March, 2002 Issue Three Stage Triangle Wheel - Pyrobin · Three Stage Triangle Wheel Introduction:...

Transcript of March, 2002 Issue Three Stage Triangle Wheel - Pyrobin · Three Stage Triangle Wheel Introduction:...

Passfire

Volume 2, Issue 3

Build This...

Three Stage Triangle Wheel

March, 2002 Issue

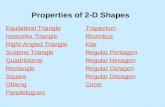

Build This: Three Stage Triangle Wheel.

Technique: Round Stars, Part II.

Tool Tips: Star Roller Comparisons

Autopsy: German Made Class B Rocket.

Summary: This wheel is one of those projects that fall under the "instant gratification" category, meaning you can crank one out and go fire it all within an hour (assuming you have the compositions already on hand). It makes for a perfect backyard celebration device, creating little noise but lots of effects. This is among the simplest types of wheels to make, and can easily be fitted with auxiliary effects such as whistles and color pots. Formulas: 1/2" Gold Driver, 1/2" Firefly Driver, 1/2" KNO3 Silver Driver, 1/2" KClO4 Silver Driver, Materials: Tools:

(3) 5" long x 1/2" I.D. x 3/4" O.D. kraft tubes 1/2" wooden or non-sparking metal rod(1) scraps of 3/16" luan plywood at least 5" square Brass hammer(6) 5" long pieces of 18 gauge wire Wire cutters(5) 5" x 3" pieces of 30lb kraft (nosing paper) Box nose pliers

Drill Press

1/2" ramming base (spindle optional)

Unmeasured Materials: fire clay (bentonite), meal powder, cotton or flax twine, white glue or wood glue, visco, black match

Copyright © 2002-2005 Passfire Labs, LLC.

file:///C|/Documents%20and%20Settings/Detrimental/My%20Documents/Work/Tutorials/Wheels/3%20stage%20triangle/p1.htm [6/24/2007 2:25:29 PM]

Passfire

Volume 2, Issue 3

Build This... Page 2

Three Stage Triangle Wheel

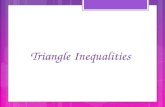

Introduction: This wheel project makes a good introduction to building revolving pieces, as it doesn't require the construction of any kind of fancy frame. Three drivers, often of a different effect each, are fastened to a triangular hub made of thin plywood, plastic or sturdy cardboard. I prefer the use of 3/16" luan plywood sold in 4x8 sheets at most home improvement centers.

Since some builders might not want to bother with cutting a full size piece of plywood into useable triangles, other materials such as lexan, acrylic or sheets of sturdy cardboard may be used. If scissors are your only cutting tool, you may be able to laminate several triangles cut from chipboard by stacking three or four of them with white glue between the layers. The finished material must be thick enough to hold the drivers on edge once they are wired onto the hub. Ideally you should be able to reuse your hubs many times over, so the more sturdy they are the better.

You can Print the Triangle Pattern with this link in order to have a template to trace onto your hub material.

Figures 1-3 shows the performance of each driver using the compositions given on page 1. When used with the ball-bearing type spin axis described at the end of this article, this wheel will spin quite fast, throwing sparks about 10 feet in all directions.

The basic design of this wheel can be enhanced easily with the addition of whistles and color pots. While whistles are strong enough to drive the wheel, they do not throw many sparks and can appear dull. It is best to fasten auxillary whistles to the sides of the main spark producing drivers, or use a whistle as the driver for an effect that produces attractive sparks but little driving force, such as glitter drivers.

More...

Figure 1: Stage 1: Ferro-titanium gold.

Figure 2: Stage 2: Firefly.

Figure 3: Stage 3: Silver flitter.

file:///C|/Documents%20and%20Settings/Detrimental/My%...nts/Work/Tutorials/Wheels/3%20stage%20triangle/p2.htm (1 of 2) [6/24/2007 2:25:29 PM]

Passfire

Copyright © 2002-2005 Passfire Labs, LLC.

file:///C|/Documents%20and%20Settings/Detrimental/My%...nts/Work/Tutorials/Wheels/3%20stage%20triangle/p2.htm (2 of 2) [6/24/2007 2:25:29 PM]

Passfire

Volume 2, Issue 3

Three Stage Triangle Wheel... Page 3

Figure 4: Home made wooden spindle.

Figure 5: Drifts made from wood or aluminum rods with oak heads.

Making the Tooling: The tooling required to make the drivers for this project can be made from parts available at most hardware stores. The spindle base can be a small 3/4" thick block of hardwood such as maple or oak. A 1/2" diameter hole is drilled half way into the base using a drill press to make sure it is straight. A 9/16" long segment of a 1/2" diameter wooden dowel rod is glued into the hole using wood glue and allowed to dry. Next a 1/8" hole is drilled into the exact center of the dowel rod, running all the way through it as shown in Figure 4. Into this hole a 1-3/16" segment of brass rod is inserted, which is held in place by a pin that runs through both the dowel rod and the brass rod. The pin can be a small nail or whatever is handy, as long as it doesn't exceed 3/32" in diameter.

Note that the brass pin is optional if the drivers will be vented using a drill press to make the hole. Using a drill also eliminates the need for the drift containing a hole in the end. In this case, you will only need to make one solid-end drift and a flat spindle with no brass pin. However, the drill method is slower, less accurate and requires caution. More on this method will be discussed later.

The drifts are made by cutting 9" long segments of 1/2" diameter wood or aluminum rods and capping them with 2" long segments of 1-1/4" oak dowel rods. The oak serves to provide more striking area when ramming, prevent damage to the ram rods and also provide a non-sparking surface so that a normal hammer may be used with them. The oak segments must be cut straight so that they will sit perpendicular to the drill stand when making the holes to receive the ram rods. The holes should be about 1" deep and centered as accurately as possible. A small nail is also used as a pin to hold the oak caps onto the rods, as seen in Figure 5.

If the ramming base is to have the brass pin, a 3/16" hole is drilled 1" deep into the bottom of one of the drifts. If wood is used to make the ram rods, they may be strengthened by dipping them in Minwax Wood Hardener for a few minutes and allowing them to dry. The inconsistent nature of dowel rod diameters may require some sanding before they will easily fit inside the tubes you will be using.

More...

Copyright © 2002-2005 Passfire Labs, LLC.

file:///C|/Documents%20and%20Settings/Detrimental/My%20Documents/Work/Tutorials/Wheels/3%20stage%20triangle/p3.htm [6/24/2007 2:25:31 PM]

Passfire

Volume 3, Issue 8

Build This...

1/2" I.D. Saxons by "Big G"

Summary: Saxons are among the easiest spinning effects to create and will make an ideal project for those just getting started in pyrotechnics. These classic devices have been around since the early days of fireworks, and are surprisingly effective for their small size and simplicity. This article describes how to make several different saxon configurations that can be turned out in only 10 to 15 minutes!

November, 2003 Issue

Letter from the Editor: Another Pyro Season

Build This: Saxon

Technique: Making Black Powder

Tool Tip: Multi-Puck Powder Die

Gallery: FPAGs Fall Festival

Class C Corner: Great Willow, Spring Festival

Formulas: Gold 1, Gold 2, Silver, Materials: Tools:

Convolute Tube, 7 in. long, 1/2in. ID, 1/8 in. wall. 1/2" Spindle and DowelBlack Match Non sparking malletTissue Paper Small brushwhite glue Drill press or hand drillpowdered clay 5/32" drill bit30# kraft

Copyright © 2002-2005 Passfire Labs, LLC.

file:///C|/Documents%20and%20Settings/Detrimental/My%20Documents/Work/Tutorials/Wheels/half%20inch%20saxon/p1.htm [6/24/2007 2:27:03 PM]

Passfire

Volume 3, Issue 8

Saxons Page 2

Figure 1: A single action saxon, driven from one end only.

Figure 2: A double action saxon driven from both ends.

Figure 3: A reversing single action saxon. The end of the first stage ignites the opposing second stage.

Figure 4: Larger saxons created by connecting single drivers to a center piece (usually a wood stick).

Introduction: Saxons are a very old fireworks piece that have been documented in many of the classical fireworks texts, including the works of Lancaster, Weingart and Kentish to name a few. In its simplest form, the saxon is a single driver that rotates around a pin driven through the center of the driver tube itself. A distinguishing feature of saxons is that they are driven from hole drilled in the side of the case instead of through the end. This results in a force perpendicular to the long axis of the case, allowing it to easily spin around a pivot point created anywhere along the length of the case (typically the center point). The simplicity of this design allows attractive pinwheel type devices to be easily made without the need for wooden or plastic hubs to hold the drivers. While not quite as impressive as a wheel, saxons can be assembled in 10-15 minutes, making them a quick fix when one hasn't "smelt the smoke" in a while.

Saxons may be driven from one or both ends of the case, and color pots are often attached for enhanced effect. Saxon type devices are also commonly used as shell inserts, sometimes alternately called whirlwinds, creepers or tourbillions. When used as a shell insert there is no pivot point of course, so no hole is drilled through the case.

Figure 1 shows the simplest type of saxon, which is driven from only one end. In this illustration half of the case is charged with clay to act as an inert counter weight. It is actually possible to charge the entire case and then hammer a small nail right through the case and comp without effecting the performance of the saxon, although some may not be comfortable driving nails through live composition.

Figure 2 shows a saxon that burns from both ends, resulting in more spark output and higher RPMs. The two opposing holes must be fused together with a piece of piped match so that they ignite simultaneously.

Figure 3 shows a reversing saxon, which is similar to a double saxon only the second exhaust hole is on the same side of the case as the first, and it doesn't take fire until the first driver is finished. A third hole at the end of the first drivers charge is used to pass fire to the second driver. The effect is a spinner that ramps up to speed, then starts slowing down, stops and finally begins picking up speed in the opposite direction.

Figures 1-3 are simple saxons that are built from only a single casing. When a larger saxon is desired, it is more common to build the two drivers separately and connect them with a wooden center piece such as a dowel rod, as seen in Figure 4. Each driver is rammed such that there is a cavity above the end plug that is deep enough to slip snugly onto a dowel rod.

More...

file:///C|/Documents%20and%20Settings/Detrimental/My%...ents/Work/Tutorials/Wheels/half%20inch%20saxon/p2.htm (1 of 2) [6/24/2007 2:27:04 PM]

Passfire

Copyright © 2002-2005 Passfire Labs, LLC.

file:///C|/Documents%20and%20Settings/Detrimental/My%...ents/Work/Tutorials/Wheels/half%20inch%20saxon/p2.htm (2 of 2) [6/24/2007 2:27:04 PM]

Passfire

Volume 3, Issue 8

Saxons Page 3

Figure 5: Rammer and Spindle. The depth marks are 1 cm (3/8 in.) apart..

Building a Single Saxon: The simplest saxon is a single driver saxon. Half the case is charged with the driver composition, while the other half is filled with clay to act as a counter balance. The clay extends a little beyond the center point by about 1 cm (3/8 inch ).

A simple set of tools can be made from a scrap of wood and a 1/2" dowel rod. First we make a half inch spindle by taking a 4x4 inch wood piece and drilling a hole in the middle of one of it faces half an inch deep. Then a short dowel, about an inch high is glued into the hole. Another piece of dowel, made from wood, brass or stainless steel is used as the rammer. The rammer is drawn with depth marks as seen in Figure 5. Note the centimeter marks on the dowel. When loading, these markings allow us to know how much composition was already placed inside the driver.

The driver being loaded in Figure 6 is half inch ID and 18 cm (7 in.) long. It was made by dry rolling a sheet of manila folder paper (or European 280gms paper) measuring 18cm x 20cm (7 in x 8 in.) around a 1/2 inch diameter rod. The last half inch was covered with white glue diluted with 50% water – and it was overlapped by a sheet of 30# kraft measuring 18cm x 10cm (7 in. x 4 in. ). The rectangle was covered with diluted white glue except for the first few inches.

The tube is first loaded with a clay plug about 1/2" thick. Next the driver fuel is charged in small increments. Before loading the comp, it is best to drill the exhaust hole just above the clay plug first. This will relieve you from having to drill through live comp, and also allows you to pre-install the fuse and ram the comp down on top of it, thus locking it in place. The exhaust hole should be about 1/3 of the size of the driver ID. Thus our 1/2 inch ID driver should have a 1/6 inch hole, which translates to about 5/32" for standard bit sizes.

After drilling the hole, insert a piece of black match about half the length of the driver into the hole. The driver composition is now loaded in increments that compress to about 1/2" each until the tube is filled about 3/8" shy of the midpoint. Marking the midpoint on your ramming rod plus another mark 3/8" above and 3/8" below this point will help when ramming saxons.

The remainder of the case is now loaded solid with powdered clay, which acts as an inert counter weight so that the saxon will not have to work as hard to spin around the center point.

In order to secure the fuse against the casing and protect it from getting battered during storage, a few turns of tissue are wrapped around the end as seen in Figure 8. Some glue is brushed on the casing, being careful not to get any on the fuse or in the area where the fuse will come in contact with, then the tissue is wrapped around it. Keep in mind that this tissue will act as quick

file:///C|/Documents%20and%20Settings/Detrimental/My%...ents/Work/Tutorials/Wheels/half%20inch%20saxon/p3.htm (1 of 2) [6/24/2007 2:27:06 PM]

Passfire

Figure 6: - Saxon filled with clay up to the mid point. The depth mark shows 7.8 cm (3 in.) from top..

Figure 7: After loading and fusing the saxon, glue is applied around the fused end to secure the nosing paper.

Figure 8: A completed single drive saxon. Note that the driver hole runs perpendicular to the spinning axis hole.

Figure 9: Washers used to space the saxon away from the launching stick, thus avoiding contact during operaion.

match as soon as the fuse burns up to it, so be sure there is enough bare match exposed to give you ample get-away time after ignition!

The last step is to drill the pivot hole at the center of the case. This needs to be drilled in the middle of the driver through both walls and clay, perpendicular to the driver hole. The diameters should be just slightly bigger then the pin you plan to mount the saxon on.

Firing the Saxon is similar to firing a wheel. It can be a simple matter of driving a nail through the Saxon hole and onto a wooden pole 2 meter high. However, such a method tends to be problematic as the Saxon hits the wood while rotating. The nail head can also dig into the tube and slow it down. An improved setup is shown in Figure 9. The driver sits between large zinc washers that prevent it from contacting both the wood and the nail head. The nail is not hammered in too deep, so the discs and Saxon sit loosely on the nail. The discs are smooth enough to create very little friction and allow the Saxon free movement.

Design Notes: Unlike end burning drivers in which the exhaust hole is drilled into clay, the exhaust hole of a saxon is drilled into the driver’s wall. This means that fire eats through the paper and makes the hole larger and larger during the display. This causes the saxon to gradually slow down and, if the hole becomes too large, can ruin the effect of a continuous circle of fire.

There are a few ways to solve this problem. The first is to use a faster burning composition that does not burn hot or long enough to erode the hole much. The most common compositions for saxons are based on meal powder, which burns cooler and quicker than most color compositions involving barium nitrate or potassium perchlorate. When color saxons are desired, then a thicker walled tube must be used to accommodate the increased hole erosion.

Another alternative is to use a conical end plug such as the type used when making tourbillions. This requires a tapered rammer to make the plug, then drilling the exhaust hole such that it passes through the thin wall of protective clay left by the taper. When making double saxons with conical plugs, the drivers would have to be made separately and connected by a wooden dowel as shown in Figure 4.

More...

Copyright © 2002-2005 Passfire Labs, LLC.

file:///C|/Documents%20and%20Settings/Detrimental/My%...ents/Work/Tutorials/Wheels/half%20inch%20saxon/p3.htm (2 of 2) [6/24/2007 2:27:06 PM]

Passfire

Volume 3, Issue 8

Saxons Page 4

Figure 10: Fusing a double action saxon with piped match.

Figure 11: Finished double action saxon.

Double Saxons: Double Saxon is still constructed using a single driver, except this time the entire driver is loaded with composition and the exhaust holes are bored at both ends. The tube will be mounted onto the spindle and loaded in the following order:

1) 3/8" of clay for end plug. 2) Composition up to the middle point minus 3/8". 3) 3/4" of clay. 4) Composition up to 1/2" from the top. 5) 3/8" of clay for end plug.

Double Saxons can be ignited using a “single stage” where both ends fire simultaneously (see Figure 2) or “two-stage” ignition where one side of the Saxon finish burning before the other end starts (see Figure 3).

Commercial outfits typically use two separate drivers that are pasted together to form the double Saxon (see Figure 4). This allows the manufacturer to utilize the same machines that load fountains and drivers to load saxons as well.

Building a Single Stage Double SaxonBegin building the saxon just as you would the single saxon described previously, except the black match used to fuse the hole needs to be long enough to reach the opposite end of the saxon. When the driver comp is rammed to 3/8" shy of the center point, only charge 3/4" of clay above it. Driver comp is then rammed above the central clay plug until within 1" of the top.

At this point you can drill the second vent hole 5/8" from the end of the tube, making sure that it points in the opposite direction as the first hole. While you could drill both holes before loading any composition, it can be hard to get the rammer past a pre-drilled hole, since it tends to cave in the tube wall slightly.

After drilling the second hole, ram more composition until the tube is filled level with the new hole. Now slip a piece of loose fitting quickmatch pipe over the blackmatch extending from the first exhaust hole, then insert the other end of the match into the second exhaust hole (see Figure 10 ). Ram another increment of driver comp so that the tube is filled to within 1/2" of the top, thus locking the black match in place. Finish by ramming the final 3/8" plug. Use tape to secure the connecting piped match to the driver so that it doesn't obstruct the area where the central pivot hole will be drilled.

Take another stick of black match and slide it into either end of the connecting piped match. This will be the ignition point for the saxon, and all it needs to do is ignite the piped match at some point (which will immediately ignite both ends of the saxon at once).

file:///C|/Documents%20and%20Settings/Detrimental/My%...ents/Work/Tutorials/Wheels/half%20inch%20saxon/p4.htm (1 of 2) [6/24/2007 2:27:07 PM]

Passfire

To give the Saxon that extra touch and good look – one can paste a Kraft #30, covered with 50/50 glue/water mix over the quick fuse casing and tube (but not over the exposed black match tips or the jet holes) and then use the same trick shown in the construction of single Saxons to cover and secure the fuses with tissue paper. Figure 11 shows the complete Saxon ready for storage and display.

More...

Copyright © 2002-2005 Passfire Labs, LLC.

file:///C|/Documents%20and%20Settings/Detrimental/My%...ents/Work/Tutorials/Wheels/half%20inch%20saxon/p4.htm (2 of 2) [6/24/2007 2:27:07 PM]

Passfire

Volume 3, Issue 8

Saxons Page 5

Building a Two Stage Double Saxon Starting with the same procedure used to build a single stage Saxon, we repeat the steps up to and including the central clay plug. We now take the Saxon off its spindle and drill 2 holes. The first hole will be 3/8" above the plug and oriented to oppose the direction of the first exhaust hole. The second hole will be 5/8" from the top of the tube so that it is in line with the first hole. This second hole may be drilled later after the comp has been rammed close to the end so that you will not have to slide the rammer past the dimple made on the inside of the case when drilling the hole.

Now take the bottom fuse and place a segment of quick match pipe over it. Push the other end into the middle hole and consolidate an increment of composition onto it to hold it in place. Keep on filling the Saxon with composition until you are par level with the top hole. Insert another fuse to this hole and consolidate your last increment over it. Plug the top with some more clay.

To finish the Saxon off, use the pasted kraft paper or foil tape to hide the quick match and make sure you cover all of the fuses holes with tissue paper. Failure to protect the passfire match can result in premature ignition of the second stage.

Upon ignition of the fuse near the top of the Saxon, the composition will burn with one type of composition until it reaches the mid point of the Saxon. Then the second fuse will ignite, and as the fire from the first jet hole dies, the second jet hole will spring into life with a different effect altogether.

The ability to mix to different effect into one Saxon makes this the most lovely of Saxons. Try to filling both halves with different compositions for an attractive effect.

Design Notes: Note that the reversing saxon shown in Figure 3 is a two stage double saxon built as described above, with the only difference being that all holes are drilled on the same side of the tube. This causes the second stage to spin in the opposite direction as the first stage.

It helps not to drill all the holes at the beginning before loading any composition. The reason is that drilling into the tube causes it to “cave in” and makes it hard to slide the rammer in and out easily. Also, some composition tends to escape out of the open holes. Therefore, I prefer to drill the holes as late as possible during assembly.

Saxons are easier to construct than related effects such as wheels, and they take only minutes to crank out if you have all the compositions on hand. However, the maximum number of effect you can put into a saxon is more limited than wheels or other complex rotating pieces. Saxons are driven by one or two jet holes at most. This means that there is a limit to how much power can be allocated for “pushing” the saxon and this limits the amount of external payloads that can be attached to them (such as color pots, whistles etc.). The fact that the exhaust hole widens with time means that the pushing pressure drops as burn time progresses, whereas this is not a problem with wheels driven by end burning drivers.

Saxons look best as a part of a larger effect. In Victorian times they were used in conjunction with large lance pieces to provide animated effects such as rotating wheels on chariots. Even today, igniting a few saxons together with large fountains in between is an impressive effect. In my house, they are still the most popular wheel around!

file:///C|/Documents%20and%20Settings/Detrimental/My%...ents/Work/Tutorials/Wheels/half%20inch%20saxon/p5.htm (1 of 2) [6/24/2007 2:27:09 PM]

Passfire

Copyright © 2002-2005 Passfire Labs, LLC.

file:///C|/Documents%20and%20Settings/Detrimental/My%...ents/Work/Tutorials/Wheels/half%20inch%20saxon/p5.htm (2 of 2) [6/24/2007 2:27:09 PM]

Passfire

Volume 6, Issue 3

Beginner Project... Page 1

Color Changing Stick Wheel by Michael Fales

Figure 1: The completed wheel mounted on a 2x4 post.

Figure 2: Wood pieces used to make the frame.

Materials:

1-1/4" wide by 24" long strip of thin plywood3/4" x 3/4" by 4" long piece of pine2" square or round of 3/4" thick pine32" of 19 gauge steel wire6 pieces of lightweight kraft paper 3" x 6"Approximately 46" of quickmatchApproximately 9" of blackmatch2 3/4" ID x 4" long parallel wound tubes2 1/2" ID x 6" long parallel wound tubes4" length of safety fuse1 3-1/2" long x 1/4" lag screw2 3/4" #6 wood screwsCotton or linen stringPVA or Wood GlueMounting Board (10' long 2x4)Bentonite clayTourbillion FormulaColor Driver Formula

Introduction: This wheel is easy to produce and will create a large spray of sparks and color that will awe even a jaded crowd. By transitioning from the color drivers to the tourbillion with titanium drivers (referred to as BP Titanium drivers through the rest of this article), the effect grows to a huge finish. It can also be used as soon as you finish it as there is no drying time or pasting required.

The Hardware: The drivers are attached to a 24" flat stick of wood. Thin plywood works very well for this purpose because of its strength and resistance to warping. Thin strips of lumber will tend to warp or twist with the grain and will not provide adequate strength. Rip a 1-1/4" wide strip of the plywood and cut to 24" long. A small spacer is attached to the center of the stick to avoid collision with the mounting post while spinning. Cut a 4" long 3/4" by 3/4" piece of wood and clamp it to the center of the stick with a bead of wood glue between the two. Finish attaching the stick to the spacer with two 3/4" x #6 long screws inserted into 3/32" diameter predrilled holes to either side of center. The predrilled holes are necessary to keep the small pine spacer from splitting while inserting the screws. Drill a 9/32" hole through the center of the face of the stick and completely through the

file:///C|/Documents%20and%20Settings/Detrimental/My%20Documents/Work/Tutorials/Wheels/2%20stage%20stick%20wheel/p1.htm (1 of 6) [6/24/2007 2:25:14 PM]

Passfire

Figure 3: Reinforcing the hub with a block of wood.

Figure 4: Drilling holes for tie-wires to pass through.

spacer. This will be the pivot point for the wheel. Cut a 2" square or disk of 3/4" thick wood and drill a 5/16" hole through the center (a plug from a hole saw will work just fine). This will become a large washer to reduce friction between the spinning wheel and mounting post.

The Drivers: A total of four drivers will be used with this wheel however you can scale up or down as you want. The drivers are sequenced to fire on opposite ends of the stick at the same time and are measured carefully to create a simultaneous change in effect. Both of the following compositions contain titanium and pressing is required rather than ramming:

Black Powder Tourbillion Formula (Ronald Lancaster) Meal D 35 Potassium Nitrate 45 Charcoal AF 15 Sulfur 5 Total 100

Personal notes regarding this composition: I use straight ball milled meal for the Meal D and I find that the particle size in the composition is so fine that it will act like a fluid while pressing or ramming. It can flow right out the top of your tube and in your face while pressing! Granulating the mix will take care of the dust problem, which involes adding about 20% water to the composition, pressing it through a window screen and allowing it to fully dry. The resulting particles hold together well enough to reduce dust by preventing them from blowing by the rammer, but are still weak enough to crush into a solid powder grain when pressing. Adding +10 titanium gives a great shower of white sparks; however you should PRESS rather than ram the composition once you add the metal to the mix!

Purple Driver Formula (John Glasswick) Red Gum 10 Parlon 20 Magnalium 20 Titanium 15 Strontium Nitrate 25 Cupric Oxide(black) 10 Potassium Perchlorate 25

These compositions burn with considerable heat and pressure which require a strong tube. The color drivers are created using Wolter Pyro Tool's 3/4" driver tooling shown in Figure 5. You can also use the simple home-made tooling as shown in Figure 7 with the BP titanium drivers and then drill out the nozzle hole by hand.

The color formula will provide a long burn time in just a 4" long tube. Place the tube over the spindle on the base and insert 1-1/2 teaspoons of clay. Press the clay nozzle hard using the hollow rammer. The nozzle will have to withstand pressure as well as erosion from burning titanium. Insert 1 teaspoon of color composition and continue to press using the hollow rammer until you clear the nozzle spindle. Switch to the solid rammer and continue pressing increments of color composition until you reach 3/4" from the top of the tube. Make sure to mark the tube where you stop so that you can fill both tubes to the same height. Fill the remaining cavity

file:///C|/Documents%20and%20Settings/Detrimental/My%20Documents/Work/Tutorials/Wheels/2%20stage%20stick%20wheel/p1.htm (2 of 6) [6/24/2007 2:25:14 PM]

Passfire

Figure 5: 3/4" driver tool set with some strong driver tubes.

Figure 6: Pressing the color driver on an arbor press.

Figure 7: Home-made tooling for the 1/2" driver.

with loose clay and press solid (approximately 3/8" thick plug). Remove the driver from the tooling and repeat with the other 3/4" driver tube. Take both drivers outside and away from flammables. Drill, by hand, using a 1/4" bit into the solid clay plug just into the color composition on both drivers. These holes will be the passfire from the colored drivers to the BP titanium drivers.

The BP titanium drivers are created using a home made set of tools which consist of a plywood base with a 1/2" diameter 1/4" tall nipple and a set of solid 1/2" diameter rammers. This formula burns fierce and fast so the tubes must be 6" or longer to produce a good burn time. At this length the 1/2" tube will need a reinforcement sleeve to keep from buckling or splitting under the pressure of pressing. Some use a split PVC sleeve in conjunction with pipe clamps. A piece of 3/4" copper pipe can also be used as a pressing sleeve. This particular Skylighter tube fits a little loose in this pipe so I wrap a few turns of 30 pound kraft before inserting snuggly into the tube. Place the tube on the base and insert 1 teaspoon of clay. Press the nozzle plug hard and solid just as with the color drivers. Insert 1/2 teaspoon of non-granulated or 3/4 teaspoon of granulated BP titanium composition and press solid. Continue to press the driver composition increments until you reach 5/8" from the top of the tube. Fill the remaining cavity with clay and press solid. It helps to switch to as short as rammer that is still practical while filling the tube. This will keep things vertical and reduce binding. Take both BP drivers outside and away from flammables. Drill, again by hand, using a 1/8" drill bit into the center of the nozzle plug end into the BP composition. Make sure to enter the composition about 1/4" to provide enough surface area to take fire as the wheel will be spinning.

Mix up a small amount of slurry of NC lacquer and meal powder. Cut six 1-1/2" pieces of black match. Two of the pieces will fit into the smaller 1/8" diameter nozzle end of the BP drivers and four of the pieces will fit into the holes at both ends of the color drivers which are 1/4" in diameter. Prepare the drivers by inserting a few grains of fine grained black powder into the nozzles to help insure ignition. Dip one end of each piece of black match into the slurry and insert it into the drivers. Make sure that the blackmatch makes good contact with the black powder and composition behind the clay plugs. After the slurry is dried, nose the drivers with 6 pieces of light weight kraft paper cut to 3" x 6". Apply glue as shown in Figure 10. Wrap the glued paper around the last inch of each end of the colored drivers and the nozzle end of the BP titanium drivers.

Attaching the drivers: The drivers on this wheel are placed so that it will change rotation upon color change. The rapid slow down and slight pause before reversing gives a nice effect of white titanium sparks. Measure in from each end of the stick and mark the center at 1/2", 1-1/2", 2" and 2-3/4". Drill through the stick using a 1/16" bit at each of the 8 marks. Cut 4 pieces of 19 gauge steel wire approximately 8" long. Center the colored driver within the first two holes on the end of the stick and make sure the nozzle is pointing the correct direction. Squirt a small amount of hot glue between the driver and the stick to hold the driver in place until the wire is attached. Place a BP titanium driver between the second set of holes with the nosing positioned next to the passfire end of the colored driver. Secure the driver with hot glue. Attach the other two drivers on the opposite end of the stick making sure to point the nozzles in the correct direction. Bend the wires into a "U" shape and insert each over a driver through the tiny holes previously drilled. Pull the wire underneath the stick and twist tightly with pliers to lock the driver in snug. Cut off the extra wire about 1/4" up from the stick.

Fusing the drivers: Cut two 8" pieces of quickmatch and bare the last inch of each end. Insert one end of the quick match into the nosing paper of the BP titanium driver and the other end into the passfire nosing of the colored driver. Tie the nosing paper down onto the quickmatch and secure the quickmatch with a small dab of glue between the nosing paper and quickmatch paper. Cut a 30" piece of quickmatch and bare the last inch of each end. Insert each end into the nozzle end of each colored driver and tie the nosing paper down onto the quickmatch and

file:///C|/Documents%20and%20Settings/Detrimental/My%20Documents/Work/Tutorials/Wheels/2%20stage%20stick%20wheel/p1.htm (3 of 6) [6/24/2007 2:25:14 PM]

Passfire

Figure 8: Pressing the 1/2" driver on an arbor press.

Figure 9: Fusing and priming the drivers.

Figure 10: Applying the outer nosing paper.

secure with glue as before. Cut a small slit near the center of the long piece of quickmatch and insert a piece of safety fuse. Hold the fuse in place with a couple turns of masking tape.

Mounting the wheel: Find a wide open space free from flammables. As seen in Figure 13, this wheel can spray titanium sparks up to 32 feet in diameter. Secure an 8 or 10 foot long 2x4 upright in the ground by burying securely. The 2x4 should be held firmly in place as the wheel will be spinning with great force. Pre-drill a 3/16" hole 2" down from top of the 2x4. Insert a 3-1/2" long by 1/4" lag screw through the center hole of the wheel followed by the wooden washer. Screw the lag screw into the predrilled hole on the 2x4 making sure to leave the wheel free to spin but tight enough to keep the wheel from wobbling back and forth. The lag screw may seem too long for what is needed, but shorter lag screws typically don't have a smooth shank behind the head that will allow the wheel to spin freely. Light the safety fuse, get back and enjoy. After the wheel has cooled you can clip the wires and remove drivers and the stick can be used again and again.

file:///C|/Documents%20and%20Settings/Detrimental/My%20Documents/Work/Tutorials/Wheels/2%20stage%20stick%20wheel/p1.htm (4 of 6) [6/24/2007 2:25:14 PM]

Passfire

Figure 11: Securing the drivers in place with hot glue and wire.

Figure 12: Fusing the drivers so the end of the 3/4" color driver ignites the 1/2" silver driver.

file:///C|/Documents%20and%20Settings/Detrimental/My%20Documents/Work/Tutorials/Wheels/2%20stage%20stick%20wheel/p1.htm (5 of 6) [6/24/2007 2:25:14 PM]

Passfire

Figure 13: The silver stage of the wheel on display in a field.

Copyright © 2002-2005 Passfire Labs, LLC.

file:///C|/Documents%20and%20Settings/Detrimental/My%20Documents/Work/Tutorials/Wheels/2%20stage%20stick%20wheel/p1.htm (6 of 6) [6/24/2007 2:25:14 PM]