Marine Nitrogen Generators, Pres Vac Brochure I

Transcript of Marine Nitrogen Generators, Pres Vac Brochure I

-

8/10/2019 Marine Nitrogen Generators, Pres Vac Brochure I

1/16

Marine Nitrogen Generators

enabling intelligent tank venting

-

8/10/2019 Marine Nitrogen Generators, Pres Vac Brochure I

2/16

2

Introduction

Contents

PSA technology 3

Overall design 6

Main features 8

Benefits 10

Specifications 12

Applications 13

Safety and compliance 14

Service and maintenance 15

Pres-Vac Marine Nitrogen Generators are a product of Pres-Vac Engi-

neering ApS, which has more than 60 years' experience in tank venting

systems. The marine nitrogen generators are the latest products in our

range of advanced tank venting solutions.

Pres-Vac Marine Nitrogen Generators provide systems for the marine- and

off-shore industry, which demands clean, dry nitrogen of high purity for

inerting, blanketing and purging.

Using Pres-Vac Marine Nitrogen Generators results in a cost reduction of

30-70% compared to conventional nitrogen generators. Safety, reliability,

simple installation and a small footprint characterise our systems.

2

-

8/10/2019 Marine Nitrogen Generators, Pres Vac Brochure I

3/16

3

PSA technology

Pressure swing adsorption (PSA) and membrane gas separation

are the two most common technologies available when producing

on-site nitrogen. Flue gas systems can also be used for inerting

cargo tanks. However, due to the high level of impurities in flue

gas, the use of these systems is limited to crude oil cargoes

and can be excluded when transporting clean cargoes, that are

vulnerable to contamination.

Traditionally, most nitrogen generators have been based on mem-

brane technology, but PSA technology has proven to be superior,

offering numerous operational advantages and greater cost

efficiency. Today, PSA technology is regarded as the technology of

the future, when it comes to the on-site production of nitrogen.

In existence for over 100 years, PSA technology is used exten-

sively for various on-shore applications. Compared to convention-

al membrane technology, PSA technology is significantly simpler

and much more energy efficient, resulting in large savings on

overall operational costs.

The base material used in the PSA process is carbon molecular

sieve (CMS), which is a non-toxic, non-flammable carbon-based

material processed into a porous material using various additives.

A stable, passive material, CMS is not consumed and does not

wear down or deteriorate when producing nitrogen.

At ambient air pressure, CMS does not react to air. When exposed

to 6-10 bars of pressurized air, however, CMS starts adsorbing

(capturing) oxygen molecules and allows nitrogen to pass.

When pressure is reduced, the adsorption process stops and the

oxygen molecules are released from the porous surface of the

CMS.

The efficiency of CMS in the Pres-Vac Marine Nitrogen Genera-

tor remains constant over the entire system life cycle. The CMS

material has a designed lifetime of more than 40,000 operation

hours.

CARBON MOLECULAR SIEVE - CMS

CMS CHARACTERISTICS

No deteriorations

Non-flammable

Non-toxic

Lifetime of more than 40,000 operation hours

Pellet size: 2-5 mm

-

8/10/2019 Marine Nitrogen Generators, Pres Vac Brochure I

4/16

PRESSURE SWING ADSORPTION (PSA)

PSA technology

4

A PSA system requires a minimum of two identical pressure ves-

sels filled with CMS. One pressure vessel is always in nitrogen

producing mode, while the other is in recovery mode. After about

one minute, the pressure between the two vessels is equalised.

Subsequently, the modes swing and when the vessel is in recov-

ery mode, it enters production mode and the pressure vessel in

production mode enters recovery mode.

This alternating process is referred to as pressure swing adsorp-

tion.

A sequence controlled valve system distributes compressed air

into the pressure vessel, as described below.

PSA production mode pressure vessel 1

Exhaust valve C1 is closed and Outlet valve A1 and Inlet valve

D1 open.

Compressed air starts to flow through the pressure vessel 1.

Oxygen is captured by the CMS and the nitrogen leaves thepressure vessel through N2outlet.

After approximately one minute the production mode stops

and Outlet valve A1 and Inlet valve D1 close.

PSA recovery mode pressure vessel 2

Outlet valve A2 and Inlet valve D2 are closed and Exhaust

valve C2 opens.

A small flow of nitrogen from tank 1 is purged into the top of

tank 2, flushing the oxygen adsorbed by the CMS out of thetank via Exhaust outlet.

D1

N2outlet

A2

Exhaust outlet

Air inlet

C1

B

A1

21

C2

D2

-

8/10/2019 Marine Nitrogen Generators, Pres Vac Brochure I

5/16

5

PRESSURE SWING ADSORPTION (PSA)

O2 N2

O2

N2

Exhaust

outlet

Exhaust

outlet

N2

CMS

-

8/10/2019 Marine Nitrogen Generators, Pres Vac Brochure I

6/16

6

Overall design

NITROGEN PROCESS MODULEFLEXIBLE DESIGN

The main components in the nitrogen process module are:

PSA adsorption modules, control system, oxygen analyser, flow

regulators and control valves. The nitrogen process module is

standard skid mounted and both coal tower and pre-micron

filter are also mounted on the skid for customer convenience.

The PSA units can also be delivered as split units. This will ena-

ble individual location of the components in the nitrogen supply

module and thereby safe installation space making Pres-Vac

Marine Nitrogen Generators ideal for retrofitting.

Pres-Vac Marine Nitrogen Generators are delivered as complete

system packages using a standard hardware platform. The

system comprises two main modules:

Air supply module

Nitrogen process module

Delivered pretested and ready to use with few external con-

nections and minimised cabling, the modules can be installed

quickly and easily.

Dry air outlet from 0-10 barsN2outlet High purity nitrogen flowsfrom PSA 0.13-0.17 bars

N2outlet High purity nitrogen flows

from PSA 0-10 bars

PSA Porous CMS material adsorbs

oxygen molecules

Filters Remove particles from

compressed air

6

-

8/10/2019 Marine Nitrogen Generators, Pres Vac Brochure I

7/16

7

Main components in the air supply module:

Compressors

Air dryers

Coal tower

Pre-micron filters

The coal tower and the filters are physically

located on the PSA unit.

Compressors and air dryers are delivered as stand-alone units,

which can be installed at individual locations.

Compressors and air dryers are advanced systems. Developing

and producing them is thus limited to a number of highly special-

ised international companies.

Because Pres-Vac is not associated with any specific manufac-

turer, we are able to meet the preferences of our customers and

thus deliver air packages from all major manufactures.

AIR SUPPLY MODULE

Compressor Increases air pressure

to required level from 4-12 bars

Air dryer Removes moisture from air by

condensation of the compressed air

Coal towerAbsorbs fractional impurities

and oil particles from the inlet air

7

Air inlet pressure From 4-12 bars

-

8/10/2019 Marine Nitrogen Generators, Pres Vac Brochure I

8/16

8

Main features

A limited number of physical inter

installation 14 different standard

Capacity range: 75-10,000 Nm3

/ N2purity range from 95-99.999

Voltage 3 x 380/440V, 50/60 Hz

Flow control of outlet flow and pr

Ideal for retrofitting

The PSA unit can be delivered as split components, which

enables individual placement and utilises limited space

optimally.

Compact design and simple installation

Modest footprint.

Easy integration few external connections.

Minimised cabling provides quick and easy installation.

No receival- or buffer tanks required.

Modular system components.

High performance

Low power consumption due to effective system utilisation.

Reduced investments in onboard generator capacity.

Avoidance of critical overload and blackouts.

Optimised off-loading conditions shorten discharge time

8

-

8/10/2019 Marine Nitrogen Generators, Pres Vac Brochure I

9/16

9

points means quick and easy

ems

re.

Advanced hardware

Dry air supplied to e.g. ballast tanks

Low noise exhaust silencer below 82 dB(A)

Alarm monitoring of filters for increased safety

Angle seated valves for more precise PSA sequence control

Operation

Easy and intuitive touch screen operator interface.

Fully automatic control system offering various operational

modes

Modbus communication enables easy integration with cargo-,

alarm- and control systems

Remote condition monitoring and optimisation via built-in

modem

Wear and tear

System efficiency remains constant over entire life cycle

CMS material does not deteriorate no replacement or up-

grades required

Few components mean less mechanical wear

Dry air means no interior corrosion

9

-

8/10/2019 Marine Nitrogen Generators, Pres Vac Brochure I

10/16

10

Benefits

+Lower investment costs and safer operation

Nitrogen generators normally operate with other heavy

energy consumers (e.g. engine, cargo and ballast pumps).

Consequently, allocating sufficient electric power without

compromising the limits of the vessels generator system is

often a challenge. The significantly lower power consump-

tion of Pres-Vac Marine Nitrogen Generators compared to

conventional membrane systems means the size of the

switchboard and generators can be considerably reduced in

most cases.

For example, the power consumption of a Pres-Vac 4,500

Nm3/hour@95 nitrogen generator is 1,030 kW. A conven-

tional membrane-based nitrogen generator with the same

capacity has a power consumption of 1,460 kW.

Consequently, using a Pres-Vac system reduces a vessels

power demand by 430 kW.

One more substantial advantage is that a lighter load on

the switchboard and generators reduces the likelihood of

overloading and blackouts.

A reduced power demand means smaller generators. In the

above example, the generator power costs are roughly

500 USD/kW. The capital expenditure savings could be

approximately 220,000 USD.

Lower operational costs (OPEX)

A Pres-Vac Marine Nitrogen Generator consumes as little as

0.23 kW per produced m3nitrogen at a purity of 95%.

Conventional membrane systems consume 42% more

energy at same purity.

At a purity of 99.9%, the power consumption of a conven-

tional membrane system is up to 85% higher compared to a

Pres-Vac Marine Nitrogen Generator system.

For example, operating a Pres-Vac 4,500 Nm3/hour@95%

nitrogen generator 1,500 hours a year can result in savings

of approximately 705,000 kWh per year.

Assuming that the on board production cost of a kWh is

0.25 USD/kWh, OPEX can be reduced by 160,000 USD/year.

+

1010

-

8/10/2019 Marine Nitrogen Generators, Pres Vac Brochure I

11/16

11

+Lower maintenance costs

CMS is a passive substance and does not degrade or dete-

riorate when producing nitrogen. The efficiency of the CMS

in the Pres-Vac Marine Nitrogen Generator remains constant

over the entire system life cycle. The CMS does not need to

be replaced or upgraded.

Maintenance is limited to daily inspections and yearly

replacement of filter cartridges. Depending on the manufac-

turer, compressors normally require service at 3,000-hour

intervals.

In conventional membrane-based systems, the vulnerability

of the membranes makes them consumables. Mechanical

and biological contamination gradually reduces their effi-

ciency. Consequently, the capacity of a membrane system

slowly decreases, resulting in the need for its replacement

every five to seven years.

Less efficient membranes entail an increase in operational

costs as more energy is required to maintain a constant

capacity. The estimated cost of replacing membranes isabout 35% of the systems total cost upon installation. Any

off-hiring during retrofitting of membranes could also gener-

ate loss in vessel earnings.

0.0

0.5

1.0

1.5

2.0

Membrane

N/A

95 99 99.9 99.998 Purity

N2%

kW/m3N2

PSA vs. membrane

difference i power consumption

PSA

Membrane

99.998 Purity

N2%

Capacity m3/h N2

System capacity at different purities

95 99 99.9

4,500

3,375

2,250

1,125

0

PSA

Membrane

Membrane

N/A

1111

-

8/10/2019 Marine Nitrogen Generators, Pres Vac Brochure I

12/16

12

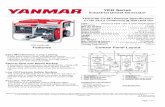

Specifications

Model Standard Capacity Number of compressors Number of dryers Number of PSA units

PV 10 75 Nm3/hour@95%

PV 20 110 Nm3/hour@95%

PV 30 160 Nm3/hour@95%

PV 40 280 Nm3/hour@95%

PV 50 450 Nm3/hour@95%

PV 60 600 Nm3/hour@95%

PV 70 900 Nm3/hour@95%

PV 80 1,250 Nm3/hour@95%

PV 90 1,800 Nm3/hour@95%

PV 100 2,300 Nm3/hour@95%

PV 110 3,500 Nm3/hour@95%

PV 120 4,500 Nm3/hour@95%

PV 130 5,800 Nm3/hour@95%

PV 140 7,000 Nm3

/hour@95%

STANDARD SYSTEM RANGE

Air supply module

Non hazardous area Non hazardous area

Nitrogen process module

Power supply

Fresh water cooling

Air inlet

Dry air outlet

(optional)

Air dryer

Pre-micron

filters

Air

compressors

PSA adsorption vessels

N2outlet

Deck storage

vessel (optional)

Oxygen analyser

Post-

micron

filter

Nitrogen flow

regulator

Carbon

tower

Hazardous

area

Double block

and bleed

(optional)

-

8/10/2019 Marine Nitrogen Generators, Pres Vac Brochure I

13/16

13

Applications

Inerting cargo tanks during discharge

Blanketing cargo tanks

Purging pipelines

Blanketing tanks during discharge

Purging

Purging drill mud

Blanketing tanks during discharge Purging

Purging drill mud

Inerting cargo tanks during discharge

and tank repair

Blanketing cargo tanks

Purging pipelines

Inerting cargo tanks during discharge

Blanketing

Purging pipelines

BOP supply

OIL AND PRODUCT TANKERS

SUPPLY VESSEL

GENERAL PURPOSE

LEG, LPG & LNG CARRIERS

DRILLING AND OFF-SHORE

-

8/10/2019 Marine Nitrogen Generators, Pres Vac Brochure I

14/16

14

Safety and Compliance

Safety. Compliance. Performance.Safety and regulatory compliance go hand in hand. Based on a firm under-

standing of the rules and requirements, Pres-Vac products are developed to

pass approval processes and to operate for many years.

REGULATORY COMPLIANCE

Pres-Vac Nitrogen Generators comply with all relevant standards.

Our goal is to be best in class .

IMO COMPLIANCE

Pres -Vac Nitrogen Generators comply with the IMO International

Convention for the Safety of Life at Sea (SOLAS).

CLASS COMPLIANCE

Pres-Vac Nitrogen Generators complies with rules from major

classification societies.

MED MARK OF CONFORMITY - WHEELMARK

Marine equipment can only be installed onboard ships flying

the flag of an EU country, Norway or Iceland (EFTA countries),

or other flag states if marked with the MED Mark of Conformity.

Pres-Vac Marine Nitrogen Generators comply with the mostrecent amendment of MED 96/98/EC. Pres-Vac Marine Nitrogen

Generators are listed in the MarED Product Database.

NOISE COMPLIANCE

Pres-Vac Marine Nitrogen Generators comply with the Code on

Noise Levels on Board Ships.

DESIGN AND MANUFACTURING

All of our models incorporate the requirements of leading agen-

cies. Every order undergoes a design assessment by a selected

agency. Pres-Vac Marine Nitrogen Generators are designed and

manufactured according to PED (97/23/EC), ISO 9001 (Quality)

and ISO 14001 (Environmental), certified by Apragaz

FACTORY ACCEPTANCE TEST - FAT

FAT inspections ensure that the system is built according to

pre-approved design documents and cover testing, scope, sup-

ply, manufacturing processes, functionality and performance.

When the FAT report is approved, the system is shipped to the

yard for installation and commissioning.

COMMISSIONING

Commissioning, which is conducted in the yard, ensures that the

system is installed and lives up to the FAT.

Participation in Sea Acceptance Test (SAT) is optional.

-

8/10/2019 Marine Nitrogen Generators, Pres Vac Brochure I

15/16

15

Pres-Vac locations

Certified Pres-Vac Service Centers SRC

Upcoming Service Centers

Active in the marine market since 1952, Pres-Vac has estab-

lished an extensive worldwide network that also includes various

international service and repair centres in strategic marine hubs.

The technical skills and marine experience these centres have in

repairing Pres-Vac equipment allow us to provide a high level of

service for all our customers.

Conveniently located around the world, our Service Repair

Centres permit rapid access to spare parts and qualified service

repair engineers.

The number of Service Repair Centres is steadily growing and

new locations will appear in the near futu.

Service and Repair Centre skills

Our service engineers have been trained and certified to overhaul

Pres-Vac products according to our specifications. Our engineers

carry individual Pres-Vac ID cards, so you know you are getting

the service you trust and expect.

Dynamic Performance and Monitoring System

Pres-Vac is currently developing a dynamic maintenance and per-

formance system (DMPS). A built-in modem enables both users

and Pres-Vac to retrieve system process and performance data.

System data are retrieved and analysed on a regular basis, while

the system performance is compared to previously recorded data

to determine whether the system should be adjusted.

This approach will ensure that the nitrogen system remains 100%

operative and that it will constantly deliver the best performance

possible. Performance data are also used for preventive main-

tenance, enabling online adjustments and live advice in order to

avoid failures or malfunctions in a timely manner.

Pres-Vac Service Repair Centres Pres-Vac locations

NETWORK OF SERVICE REPAIR CENTRES

Service and Maintenance

-

8/10/2019 Marine Nitrogen Generators, Pres Vac Brochure I

16/16

Pres-Vac Engineering ApS

Svanevang 3-5

DK-3450 Allerd

Denmark

Tel. +45 48 17 40 55

Fax +45 48 17 17 88

Email [email protected]

Website www.pres-vac.com

nitrogen

About Pres-Vac Engineering ApS

For more than 60 years, Pres-Vac Engineering

has been supplying pressure/vacuum valves

and venting equipment to the tanker shipping

industry.

Today, we are the worlds leading supplier of

intelligent tank venting and roughly 50% of

all tanker vessels world-wide use Pres-Vac

equipment.

We work with shipyards, naval architects and

other partners on all continents. We have a

network of highly professional, experienced

agents and distributors in all major ship own-

ing and ship building countries.

002/liOktober2014

Thiscatalogue

issubj

ectto

change

and

/orprinting

errors.