The Giant Gold Diggers: California's Land .. Going Fleet of Dredges

Martin J P.hopper Dredges and C.apr.1983.MT

-

Upload

federico-babich -

Category

Documents

-

view

8 -

download

1

description

Transcript of Martin J P.hopper Dredges and C.apr.1983.MT

-

Marine Technology, Vol. 20, No. 2, April 1983, pp. 164-176

Hopper Dredges and Certain Aspects of Their Design

John P. Martin 1 and Louis J. Mauriello 2

In recent years there has been a resurgence of hopper dredge construction and consequently a renewed interest in the design of such vessels. Principal physical and operational characteristics of this type of dredging plant are described briefly. Certain aspects of their design are discussed with particular reference to proposed regulatory requirements, various features of new hopper dredges recently constructed or pres- ently under construction both for the Government and private dredging contractors, and other current devel- opments.

Introduct ion

THE SEAGOING trailing suction hopper dredge is generally rec- ognized as a most important dredging plant for constructing, improving and maintaining navigation channels, particularly approaches to coastal ports. The modern hopper dredge repre- sents well over a century of development and operational expe- rience. Unfortunately, much of this experience is unrecorded.

Until recently (1977), hopper dredges used for navigation channel dredging in the United States were owned and operated exclusively by the U.S. Army Corps of Engineers. In the 25-year period immediately preceding 1977, only two new hopper dredges (the Markham in 1960 and the McFarland in 1967) were built in the United States. During the past few years, as a result of Federal legislative actions and new Corps of Engineers policies governing contractual procedures relating to dredging, several private dredging contractors have constructed a number of hopper dredges. In addition, the Corps of Engineers expects to continue to own and operate a minimum number of hopper dredges based mainly upon requirements for national defense and other emergency purposes. Consequently, the Corps has resumed dredge construction with a program of three new hopper dredges. One of these new dredges was completed during the past year and the other two are presently under construction.

This resurgence in hopper dredge construction has served to generate renewed interest in the design of such vessels, and the U.S. Coast Guard has proposed new regulations applicable to load line and stability requirements. This paper discusses various physical characteristics and operational considerations that affect the design of this type of plant, including the aforementioned proposed regulatory requirements, the characteristics of certain new vessels recently constructed or presently under construction, and other current developments of interest. It is intended to be a brief discussion of various aspects of hopper dredge design and related current developments rather than a comprehensive or detailed treatment of the subject. A brief section describing certain fundamentals of dredging and dredges, with particular emphasis on how hopper dredges work, has been included as a preface to the main body of the paper and a possible benefit to those who may not be acquainted with this specialized segment of the marine industry.

D r e d g i n g and d r edges

Dredging may be defined simply as any process for the removal

1 President, Dredge Technology Corp., New York, N.Y. 2 Marine and Dredging Consultant, Ocean, N.J. Presented at the September 24, 1981 meeting of the New York Met-

ropolitan Section of THE SOCIETY OF NAVAL ARCHITECTS AND MA- RINE ENGINEERS.

of materials from underwater and the disposal of these materials on shore, in deep water, or elsewhere. The dredging process comprises three distinct operations:

excavation of the material, transport or conveying of the excavated material from the

digging point to the disposal point, and disposal of the material. Plant and machinery for dredging vary greatly in both design

and construction, but it may be stated that all dredges fall into one of two distinct classes. One class includes those dredges which excavate mechanically, such as bucket dredges, dipper dredges and grab or clamshell dredges. The other class, which is by far the more extensive and important, includes all dredges which excavate hydraulically, that is by pumping the material excavated as a mixture (or slurry) with water.

Due to their comparative simplicity, dredges of the mechanical type were the first to be developed. While they continue to be especially suitable for use on certain work, the range of disposal of mechanical dredges is restricted. Barges and tugs usually are required in conjunction with their operation. In modern dredging practice, the hydraulic dredge is recognized to be a more versatile and efficient piece of equipment. The two principal types of hydraulic dredges are the pipeline dredge and the seagoing hopper dredge.

The pipeline dredge operates in a more or less stationary po- sition which is maintained by spuds or by anchors (Figs. 1 and 2). It is equipped with a centrifugal dredge pump and discharges the excavated material through a pipeline (either floating or submerged) to the point of disposal on shore or in open water. This type of dredge usually is nonpropelled, has a barge-like hull, and is tended by a tug during operation. It is used principally in sheltered inland waters, rivers and harbors since its normal working capability is limited to a wave height of 3 to 4 ft.

The seagoing hopper dredge operates on the same principle as the pipeline dredge in bringing the excavated material to the surface, but here the similarity ends. The seagoing hopper dredge is a self-propelled and sturdily built seagoing vessel with a ship form hull (Fig. 3). It is a self-contained and self-sufficient dredging plant that operates underway, requiring no anchors or mooring devices while dredging and requiring no tug assistance. It is designed for ocean service and for work in coastal waters and is utilized principally for the improvement and maintenance of navigation channels in locations where wave action or heavy traffic does not permit the employment of stationary dredges. In its normal mode of operation, the hopper dredge pumps bot- tom materials, such as mud and sand, into its hoppers through trailing suction pipes (dragarms) and, when loaded, proceeds under its own power to a deepwater disposal area where the dredged material is disposed of by gravity-dumping through gates

164 0025-3316183/2002-0164500.51/0 MARINE TECHNOLOGY

-

Fig. 1 Cutterhead pipeline dredge Fig, 2 Cutterhead pipeline dredge with floating discharge pipeline

or doors in the bottom of the hoppers. In recent years, some hopper dredges of the split-hull type have been built in order to facilitate the dumping operation. Also, some hopper dredges are equipped with self-unloading facilities that permit the hopper load to be pumped ashore through long discharge pipelines. In some cases, rather than loading the hoppers, the dredged material is pumped overboard (often through the overflow system) with the objective that a major portion will be transported and de- posited outside channel limits by tidal, river or littoral currents. This method of dredging is called "agitation dredging" and is used by the Corps of Engineers in certain entrance channels along the Gulf Coast, such as the Mississippi River Passes. In the in- terest of developing more effective high-capacity agitation dredging tools, a few hopper dredges have been equipped with boom-supported discharge pipes that permit the discharge of the dredged material at a point some distance from the ship's side. This type of agitation dredging is known as "side-casting."

Regardless of the method used for disposal, the hopper dredge invariably operates while underway with its dragarms in a trailing position on the channel bottom during the dredging or pumping phase. It provides a temporary depository (the hoppers) for the dredged material until it can be transported to a disposal area. It must be highly maneuverable and, most important, its con- struction and dredging equipment must be suitable to permit dredging operations under adverse conditions (waves and swells). These principal characteristics of hopper dredges need to be kept foremost in mind in any considerations relating to their de- sign.

General considerations

Dredging is a subaqueous earthmoving technique and therefore dredges nominally are considered to be tools of the civil engineer. The civil engineering discipline usually sets the performance standards for dredging projects and these standards have an important impact upon the design of dredges. These standards relate to productive capability and the ability to accomplish work in an orderly manner pursuant to established job specifications. However, the actual design of dredges requires a blend of many engineering disciplines with particular emphasis on naval ar- chitecture and marine engineering. This is especially true for hopper dredges.

As in the case of other construction-type floating plant and ships in general, the design of dredges is dictated mainly by the proposed service and use, with due consideration of work re- quirements and prevailing environmental conditions. A hopper dredge can be designed for operation in a particular waterway or channel project involving the removal, transport and disposal in a specified manner of a certain volume or quantity of a par-

ticular type of bottom material. However, in practice, such a single-purpose dredge rarely can be economically justified unless there exists a known requirement to meet constant operating conditions over a long time period. Such requirements do not exist in coastal port areas of the United States. Consequently, hopper dredges are normally designed for multiproject use and must be generally suitable for excavating, transporting and dis- posing of many types of bottom materials over a broad spectrum of operational conditions in any coastal region. For example:

Materials to be dredged generally range from light, fine- grained, clayey silts to heavy, coarse sand and gravel.

Haul distances vary from 1 mile or less to as much as 30 miles or more, with the average presently running about 5 miles.

Environmental considerations in certain projects preclude pumping beyond overflow during hopper loading operations, and, in other cases, require that the dredged material be disposed of by pumping into confined disposal areas or onto beaches (for restoration or nourishment purposes) rather than by conventional dumping in open-water disposal areas.

In addition, the dimensions (depth and width) of navigation channel projects in the United States in which trailing suction hopper dredges are employed vary widely. Obviously, dredges of suitable sizes to meet dimensional limitations (mainly length and draft) with compatible hopper capacities are required. In this connection, the Corps of Engineers hopper dredge fleet, both existing and projected for the future, is composed of vessels in three arbitrary but distinct categories based 0n hopper capacity, as follows:

Small Class Hopper Dredge (SCHD)--hopper capacity of 1000 yd 3 or less.

Medium Class Hopper Dredge (MCHD)--hopper capacity of over 1000 yd 3 up to 6000 yd 3.

Large Class Hopper Dredge (LCHD)--hopper capacity of over 6000 yd 3.

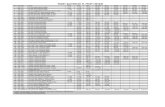

Figures 4 through 6 show the three new Corps of Engineers hopper dredges, each of which represents one of the classes just described. The SCHD Yaquina was completed late last year (1980) and presently is in operation on the West Coast. The medium and large class dredges depicted are still under con- struction. Each of these designs is described more fully in refer- ences [1] 3 and [2]. Figures 7 through 9 illustrate three similar commercially owned hopper dredges of diverse sizes that have been recently constructed and are now in operation. Table 1 is a tabulation of physical and other data pertaining to new hopper dredges, both Government and commercial.

The high acquisition and operating costs of hopper dredges

3 Numbers in brackets designate References at end of paper.

APRIL 1983 165

-

~L" . . . . ~ " ~ , > ~ l ~ t ............ D~ "~I,. i~, t~. . - - ' ' ~ ~ ~ ~ , > ~ i ' : . ~l /G

._ + " - - 47.,~+ < ,-oo ! . t < . -

[ . ~ , rtltltlt'@lt " I~D' ~ . . . . . .J-."":' ~ 17~I , -~ C - ~ #

-

Fig. 4 Hopper dredge Yaquina

make maximum utilization mandatory. Every effort is made to keep them fully utilized and, when working, they are usually operated on a continuous 24-hours-a-day, 7-days-a-week schedule, with an average downtime of one day or less every two weeks for fueling, provisioning and preventative maintenance and about one month a year for major repairs and shipyard overhaul. Under such work schedules, crew members in most cases must remain aboard the dredge for continuous periods of two weeks or more. Accordingly, suitable accommodations and facilities are provided for operating personnel. The geographical distribution of work projects or range of potential assignments of the dredge is another factor that must be given consideration, and movement from one coastal location to another can involve transit distances of 1000 miles or more.

In conventional dredging, hauling and dumping operations, the productivity of hopper dredges generally varies with hopper capacity. Figure 10 shows the estimated annual production of hopper dredges according to size (hopper capacity) in terms of the volume of dredged materials as measured in the hopper ("bin measurement"). The operating schedule, design speeds and other conditions upon which this graph is based are representative assumptions of the normal operation of a general-purpose hopper dredge in the United States and the results that can be expected.

Curves based on average hauls of 5 and 10 miles, respectively, have been included to illustrate the significant effect that hauling distance has on hopper dredge production.

Hopper dredges generally are designed and built for "ocean" service in accordance with applicable rules and requirements of the U.S. Coast Guard (USCG) and the American Bureau of Shipping (ABS) and thus carry the prescribed ship service ma- chinery, navigational equipment, life saving and fire fighting apparatus, and communications equipment. They are completely self-contained in that they have quarters, mess and sanitary fa- cilities typical of a comparably sized seagoing vessel. As indicated in the preceding, overall dimensions and hopper capacities vary to suit the required operations.

Hull and hopper capacity

Hopper dredges have many of the characteristics of other seagoing ships, such as tankers and bulk carriers. They go to sea both to discharge hopper loads and to move from port to port as dredging requirements dictate. Therefore, the hull form is similar in many respects to that of a conventional merchant ship and the design process is subject to the same considerations.

Hopper door openings in the hull bottom, required for emptying the hoppers during dumping operations, present re- sistance and structural design problems that must be considered. Corps of Engineers hopper dredges, in particular, are equipped with hinged dump doors that do not extend below the ship's bottom when opened in order to eliminate or reduce the risk of damage when dumping is relatively shallow ocean disposal areas. Consequently, these doors are recessed within wells or troughs of sufficient dimensions (longitudinally, transversely and in depth) to accommodate the doors. In order to minimize such problems, horizontal sliding doors have been used on a few hopper dredges of European design. However, this design has some disadvantages, particularly with respect to the relative inaccessibility of door operating gear for operational mainte- nance.

Split-hull hopper barges (mainly nonpropelled) for the transport of dredged material have been common for the past 20 years or more. These barges are divided in half longitudinally, and the two halves are swung apart for discharging the hopper load. The halves are connected by massive hinges at the main

/ 1! i ! II Itl

t i ii ===========================================

/t

r e * "~ I I

Fig. 5 Hopper dredge Essayons

APRIL 1983 167

-

0 0 0 0 0 0

i

OUTBOARD PROFI LE

- P H DECK UPPER BR DECK / I l

] 1 FCSLEI / I

_. , ~ ' T ~ ~ ] ~EC

WT WT W7 WT ~T WT WT wm I_.. D" . . . . . . LTANK

4 16 28 40 61 117 136 149 TOP

I N BOARD PROFI LE

Fig. 6 Hopper dredge Wheeler

168 MARINE TECHNOLOGY

-

Fig. 7 Hopper dredge Manhattan Island Fig. 8 Hopper dredge Eagle I

deck level. Opening and closing are accomplished primarily by buoyancy forces, with the operation being controlled by hydraulic rams located fore and aft of the hopper compartment.

The principle of operation of these barges has been adopted in the design of most of the commercial hopper dredges con- structed (or under construction) in the United States during recent years. Split-hull type hopper dredges have a number of advantages--particularly when handling cohesive or other dif- ficult-to-dump dredged material--over the single conventional hull type equipped with bottom dump doors, because:

The discharge aperture area is substantially larger than is available with conventional systems.

The absence of any door-operating mechanism within the hopper greatly reduces any resistance to dumping of the material.

Possible "arching" of the consolidated material is virtually eliminated because, as the longitudinal hopper walls move apart, the cross-sectional area of the hopper increases sig- nificantly.

There is a reduced risk of damage as a result of dumping in shallow water.

Maintenance cost is reduced due to elimination of doors and operating gear.

The structure in way of bottom doors is eliminated, thereby allowing a "clean" hopper with greater capacity.

As indicated, there is no question that the split-hull hopper dredge possesses better dumping characteristics and has other advantages over its conventional counterpart. However, it must be recognized that the aperture extending over the entire length of the ship makes it imperative that an effective simple and maintenance-free sealing arrangement be provided in the hopper area to preclude the loss of dredged material during the course of loading or transit from dredging to disposal areas. Limitations imposed by actuating cylinder dimensions (bore and stroke) that grow in proportion to overall ship size and displacement also cannot be overlooked. The largest split-hull hopper dredge built in the United States is the 340-ft Eagle I, which was completed and placed in operation in April 1981. The opening and closing cylinders of this dredge have a bore and stroke of 43.3 by 181 in. and a hydraulic working pressure of 4000 psi. One solution to this limitation that has been used in European newbuildings is in- stallation of four cylinders, two each in the forward and aft cyl- inder spaces.

The longitudinal strength calculations carried out for split-hull designs differ significantly from the normal ship calculations in that the section modulus for each hull half will vary considerably when the ship is in the open or closed position. The forces in the hull hinges and cylinders, as well as additional induced horizontal and vertical forces caused by beam or oblique seas, must be cal-

culated. Because of the numerous variations that are possible, the most practical approach to solving these problems is through the use of computer programs as described in reference [3].

With respect to hopper capacity, the general design practice is to provide the largest volumetric hopper space that can be physically accommodated within a hull size which may be limited by work project dimensions and other considerations related to the contemplated area of operation. As mentioned previously, channel bottom materials vary over a broad range. The in-place density of such materials ranges from about specific gravity 1.3 or less for light fine-grained silts to specific gravity 2.0 or more for heavy granular materials such as sand and gravel. The average density of materials generally encountered on hopper dredging projects in the United States is in the order of specific gravity 1.5 to 1.6. Consequently, hopper dredges designed for general-pur- pose use should have a hopper volume sufficient to permit es- sentially full loads of materials in that density range to be dredged

Fig. 9 Hopper dredge Atchafalaya

APRIL 1983 169

-

Table 1 Physical and general data

Manhattan Wheeler Essayons Yaquina Island Atchafalaya Stuyvesant (LCHD) (MCHD) (SCHD) (see Note 1) (see Note 2) Eagle I Dredge

350 ft 200 ft 281 ft 197 ft 340 ft 372 ft 333 ft 193 ft 265 ft 193.3 ft 311 ft 338 ft

Length overall 409 ft Length between 384 ft

perpendiculars Breadth 78 ft 68 ft 58 ft Depth 39.5 ft 35 ft 17 ft Draft (loaded) 29.5 ft 27 ft 12 ft Hopper volume 8400 CY 6000 CY 825 CY Propulsion power 2-5280 hp 2-3600 hp 2-1125 hp

each each each Speed (loaded) 14.5 knots 13.4 knots 10 knots Dredging depth 80 ft (see Note 3) 80 ft 45 ft

(max) (94 ft w/ (94 ft w/ (55 ft w/

extension) extension) extension) DREDGE PUMPS: Dragarm mounted

number 2 2 . . . discharge dia. 26 in. 26 in . . . . power 1600 hp each 1450 hp each . . .

Inboard number 2 2 2 discharge dia. 30 in. 26 in. 16 in. power 1800/3600 hp 1500/3000 hp 565 hp each

each each (see Note 4) (see Note 4)

Accommodations 40 38 28 Owner Corps of Corps of Corps of

Engineers Engineers Engineers Shipbuilder Avondale Sun Ship/Bath Norfolk

Shipyards, Iron Works, Shipbuilding Inc. Inc. & D D Co.

Year built under under 1980 construction construction

52 ft 40.7 ft 68.3 ft 72 ft 21.5 ft 16.3 ft 24.3 ft 34 ft 19.5 ft 14.5 ft 22.4 ft 28.3 ft

3600 CY 1308 CY 5514 CY 8830 CY 2-1500 hp 2-850 hp 2-3730 hp 2-6900 hp

each each each each 11.5 knots 9 knots 14 knots 14 knots

70 ft 45 ft 80 ft 70 ft

(65 ft w/ extension)

2 1 2 2 24 in. 20 in. 33.5 in. 36 in.

850 hp each 600 hp each 1400 hp each 1852 hp each

22 16 28 32 North American Gulf Coast Bean Dredging Stuyvesant

Trailing Corp. Trailing Co. Corp. Dredging Corp. Southern Twin City Avondale Avondale

Shipbuilding Shipyard, Shipyards, Shipyards, Corp. Inc. Inc. Inc.

1977 1980 1981 under construction

NOTES:

(1) First of a class of four dredges. Essentially similar vessels (and year built) are: Sugar Island (1979), Dodge Island (1980), and Padre Island (under construction).

(2) The Mermentau, a vessel of the same class, except that it will be equipped with two dragarms and two dredge pumps, 18 in. and 472 hp each, is under construction at Twin City Shipyard, Inc.

(3) The Wheeler is also equipped with a 42-in.-diameter center dragarm capable of dredging to 60 ft. (4) Electric motor drive designed for dual power operation with higher power indicated for direct pumpout operation.

and transported at the design draft or assigned working load- line.

Using data contained in Table 1, the maximum hopper ca- pacities (volumetric) of the various new hopper dredges have been plotted in Fig. 11 against a function of hull cubic (length between perpendiculars by breadth by depth) of the vessels disregarding any differences in hull forms and block coefficients. Curves indicating average trends for a number of representative hopper dredges, both conventional and split-hull types of modern European design, are shown as a basis of comparison. These curves demonstrate that the split-hull-type construction gen- erally is slightly more cubic-efficient than its conventional counterpart due to the lack of internal structure in the hopper mentioned earlier, although some cubic is lost to the cylinder spaces. Most of the hopper dredges recently built or currently under construction for private U.S. dredging contractors are of the split-hull type. The exception is the largest, an 8830-yd 3- capacity hopper dredge for Stuyvesant Dredging (See Table 1). All of the new Corps of Engineers dredges are of conventional construction.

It can be assumed that the vessels above the average curves would be "deadweight limited" whereas those falling below the average would be "cubic limited." Ships that are deadweight limited would not be able to carry a full hopper of heavy materials without exceeding the assigned load line. This condition can sometimes be minimized by carrying fewer consumables such as

fresh water and fuel oil. Benefits of the larger hopper volume would be realized when carrying lighter dredged material. On the other hand, dredges that are cubic limited would be able to reach the assigned load line only when carrying relatively dense dredged material. Such a ship would be able to carry large amounts of fuel oil and fresh water without affecting its ability to carry a full hopper of any dredged material.

It is noted that all of the Corps dredges fall below the average line (cubic limited), while all of the commercial dredges are above the average line (deadweight limited). The reasons for this sig- nificant difference are varied and are probably the result of taking into account the many possible operational requirements and resulting design criteria. These different requirements and design criteria may not be significant when considered singly. However, when design decisions are based on a clearly defined design philosophy, the end results are significant. The following indicate some of the major differences that affect the comparative de- signs.

The Corps of Engineers dredges are designed to have the capability of operating in remote areas during national de- fense emergencies. The crew complement and the capability of carrying the relatively large amounts of consumables re- quired for such operations are considered to be of prime importance.

Dredging work performed under contract is usually paid for

170 MARINE TECHNOLOGY

-

o

D J o

i -

o

o 31:

I O 0 0 0

9000

8 0 0 0

7 0 0 0

6 0 0 0

5000- o

4 0 0 0 "

3 0 0 0 "

2 0 0 0 "

I 0 0 0 '

Fig. 10

~y , y

~'/ 47

CURVES SASED ON O~ERAT,ON / ~ A Y ,

/ 7 DA~/ W~EK WOR~ SD.EDOLE AND FOLLOWING ASSUMED AVERAGES:

900/0 OF WORK TtME EFFECTIVE SPEED - I0 M I L E S / HOUR LOADING TIME - 60 MINUTES DUMPING TIME - I0 MINUTES AVERAGE LOAD - 70O/o HOPPER CAPACITY

( VOLUMETRIC )

! i i , ,

2 4 6 S IO 12 I4 IS lS

MILL ION CUBIC YARDS ESTIMATED ANNUAL PRODUCTION (BIN MEASUREMENT )

Estimated annual production of hopper dredges according to size (hopper capacity)

I 0

o 8

_z

~6 g

o =: 4

Stuyvesant Dredge O WHEELER

Representative European / /~ design (average)

~ ' ~ 0 ESSAYONS

M A N H A T T A N IO. C L A S S r~ /

Q CONVENTIONAL HULL - CORPS OF ENGRS A CONVENTIONAL HULL - PRIVATE U.S.

[ ] SPLIT H U L L - P R I V A T E U S

ATCHA F A ~ / ' ~ O YAOUINA

i i i i i i

5 I0 15 ZO Z5 50 35 4 0 45

L B P x BEAMx DEPTH IN C Y x l O 3

Fig. 11 Hopper volume/ship size relationship

I 50

APRIL 1983 171

-

on the basis of the volume (cubic yards) of in-place material removed from a specified area. A prime consideration of commercial interests is to be able to load and carry the largest possible volume regardless of the weight or specific gravity of the dredged material.

The Corps dredges are designed to operate without relying on the use of auxiliary plant or equipment, such as tugs and booster pumping stations, for disposal of dredged material by direct pumpout over long distances. For instance, the inboard pumps on the Wheeler (LCHD) and Essayons (MCHD) have about twice the power available then those on the comparable Bean and Stuyvesant dredges. Naturally, higher installed power requires a portion of ship volume that is not available for the hopper section.

The shape of the bottom of the hoppers on the Corps dredges substantially reduces the hopper volume in order to keep the dump doors recessed within the hull.

The Wheeler has a centerwell in the hopper area to allow installation of a third dragarm.

Space and weight considerations are most important factors in hopper dredge design. The large amount of relatively heavy components of the dredging systems and their associated power machinery oftentimes present critical problems. In order to en- sure that a full payload can be carried throughout most of the range of expected specific gravities, it is desirable that some reasonable margin (say equivalent to 3 to 5 percent of the esti- mated displacement) be provided for during the contract design phase. Experience indicates that weight estimates generally in- crease as designs are refined and engineering details are devel- oped. Alterations and modifications to hopper dredges during the course of their long-term economic lives are often accompa- nied by increases in machinery weight and vessel displacement that can have significant adverse effects on loading capabili- ties.

Load line and stability requirements

As previously indicated, U.S. hopper dredges were owned and operated exclusively by the Government until nearly five years ago when commercial dredging companies entered the hopper dredging field. The area and mode of operation of hopper dredges subject them to significant risks of damage from collisions, groundings, etc. Although no applicable regulatory requirements existed until recently, the Corps of Engineers has long recognized a need for hopper dredge hulls to be designed to survive damage from such casualties. This agency has followed a policy that, whenever practicable, all of its hopper dredges would be designed to survive flooding of any two adjacent hull compartments when operating at the maximum loaded draft. No less than a one- compartment standard of subdivision would be provided in any case.

When the construction and operation of privately owned hopper dredges became imminent, the U.S. Coast Guard issued, in the Federal Register of August 2, 1976, an Advance Notice of Proposed Rule Making entitled "Damage Stability Standards of Hopper Dredges." At that time, both the Corps and private industry were developing plans for the new dredge construction, and individual prospective owners and design agents had com- municated with the Coast Guard with respect to requirements under which a "working freeboard" would be permitted. Rules similar to those established by Bureau Veritas were sought. Such requests were answered on an individual basis, indicating that pending further consideration by the Coast Guard of the problem of stability standards specifically applicable to hopper dredges pursuant to the aforementioned Advance Notice, existing load line regulations did not permit freeboard less than the minimum permitted for coastwise and international voyages. However, the Coast Guard agreed that a working freeboard of up to one-half the tabular B/100 freeboard might be authorized subject to

various conditions patterned somewhat after those prescribed by Bureau Veritas [4].

Subsequently, the Coast Guard issued proposed rules on "Hopper Dredges; Load Line and Stability Requirements" which were published in the Federal Register on December 10, 1979 [5]. Fundamentally, these proposed rules would amend 46 CFR Parts 42 and 93 of the USCG regulations to permit the assignment to a seagoing, self-propelled hopper dredge of a reduced working freeboard that is one-half the B/100 freeboard allowed under 46 CFR 42.20-10 provided the vessel has sufficient structural strength for the corresponding draft and does not operate more than 20 nautical miles from shore or in conditions exceeding 10-ft seas and 35-knot winds. In addition, all dredges must meet, at their operating drafts, certain requirements specified for intact and damage stability. Essentially, these proposed rules would require hopper dredges to be designed to survive both side and bottom damage assuming a spoil level and density in the hopper which would result in the most critical condition of stability after damage. Required calculations must assume that settling of the dredged material does not occur and the spoil is an homogeneous liquid regardless of its specific gravity and further that dumping of the hopper load would not be permitted. The maximum angle of heel permitted after damage would be 30 deg, or any lesser angle where downflooding occurs. There are requirements for calculation of minimum righting arm (GZ) and 20 deg range of positive GZ after damage. Outflow of the dredged material in the hopper when the ship is heeled over is taken into account.

The various marine interests involved, including commercial hopper dredge owners, the Corps of Engineers, and design agents have been taking an active part in assisting the Coast Guard in developing appropriate rules. Most of these concerned believe that the rules, as presently proposed, are unduly restrictive in several aspects particularly with respect to not permitting the hopper load to be dumped under any circumstance, requiring high-density materials in the hopper to be treated as liquids in all cases and the proposed extent of damage to the double bottom. Comments expressing these views have been submitted by var- ious parties concerned for consideration by the Coast Guard in developing the rules in final form. The application of these rules will have a significant effect on operational efficiency. For in- stance, as a result of various considerations and other circum- stances over the past five years (as the proposed rules were being developed) the Corps' Wheeler and Essayons have design drafts that are less than their respective scantling drafts. This situation imposes a deadweight restriction on vessels that are cubic limited. It is hoped that the Coast Guard will reconsider the proposed rules in the light of the aforementioned comments and will issue appropriate guidelines for future designs as soon as practi- cable.

House and superstructure

In the past, it was often necessary to provide a superstructure containing the pilothouse and quarters for deck personnel for- ward of the hoppers as well as a deckhouse aft in order to accom- modate the remainder of the crew complement. Hopper dredges of current design with modern marine power plants and auto- mated control systems require significantly fewer operating personnel. Consequently, the house and superstructure are lo- cated in a single structure aft of the hoppers. This arrangement also facilitates the centralization of all dredging system controls in the pilothouse area so that a single operator can control the entire dredging system from a station on the bridge.

Deckhouse and superstructure decks generally are of con- ventional steel construction conforming to current marine practice. In some cases, particularly in SCHD's with very strin- gent draft limitations, the use of an aluminum alloy structure to reduce overall weight may be indicated. Consideration of this option must include provisions for increased fire-retarding in-

172 MARINE TECHNOLOGY

-

sulation as required to meet the applicable s tandards of regula- tory bodies.

Spli t -hull- type hopper dredges present a special design problem with respect to the house and superstructure. Obviously, dividing the house into two separate halves in a manner similar to the hull is impractical. Accordingly, the entire deckhouse is mounted on pivoting supports so that the entire above-deck structure remains in a horizontal position during all phases of the opening and closing process. The deckhouse unit lends itself to modularized construction which is part icularly desirable for joiner work. In addition, the deckhouse can be placed longitu- dinally to correct tr im problems.

Regardless of the type of construction involved, there is one aspect of the deckhouse design that is of prime importance. The pilothouse of a hopper dredge is the nerve center of its operations both as a dredge and as a ship. Consequently, the pilothouse ar- rangement and especially the location of the consoles associated with the operation and control of dredging systems are mat ters tha t must be given a great deal of at tention. Those consoles providing the controls and instrumentat ion to conduct and monitor dredging operations fihould be as compact as practicable. Also, notwithstanding the development of automated dredging systems and associated instrumentat ion displays that permit remote operation of the dragarms and other elements, the ability of the operator to visually observe the operation of dredging system components over the entire hopper area and as much as possible over the sides of the vessel is most important and de- sirable. A prime consideration in developing the bridge design must be this maximization of operator visibility.

Propulsion

Since they must be highly maneuverable vessels capable of turning in tight quarters, particularly when dredging in relatively narrow navigation channels which may be only slightly wider t han the length of the dredge, it has long been the general practice to equip hopper dredges with twin screws and rudders. This ar- rangement also is desirable, if not essential, when dredging along channel edges (banks) and for maintaining course in cross cur- rents encountered in certain projects. Most modern hopper dredges also are equipped with bow thrusters that serve to im- prove dredge control at slow propulsive speeds and facilitate mooring operations particularly when engaged in direct pumpout operations.

Considering the full-bodied hull form of hopper dredges and taking into account that most hopper dredging operations involve hauling distances that average about 5 miles and rarely exceed 30 miles, propulsive speeds in the 10-to-15-knot range when free-running at loaded draf t generally are adequate. However, from the s tandpoint of design, consideration of power require- ments during trailing suction dredging operations is considered to be most important. Hydraulic drag of the suction arms as well as the friction of the draghead against the bottom must be taken into account. In the past, a significant number of dredges proved to be underpowered in this respect notwithstanding the at tain- ment of design speeds of 10 knots or more in the free-running mode. The effectiveness of trailing suction dredging depends largely upon the nature of the bottom material and the speed of the suction draghead (and consequently the dredge itself) over the bottom. Experience has shown that optimum dredging speeds vary from 1 knot or less to 6 knots or more for various types of materials under diverse job conditions. For general design pur- poses, a propulsive power sufficient to permit dredging at trailing speeds of 4 knots against a 4-knot current is considered to be a reasonable requirement. This criterion is generally used in the U.S.; other areas may require more or less depending upon pre- vailing soils and currents. In addition, the adverse effect of pre- vailing shallow-water conditions at dredging sites should not be overlooked in the determinat ion of speed design requirements.

As indicated in Table 1, the propulsion power (on each pro- peller) of the various hopper dredges recently built or under construction ranges from 1000 hp for smaller vessels up to about 7000 hp for the largest. Diesel engines were the unanimous choice for propulsion plants on the ships listed. In this connection, it is noted that medium-speed (400 to 600 rpm) engines are preferred for the larger dredges (such as the Corps' Wheeler and the Stu- yvesant dredge); however, more severe space and weight con- straints on medium- and small-size hopper dredges dictate the selection of higher-speed engines (900 to 1200 rpm or more) that are more compact and lighter in weight.

Controllable-pitch (CP) propellers have been adopted by the Corps of Engineers for its new hopper dredges. The suitabil i ty of such propulsion systems has been demonstra ted from the standpoint of being able to effectively provide full power during all three principal modes of dredge operation (that is, trailing suction dredging, free-running loaded to the disposal area, and free-running light while returning to the dredging site). However, CP propeller systems are more costly than comparable fixed- pitch propeller installations. The vulnerability of hopper dredges to propeller damage due to striking submerged obstructions, steep channel banks, etc. during dredging operations also may be a factor. Fixed propellers were selected for all of the new commercial hopper dredge designs mentioned in this paper. If a fixed-pitch propeller is used, the condition selected for propeller design should be determined with care and weighted toward the trailing (dredging) conditions. I t is noted that the privately owned dredge Atchafalaya is equipped with Z-drive propulsion units with 360-deg steerable propellers.

D r e d g i n g systems

The basic mission and capabil i ty requirements of hopper dredges are given prime consideration in selecting and estab- lishing design criteria for the various elements of the dredging systems and associated power plants. To a large extent, hopper capacity and configuration dictate the size and fundamental characteristics of the pumping plant. In addition, the factors that influence most significantly the selection and design of the dredging systems are maximum dredging depth and dredged material disposal methods, part icularly with respect to require- ments for direct pumpout through long discharge pipelines and special agitation dredging considerations.

The principle elements (or subsystems) of dredging systems on hopper dredges are the following:

dragarm (suction) assemblage dredge pumps hopper distr ibution (discharge) system hopper overflow system hopper dumping system hopper pumpout system instrumentat ion

Brief discussions of these individual components, with particular reference to installations on the new hopper dredges, both Gov- ernment and commercial, are given next.

D r a g a r m (suc t ion) a s semblage . Modern hopper dredges generally are equipped with side dragarms (one port, one star- board) and sliding trunnions tha t permit each art iculated as- semblage to be raised and breasted in for stowage on deck when not in use. All of the hopper dredges recently constructed (or currently under construction) in the United States are so equipped, except for Atchafalaya, which has only a single dra- garm on the s tarboard side. In addit ion to its two conventional side dragarms, the Wheeler has a third dragarm located in a well on the longitudinal centerline of the hopper area. This dragarm, which is intended for use principally during agitation dredging operations, is provided with a sliding trunnion, but can be raised only to deck level for stowage or maintenance or both. As indi-

APRIL 1983 173

-

cated in Table 1, most of these dredges have maximum dredging depths of 70 to 80 ft, except for those of smaller hopper capacities which are designed mainly for use in nagivation channels of project dimensions (including depth) that are relatively shallow. All dragarms are breasted, lowered, positioned for dredging, raised and rebreasted by an integrated system of davits (or gantries), winches and swell compensators. The size, strength and power of components required for satisfactory operation of this system are determined by the weight of the dragram filled with dredged material, the line speed, and the clearance between the hull and dragarm under dynamic conditions. An exhaustive in- vestigation of the line pulls with different dredging depths, soil mixtures and various positions during the dredging cycle is considered necessary.

Winches can be electric or hydraulic depending on power re- quirements. Davits are usually fitted with hydraulic cylinders for breasting but could also be breasted with the winches. The design of the trunnion gantry is interesting in that it provides for automatic locking of the trunnion (or sliding piece at the forward end of the dragarm) in the inboard position. In the outboard position the trunnion is automatically aligned with the track recessed within the hull and released for lowering. The swell compensator, which is normally mounted adjacent to the drag- head davit, is the device that allows trailing suction dredging to continue to operate in moderate sea states. This device consists of a hydraulic cylinder with a farily long stroke which compen- sates for vertical movement of the ship in accordance with a preset pressure. This preset pressure is realized by use of vessels with a gas-hydraulic fluid interface pressure that must be ad- justed in accordance with the weight of the dragarm and the material being dredged.

In view of the relatively long life-span of hopper dredges and continuing long-range trends toward deeper nagivation channel depths, it is advisable that the dragarm hoisting and handling gear be designed to permit some reasonable increase in maximum dredging depth capabilities. In this regard, any possible future modifications to dragarms, such as active dragheads, submerged pumps or jetting systems, probably will necessitate significant increases in the overall weight of the assemblages. Consequently, provisions for such future increases in weight in the original de- sign are considered prudent when developing design require- ments.

Dredge pumps. The dredge pump generally is categorized as the "heart" of a hydraulic dredge. Consequently, the selection of the most suitable dredge pump for individual hopper dredges is a matter of prime importance. Dredge pumps on hopper dredges normally are low-head high-volume centrifugal pumps as opposed to those on pipeline dredges, which are high-head units. The design of dredge pumps on hopper dredges is devel- oped by analyzing each element of the suction and discharge system to determine the total head and estimating the quantity and nature (that is, density, etc.) of the dredged mixture to be handled. In development of the pump design, the volume and surface areas of the hoppers are significant factors that need to be considered. For hopper dredges equipped for direct pumpout operations, where the same pumps (either singly or in series) are used for unloading the hoppers and pumping the dredged ma- terial through long pipelines, the design must take this high-head operation into account as well as the low-head operation involved when loading the hoppers. Oftentimes, this results in the selection of pump component dimensions (such as impeller diameter) and operating range of rotative speeds that are practical compromises rather than the optimum for either operating condition. All of the new hopper dredges discussed in this paper, with the excep- tion of the Yaquina, are either equipped for direct pumpout o.r can readily be so equipped by the addition of required facilities (for example, collection system, valves or doors, discharge piping, valves) for that purpose. The future addition of such facilities is usually considered in original designs. Dredge pumps in hopper

dredges generally are located as low as possible in the hull in order to minimize the suction lift. At dredging depths of 70 ft or more, the performance of inboard dredge pumps normally drops off sharply and, as demonstrated in reference [1], the use of sub- merged dragarm-mounted pumps is indicated.

Such installations have the added advantage of providing in- creased effectiveness by being able to handle dredged mixtures of greater specific gravity than possible with inboard pumps when operating at most current channel depths. The desirability of locating the dredge pump in the suction assemblage has been long recognized, but problems associated with transmitting the power (mechanical, electrical or hydraulic) required for this purpose and the at tendant operational and handling difficulties were discouraging factors. However, the development in recent years of relatively large electric motors (in the order of 1500 hp) spe- cifically designed for underwater applications has made the in- stallation of submerged dredge pumps practical. Such pumps usually are located about halfway up the dragarm and increase significantly overall dragarm weights. Therefore, heavier sup- porting structures and handling gear (including more winch power, etc.) are required. The Wheeler and the Essayons are being equipped with submerged dredge pumps on their side dragarms that are driven by submersible a-c electric motors. The motors on the Wheeler are oil-cooled and those on the Essayons are water-cooled, thereby providing a basis for obtaining com- parative operating characteristics, maintenance experience, etc. of these two different design types in actual practice.

Hopper d is t r ibut ion (discharge) system. The hopper distribution system (piping, valves, chutes, troughs, gates, etc.), which conveys the dredged mixture from the dredge pump to the point(s) of discharge into the hopper, usually is a subject of much discussion during the course of the design development. Dredge designers and operations managers often disagree as to the effi- cacy of alternative arrangements to load the hoppers uniformly and effectively (minimum overflow losses) with diverse types of materials ranging from heavy (rapidly settling--retainable) materials such as coarse sand and gravel to fine-grained, light, silty materials that settle very slowly and are essentially nonre- tainable after overflow in reached. Consequently, the configu- ration of hopper distribution systems on new dredges varies to some degree. In most cgses, however, the system consists of a pipe or chute fitted with gate-type or other valves that permit the dredged mixture to be distributed over the length and breadth of the hopper. The chute generally terminates in a baffled di- vergent section or diffuser that serves to reduce the flow velocity and spread the material as it drops into the hopper. This is especially desirable when handling relatively nonretainable materials. The distribution pipe or lander over the hopper is generally provided with a number of controllable discharge gates or openings along its entire length to permit discharge when handling relatively retainable materials. This helps effect uni- form hopper loading. The need for providing a means of con- trolling material distribution in the hoppers, and satisfactorily controlling vessel draft, list and trim during the hopper loading process is a most important design consideration. In addition, hopper distribution systems generally are subject to severe wear, particularly when handling erosive granular materials; therefore, ease of replacement must be given due consideration.

Hopper overf low system. During the course of loading, hoppers can be filled only to an overflowievel. When pumping beyond this level, excess water and/or lighter fractions of the dredged mixture are discharged overboard. As indicated in the previous discussion of hopper capacity, the in-place density of bottom materials generally handled by hopper dredges varies over a broad range. Consequently, with any given loaded draft or load line, the volume of dredged material that can be carried in the hoppers will vary inversely with its in situ specific gravity. The lighter the material, the greater the volume (up to the maximum hopper capacity) that the dredge can carry. In order

174 MARINE TECHNOLOGY

-

to provide some degree of flexibility in the use of hopper capacity (volumetric) most suited to the particular material being dredged, most dredges are provided with several overflow levels. These levels are predetermined on the basis of the range of densities expected to be encountered and provide a practical means of readily selecting, for a particular dredge, the hopper capacity that is most economically compatible with its design draft for the specific material being dredged. In its three new hopper dredges, the Corps of Engineers has gone a step further toward optimizing production by providing them with continuously variable over- flow levels which readily permit height adjustment, either manually or automatically, during the hopper loading process. This continuous adjustment is particularly useful when dredging readily retainable materials (such as heavy coarse-grained sand), by taking advantage of the burnout of consumables (fuel, etc.) aboard the dredge.

Hopper dumping system. As previously indicated, one of the basic design criteria for Corps hopper dredges is tha t the dump doors in the open position shall not extend below the ship's bottom. Also, in the case of its new dredges, door openings are substantial ly larger in relation to hopper area and volume than in any of its previous designs. No undue difficulty is anticipated in dumping dredged material usually encountered on hopper dredge projects. Jet t ing systems are provided that can be em- ployed for hopper washdown as may be required to facilitate dumping of any "sticky" materials or those tha t may have a tendency to arch over the dump door openings. The dump doors on the Yaquina are electrically operated and those on the Wheeler and Essayons are hydraulically operated. In all cases these doors can be operated singly, in pairs (port and starboard) or all at one time as circumstances may require. As indicated in the preceding discussion of hull and hopper capacity, spli t-hull hopper dredges are distinctly advantageous from the s tandpoint of dumping operations. The continuous wide opening tha t is unobstructed and runs the entire length of the hopper as the hull is opened permits rapid and uniform dumping of diverse types of dredged materials.

Hopper pumpout system. Except for the Yaquina, which is a small-capacity dredge intended for use mainly in shallow ocean bar inlet channels on the West Coast, all of the new hopper dredges in the United States are equipped or can be readily modified for direct pumpout operations. I t is ant icipated tha t this disposal method will become more prevalent, part icularly in coastal areas where there is a need for sand for beach rehabil- i tat ion and nourishment purposes. In recognition of this antici- pated need, the pumping plants of the Wheeler and Essayons have been designed so that sand can be pumped through dis- charge lines of two miles or more without the use of booster pumping stations. Since these Corps dredges are also equipped with submerged dragarm-mounted dredge pumps that are de- signed exclusively for hopper loading, the design of the inboard pumps is based principally upon their use for direct pumpout operations, and more than satisfies this long-distance pumping requirement when operating in series. In this connection, it ap- pears that the dredge pumps on the commerical hopper dredges discussed in this paper are designed mainly for the normal, rel- atively low-head operation required for hopper loading and have a l imited discharge capabil i ty for direct pumpout operations. Series operation of inboard pumps is generally provided for pumpout.

The hopper collection (or suction) system required for direct pumpout operations essentially consists of piping or ducts with necessary valves or doors and a sea suction (for dilution water) running longitudinally the entire length of the hoppers to permit controlled unloading of its contents. Also, a jet t ing system is provided in most cases to minimize any possibility of plugging. The internal spaces of the void compartments surrounding the hopper are extremely restricted, making it very difficult to fit in the facilities required, and thus present problems in construction

as well as future maintenance and repair. This is particularly true in the case of the Corps designs.

I n s t r u m e n t a t i o n . The progress and results of dredging operations usually are determined by making hydrographic surveys before, during and after dredging, and computing the volume of material removed from within project limits between surveys. However, as discussed in reference [6], these means of gaging dredge performance are based on after- the-fact field measurements tha t are of l imited value for control purposes aboard the dredge itself during actual operations. Inst rumenta- tion for measuring and controlling various elements of the hy- draulic dredging process is considered essential to ensure tha t dredge productivity is maintained at levels comparable to desgin capabilities. The need for instrumentat ion on hopper dredges has been long recognized by responsible management personnel and the development of equipment tha t is reliable and maintai- nable has been going on for many years, both in the United States and abroad. Devices and systems specially designed for dredge use that display or provide continuous information on draghead depth, dragarm position, dredge pump suction vacuum/discharge pressure, flow velocity/density, solids flow rate/ total izer and hopper load/draft are now available and given general acceptance by dredge owners. The Corps of Engineers has been in the fore- front of efforts in the United States to develop, test and evaluate such instrumentat ion as a means toward improving its dredges and their operation. The new hopper dredges, both commercial and Government owned, are equipped with all of the aforemen- t ioned systems. These instruments also serve to provide intelli- gence or signals or both required for automatic control of various elements of the hopper dredging process as discussed under the following sections on automation and other developments.

Automat ion

Significant new developments in hopper dredge design tha t have been mentioned or described in preceding sections of this paper include:

split-hull construction submerged dragarm-mounted dredge pumps continuously variable level overflows

In addition, pr imari ly in order to reduce crew requirements, automation of both ship and dredging machinery has been in- corporated to a large extent in all of the new hopper dredges for operation in the United States: With respect to propulsion and other ship systems, these vessels generally are built with the ca- pabil i ty for operation with unat tended engine rooms in accor- dance with USCG Navigation Circular No. 1-69, dated 8 January 1969 and are inspected and classed by ABS with Maltese Cross ACCU certification. Also, in all cases, the dredging system as a whole on these vessels is designed to be operated by a single of- ficer (or dredgemaster) at a central control station on the bridge. On all Corps dredges, dragarm handling is completely automatic from the stowed position on deck to the dredging positions, during the dredging cycle and return to the stowed position. Also, on the Wheeler and Essayons, the Corps has provided for auto- mation to the maximum extent practicable of various elements of the hopper dredging process as means for at taining more ef- fective control and opt imum efficiency of operation. Major por- tions of the automation system or devices or both being provided on the aforementioned hopper dredges are prototype designs or applications, as described in some detail in reference [7]. In particular, "f i rs t - t ime" automatic control systems are included that provide for:

governing hopper loading by automatically raising and lowering variable overflow levels (forward or aft, port or starboard) in response to preset instructions and to vessel trim, list and draft;

control of the hopper dumping operation by opening/closing

APRIL 1983 175

-

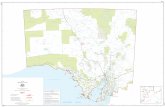

Fig. 12 Hopper dredge/oil recovery vessel (Cosmos)

dump doors in timed sequence pursuant to preset instruc- tions, and

automatic control of hopper unloading (including prevention of discharge line plugging) during direct pumpout opera- tions.

Other developments

Other new developments worthy of mention, but which have not as yet been adopted on any hopper dredges in the United States, are discussed briefly in the following:

Active dragheads . Standard dragheads are relatively in- efficient in hard compact soils, particularly in plastic clay. Fitting suction heads with scrapers or cutting edges to improve efficiency in these soils is a solution that has been tried with many varia- tions. It is noted that, with such installations, the cutting forces developed must be transferred through the suction pipe from the propulsion system. In the case of compacted sands, the use of water jetting nozzles fitted to the draghead has served to increase production, and a further increase in production in such materials can be gained by recirculating the overflow mixture through the draghead jetting system. However, the most significant im- provement that can be gained in both compacted sands and plastic clays is by the application of hydraulically driven rotary cutters within the draghead itself. Tests with developmental and prototype units in The Netherlands have shown dramatic in- creases in production in such materials. Plastic clay is very co- hesive and the loading of relatively large masses or "balls" of this material could cause severe dumping problems in hopper dredges with conventional dumping doors. The split-hull type dredge is particularly advantageous for use in conjunction with active ro- tary dragheads if substantial quantities of this type of soil must be dredged in locations where heavy traffic or adverse sea con- ditions make the use of conventional cutterhead pipeline dredges impractical.

Multipurpose hopper dredge. The Cosmos, a combination trailing suction hopper dredge and oil pollution control vessel, was recently delivered in The Netherlands. The primary use of this dredge is maintenance dredging of Europort channels in the Rotterdam area; and it is designed and fitted with all the normal equipment required to carry out this mission. However, the vessel is also equipped with oil recovery arms for skimming and re- moving spilled oil from the water surface. For this purpose an oil pump room is provided and, since the oil is collected in the hop-

pers, all the requirements of regulatory bodies that normally are applicable to tankers must be met. Details of this dual-purpose plant are given in reference [3]. Figure 12 is a photograph that shows some details of the Cosmos.

Unfortunately, the extensive changes required to meet oil tanker rules make it impractical to convert an existing hopper dredge to perform oil spill cleanup operations.

Conclusion

Seagoing trailing suction hopper dredges are distinctive ships as well as complex, highly versatile dredging plants that are es- sential for the construction and maintenance of coastal port channels. The design of these vessels involves many consider- ations and this paper only highlights certain aspects that are considered of interest. As indicated, the construction of a number of new hopper dredges in the United States has resulted in in- creased attention being given to their design and construction by all elements of the marine industry, including designers, manufacturers, suppliers, and shipbuilders. This renewed activity has contributed significantly toward the development of new hopper dredges that are able to perform effective and economical dredging operations required for the improvement and mainte- nance of navigation channels. It is hoped that this paper will serve to encourage and sustain a continuing interest in the subject by those concerned with hopper dredge design, construction, op- eration, and maintenance.

Metric Conversion Factors

1 ft = 0.3048 m 1 in. = 25.4 mm

1 yd 3 = 0.7645 m 3 I mile = 1.6 km

1 nautical mile = 1.852 km 1 psi = 6.894 kPa 1 hp = 0.7457 kW

References

1 Fortino, Ernest P., "New Approaches to the Design of Hopper Dredges," MARINE TECHNOLOGY, Vol. 17, No. 4, Oct. 1980, pp. 371- 384.

2 Murden, William R. and Mauriello, Louis J., "Hopper Dredge Design Considerations," Proceedings, Ninth World Dredging Conference (WODCON IX), Vancouver, B.C., Canada, Oct. 29-31, 1980, pp. 149- 173.

3 van Dooremalen, J. J. C. M. and van Drimmelen, N. J., "The Ef- fective Combination of Modern Dredging and Oil Spill Recovery Tech- nologies on the 'Slicktrail,' "SNAME, New York Metropolitan Section, Oct. 1979.

4 "Freeboard of Dredgers and Barges Fitted with Bottom Doors," Bureau Veritas, Guidance Note N.I. 144 BM.1, Oslo, Norway, Jan. 1971.

5 Federal Register, Vol. 44, No. 238, Monday, Dec. 10, 1979, Proposed Rules, "Hopper Dredges; Load Line and Stability Requirements," issued by the U.S. Coast Guard, Dec. 5, 1979.

6 Mauriello, Louis J. and Denning, Rick A., "Assessing and Con- trolling Hydraulic Dredge Performance," Proceedings, World Dredging Conference (WODCON 1968) Oct. 1968, pp. 486-506.

7 van Dooremalen, J. J. C. M., Lohman, T. A. M., and Cornelis, C. A., "Automation on Trailing Hopper Dredges," Proceedings, Ninth World Dredging Conference (WODCON IX), Vancouver, B.C., Canada, Oct. 29-31, 1980, pp. 873-887.

Discusser

Alexander Izett

176 MARINE TECHNOLOGY