Marginal Cost Accounting-1

-

Upload

laxman-zagge -

Category

Documents

-

view

19 -

download

0

description

Transcript of Marginal Cost Accounting-1

Cost accounting Cost accountingis a process of collecting, analyzing, summarizing and evaluating various alternative courses of action. Its goal is to advise the management on the most appropriate course of action based on the cost efficiency and capability. Cost accounting provides the detailed cost information that management needs to control current operations and plan for the future. Since managers are making decisions only for their own organization, there is no need for the information to be comparable to similar information from other organizations. Instead, information must be relevant for a particular environment. Cost accounting information is commonly used infinancial accountinginformation, but its primary function is for use by managers to facilitate making decisions. Unlike the accounting systems that help in the preparation offinancialreportsperiodically, the cost accounting systems and reports are not subject to rules and standards like theGenerally Accepted Accounting Principles. As a result, there is wide variety in the cost accounting systems of the different companies and sometimes even in different parts of the same company or organization.DEFINITION OF 'FULL COSTING' A managerial accounting method that describes when all fixed and variable costs, including manufacturing costs, are used to compute the total cost per unit. Full costing includes these costs when computing the amount of money it takes to produce and distribute one unit of output.

Full costing is also known as "full costs" or "absorption costing".Cost: The total money, time, and resources associated with a purchase or activity. METHODS OF COSTINGFixed cost:Includes all costs that do not vary with activity for an accounting period. Fixed costs are, at any time, the inevitable costs that must be paid regardless of the level of output and of the resources used. A Fixed Cost is therefore not an Opportunity Cost. Overhead is considered a fixed cost, even though it may vary somewhat according to the amount of activity. Any cost that does not vary depending on production, volume, use, or sales levels, such as rent, property tax, insurance, or interest expense. Related Terms: variable cost, total cost, fixed expenses Variable cost: All other costs that are some function of activity. They are usually considered linear because the unit cost is computed by dividing the total other costs for a period, or event, by the amount of activity in the period. The linear assumption is a matter of convenience. As the level of activity is varied, the non linearnature of the variable costs are revealed. A cost of labor, material or overhead that changes according to the change in the volume used. Combined with fixed costs, variable costs make up the total cost. While the total variable cost changes with increased usage, the total fixed cost stays the same. Related Terms: fixed cost, break-even analysis Total costs are usually expressed as Fixed + Variable Total Cost Definition 1: In accounting, the sum of fixed costs, variable costs, and semi-variable costs. Definition 2: In the context of investments, the total amount spent on a particular investment, including the price of the investment itself, plus commissions, fees, other transaction costs, and taxes. Related Terms: average price per share, original cost Mixed Cost: A cost with both fixed and variable elements.Direct cost: Costs that can be identified directly with a particular process, project, or program.Indirect cost: Costs associated with an enterprise, activity, etc. which are not identified as direct costs, but which may be included in the accounting. Incremental Costs (& Revenue): Those costs (or revenues) that change due to an incremental change in activity, as compared those that are unaffected.

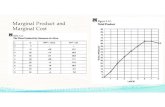

Marginal Cost: The cost associated with one additional unit of production or use, also called incremental cost. Opportunity Cost: The benefit foregone by choosing one course of action over another, or the net revenue that is forgone by not allocating resources to another alternative use. The opportunity cost is the correct measure of the cost of resources for Systems Analysis. Whereas it can be equal to the price paid for a resource, it is often different from the outlay cost. Resources may cost something to use (or not use) even though no monetary price is paid to another entity for them. The opportunity cost is the Shadow Price of a resource. In effect opportunity costs, in representing the cost of having less of a resource, measure the rate of change of benefits per unit change in resource. The opportunity cost of money is a measure of the maximum benefit that, for any given situation, can be obtained from any extra unit of capital. A useful distinction can be made between resources that can be identically replaced (such a materials, money, etc.) and those that are somehow unique (e.g. a piece of property). For strictly replaceable resources for which there is a ready market, the opportunity cost is simply the market cost of replacement, or equivalently, the salvage price of the resource if it is already at hand and will not be replaced. Measuring opportunity cost is not particularly easy. For example, if an asset such as capital is used for one purpose, the opportunity cost is the value of the next best purpose the asset could have been used for. Opportunity cost analysis can be an important part of a decision-making processes, but is not treated as an actual cost in any financial statement. Related Terms: cost of capital, cutoff point, idle, comparative advantage, economic value added Sunk Costs: -Theoretically those prior costs which cannot be recovered. For normal private sector accounting purposes, the sunk cost is the difference between book value and salvage value of an asset. This definition is disputed by some accountants as there is a historical cost element (any prior spending), and a future (negative cost or) revenue element, if salvage is eventually undertaken. For the public sector it is usually any money spent previously on a program or project that can never be recovered, i.e., costs already incurred which cannot be recovered regardless of future events. Sunk costs should be ignored in determining whether a new investment is worthwhile.

Life Cycle It Costs are the total cost to an organization for acquisition and ownership of a product or asset over the life of the asset. For example, the life cycle cost of a school includes all of the future maintenance and repairs, as well as the initial construction and fixtures cost. This is sometimes referred to as capital costs plus operating costs, or onetime costs plus recurring costs. Any program should calculate life cycle costs. Cost-Effectiveness Analysis. A program is cost-effective if, on the basis of life cycle cost analysis of competing alternatives, it is determined to have the lowest costs expressed in present value terms for a given amount of benefits. Cost-effectiveness analysis can also be used to compare programs with identical costs but differing benefits. In this case, the decision criterion is the discounted present value of benefits. The alternative program with the largest benefits would normally be favored. OMB Circular No. A-94 Depreciated Cost: The original cost of an asset minus total its depreciation thus far, also called net book value or written-down value. Standard Costing: A management tool used to estimate the overall cost of production, assuming normal operations. Transaction Costs: Costs incurred when buying or selling assets, such as commissions and the spread. Unit Cost: Cost per item.

Meaning Marginal Cost: The tenn Marginal Cost refers to the amount at any given volume of output by which the aggregate costs are charged if the volume of output is changed by one unit. Accordingly, it means that the added or additional cost of an extra unit of output. Marginal cost may also be defined as the "cost of producing one additional unit of product." Thus, the concept marginal cost indicates wherever there is a change in the volume of output, certainly there will be some change in the total cost. It is concerned with the changes in variable costs. Fixed cost is treated as a period cost and is transferred to Profit and Loss Account. Marginal Costing: Marginal Costing may be defined as "the ascertainment by differentiating between fixed cost and variable cost, of marginal cost and of the effect on profit of changes in volume or type of output." With marginal costing procedure costs are separated into fixed and variable cost. According to J. Batty, Marginal costing is "a technique of cost accounting pays special attention to the behaviour of costs with changes in the volume of output." This definition lays emphasis on the ascertainment of marginal costs and also the effect of changes in volume or type of output on the company's profit. Marginal costing extends the contribution idea that is used for CVP analysis through to the routine operating statements that are prepared to assist management control. In a marginal costing system a products production cost is its variable production cost.Therefore, any unsold production, i.e. closing stocks or work in progress, will also be valued at its variable production cost. Contribution will be revenue less the variable cost of sales.The variable cost of sales is the variable production cost of the goods or services sold in a period plus any variable selling and distribution costs.All the fixed costs for a period will be charged to that periods profit and loss account. The CIMA Official Terminology defines marginal costing as The accounting system in which variable costs are charged to cost units and fixed costs of the period are written off in full against the aggregate contribution. Its special value is in recognising cost behaviour, and hence assisting in decision-making.

FEATURES OF MARGINAL COSTING (1) All elements of costs are classified into fixed and variable costs. (2) Marginal costing is a technique of cost control and decision making. (3) Variable costs are charged as the cost of production. (4) Valuation of stock of work in progress and finished goods is done on the basis of variable costs. (5) Profit is calculated by deducting the fixed cost from the contribution, i.e., excess of selling price over marginal cost of sales. (6) Profitability of various levels of activity is detennined by cost volume profit analysis.

Absorption Costing Absorption costing is also termed as Full Costing or Total Costing or Conventional Costing. It is a technique of cost ascertainment. Under this method both fixed and variable costs are charged to product or process or operation. Accordingly, the cost of the product is determined after considering both fixed and variable costs.

Absorption Costing Vs Marginal Costing: The following are the important differences between Absorption Costing and Marginal Costing: (1) Under Absorption Costing all fixed and variable costs are recovered from production while under Marginal Costing only variable costs are charged to production. (2) Under Absorption Costing valuation of stock of work in progress and finished goods is done on the basis of total costs of both fixed cost and variable cost. While in Marginal Costing valuation of stOl!k of work in progress and finished goods at total variable cost only. (3) Absorption Costing focuses its attention on long-term decision making while under Marginal Costing guidance for short-term decision making. (4) Absorption Costing lays emphasis on production, operation or process while Marginal Costing focuses on selling and pricing aspects.

Differential Costing Differential Costing is also termed as Relevant Costing or Incremental Analysis. Differential Costing is a technique useful for cost control and decision making. According to ICMA London differential costing "is a technique based on preparation of adhoc information in which only cost and income differences between two alternatives / courses of actions are taken into consideration." Marginal Costing and Differential Costing: The following are the differences between Marginal Costing and Differential Costing: (1) Differential Costing can be made in the case of both Absorption Costing as well as Marginal Costing (2) While Marginal Costing excludes the entire fixed cost, some of the fixed costs may be taken into account as being relevant for the purpose of Differential Cost Analysis. (3) Marginal Costing may be embodied in the accounting system whereas Differential Cost are worked separately as analysis statements. (4) In Marginal costing, margin of contribution and contribution ratios are the main yardstick for the performance evaluation and for decision making. In Differential Cost Analysis.differential costs are compared with the incremental or decremental revenues as the case may be.

Advantages of Marginal Costing (or) Important Decision Making Areas of Marginal Costing The following are the important decision making areas where marginal costing technique is used :(I) Pricing decisions in special circumstances :(a) Pricing in periods of recession; (b) Use of differential selling prices. 538 A Textbook of Financial Cost and Management Accounting, (2) Acceptance of offer and submission of tenders. (3) Make or buy decisions. (4) Shutdown or continue decisions or alternative use of production facilities. (5) Retain or replace a machine. (6) Decisions as to whether to sell in the export market or in the home market. (7) Change Vs status quo. (8) Whether to expand or contract. (9) Product mix decisions like for example : (a) Selection of optimal product mix; (b) Product substitution; (c) Product discontinuance. (10) Break-Even Analysis.

Disadvantages 1. The separation of costs into fixed and variable is difficult and sometimes gives misleading results. 2. Normal costing systems also apply overhead under normal operating volume and this shows that no advantage is gained by marginal costing. 3. Under marginal costing, stocks and work in progress are understated. The exclusion of fixed costs from inventories affect profit, and true and fair view of financial affairs of an organization may not be clearly transparent. 4. Volume variance in standard costing also discloses the effect of fluctuating output on fixed overhead. Marginal cost data becomes unrealistic in case of highly fluctuating levels of production, e.g., in case of seasonal factories. 5. Application of fixed overhead depends on estimates and not on the actuals and as such there may be under or over absorption of the same. 6. Control affected by means of budgetary control is also accepted by many. In order to know the net profit, we should not be satisfied with contribution and hence, fixed overhead is also a valuable item. A system which ignores fixed costs is less effective since a major portion of fixed cost is not taken care of under marginal costing. 7. In practice, sales price, fixed cost and variable cost per unit may vary. Thus, the assumptions underlying the theory of marginal costing sometimes becomes unrealistic. For long term profit planning, absorption costing is the only answer.

Limitations of Marginal Costing (1) It may be very difficult to segregation of all costs into fixed and variable costs. (2) Marginal Costing technique cannot be suitablf> for all type of industries. For example, it is difficult to apply in ship-building, contract industries etc. (3) The elimination of fixed overheads leads to difficulty in determination of selling price. (4) It assumes that the fixed costs are controllable, but in the long run all costs are variable. (5) Marginal Costing does not provide any standard for the evaluation of performance which is provided by standard costing and budgetary control. (6) With the development of advanced technology fixed expenses are proportionally increased. Therefore, the exclusion of fixed cost is less effective. (7) Under marginal costing elimination of fixed costs results in the under valuation of stock of work in progress and finished goods. It will reflect in true profit. (8) Marginal Costing focuses its attention on sales aspect. Accordingly, contribution and profits are determined on the basis of sales volume. It does nnt con:::ider other functional aspects. (9) Under Marginal Costing semi variable and semi fixed costs cannot be segregated accurately.

COST VOLUME PROFIT ANALYSIS Cost Volume Profit Analysis (C V P) is a systematic method of examining the relationship between changes in the volume of output and changes in total sales revenue, expenses (costs) and net profit. In other words.it is the analysis of the relationship existing amongst costs, sales revenues, output and the resultant profit.To know the cost, volume and profit relationship, a study of the following is essential :(1) Marginal Cost Formula 2) Break-Even Analysis Marginal Costing and Cost Volume Profit Analysis (3) Profit Volume Ratio (or) PN Ratio (4) Profit Graph (5) Key Factors and (6) Sales Mix

Objectives of Cost Volume Profit Analysis The following are the important objectives of cost volume profit analysis: (1) Cost volume is a powerful tool for decision making. (2) It makes use of the principles of Marginal Costing. (3) It enables the management to establish what will happen to the financial results if a specified level of activity or volume fluctuates. (4) It helps in the determination of break-even point and the level of output required to earn a desired profit. (5) The PN ratio serves as a measure of efficiency of each product, factory, sales area etc. and thus helps the management to choose a most profitable line of business. (6) It helps us to forecast the level of sales required to maintain a given amount of profit at different levels of prices.

Principles of Marginal costing The fixed costs will be the same for any volume of sales and production (provided that the level of activity is within the relevant range). Revenue will increase by the sales value of the item sold. Cost will increase by the variable cost per unit. Profit will increase by the amount of contribution earned from the extra item. a) The volume of sales falls, the profit will fall from amount of contribution. b) Profit measurement should base on of total contribution since fixed costs relate to period of time and do not change with increases or decreases in sales volume.

Marginal Cost Equation The Following are the main important equations of Marginal Cost :Sales = Variable Cost + Fixed Expenses Profit I Loss(or)Sales - Variable Cost = Fixed Cost Profit or Loss (or) Sales - Variable Cost = Contribution Contribution = Fixed Cost + Profit The above equation brings the fact that in order to earn profit the contribution must be more than fixed expenses. To avoid any loss, the contribution must be equal to fixed cost.

Contribution The term Contribution refers to the difference between Sales and Marginal Cost of Sales. It also termed as "Gross Margin." Contribution enables to meet fixed costs and profit. Thus, contribution will first covered fixed cost and then the balance amount is added to Net profit. Contribution can be represented as:Contribution = Sales - Marginal Cost Contribution = Sales - Variable Cost Contribution = Fixed Expenses + Profit Contribution - Fixed Expenses = Profit Sales - Variable Cost = Fixed Cost + ProfitC=S-V.C (or) Where: C=F.C+P S-V C = ContributionC=F.C+P S-V. S = Sales C=F.C+P F ;:: Fixed Cost C-F.C=P P = Profit V = Variable CostIllustration: 1 (or) A Textbook of Financial Cost and Management Accounting Where: C = Contribution S = Sales F ;:: Fixed Cost P = Profit V = Variable Cost

Illustration: 1 (or) A Textbook of Financial Cost and Management Accounting Where: C = Contribution S = Sales F ;:: Fixed Cost P = Profit V = Variable Cost From the following information, calculate the amount of profit using marginal cost technique: Solution: Fixed cost Rs. 3,00,000 Variable cost per unit Rs. 5 Selling price per unit Rs. 10 Output level 1,00,000 unitsSolution:Contribution = Selling Price - Marginal Cost = (1,00,000 x 10) - (l,OO,OOO x 5) =10,00,000 - 5,00,000 =Rs.5,OO,OOOContribution = Fixed Cost + ProfitRs. 5,00,000 =3,00,000 + ProfitProfit =Contribution - Fixed CostProfit = Rs. 5,00,000 - Rs. 3,00,000= Rs. 2,00,000

Break-Even Analysis: Break-Even Analysis is also called Cost Volume Profit Analysis. The term Break-Even Analysis is used to measure inter relationship between costs, volume and profit at various level of activity. A concern is said to break-even when its total sales are equal to its total costs. It is a point of no profit no loss. This is a point where contribution is equal to fixed cost. In other words, the break-even point where income is equal to expenditure {or) total sales equal to total cost.The break-even point can be calculated by the following formula: Break-Even Point in Units Total Fixed Cost(1) Break-Even Point in Units =-----------------------------Contribution per unit

Margin of Safety: The term Margin of safety refers to the excess of actual sales over the break-even sales. It is known as the Margin of Safety. Margin of safety can also be expressed as a percentage of sales. Margin of safety can be improved by :(a) Increasing the selling price (b) Reducing the variable cost (c) Selecting a product mix of larger PN ratio items (d) Reducing fixed costs (e) Increasing the output

Margin of Safety can be calculated by the following formula:(1) Margin of Safety = Total Sales - Break-Even Sales

profit(2) Margin of Safety = ---------------- P/V ratio

profit(3) Margin of Safety =----------------------x salesContibution

(4) Profit = Margin of Safety x P I V ratio

I. Break-Even Chart

A break-even chart is a graphical presentation which indicates the relationship between cost, sales and profit. The chart depicts fixed costs, variable cost, break-even point, profit or loss, margin of safety and the angle of incidence. Such a chart not only indicates break-even point but also shows the estimated cost and estimated profit or loss at various level of activity. Break-even point is an important stage in the break-even chart which represents no profit no loss.

MARGINAL COSTING PRO-FORMA

Sales Revenue xx xxxLess Marginal Cost of SalesOpening Stock (Valued @ marginal cost) xxxxAdd Production Cost (Valued @ marginal cost) xxxxTotal Production Cost xxxxLess Closing Stock (Valued @ marginal cost) (xxx)Marginal Cost of Production xxxxAdd Selling, Admin & Distribution Cost xxxxMarginal Cost of Sales (xxxx)Contribution xxxxxLess Fixed Cost (xxxx)Marginal Costing Profit xxxxx

1.Marginal costing in manufacturing

Variable production overheads In a manufacturing business the variable product costs will be materials, direct labour (provided it varies with output), sales commission, packaging, delivery, royalties and variable production overheads. Variable production overheads are hard to identify. In fact CIMA Official Terminology does not have a definition for variable production overheads. Obviously they are those overheads that alter with the level of manufacturing activity, but in practice variable production overheads are often insignificant. The cost of some overheads, such as machine lubricants, disposable tools, some machine maintenance activities, and factory power, will tend to change in line with output, but it can be hard to identify them with specific products. Even so, you will often have to deal with manufacturing problems that contain variable production overheads. As some of these variable overheads will be part of semi-variable costs, such as factory power, you may be expected to use the high-low method described in section 2.3 to separate out the fixed from the variable cost elements.

Fixed costs Where possible, the fixed costs shown on an operating statement should be grouped into logical categories, such as fixed production overheads, fixed selling overheads, fixed distribution and fixed administration costs.

2. Marginal costing in service industries The format for marginal costing operating statements in service industries is similar to that used in manufacturing.The only difference is that there are no stocks, variable production overheads or fixed production costs.These will be replaced by the variable and fixed costs that are relevant to the particular service activity. Variable materials costs will still occur in service activities such as restaurants and power generation.

3. Marginal costing in extractive industries There will be little difference between the style of marginal costing operating statement used for extractive industries and that used in manufacturing.There may be no variable material costs if the business owns the sites from which it operates. However, mining and similar firms often have to pay a fee or royalty, based on the weight or volume of raw material extracted, to the owners of the mineral rights.

Practical Use of Monte Carlo Simulation for Costing of Yarn in Textile Industry

ABSTRACTNow days, the costing of products are very important in any organization. There is a huge competition among the manufacturing companies to sell the products in reasonable price to the customers across the whole world. Every company wants to make high quality products in less price for achieving the targets, expectation and satisfaction of the consumers. In South Asia, there is big textile industry for making the high quality products from raw cotton to finish garments. Due to large industry of textile in Pakistan, there is also big competition among the companies regarding quality of product at low prize. Cost of product is important factor to market the product successfully across the whole world. Providing the good quality of products at low prize to the customers is the best strategy to capture the textile market and enhance the customer satisfaction. To achieve the product cost to its reasonable prize, its better to highlight the main factors in costing of textile products. Firstly, focused on the factors that can affect more severe on the product costing and took the other factors and so on. For this purpose, make the analysis by some tools or software to forecast the situation on costing of product. It gave the clear picture for better understanding on costing and helpful for future strategy to maintain the costing of products for national and international market.

Introduction of textile processesThere are different manufacturing processes used in making the yarn product from raw materialto finish yarn. Following are the main processes in textile plant; - Blow room process - Carding process - Drawing process - Combing process - Roving process - Ring spinning process - Winding process - Packing process These are the major sub departments in textile plant for making yarn product. All these process play very active role on the costing of products and affect on the overall budget of the textile plant. Due to some rejected materials in every department, overall yield %age is effected and thus increase the manufacturing cost of products.

Finding & Discussion ResultsIn this case study, analysis the quantitative data regarding costing and what is profit per pound of different textile products in the process. On the basis of actual data, technical experience and through discussion with supervisor for the product of 40/CM weaving non-compact on G33, 40/CM weaving compact on K44, 60/CM weaving compact on K44 and 80/CM weaving compact on K44, found the different scenario regarding increase the profit margin per pound as well as reduce the cost of product. I focused mainly on significant factors (KPIs) of costing such as cotton rate, yield %age, yarn cost rate & sale rate per pound of the product. Comparison of two products showed the clear picture of which product is best & valuable for the company and what will the profit margin? Following details will give the clear understanding between two products regarding parameters affect on costing and profit margin per pound; In case of yarn 40/CM weaving, compared the same product but on made different machines one was non-compact making yarn machine and other compact making yarn machine. Actually the compact making machine produce good quality yarn as compared to non-compact product but only verified which product can give more profit and has market value as compared to other then. From the probability distribution of figure 7 & figure 8, the maximum probability (90%) for gaining the profit per pound was varied for these two products. It was more for made the compact yarn and less for the non-compact yarn. In the study of 60/CM and 80/CM compact yarn, compared the different product but made on same machine type K44 and both were most usable products for making shirting fabric and summer wearing clothes. From the view of probability distribution of figure 9 & figure 10, there is little difference for achieving the profit margin for the maximum probability (90%). It was more for making the product of 80/CM compact as compared to other one.

ConclusionAfter finding and results from the analysis of data, its easy to describe the conclusion andrecommendation for further research and study. For the better understanding of costing of product, took the two types of scenario: 1st was compared the data of same product but on different machines and 2nd compared the different product data on same machine. From the study of process data, analysis of data and probability distribution, its clear that 40/CM weaving compact is more profitable and market value product as compared to the same product on non-compact machines. Due to compact product and high strength, it has good working & smooth running on machines, thats why production, quality and yield %age increased of this type of yarn product as compared to non-compact product with the chances of loss of production, quality and yield %age. If we see with respect to market value, the consumption of this production is so high for the manufacturing of major in suiting, bed sheeting and upholstery fabrics for all over the world. On the basis of analysis of costing data, my professional experience and market value: I will recommend for the yarn manufacturing companies, 40/CM weaving compact product should be in manufacturing plan for getting the more profit per pound. In case of other product for profit per pound from the analysis of data, such as 80/CM compact has slightly more profit as compared to 60/CM weaving compact in the process. Due to high market value, consumption and more profit per pound as described in previous chapter; the 80/CM weaving compact is more preferable product in the textile industry to achieve the customer expectations and profit for the progress of the company.24 | Page