEPOWERPER GROOVE SPEED OF FASTER SHAFT (RPM)

PULLEY PITCHDIAMETER 1100 1250 1275 1350 1400

5.0 5.3 5.9 5.9 6.2 6.4

5.2 5.6 6.2 6.3 6.5 6.7

5.4 5.9 6.5 6.6 6.9 7.0

5.6 6.2 6.8 6.9 7.2 7.4

5.8 6.5 7.1 7.2 7.5 7.7

6.0 6.8 7.4 7.5 7.8 8.1

6.2 7.0 7.7 7.8 8.2 8.4

6.4 7.3 8.0 8.1 8.5 8.7

6.6 7.6 8.3 8.4 8.8 9.0

6.8 7.9 8.6 8.7 9.1 9.4

7.0 8.1 8.9 9.0 9.4 9.7

7.2 8.4 9.2 9.3 9.7 10.0

7.4 8.7 8.5 9.6 10.0 10.3

8.0 9.5 10.4 10.5 10.9 11.2

8.6 10.0 11.0 11.2 11.6 11.9

9.4 11.3 12.3 12.5 13.0 13.3

PULLEY DIAMETER SELECTION - STANDARD B SECTION DRIVESNOTE: The horsepower guresshown for the various pulleys and

speeds do not include a service

factor to allow for wear and shock

loads exerted during start up of

the system. To ensure the drive

system is adequate to power the

pump, the power requirements

of the pump should be multiplied

bey a factor of 1.3 and the pulleys

selected to supply the resulting

number. For example, if the pump

requires 20 horsepower at a givenRPM and pressure level, the drive

should be designed to supply

20 x 1.3 = 26 horsepower.

-

8/12/2019 Masport Manual H HXL

12/47

7

HORSEPOWERPER GROOVE

SPEED OF FASTER SHAFT (RPM)

PULLEY PITCHDIAMETER

1100 1250 1275 1350 1400

5.3 4.3 4.9 4.9 5.2 5.4

5.6 4.7 5.2 5.3 5.6 5.8

6.0 5.1 5.7 5.8 6.1 6.3

6.5 5.5 6.3 6.4 6.7 6.9

6.9 6.6 6.7 6.8 7.2 7.4

8.0 8.9 8.0 8.1 8.5 8.8

10.6 10.6 10.8 11.0 11.5 11.9

PULLEY DIAMETER SELECTION - 3V SECTION DRIVES

HORSEPOWERPER GROOVE

SPEED OF FASTER SHAFT (RPM)

PULLEY PITCHDIAMETER

1100 1250 1275 1350 1400

7.1 13.8 15.4 15.6 16.4 16.9

7.5 14.9 16.7 16.9 17.8 18.4

8.0 17.1 18.3 18. 19.6 20.2

9.0 18.5 19.9 20.3 21.3 21.9

9.25 19.6 21.5 21.8 23.0 23.7

9.75 20.6 22.3 22.6 23.8 24.5

10.3 22.1 23.8 24.2 25.4 26.2

10.9 23.7 25.6 26.0 27.3 28.1

PULLEY DIAMETER SELECTION - 5V SECTION DRIVES

-

8/12/2019 Masport Manual H HXL

13/47

8

3.) Pulley Horsepower Transfer Requirements Equation

The rst step in the design is to determine the design horsepower requirements of the

pump being driven.

A= Maximum Horsepower Required by the PumpB= 1.3 Service FactorC= Design Horsepower

Ax B= C

Example: A HXL75V is to be run at 1250 RPM and at 20 psi. The pump requires 18.5 HP

(from the table on page 4) to produce 20 psi at 1250 RPM. Using the above formula, 18.5

x 1.3 = 24.1 Design Horsepower. The pulley drive system will now be designed to transfer

24.1 HP.

C= Design Horsepower

D= Number of Belts to be UsedE= Horsepower per Belt (Groove)

Cdivided by D= E

The number of belts used to drive the vacuum pump will depend on the amount of room

that is available. On most installations three to four belts are used to drive the vacuum

pump.

4.) Drive Ratio Equations (Large Pulley Sizing)

In some cases the truck PTO will turn at a different speed, usually slower, than the pump

shaft. To arrive at the right pump RPM, a combination of two different size pulleys must be

used to achieve the right ratio.

G= PTO shaft speedP= Pump shaft speedR= Drive RatioT= Diameter of smaller (Faster) pulley (Selected from chart in previous section)

Y= Diameter of larger pulley

FORMULA #1P divided byG =R R xT =Y

Referring back to our example in the previous section, where the pump speed (P) is 1250

RPM, and the PTO speed (G) is 1000 RPM, the pump is turning faster than the PTO, we

therefore use Formula #1 to nd the diameter of the larger (PTO) Pulley.

-

8/12/2019 Masport Manual H HXL

14/47

9

5.) Pump Rotation

All Masport HXL-Series Pumps are designated clockwise or counter-clockwise rotation.

This is because the oil pump in the lubricator is not a bidirectional pump and must be

driven in the proper rotation. If this is not done the oil pump will not properly lubricate the

vacuum pump. To determine rotation of pump face drive-end and spin the pump in thedirection of the arrow on the pump casting.

H-Series pumps are supplied in a double end shaft conguration. This is so the pump can

be driven from either end to allow use with either a clockwise or counter-clockwise drive

system. This does not mean the pump mechanism can turn in either direction, it simply

means it can be driven from either end, and proper rotation of the pump can be achieved

by simply turning the pump around and driving it from either end.

To determine the direction the pump is to turn, examine the lower section (cylinder) of the

pump approximately 3 inches below the 1/4 NPT oil inlet on the face of the cylinder. At

this point there is an arrow cast into the cylinder pointing at the foot of the pump. This

arrow indicates the proper rotation of the pump. Turning in the opposite direction willresult in damage of the pump.

If the liquid cooling is to be supplied by a self contained cooling system, the non-drive

shaft can be used to drive the coolant circulation pump.

6.) Belt Tension and Alignment

Belt tension is as individual as the belt drive itself. Tension is relative to the diameter of

the pulleys used, and the length of belt span between the two pulleys. There is no correct

way to tension a belt drive without the use of a belt Tension Gauge. Belt Tension Gauges

are available from belt drive suppliers.

Alignment of the belt drive can be accomplished by running a straight edge of some kind

across the faces of the pulleys and adjusting their location on the shafts to bring them

parallel. The pulleys should be as parallel as possible to prevent excessive side loads

being exerted on the pump and drive shaft bearings, and to prevent uneven wear and loss

of performance from the belts themselves.

NOTE: When one belt of a multiple belt drive system is damaged or fails, the complete set should be replaced to ensurematched belt length and equal belt tension. Failure to do so can result in damage to the equipment.

C. POWER TAKE OFF INSTALLATIONS

The Masport H-Series Pump is equipped with End Thrust Protection. This means the

pump bearings are equipped with adjustable stops to limit the travel of the pump rotor from

side to side in the cylinder, thus preventing the ends of the rotor from contacting the end

covers. This is an important feature of the Masport Pump in that it allows the pump to be

direct driven from the truck PTO without damage to the end cover or rotor due to loads

exerted by the PTO shaft.

-

8/12/2019 Masport Manual H HXL

15/47

10

When direct PTO driving a Masport Pump, care should be taken to see that the drive shaft

to the pump is not set at too great an angle and that the yoke used on the pump shaft is

properly sized.

Installation of this type of drive system should be left to qualied personnel to ensure

proper performance.

NOTE: Installation of a Masport pump on a PTO system without the use of a telescopic joint in the interconnecting driveshaft will result in damage to the PTO, pump or both from excessive loading by the drive shaft.

D. HYDRAULIC SYSTEM INSTALLATION

If a hydraulic system is to be used to power the Masport Pump a qualied hydraulic

equipment distributor should be consulted. To get the correct size pump and motor, the

main considerations will be the RPM and horsepower requirements for the vacuum pump.

These factors must be taken into account to ensure proper operation of the system.

Speed and horsepower gures can be found in the charts provided in the Horsepower

Requirements Section.

As with other types of drives, failure to keep the Masport Pump supplied with adequate

power and RPM will result in damage to the pump and untimely failure.

Two important considerations when selecting the type of exible coupling to use between

the hydraulic motor and Masport Pump are horsepower handling capability and ability to

handle angular misalignment without exerting excessive lateral thrust on the pump and

motor shafts.

There are a number of good quality ex couplers on the market. Some bolt to a exible

rubber tire, some have pins that t into a exible element, and others have a molded metal

ange, as in the case of the WOODS SURE-FLEX.

V. PLUMBING REQUIREMENTS

A. PIPE SIZE RECOMMENDATIONS

The H75V and H5-Series pumps are supplied with 2 1/2 N.P.T. porting. Due to the high

volumes of air handled by the pump, none of the plumbing attached to the pump should be

smaller than 2 1/2 N.P.T.

The H75F and H5F-Series pumps are supplied with 2 N.P.T. porting. Due to the high

volumes of air handled by the pump, none of the plumbing attached to the pump should besmaller than 2 N.P.T.

Some type of pipe sealer should be used on the threads of all pipe ttings to prevent

leaks. LOCTITE Pipe Sealer with Teon has proven to be the easiest and most effective

product Masport has tested. Teon tape should not be used as pieces of the tape can be

drawn into the pump and cause vanes to stick.

-

8/12/2019 Masport Manual H HXL

16/47

11

NOTE: Make certain that all ttings used in the installation of the pumping system are free from metal chips sometimes leftin the tting when it is produced. These chips can cause considerable damage to the pump on initial start up if allowed to

remain in the system.

B. HOSE SIZE AND TYPE RECOMMENDATIONS

Hose between the Pump, Accessories, and Tank should be no smaller than the pumpporting. Doing so will restrict the airow of the vacuum pump.

When selecting the type of hose to use, keep in mind that the Masport Pump is capable of

up to 28 Hg and 25 PSIG. It is therefore important to select an interconnecting hose rated

for full vacuum service and adequate pressure.

Material used in the construction of the hose for systems using vacuum to load, and

gravity off-loading, are not as critical as for those using pressure off-loading. When

pressure off-loading, hose from the pump to the tank is subject to an air/oil mix from the

pump exhaust with temperatures up to 300F. This combination of high temperature and

oil can have a damaging effect on the liner of some types of hose. If the liner of the hose

is damaged, it can break away from the outer layers of the hose and collapse to act as

a check valve between the pump and the tank. It this condition occurs, it will cause the

pump to operate at high vacuum levels at the pump, not at the tank, with overheating and

damage to the pump being the result.

To avoid this condition, Masport recommends that Hot Tar and Asphalt Hose be used

on systems intended for pressure and vacuum operation. Hot Tar and Asphalt Hose is

designed for use with oil and high temperatures and has a life expectancy far beyond that

of standard suction hose.

NOTE: The vacuum pump should be plumbed with the vacuum side of the integral going to the tank and the pressure sidegoing to the atmosphere. Although it is perfectly acceptable to plumb the system opposite of this, but remember that the

valve operation will be reversed.

C. HF - SERIES INSTALLATION RECOMMENDATIONS

The Masport HF-Series pump is particularly useful when the pump is to be mounted under

the frame of the truck as in the case of a direct PTO driven system. Installation diagram

90414 details the layout of a system used for pressure and vacuum operation with the

installation of a Masport four way remote valve. This diagram shows the components

necessary for a properly operating system in the correct relationships. Deviation from this

layout can cause failure of the system to function properly and possible damage to the

system.

D. HV - SERIES INSTALLATION RECOMMENDATIONS

The Masport HV-Series pump is applicable on systems where the pump can be mounted

in such a way as to permit easy access to the integral valve handle to control the mode

the pump is functioning in. This situation also lends itself well to the use of the integral

lubrication and XL-Lubrication systems as outlined in the Lubrication Section. Installation

diagram 90417 details the correct location of the components. Components not in the

proper location can result in damage to the equipment.

-

8/12/2019 Masport Manual H HXL

17/47

12

VI. PUMP PROTECTION COMPONENTS

A. PRIMARY AND SECONDARY TRAP SYSTEMS

In order to perform properly, the pump must be protected at all times from liquid or foreign

materials entering the mechanism. Pump protection can be achieved by the use of aproperly designed primary and secondary moisture trap scrubbers. Due to the high air

ow rates and rapid loading capability of the system, both a primary and secondary trap

system are recommended to avoid the possibility of foreign material entering the pump.

Masport offers a primary and secondary moisture trap scrubber that match the needs of

the vacuum/pressure pump system. These trap systems are available through the Local

Masport Representative or Masport Incorporated.

B. INLET FILTER

By capturing particles that could damage the vacuum/pressure pump, the inlet lter

extends your systems life and performance. Each Masport Inlet Filter is equipped with

durable iron wing nuts which allow the lid to be removed quickly and easily. The uniquedesign features a 300 micron washable stainless steel element. An inlet lter is a must in

any system to prevent contamination of the vacuum pump from foreign particles.

C. VACUUM RELIEF VALVE

A vacuum relief valve must be installed on any vacuum system. This valve acts to limit

the maximum vacuum level the pumping system can achieve to a preset level. Failure

to install a vacuum relief valve on your system can result in damage to the pump due to

overheating caused by high vacuum operation for extended periods of time. The relief

valve should be installed between the pump and the secondary moisture trap scrubber

so that in the event the trap system is activated closing off the vacuum line, the pump willstill be protected by the valve. Vacuum relief valves are available from the local Masport

Representative or Masport Incorporated.

D. PRESSURE RELIEF VALVE

When using the system for vacuum loading and pressure unloading, a pressure relief

valve is an Absolute Necessity. Failure to prevent over pressurizing the pump, tank, or

other system components with a properly sized relief valve could result in damage to the

equipment and injury to the operator.

Masport offers ASME code type pressure relief valves in a number of sizes and pressuresettings for use with the HW-Series Pumps. Refer to Installation Diagram 90417 for

correct location of the pressure relief valve.

-

8/12/2019 Masport Manual H HXL

18/47

E. PRESSURE/ VACUUM GAUGE

Installation of a vacuum or pressure/vacuum gauge on the system ins necessary to

properly monitor the performance of the system. Without a gauge it is impossible to

accurately adjust the vacuum relief valve and prevent pump overheating due to operation

beyond the recommended operational levels. The gauge used to monitor pump

performance should be installed between the pump and secondary trap to prevent the

product being pumped from coming in contact with the gauge.

F. OIL SEPARATOR / OIL CATCH MUFFLER

Masport High Efciency Oil Separators reduce average vacuum pump exhaust noise

below 82dBA. Along with greatly reducing exhaust noise, the highly efcient Masport

design captures exhausted oil, eliminating job site mess and clean up. When the vacuum

pump operates in the pressure mode, the oil catch mufer functions as an oil bath cleaner

to prevent dust and foreign material from entering the pump. There are no lter screens,

cartridges or bags to replace eliminating the extra cost of maintenance. A quick-openingbrass ball valve is supplied for convenient draining. High Efciency Oil Separators are

available from the Local Masport Representative or Masport Incorporated.

G. REMOTE 4 - WAY VALVE

On systems where vacuum loading and pressure off-loading is desirable, but available

space will not allow the use of a pump equipped with an integral valve, the Masport remote

four way valve is a possible solution. With on side of the valve attached to the exhaust

side, the mode of operation can be changed from vacuum to pressure by simply turning

the selector lever on the valve. When using the remote valve, a swing check valve must

be installed to prevent damage to the pump from backspin when the drive system is put inneutral with vacuum or pressure in the tank.

H. SWING CHECK VALVE

A swing check valve is necessary when using an H75WF-Series pump for vacuum,

pressure, pressure/vacuum operation. Unlike the H75W, the H75WF does not have an

anti spin check valve built into the pump. The check valve prevents the pump spinning

backwards when the drive system is shifted into neutral with vacuum or pressure in the

tank. An in line check valve is not necessary with the H15WF due to the fact that the

check valves are built into the manifold plate of the pump.

13

-

8/12/2019 Masport Manual H HXL

19/47

14

VII. LUBRICATOR SYSTEMS

A. THEORY OF OPERATION

1.) Pump Pressure Actuated

Masport pump pressure actuated lubricators consist of an oil reservoir and a three or four

point adjustable sight feed metering device. One of the sight feed valves, or two in the

case of the H15V, meter oil to the center of the pump cylinder to lubricate the vanes. The

two valves feed oil to the bearings at each end of the pump and on through to the outside

edges of the vanes. Each sight feed valve is independently adjustable to allow ow rate

adjustment to each point.

When operating in the vacuum mode, oil is drawn from the oil reservoir into the sight feed

valves by the vacuum produced by the pump. When operating in the pressure mode the

oil reservoir is pressurized, forcing oil to the sight feed valves and on into the pump.

Once a pump pressure actuated lubricator is installed and the oil ow rate set, the actual

ow rate will vary up and down with the operating pressure or vacuum of the system. The

ow rate will increase as the pressure or vacuum level increases and decrease as the

pressure or vacuum decreases.

2.) Air Brake Actuated

In situations calling for very low vacuum-high air ow operation, as in a vacuum skimming

operation, it may be necessary to use an Air Brake Pressure Actuated Lubricator or

XL-Lubricator if the pump is to operate below the minimum levels required to actuate the

lubricator for extended periods of time.

An air brake pressure actuated lubricator works in basically the same way as the pump

pressure actuated unit. The difference lies in the fact that the air brake pressure actuated

unit is not dependent on the vacuum or pressure level the pump is operating at to move

the oil through the sight feed valves. Air brake pressure actuated units are supplied with a

regulator and gauge to allow the oil reservoir pressure to be regulated to a sufcient level

to move the oil when connected to the trucks air brake system. This type of lubricator

allows the pump to operate at very low vacuum and pressure levels for extended periods

of time without damage from oil starvation.

NOTE: Due to the fact that the oil is moved through the sight feed valves by the vacuum or pressure produced by thepump, no oil will ow until the system has reached a sufcient operating level to cause the oil to move. The minimum levels

necessary to actuate the lubrication system adequately are 5 Hg or 2 1/2 PSIG. Due to the high air ow capacity of the

Masport HW-Series pumps it does not take long for a tank to reach these levels and is therefore not a problem.

3.) XL-Lubricator

The XL-lubricator pump is a positive displacement pump so vacuum and pressure levels

do not effect the performance of the lubricator pump. This lubricator works extremely

will for any application of Masport Vacuum Pumps. Because the XL-Lubricator has no

drippers to adjust or maintain, pump operation is simplied and pump life is extended.

-

8/12/2019 Masport Manual H HXL

20/47

15

B. MOUNTING OPTIONS

Masport Integral Lubricator systems are designed to mount directly to the side of the

pump by means of special bolts supplied with the system. This type of lubrication system

is applicable in situations where the pump is located in an area that allows access to the

sight feed valves for adjustment and visual check of the oil ow rate. Each lubrication

package is furnished with all the necessary ttings and hose to install it on the pump. The

XL-Lubricator is a Integral that mounts to the non drive side of the vacuum pump.

Remote lubricators offer both exibility in mounting and a larger capacity oil reservoir.

This lubrication system is desirable when the pump is not readily accessible for operator

service, as in under frame mounting for direct power take off drive. Remote Lubricator

Systems can be mounted anywhere on the truck, preferable within three to four feet of the

pump, to allow operator adjustment of the oil ow rate and relling of the reservoir. The

comparatively large oil capacity, 1.64 U.S. gallons, allows long continuous run periods with

less frequent rell intervals.

C. INSTALLATION RECOMMENDATIONS

When doing the actual installation of either a Remote or Integral Mounted Lubrication

system the following points should be considered.

1. Once the oil is metered into drops by the sight feed valve at the lubricator, the drop is

carried to the pump by way of gravity. To avoid delays in oil reaching the pump, all oil

lines from the lubricator to the pump should ow in a downward direction.

2. All ttings used to install the lubrication system should be treated with pipe sealer to

avoid air leaks causing erratic ows conditions. The fact that the ttings are brass does

not in itself ensure adequate sealing and should therefore have sealer applied.

3. Remote lubricators should be mounted within three to four feet of the pump to allow oil

to travel through the lines and into the pump in a reasonable length of time.

4. In no case should a lubricator be mounted below the level of the pump due to the fact

that oil will pool in the lines and sight glasses, making correct adjustment of the ow rate

impossible.

5. Oil lines and ttings are all of a self locking type and require no hose clamps up to 200

PSIG. A drop of oil on the hose insert and in the end of the hose will ease installation.

6. IMPORTANT: On systems using the Lube Devices sight feed assemblies, the sight feedblocks are held to the manifold block by means of brass mounting bolts. These bolts are

sealed to the assembly by O-rings in half making replacement necessary.

7. IMPORTANT: A new pump may not have been test run from some time. It is therefore

necessary to pre-lubricate the pump by putting 1 ounce of oil down each of the bearing oil

ports, and 1 ounce of oil into the cylinder oil port to ensure adequate lubrication on initial

start up following installation.

-

8/12/2019 Masport Manual H HXL

21/47

16

D. LUBRICANT RECOMMENDATIONS

Due to the fact that pressure/vacuum pumps operate at comparatively high temperatures,

the type of oil used is extremely important. Standard AUTOMOTIVE OILS ARE NOTACCEPTABLEfor use in a Rotary Air Pump due to their detergent and viscosity stabilizingagents not tolerating exposure to temperatures encountered in this type of equipment.

If automotive oils are used, the additives in the oil will break down and build up on the

internal surfaces of the pump in the form of carbon deposits and varnish. These deposits

cause the vanes to stick in their slots and produce a hammering action on the cylinder

rather than sliding smoothly around the diameter. This hammering action will cause the

cylinder to corrugate across the bore, causing undue stress on the vanes, and eventually

pump failure.

In order to maintain the performance of the vacuum pump a high quality ROTARY

COMPRESSOR OIL or ROTARY TURBINE OIL should be used. These types of lubricant

are designed for high temperature operation and will out perform other types of lubricant in

this application. A list of suitable oils is on page 40.

When selecting a lubricant, the weight should be approximately a 30 weight for summer

use and 10 to 20 weight for cold weather operation.

If there is not a local source for acceptable lubricant, Masport supplies approved Rotary

Pump Oil. Masport Rotary Pump Oil is available through the local Masport Representative

or from Masport Inc. in single U.S. Gallons or cases of six U.S. Gallons.

If Rotary Pump Oils are not available in the immediate area, a high quality, non-detergent,

straight weight diesel engine oil is an acceptable compromise but will not produce the

same results as the Rotary Pump Lubricants.

E. LUBRICANT FLOW RATE

1.) Pump Pressure Actuated Lubricator

On systems equipped with Pump Pressure Actuated Lubrication, the lubricant ow rate

is regulated in part, by the vacuum or pressure level the pump is operating at, and in part

by the setting of the needles on the sight feed valves. This type of lubrication system

will not dispense any oil until the vacuum pump is operating under a vacuum or pressure

condition.

Once the pump is installed and a vacuum can be drawn, start the pump and adjust theRPM to give the correct pump speed. Check pump speed at the shaft and make note of

the engines tachometer speed for future reference. With the valves on the truck closed,

continue to draw a vacuum until the gauge reaches 15 Hg. At this point the sight feeds

should be adjusted to deliver 30 to 60 Drops per Minute at each of the sight feed.

-

8/12/2019 Masport Manual H HXL

22/47

17

Once the ow rate is set the needle packing nuts can be snugged up to help maintain

the setting. Care should be taken to not over tighten the packing nuts as damage to the

packing will result.

When the system is used for pressure, the ow rate should be adjusted when the tank

pressure is at approximately 10 PSIG. Exact ow rates are not critical as long as the

system is operating in the 30 to 60 DPM range at its normal operating vacuum or pressure.

IMPORTANT: A new pump may not have been test run for some time. It is necessary to pre lubricate the pump by putting 1ounce of oil down each of the bearing oil ports, and 1 ounce of oil into the cylinder oil port to ensure adequate lubrication on

initial start up following installation.

2.) Air Brake Pressure Actuated Lubricator

Oil ow rates for systems equipped with Air Brake Pressure Actuation are the same as

with the Pump Pressure Actuated systems. Approximately 30 to 60 DPM at each of the

sight feeds will be adequate. Regardless of the vacuum or pressure the pumping system

is operating at the oil reservoir can be pressurized to achieve adequate oil ow rates.

Here again, the ow rate need not be stop watch accurate. Keep in mind that the pressure

the regulator is maintaining must be at least 5 PSIG higher than the pressure the pumping

system is working at. If the two pressures become equal the oil ow will stop.

CAUTION: The three way valve mounted on the pressure regulator system must be turned on during pump operation for oilto ow and turned off at the end of the pumping operation to prevent oil from continuing to ow.

3.) XL-Lubricator

The XL-Lubricator requires no adjustment to the ow rate because it is preset at the

factory. With this setting the XL-Lubricator delivers the correct amount of lubricant to the

vacuum pump under all conditions. With this in mind the XL-Lubricator is especially goodin all applications with the advantage of being easy to maintain.

VIII. COMPONENT CHECK LIST

The following lists are provided as a reference to aid in the design and installation of

Masport Pressure/Vacuum Pumps. All necessary components that comprise a reliable

Vacuum or Pressure/Vacuum System are listed on the following page with their Masport

part numbers. We feel the Masport Components are the nest available to protect the

pump and provide a reliable, protable pumping system.

Whether using Masport components or another manufactures, the components listed are

necessary to ensure success of the pumping system.

(See Table on following page).

-

8/12/2019 Masport Manual H HXL

23/47

18

Size by Masport Vacuum/PressurePump Model

H5V, H5F,HXL5V, HXL5F

HXL75V, HXL75F,H75V, H75F

HXL75WV,HXL75WF, H75WV,

H75WF

HXL15WV,HXL15WF,

H15WV, H15WF,HXL20WV,HXL20WF

Size by Pump Air Flow C.F.M. @ 0 Hg 90-180 180-300 180-300 300-400

Primary Shut-Off Trap 16311 16321 16321 16331

Secondary Moisture Trap-Scrubber 16410 16420 16420 16436

Inlet Filter 15115 15116 15116 15118

Oil Separator 15462-5 15463 15463 15466

Vacuum Relief Valve 25056 25056 25056 25056

Vacuum Gauge - 2 1/2 Face 21028 21028 21028 21028

Vacuum/Pressure Gauge - 2 1/2 Face 21051 21051 21051 21051

Vacuum/Pressure Gauge - 3 1/2 Face 21052 21052 21052 21052

Pressure Relief Valve - A.S.M.E. CodeAvailable in factory set pressure of 5-35 P.S.I. for all pump models.

Contact your Masport Representative or Masport Incorporated for individual

application requirements.

Remote 4-Way Valve 968106 968106 968106 968106

Swing Check Valve 25129 25130 25130 25132

Masport Hose Adaptor 968107 968107 968107 968107

IX. OPERATION INSTRUCTIONS

A. NORMAL SUMMER CONDITIONS

Once installation is completed according to the recommendations set forth in this manual,

normal operation of the system is quite simple. The main operational tips are as follows.

1.) Always engage the pump drive system with the engine at an idle to avoid shock loads

to the system.

2.) Do not operate the pump during the drive to the job site as the RPM at the pump could

be abnormally low or high.

3.) Make frequent checks of the oil level in the tank and the oil ow rate at the sight feed

valves.

4.) Do not remove the lubricator cap when the system is in operation.

5.) When using an Air Brake Pressure Actuated Lubrication System, be sure to turn thevalve on at the start of pumping, and off when nished.

6.) Set the Vacuum Relief Valve at 20 Hg or lower when pumping for extended periods of

time.

7.) Maintain the proper pump RPM at all times.

-

8/12/2019 Masport Manual H HXL

24/47

19

8.) Keep all drive system components well lubricated and belts tightened properly.

9.) When using an HV or HF-Series pump with an Integral or Remote Valve, move the

valve handle to the middle of its travel, (Neutral Position), to relieve any vacuum

or pressure left in the tank after the pumping job is nished to prevent the lubricator

continuing to dispense oil.

10.) WARNING! The primary or secondary shutoff, if activated, will prevent any pressurein the tank from bleeding off through the vacuum pump or secondary. We

recommend that a bleed off valve be installed in the tank. Always relieve all pressure

in the tank before attempting to open hatches, manways, and trap shutoffs.

11.) When using pressure to off-load, a Pressure Relief Valve with the proper setting must

be used.

12.) Never open the drain valve on the Secondary Trap to relieve vacuum in the system.

The air stream created through the trap can carry foreign material from the trap into

the pump.

13.) Always drain the Secondary Trap after each job and at the end of each working day.

14.) If foreign material enters the pump follow the ushing instructions in the following

maintenance section.

15.) Use the proper type and weight oil for the local temperature conditions.

B. COLD WEATHER CONDITIONS

When operating the pumping system during freezing conditions the following steps should

be taken at the end of each day to prevent the pump freezing due to condensation.

1.) Before leaving the last job site of the day, establish enough vacuum or pressure in the

system to cause the lubrication system to function. Once the lubricator is functioning

open the sight feed valves far enough to allow a full stream of oil to ow into the

pump for 3 to 5 seconds. This will, in most cases, allow enough oil to remain in the

pump mechanism to prevent freezing and damage to the pump during morning start

up.

2.) Drain the Secondary trap at the end of each job and the end of each working day to

prevent the oat mechanism freezing and subsequent failure of the trap to operate.

3.) Use the proper type and weight oil for the local temperature conditions.

4.) Observe all the operating instructions in the Normal Summer Weather Section.

-

8/12/2019 Masport Manual H HXL

25/47

20

X. PUMP MAINTENANCE

A. PERIODIC MAINTENANCE

To eliminate buildup of foreign material on the inner working surfaces of the pump and

ensure smooth operation and maximum pump life, it is recommended the pump be ushedwith Masport ushing uid daily, preferably at the end of the workday. Flush the pump

more often if carry-over from traps contaminate the pump.

A Masport Vane Pump Flushing Kit can be purchased from your Masport Representative

or contact Masport Incorporated for more information. To ush the pump follow the simple

procedure below:

Masport Vane Pump Flushing KitFlushing Procedure:1.) Start vacuum pump and bring vacuum to 15 Hg.

2.) Open ball valve to begin ushing uid ow.

3.) Continue to run pump until uid level drops

1 graduation (Approx. 7 uid ounces).

4.) Close ball valve.

5.) Continue to operate the pump 1 additional

minute to ensure all uid is purged from pump.

6.) Stop vacuum pump.

7.) Drain Oil Catch Mufer or Oil Separator and

dispose used uid at approved recycling site.

NOTE:If for any reason the pump begins to hammeror clatter, it should be stopped immediately and the

problem corrected to prevent permanent damage.

this type of problem is most commonly caused by

foreign material entering the pump. If this is the case

the ushing instructions should be followed.

Pump clattering can also be caused by overheating

due to operation beyond the recommended limits. If

this is the case the pump should be allowed to cool

and the problem corrected.

B. STORAGE

If the pump is likely to remain idle for an extended period of time it is advisable to follow

the ushing instructions prior to storage to prevent rusting of internal parts. In storage

situations, oil should also be poured into the bearing lubrication ports to protect the

bearing surfaces.

C. VANE WEAR CHECK

The pump should be inspected for vane wear at least once a year. If the vane wear is not

monitored they can become too short, be forced out of their slots during operation, and

cause major structural damage to the pump.

-

8/12/2019 Masport Manual H HXL

26/47

21

When removing the end cover, remove only the bolts around the perimeter of the

endcover. Once these bolts have been removed the cover can be removed by placing two

of the bolts in the threaded endcover jacking hole and tightening them evenly to pull the

cover free of the location dowel pins. In no case should the cover be hammered or pried

as damage to the pump surfaces will result.

Once the cover is removed the vanes can be removed and measured. New vanesmeasure 2 1/2 wide. The old vanes should be no less than 2 1/4 wide. If they are, they

should not be reused as damage to the pump may result.

If the vanes are worn to the point that they need to be replaced, it may be time for the

bearings and oil seals to be replaced also. If this is the case, Masport offer Repair Kits

for pumps that require replacement parts, but are not worn badly enough to require boring

and honing.

D. PUMP REPAIR KITS (From Masport)

The repair kits include vanes, bearings, oil seals, o-rings, exhaust ap assembly, valvegaskets, and end cover gaskets.

Its a good idea to keep a repair kit for the pump in stock to prevent down time in the

event some of the parts become damaged due to wear or foreign material entering the

mechanism.

For parts assistance or questions with installation or operations of the Masport H-Series

Pump contact your local Masport Representative or:

Masport Incorporated6140 McCormick Drive

Lincoln, NE 685071-800-228-4510

www.masportpump.com

-

8/12/2019 Masport Manual H HXL

27/47

90417 MASPORT INCORPORATED All Rights Reserved

PUMP SYSTEM INSTALLATION RECOMMENDATIONS

1. Follow Owner/Operator Instructions on pump operating limits covering vacuum/pressure, speeds, and in

the case of the liquid cooled pumps, the temperature recommendations. Please also note lubrication,

maintenance and sevice data.

2. A primary shut-off trap and moisture trap/scrubber must be used on all vacuum/pressure pump

installations to stop liquid or solids from entering the pump. The primary shut-off should be installed down

in the tank rather than in the dome lid area, as the tank will continue to ll after the oat shuts off the

vacuum if the vacuum tank is in the higher ranges.

3. Iron pipe size should not be reduced from pump inlet or exhaust port size, or restricted in any way.

(Do not use street elbows.)

4. A exible hose section should be used between pump and trap and between trap and tank. Inside

diameters of the hose connector and the hose should not be smaller than the iron pipe I.D.

5. Install vacuum relief valve, pressure relief valve and gauge between pump and moisture trap/scrubber.

NEW ZEALAND

INSTALLATION DIAGRAM 90417Integral Valve

22

-

8/12/2019 Masport Manual H HXL

28/47

90414 MASPORT INCORPORATED All Rights Reserved

PUMP WITH REMOTE 4-WAY VALVE INSTALLATION RECOMMENDATIONS

1. Follow Owner/Operator Instructions on pump operating limits covering vacuum/pressure, speeds, and in

the case of the liquid cooled pumps, the temperature recommendations. Please also note lubrication,

maintenance and sevice data.

2. A primary shut-off trap and moisture trap/scrubber must be used on all vacuum/pressure pump

installations to stop liquid or solids from entering the pump. The primary shut-off should be installed down

in the tank rather than in the dome lid area, as the tank will continue to ll after the oat shuts off the

vacuum if the vacuum tank is in the higher ranges.

3. Pump intake or exhaust may be connected to either side of the 4-way valve.

4. Iron pipe size should not be reduced from pump inlet or exhaust port size, or restricted in any way.

(Do not use street elbows.)

5. A exible hose section should be used between pump and trap and between trap and tank. Inside

diameters of the hose connector and the hose should not be smaller than the iron pipe I.D.

6. Install vacuum relief valve, pressure relief valve and gauge between pump and moisture trap/scrubber.

INSTALLATION DIAGRAM 90414Remote 4-way valve

23

-

8/12/2019 Masport Manual H HXL

29/4724

DIMENSIONAL DATA:

NEW ZEALAND

Masport

KEYWAY

NPT

NEWZEALAND

Masport

DIA.MTG.

HOLES

1/2"UNC

NPT

NPT NPT

Masport

NEW ZEALAND

NPT

KEYWAY

Masport

NEW ZEALAND

DIA.MTG.

HOLES

1/2"UNC

NPT

NPT

Masport

NEW ZEALAND

NPT

Masport

NEW ZEALAND

1/2"UNC

DIA.MTG

HOLES

KEYWAY

NPT

NPT

NPT

HXL75V II HXL75F II

A 8 5/8 8 5/8

B 15 13 1/4

C 20 25/32 6 9/32

D 21 13/16 21 1/8

E 12 5/8 12 5/8

F 7 1/2 7 1/2G 3 25/32 3 25/32

H 4 3/8 4 3/8

J 5 5/32 5 5/32

K 8 5/32 8 5/32

L 4 13/16 4 13/16

M 4 17/32 4 17/32

N 3 5/8 3 5/8

P 8 5/32 8 5/32

Q 9/16 9/16

R 5/16 X 5/16 X 2 5/16 X 5/16 X 2

S 1 3/8 1 3/8T 3 5/8 3 5/8

U 1/8 1/8

V 2 1/2 2 1/2

W 1/4 1/4

X 8 15/32 8 15/32

Y 7 1/4 7 1/4

HXL15V II HXL15F II

A 14 9/32 15 1/32

B ------- 6 1/16

C 22 5/16 21

D 8 11/16 8 11/16

E 16 7/32 17 3/32

F 25 29/32 25 29/32

G 12 5/8 12 5/8

H 7 7/16 7 7/16

J 3 25/32 3 25/32

K 4 1/4 4 1/4

L 5 1/32 5 1/32

M 8 1/32 8 1/32

N 9 7/16 9 7/16

P 4 13/32 4 13/32

Q 8 1/32 8 1/32

R 9/16 9/16

S 5/16 X 5/16 X 2 5/16 X 5/16 X 2

T 1 3/8 1 3/8

U 4 1/8 4 1/8

V 1/8 1/8

W 3 3

X 1/4 1/4

Y 8 15/32 8 15/32

Z 7 1/4 7 1/4

HXL75V II

HXL75F II

HXL15V II

HXL15F II

E

A

B

C

ND

F

T

Y

VNPT

XNPT

SKEYWAY

RDIAMETER

MTG. HOLES

G

H

J K

L

M Q

U

1/2UNCO P

Z

WNPT

-

8/12/2019 Masport Manual H HXL

30/47

REF. DESCRIPTION H75 H75 Qty.

1. 2. 3. 4. 5. 6.

7. 8. 9.10.

11.12.13.14.15.16.17.18.19.20.21.

8mm X 35mm BoltFlange Plat (Air Cooled)Gasket (H5, H75)Flap AssemblyCylinder (Air Cooled)Valve Body (Newer 2 1/2" NPT)Valve Body (Older 2" NPT)Valve Handle8mm X 25mm BoltWasher (Handle Retainer)Oil Seal

8mm LockwasherValve CapValve SpringValve Spool12mm X 55mm Bolt (Older 2" Valve)*12mm Lockwasher*4mm OD Nylon Tubing (HXL Only)Elbow (HXL Only)10mm X 25mm BoltO-Ring (H Thrust Nut)Shaft Guard

41111111513

411144431621

90023 MASPORT INCORPORATED All Rights Reserved Effective 12-2000

501666968706568610968026968401968010968711968037501617501550501674

501610968035568038968094501880500203600293568086501569501672668608

PARTS LISTH5F, H5VH75F, H75V

H5F, H5V, H75F, H75V AIR COOLED PRESSURE / VACUUM PUMP PARTS LIST

22.23.

24.25.26.27.28.29.30.31.

32.33.34.35.36.37.

38.

Thrust NutDowel Pin (Older 7.8mm X 25mm)Dowel Pin (Newer 8mm X 30mm)Allen ScrewEndcover(Same as #10)BearingBearing SpacerVaneRotor Assembly (Includes 27, 28)(Same as #24)

Fiber Pad8mm X 16mm BoltEndcover O-Ring*2 1/2" Integral Valve Assembly*2" Integral Valve Assembly*Endcover Shim Gasket * .002" Thickness .003" ThicknessValve Cap Gasket*

968607942313503258501273968603---------501669968611975402968605---------

568072501571501673968003942453

542011542012568044

Qty.

24422--2241--

23211

****1

REF. DESCRIPTION

* Not Shown ** Quanity Varies

H5 H5

501666968706568610968026975334968010968711968037501617501550501674

501610968035568038968094501880500203600293568086501569501672668608

968607942313503258501273968603---------501669968611975306968655---------

568072501571501673968003942453

542011542012568044

25

-

8/12/2019 Masport Manual H HXL

31/47

PARTS LIST968851 - CW968852 - CCW

REF. DESCRIPTION Part No. Part No. Qty.

1. 2. 3. 4. 5. 6.

7. 8.

9.10.11.12.

Drive Coupling8mm x 12mm ScrewO-RingOil Reservoir (inner half)1/2 PlugO-Ring

8 mm x 80mm ScrewOil Pump (Clockwise)Oil Pump (Counter-Clockwise)8 OD x 1/2 ConnectorBanjo Body Bolt4mm OD Nylon Tubing (ft.)Oil Reservoir (outer half)

111111

3111411

90673 MASPORT INCORPORATED All Rights Reserved Effective 11-1-96

968015501831501003968013147621501673

501014568018568019568084568082600293968014

MASPORTXL LUBRICATOR PARTS LIST - 968851 (Clockwise), 968852 (Counter-Clockwise)

13.14.15.16.17.18.

19.20.21.22.23.24.25.

Gasket (Included with #14)Sight PlugNylon Washer6mm x 880mm BoltNo Longer Used6mm x 12mm Screw

4 OD x 1/8 ConnectorGasket (Included with #21)Oil Fill Plug4 OD x 1/8 Swivel ElbowOil Pickup Tubing (1)1/8 Plug*4 OD x 1/4 Swivel Elbow*

----------568017501019501010----------501959

568083----------568016568085600294143901568086

Qty.

---344---2

4---14114

REF. DESCRIPTION

* Not Shown

26

-

8/12/2019 Masport Manual H HXL

32/47

90412 MASPORT INCORPORATED All Rights Reserved

Masport Installation Diagram 90412A. Assembly A is a 1/8 NPT Street Elbow #27004 and a 1/8 NPT Hose Insert #27003. Assembly A

and B and the interconnecting hose make-up the Lubricator pressure line that actuates the lubricator

when working in the pressure mode.

B. Assembly B is a 1/4 NPT Street Elbow #27002 and a 1/4 NPT Hose Insert #27001. This assemblyattaches to the top of the lubricator tank to pressurize the tank during pressure operation.

C. Assembly C is a 1/4 NPT Hose Insert #27001 screwed into each of the two pump bearing housings.These two inserts are connected to the Oil Sight Feed Assembly to supply oil to the bearings, outside

edges of the pump rotor assembly and vanes.

D. Assembly D is a 1/4 NPT Street Elbow #27002 and a 1/4 NPT Hose Insert #27001. This assemblyscrews into the threaded hole on the intake side of the pump cylinder. Connected to the Oil Sight Feed

Valve Assembly, assembly D provides lubrication to the center of the pump to lubricate the center portion

of the vanes.

CAUTION: Make certain all interconnecting lines are attached as shown or damage to the pump will likelyoccur.

Installation Diagram 90412

27

-

8/12/2019 Masport Manual H HXL

33/47

90411 MASPORT INCORPORATED All Rights Reserved

Masport Installation InstructionsA. Assembly A consists of a 1/8 NPT Street Elbow #27004 and a 1/8 NPT Push Lock

#27003. Assembly A and B and the interconnecting hose make-up the LubricatorPressure Linethat actuates the lubricator when working in the pressure mode.

B. Assembly B consists of a 1/4 NPT Elbow #27000 and 1/4 NPT Push Lock #27001.This assembly attaches to the top of the lubricator tank to pressurize the tank during

pressure operation.

C. Assembly C is a 1/2 NPT Push Lock #27001 screwed into each of the two pumpbearing housings. These two inserts are connected to the Oil Sight Feed Assembly to

supply oil to the bearings, outside edges of the pump rotor assembly and vanes.

D. Assembly D consists of a 1/4 NPT Street Elbow #27002 and a 1/4 NPT Push Lock#27001. This assembly screws into the threaded hole on the intake side of the pump

cylinder. Connected to the Oil Sight Feed Valve Assembly, assembly D provides

lubrication to the center of the pump to lubricate the center portion of the vanes.

CAUTION: Make certain all interconnecting lines are attached as shown or damage to thepump will likely occur.

Installation Diagram 90411

28

-

8/12/2019 Masport Manual H HXL

34/47

90690 MASPORT INCORPORATED All Rights Reserved

Masport Integral 3 Feed Lubricator 13451(Pump Pressure Actuated)

Reference: Description Part Number Qty

1 Oil Reservoir 18051 1

2 O-Ring (For Cap) 36112 1

3 Lubricator Cap 27200 1

4 3- Point Sight Feed 25320 1

5 1/8 Brass Street Elbow 27004 5

6 1/8 Brass Push Lock 27003 5

7 Level Indicator Elbow 27008 28 1/4 OD Poly Tubing (in.) 24300 6

9 1/4 Brass Push Lock 27001 3

10 1/4 Brass Street Elbow 27002 1

11 10mm x 35mm Bolt 501878 4*

12 10mm Lock Washer 32501 4*

13 1/4 Push Lock Hose (ft.) 24299 5*

* Not Shown

Integral 3 Feed Lubricator13451

29

-

8/12/2019 Masport Manual H HXL

35/47

90699 MASPORT INCORPORATED All Rights Reserved

Integral 3 Feed Lubricator Assembly (Air Brake Pressure Actuated)

Ref. No: Description Part No. Qty

1 Oil Reservoir 18052 1

2 O-Ring (for cap) 36112 1

3 Lubricator Cap 27200 1

4 3-Point Sight Feed 25320 1

5 1/8 Brass Street

Elbow

27004 4

6 1/8 Brass PushLock 27003 4

7 Level Indicator

Elbow

27008 2

8 1/4 OD Poly

Tubing (in.)

24300 6

9 1/4 Brass Push

Lock

27001 5

Ref. No: Description Part No. Qty

10 1/4 Brass Street

Elbow

27002 2

11 1/4 x 1/8 Bushing 27350 1

12 1/8 Close 30038 1

13 3 - Port Valve 25176 1

14 1/4 x 1 1/2 Nipple 30251 1

15 Pressure Regulator 25401 1

16 Pressure Gauge 21001 1

17 10mm x 35mm Bolt 501878 4*

18 10mm Lock

Washer

32501 4*

19 1/4 Push Lock

Hose (ft.)

24299 15*

13452 Integral 3 FeedLubricator Assembly

*Not Shown30

-

8/12/2019 Masport Manual H HXL

36/47

90700 MASPORT INCORPORATED All Rights Reserved

Integral 3 Feed Lubricator Assembly (Pump Pressure Actuated)

Ref. No: Description Part No. Qty

1 Oil Reservoir 18060 1

2 O-Ring (for cap) 36112 1

3 Lubricator Cap 27200 1

4 3-Point Sight Feed 25320 1

5 1/8 Brass Street

Elbow

27004 5

6 1/8 Brass Push

Lock

27003 5

Ref. No: Description Part No. Qty

7 Level Indicator

Elbow

27008 2

8 1/4 OD Poly

Tubing (in.)

24300 6

9 1/4 Brass PushLock

27001 3

10 1/4 Brass Street

Elbow

27002 1

11 10mm x 35mm Bolt 501878 4*

12 10 mm Lock

Washer

32501 4*

13 1/4 Push Lock

Hose (ft.)

24299 5*

13471 Integral 3 Feed LubricatorPump Pressure Actuated

*Not Shown

31

-

8/12/2019 Masport Manual H HXL

37/47

90697 MASPORT INCORPORATED All Rights Reserved

13459 Remote 3 Feed LubricatorPump Pressure Actuated

Reference: Description Part Number Qty

1 Oil Reservoir 18059 1

2 O-Ring (for cap) 36112 1

3 Lubricator Cap 27200 1

4 1/8 Brass Pushlock 27003 5

5 1/8 Brass Street Elbow 27004 2

6 3 Point Sight Feed 25320 1

7 1/4 Brass Street Elbow 27002 2

8 Level Indicator Elbow 27008 2

9 1/4 OD Poly Tubing (in.) 24300 6

10 1/4 Brass Pushlock 27001 3

11 1/4 Pushlock Hose (ft.)* 24299 15

* Not Shown

Parts List 13459Remote 3 Feed Lubricator

32

-

8/12/2019 Masport Manual H HXL

38/47

90696 MASPORT INCORPORATED All Rights Reserved

Remote 3 Feed Lubricator Assembly (Air Brake Pressure Actuated)

Ref. No: Description Part No. Qty

1 Oil Reservoir 18059 1

2 O-Ring (for cap) 36112 1

3 Lubricator Cap 27200 1

4 1/4 Brass Push

Lock

27003 5

5 Pressure Regulator 25401 1

6 1/4 x 1 1/2 Nipple 30001 1

7 1/4 - 3 Port Valve 25176 1

8 1/4 Brass Street

Elbow

27002 3

9 1/4 x 1/8 Bushing 27350 1

Ref. No: Description Part No. Qty

10 1/8 Close 30038 1

11 Pressure Gauge 21001 1

12 3 Point Sight Feed 25320 1

13 Level Indicator

Flow

27008 2

14 1/4 OD Poly

Tubing (in.)

24300 6

15 1/8 Brass Push

Lock

27003 3

16 1/4 Push Lock

Hose (ft.)*

24299 15

17 1/8 Plug* 27451 1

13462 Remote 3 Feed LubricatorAir Brake Pressure Actuated

*Not Shown

33

-

8/12/2019 Masport Manual H HXL

39/47

90896 MASPORT INCORPORATED All Rights Reserved

25320 Three Point Sight Feed Assembly

Ref. No: Description Part No. Qty

1 Mounting Bolt 25932 3

2 Washer 25933 3

3 O-Ring 25934 6

4 Mounting Block 25935 15 O-Ring 25936 2

6 Manifold 25937 1

7 Pipe Plug 25939 2

8 Washer 25940 1

9 Lock Washer 25941 2

Ref. No: Description Part No. Qty

10 Mounting Bolt 25942 1

11 Valve Stem 25943 3

12 Packing Nut 25944 3

13 Packing 25945 314 Valve Body 25946 3

15 Solid Gasket 25947 6

16 Sight Glass 25948 3

17 Closure Nut 25949 3

18 Sight Feed Assy 25304 *

25320 Three Point Sight FeedAssembly

*Note: This part number includes parts 11-17 assembled into one sight feed.

34

-

8/12/2019 Masport Manual H HXL

40/47

HXL75V SERIES II AIR COOLED PRESSURE / VACUUM PUMP PARTS LIST (968675)

PARTSLISTHXL75V II

* * NOT SHOWN. * * * QUANTITY VARIES.

90030 MASPORT INCORPORATED All Rights Reserved Effective 4-1-2007

Ref Description Part No. Qty. Ref Description Part No. Qty.

1 Bolt 501569 16 24 Gasket 568044 12 Nut 504278 6 25 Gear 568158 1

3 Set Screw 504276 3 26 Endcover 968854 1

4 Endcover 968843 1 27 Swivel Elbow 568085 1

5 Swivel Elbow * 568086 3 28 Bolt 501571 3

6 O-Ring 501677 2 29 Set Screw 504277 3

7 Oil Seal 501015 3 30 Shaft Guard 568622 1

8 Bearing 503098 2 31 Drive Shaft Assembly 968045 1

9 Bearing Spacer 968611 2 32 Oil Pump 575437 1

10 Rotor Assembly (Incl. 8, 9) 968614 1 33 Cap Screw 504262 1

11 Cylinder 968401 1 34 Cap Screw 504261 1

12 Flap Assembly 968026 1 35 Dowel Pin 503258 4

13 Gasket 568610 1 36 Set Screw 504264 1

14 Valve Body 968010 1 37 Plug 27300 1

15 Washer 500203 4 38 Vane Pack (4) 975539 1

16 Bolt 501666 4 39 Integral Valve Assembly 968003 1

17 Cap 968035 1 (Incl. 7, 14, 17, 18, 19,18 Washer 501610 4 20, 21, 22, 23, 24)

19 Bolt 501617 5 40 Endcover Shim Gasket * *

20 Washer 501550 1 .002 Thickness 542011 * * *

21 Handle 968037 1 .003 Thickness 542012 * * *

22 Spring 568038 1 41 Oil Line (ft.) * * 600293 * * *

23 Spool 968094 1

35

-

8/12/2019 Masport Manual H HXL

41/47

PARTSLISTHXL75F II

90031 MASPORT INCORPORATED All Rights Reserved Effective 4-1-2007

HXL75F SERIES II AIR COOLED PRESSURE / VACUUM PUMP PARTS LIST (968685)

* * NOT SHOWN. * * * QUANTITY VARIES.

Ref Description Part No. Qty. Ref Description Part No. Qty.

1 Bolt 501569 16 17 Endcover 2-Start 968853 1

2 Nut 504278 6 6-Start 968854 1

3 Set Screw 504276 3 18 Swivel Elbow * 568085 1

4 Endcover 968843 1 19 Bolt 501571 3

5 Swivel Elbow * 568086 3 20 Set Screw 504277 3

6 O-Ring 501677 2 21 Shaft Guard 568622 1

7 Oil Seal 501015 2 22 Drive Shaft Assembly 968045 1

8 Bearing 503098 2 23 Oil Pump 575437 1

9 Bearing Spacer 968611 2 24 Cap Screw 504262 1

10 Rotor Assembly (Incl. 8, 9) 25 Cap Screw 504261 1

2-Start (Serial # < 91062) 968668 1 26 Dowel Pin 503258 46-Start (Serial # > 91061) 968614 1 27 Set Screw 504264 1

11 Cylinder 968401 1 28 Plug 503416 1

12 Gasket 568610 1 29 Vane Pack (4) 975539 1

13 Flange Plate 968706 1 30 Endcover Shim Gasket * *

14 Washer 500203 4 .002 Thickness 542011 * * *

15 Bolt 501666 4 .003 Thickness 542012 * * *

16 Gear 2-Start 575439 1 31 Oil Line (ft.) * * 600293 * * *

6-Start 568158 1

36

-

8/12/2019 Masport Manual H HXL

42/47

PARTSLISTHXL15V II

HXL15V SERIES II AIR COOLED PRESSURE / VACUUM PUMP PARTS LIST (968880)

90036 MASPORT INCORPORATED All Rights Reserved Effective 4-1-200

* NOT SHOWN. * * QUANTITY VARIES.

Ref Description Part No. Qty. Ref Description Part No. Qty.

1 Bolt 501569 16 24 Spring 568038 12 Nut 504278 6 25 Spool 968804 1

3 Set Screw 504276 3 26 Gasket 568044 1

4 Endcover 968843 1 27 Gear 568158 1

5 Swivel Elbow 568086 3 28 Endcover 968854 1

6 O-Ring 501677 2 29 Swivel Elbow 568085 1

7 Oil Seal 501015 2 30 Bolt 501571 3

8 Bearing 503098 2 31 Set Screw 504277 3